A kind of method for preparing ferromanganese spinel material

A spinel, ferromanganese technology, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of long roasting time and high roasting temperature, and achieve short roasting time, reduce reduction roasting temperature, and excellent magnetic properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

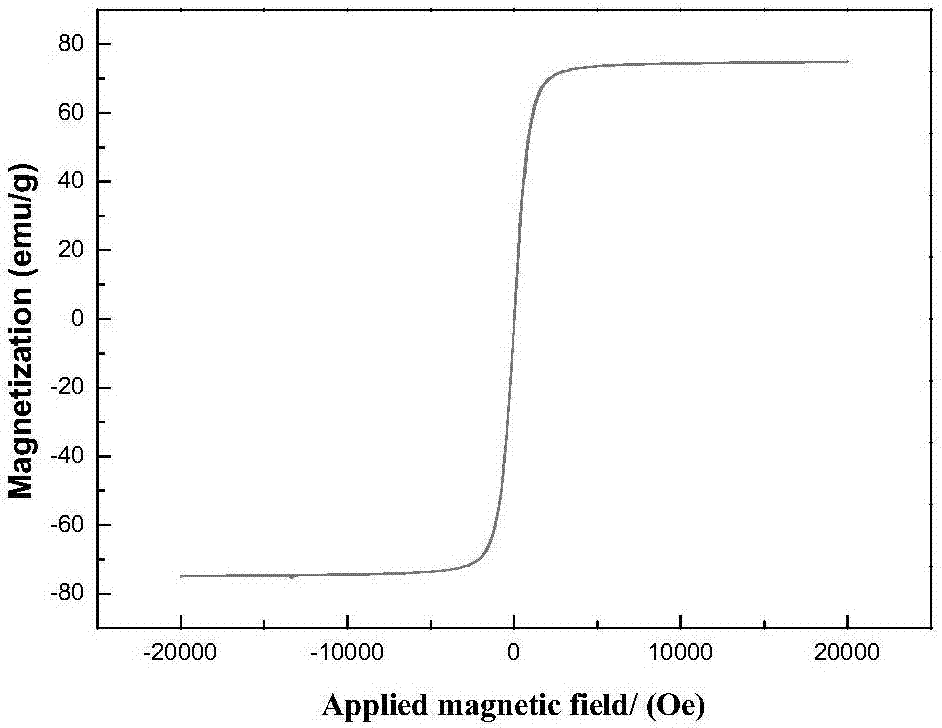

[0031] MnO 2 with Fe 2 o 3 Dosing according to the mass ratio of 0.5, where MnO 2 with Fe 2 o 3 The mass percentage of -325 mesh particle size is 99.5%, then add 0.5% CMC and 8% moisture to pelletize, then dry, and dry the sample in CO / (CO+CO 2 ) in an atmosphere with a concentration of 1% by volume from room temperature to 1300°C at a rate of 20°C / min, roasting for 3h, and then in N 2 The atmosphere was lowered to room temperature at a rate of 20°C / min, and then the roasted sample was ground until the -325 mesh size accounted for 100% by mass, and the obtained roasted product was spherical ferromanganese spinel material. The hysteresis loops of the samples obtained under this condition are as follows figure 1 As shown, the SEM picture of the particle morphology is as follows Figure 6 shown. Depend on Figure 6 It can be seen that the ferromanganese spinel particles have a spherical structure.

Embodiment 2

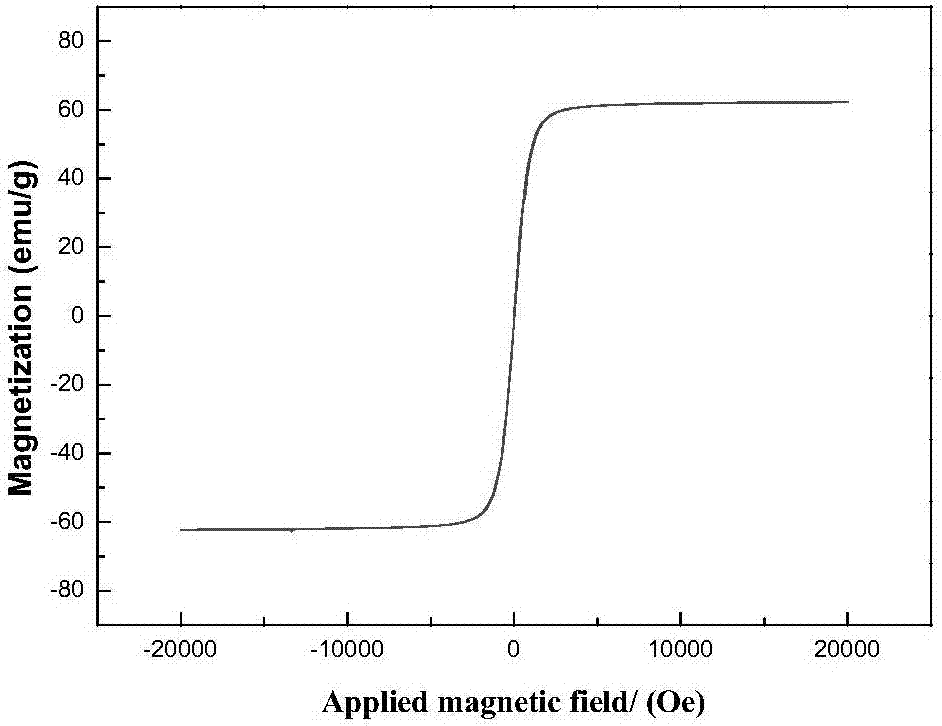

[0033] MnO 2with Fe 2 o 3 Dosing according to the mass ratio of 0.6, where MnO 2 with Fe 2 o 3 -325 mesh particle size accounts for 100% by mass, then add 0.5% humic acid and 8% moisture to make pellets, then dry, and dry the sample in (H 2 +CO) / (H 2 +CO+CO 2 ) volume percent concentration is 18.5%, H 2 / CO volume percent concentration of 20% in the atmosphere from room temperature at a rate of 20 ° C / min to 800 ° C, roasted for 10 h, and then in an Ar atmosphere at a rate of 20 ° C / min to room temperature, and then the roasted sample was ground The mass percent content of the particle size as fine as -325 mesh is 100%, and the obtained roasting product is coral reef-like ferromanganese spinel material. The hysteresis loops of the samples obtained under this condition are as follows figure 2 shown. The SEM pictures of the particle morphology are as follows Figure 7 shown. Depend on Figure 7 It can be seen that the ferromanganese spinel particles have a cora...

Embodiment 3

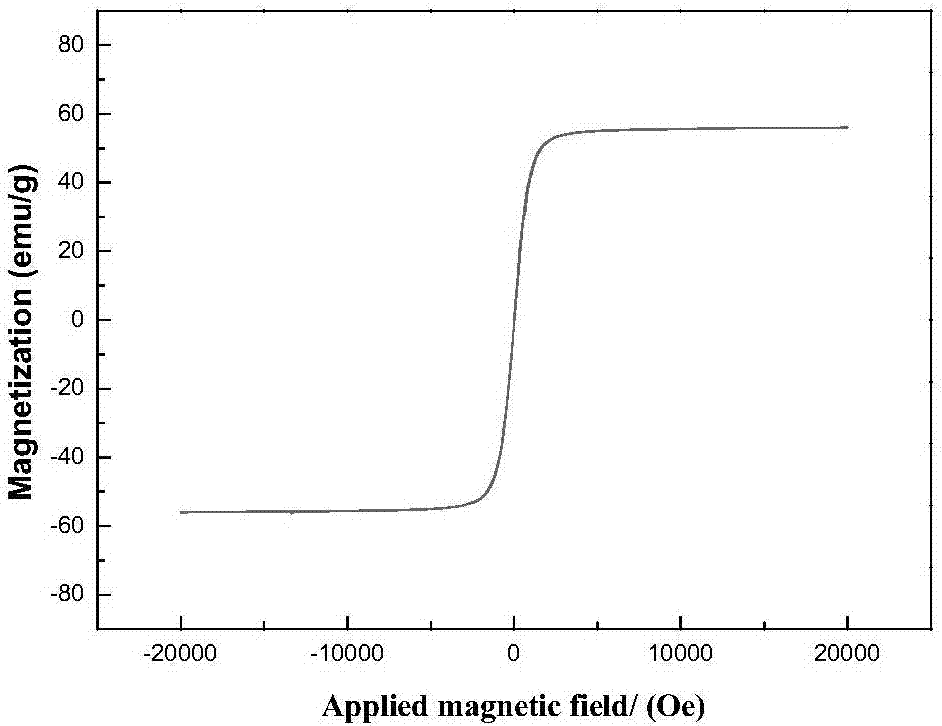

[0035] MnO 2 with Fe 2 o 3 Dosing according to the mass ratio of 0.55, where MnO 2 with Fe 2 o 3 -325 order particle size accounts for mass percent and composition is 100%, then add 0.5% CMC and 7% moisture to pelletize, then dry, the sample after drying is in (H 2 +CO) / (H 2 +CO+CO 2 ) volume percent concentration is 10%, H 2 / CO volume percent concentration of 10% in the atmosphere from room temperature at a rate of 20 ° C / min to 1200 ° C, roasted for 5 hours, and then in an Ar atmosphere at a rate of 20 ° C / min to room temperature, and then the roasted sample was ground The mass percent content of the particle size as fine as -325 mesh is 100%, and the obtained roasted product is spherical ferromanganese spinel material. The hysteresis loops of the samples obtained under this condition are as follows image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com