A kind of method that manganese oxide gas-based reduction prepares manganese carbide

A technology of manganese oxide and manganese carbide, which is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of high smelting temperature, reduce the reduction roasting temperature, shorten the production process, and have a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

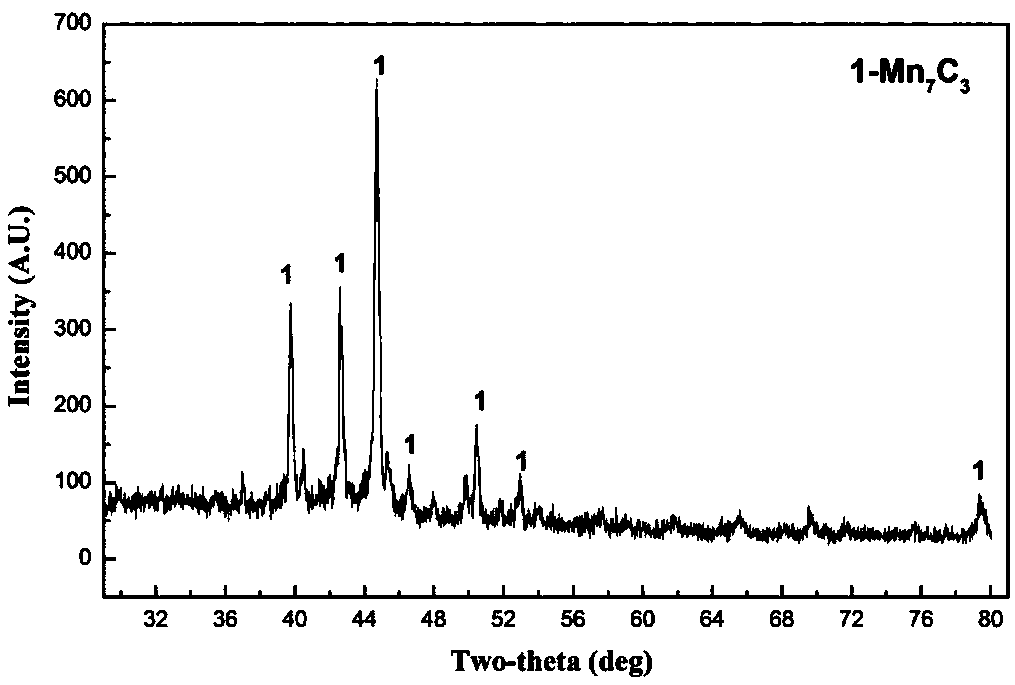

[0025] The mass percentage of -325 mesh particle size is 90% of the mixture of analytically pure manganese dioxide and trimanganese tetraoxide, added with 0.5% of CMC and 7.5% of water, then pelletized, and then dried, the dried Sample in CH 4 10% by volume, H 2 Volume percentage 30%, CO volume percentage 10%, N 2 Carry out roasting in the atmosphere of 50% volume percent, roasting temperature 1150 ℃, roasting time is 120min, then in N 2 After cooling to room temperature in the atmosphere, the obtained roasted product is a manganese carbide product, and the conversion rate of manganese dioxide is 95%. The XRD pattern of manganese carbide obtained under this condition is as follows figure 1 As shown, the SEM pictures of manganese carbide particles are as follows figure 2 shown.

Embodiment 2

[0027] The -325 mesh particle size accounted for 92% pure mineral manganese dioxide, added 0.5% bentonite and 7.5% moisture, then pelletized, then dried, and the dried sample was placed in CH 4 8% by volume, H 2 Volume percentage 62%, CO volume percentage 20%, N 2 Carry out roasting in the atmosphere of 10% volume percent, roasting temperature 1250 ℃, roasting time is 30min, then in N 2 After cooling to room temperature in the atmosphere, the obtained roasted product is a manganese carbide product, and the conversion rate of manganese dioxide is 94%.

Embodiment 3

[0029] The -325 mesh particle size accounted for 95% pure mineral manganese oxide, added 0.5% humic acid and 7.5% water, then pelletized, then dried, and the dried sample was placed in CH 4 20% by volume, H 2 Volume percentage 60%, CO volume percentage 12%, N 2 Carry out roasting in the atmosphere of 8% volume percent, roasting temperature 1200 ℃, roasting time is 90min, then in N 2 After cooling to room temperature in the atmosphere, the obtained roasted product is a manganese carbide product, and the conversion rate of manganese dioxide is 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com