Expansion member of leak-proof water inlet pipe component

A technology of expansion parts and water inlet pipes, applied in the field of expansion parts, can solve the problems of slow response of valve mechanism, inaccurate cutting and closing, difficult material acquisition, etc., and achieves the effects of sensitive response, convenient material acquisition and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

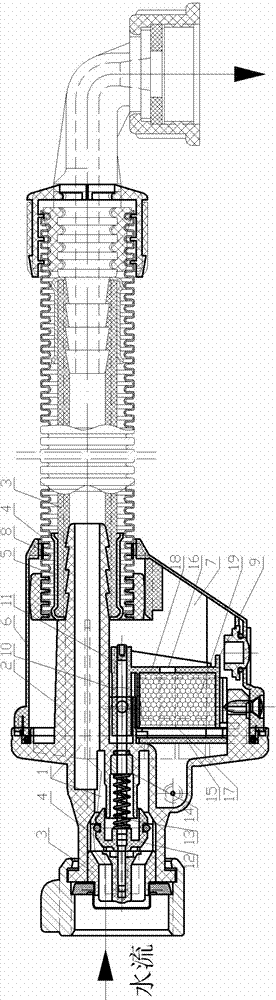

[0009] See figure 1 , which includes a central pressure pipe 1, an outer casing 2, a PVC pressure hose 3, and a corrugated pipe 4 in the central part. The outer casing 2, the PVC pressure hose 3, the outer casing 2, The connection of the PVC pressure hose 3 is buckled and fastened by the aluminum sealing tube 5. The outer ring surface of the PVC pressure hose 3 is covered with a bellows 4, and the outer casing 2 is covered with a fixing piece 6, which is encapsulated in the corrugated piece. The outer ring surface of the pipe 4, the fixing piece 6 and the outer shell 2 form a cavity 7, and the inner compartment cavity 8 of the bellows 4 communicates with the cavity 7, and the expansion block installation box 9 is arranged in the cavity 7, and the expansion block is installed The top of the box 9 is provided with a mounting hole 10, the valve rod 11 runs through the mounting hole 10, the front part of the valve rod 11 is located in the front central pressure pipe 1 of the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com