A kind of modified silica fume wool and its preparation method and application

A technology of modifying silicon and silica fume cotton, which is applied in the direction of chemical instruments and methods, mechanical equipment, brake types, etc., can solve the problems of limited friction coefficient and failure to meet the new standard requirements of disc brake pads, and achieve improved friction resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024]

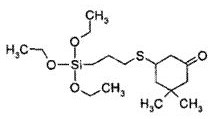

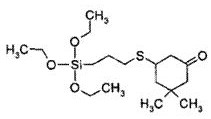

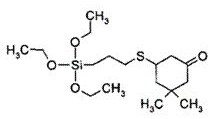

[0025] Preparation of the compound of formula I: To a solution of 1.00 g (8.10 mmol) of 5,5-dimethyl-cyclohex-2-enone in 10 ml of dry toluene was added 0.02 g of tert-butyl at room temperature under nitrogen potassium alkoxide, followed by the addition of 1.93 g (8.10 mmol) of 3-mercaptopropyltriethoxysilane. The reaction was stirred at room temperature for 18 hours. Ethyl acetate was added and the organic phase was washed twice with brine. The organic layer was dried over sodium sulfate, filtered and concentrated using a vacuum rotary evaporator to give 3.70 g of a colorless liquid. 1H NMR (400MHz, CDCl 3 ): δ=3.83 (q, J=6.8Hz, OCH 2 CH 3 , 6H); 3.10-3.00 (m, SCH, 1H); 2.70-2.55 (m, 3H); 2.30-2.05 (m, 3H); 1.95-1.85 (m, 1H); 1.75-1.55 (m, 3H) ; 1.24(t, J=6.8Hz, OCH 2 CH 3 , 9H); 1.10 (s, CH 3 , 3H); 0.91 (s, CH 3 , 3H); 0.80-0.65 (m, SCH 2 CH 2 CH 2 Si, 2H). 13C NMR (100MHz, CDCl 3 ): δ=209.13(s); 58.41(t); 54.13(t); 48.10(t); 45.62(t); 38.95(d); 35....

Embodiment 2

[0027] A preparation method of modified silica fume wool is carried out according to the following steps:

[0028] (1) Dissolve 3-isocyanatopropyltrimethoxysilane in water to prepare an aqueous solution with a mass concentration of 20%;

[0029] (2) the compound described in formula I is dissolved in dehydrated alcohol, and is mixed with the ethanolic solution that mass concentration is 20%;

[0030] (3) Mix the solutions prepared in steps (1) and (2) according to the volume ratio of 1:1, add silica fume wool, and the amount-to-mass ratio of the silica fume wool and the silane coupling agent solution is 1:2, and the water bath Heating and stirring for 12 min, then filtering, air-drying naturally, placing in an oven, and drying at 80° C. for 1.5 h to obtain the silica fume wool modified by the coupling agent.

Embodiment 3

[0032] A preparation method of modified silica fume wool is carried out according to the following steps:

[0033] (1) Dissolve 3-isocyanatopropyltrimethoxysilane in water to prepare an aqueous solution with a mass concentration of 20%;

[0034] (2) Add silica fume wool to the silane coupling agent solution prepared in step (1), the dosage and mass ratio of the silica fume wool and the silane coupling agent solution is 1:2, heat in a water bath and stir for 12 minutes, then filter and air dry naturally , put it in an oven, and dry it at 80 °C for 1.5 h to obtain a silica fume wool modified with a coupling agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com