Method for enriching nickel concentrate from low-grade laterite nickel ore

A kind of laterite nickel ore, low-grade technology, applied in the fields of chemical mineral processing and metallurgical chemical science, can solve the problem of insignificant selective reduction effect, and achieve the effects of high reduction performance and cleanliness, low power consumption, and low equipment wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

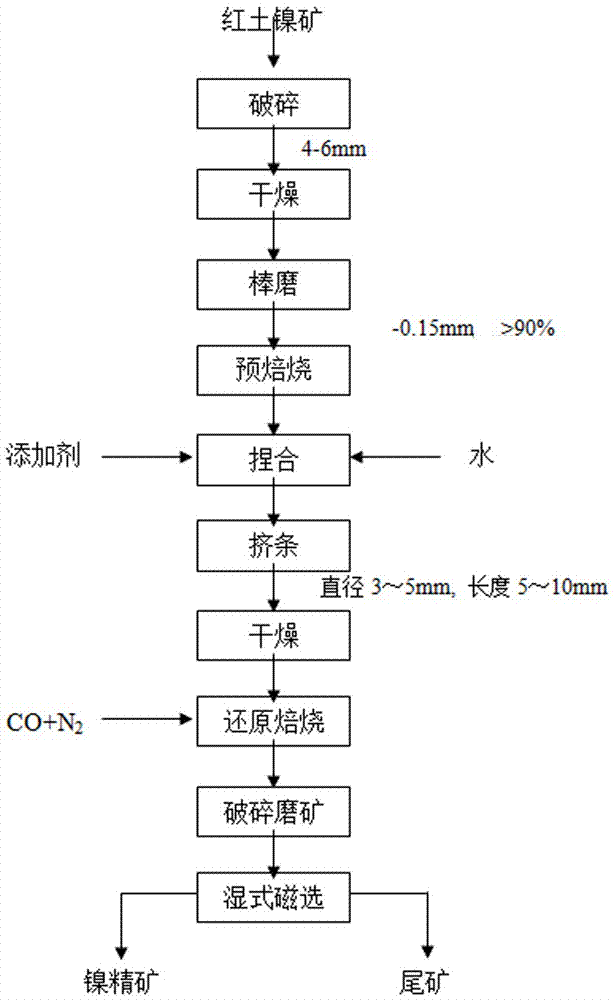

Embodiment 1

[0025] Low-grade lateritic nickel ore (TNi: ~1.34 wt.%) is crushed to 4-6mm with a jaw crusher, and then dried in an oven at 80°C. The dried laterite nickel ore is ground with a rod mill to a fineness of -0.15 mm, accounting for more than 90%, and placed in a muffle furnace for pre-roasting. Then independently add sodium thiosulfate (Na 2 S 2 o 3 ), or potassium thiosulfate (K 2 S 2 o 3 ), or calcium thiosulfate (CaS 2 o 3 ), or barium thiosulfate (BaS 2 o 3 ) additives, mixed evenly and kneaded with appropriate amount of water, placed in extruder and extruded to obtain columnar particles with a diameter of 3 to 5 mm and a length of 5 to 10 mm, and the columnar particles were dried in a drying oven to obtain dried and shaped laterite nickel ore . Put the dried laterite nickel ore into the fixed bed reaction device under the inert gas N 2 Heating in the atmosphere to 1200°C, and then passing a mixed gas containing 80% CO reducing gas by volume fraction, the space vel...

Embodiment 2

[0027]Low-grade laterite nickel ore (TNi: ~1.34 wt.%) is crushed to 4-6mm with a jaw crusher, then dried in an oven at 80°C, and the dried laterite nickel ore is ground to fineness with a rod mill -0.15mm accounts for more than 90%, put it in the muffle furnace for pre-roasting, add 5%, 10%, 15%, 20% and 25% of the weight of laterite nickel ore to the pre-roasted laterite nickel ore respectively Sodium sulfate (Na 2 S 2 o 3 ) additives, mixed evenly and kneaded with appropriate amount of water, placed in extruder and extruded to obtain columnar particles with a diameter of 3 to 5 mm and a length of 5 to 10 mm, and the columnar particles were dried in a drying oven to obtain dried and shaped laterite nickel ore . Put the dried laterite nickel ore into the fixed bed reaction device under the inert gas N 2 Heating in the atmosphere to 1200°C, and then passing a mixed gas containing 80% CO reducing gas by volume fraction, the space velocity of the mixed gas is 1000h -1 , the ...

Embodiment 3

[0029] Low-grade laterite nickel ore (TNi: ~1.34 wt.%) is crushed to 4-6mm with a jaw crusher, then dried in an oven at 80°C, and the dried laterite nickel ore is ground to fineness with a rod mill -0.15mm accounts for more than 90%, put it in the muffle furnace for pre-roasting, add 20% sodium thiosulfate (Na 2 S 2 o 3 ) additives, mixed evenly and kneaded with appropriate amount of water, placed in extruder and extruded to obtain columnar particles with a diameter of 3 to 5 mm and a length of 5 to 10 mm, and the columnar particles were dried in a drying oven to obtain dried and shaped laterite nickel ore . Put the dried laterite nickel ore into the fixed bed reaction device under the inert gas N 2 The atmosphere is heated to a given temperature of 800°C, 900°C, 1000°C, 1100°C, and 1200°C respectively, and then a mixed gas containing a volume fraction of 80% CO reducing gas is introduced, and the space velocity of the mixed gas is 1000h -1 , the reduction roasting time is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| magnetic susceptibility | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com