Patents

Literature

59results about How to "High degree of compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing environment-friendly type organosilicon modified acrylic ester binding agent

InactiveCN101423735APromote environmental protectionImprove stabilityFibre treatmentEster polymer adhesivesPolymer scienceAdhesive

The invention relates to a method for preparing an environment-friendly silicone-modified acrylate adhesive. Raw materials of the preparation method comprise a basic monomer, a modified monomer and an auxiliary agent, wherein the basic monomer comprises a hard monomer, a soft monomer and a crosslinking monomer; the modified monomer comprises a silane monomer, a coupling agent and inorganic nano-powder; the crosslinking monomer is glycidyl acrylate or glycidyl methacrylate; and the grain diameter of the inorganic nano-powder is less than 80 nanometers. In the preparation method, the crosslinking monomer adopts the glycidyl acrylate or the glycidyl methacrylate so as to be environment-friendly. The product prepared by the method is a nanometer / silicone double-modified molecular composite polymer material. The molecular composite material is combined with the advantages of two polymer materials, namely silicone and polyacrylic ester and an inorganic nanometer material, and has better performance and broad application.

Owner:WUHAN TEXTILE UNIV

Method for preparing organosilicon modified acrylic ester binding agent

InactiveCN101423734AThe emulsion system is stableImprove stabilityFibre treatmentEster polymer adhesivesHigh concentrationPolymer science

The invention relates to a method for preparing a silicone-modified acrylate adhesive, which comprises the following: (1) a step of the pre-polymerization of a modified monomer, in which the modified monomer, a modified monomer catalyst, an emulsifying agent and deionized water are pre-polymerized to obtain a silicone pre-polymerization emulsion; (2) a step of emulsification, in which the silicone pre-polymerization emulsion and a basic monomer are emulsified to obtain an intermediate pre-emulsion; and (3) a step of the polymerization of acrylic ester, in which the intermediate pre-emulsion is polymerized with a basic monomer catalyst and the deionized water to obtain a finished product. The method adopts a fractional step method to emulsify according to the hydrophilicity of various monomers. During the emulsification step by step, a polymeric monomer with stronger hydrophobicity which is added first can be effectively and steadily dispersed under the condition of relatively higher concentration of the emulsifying agent, which strengths the stability of a monomer pre-emulsion. The grain diameter of the prepared adhesive emulsion is smaller and has narrower distribution, the emulsion system is also more stable, and various application performances are superior to those of adhesive products prepared by the prior method.

Owner:WUHAN TEXTILE UNIV

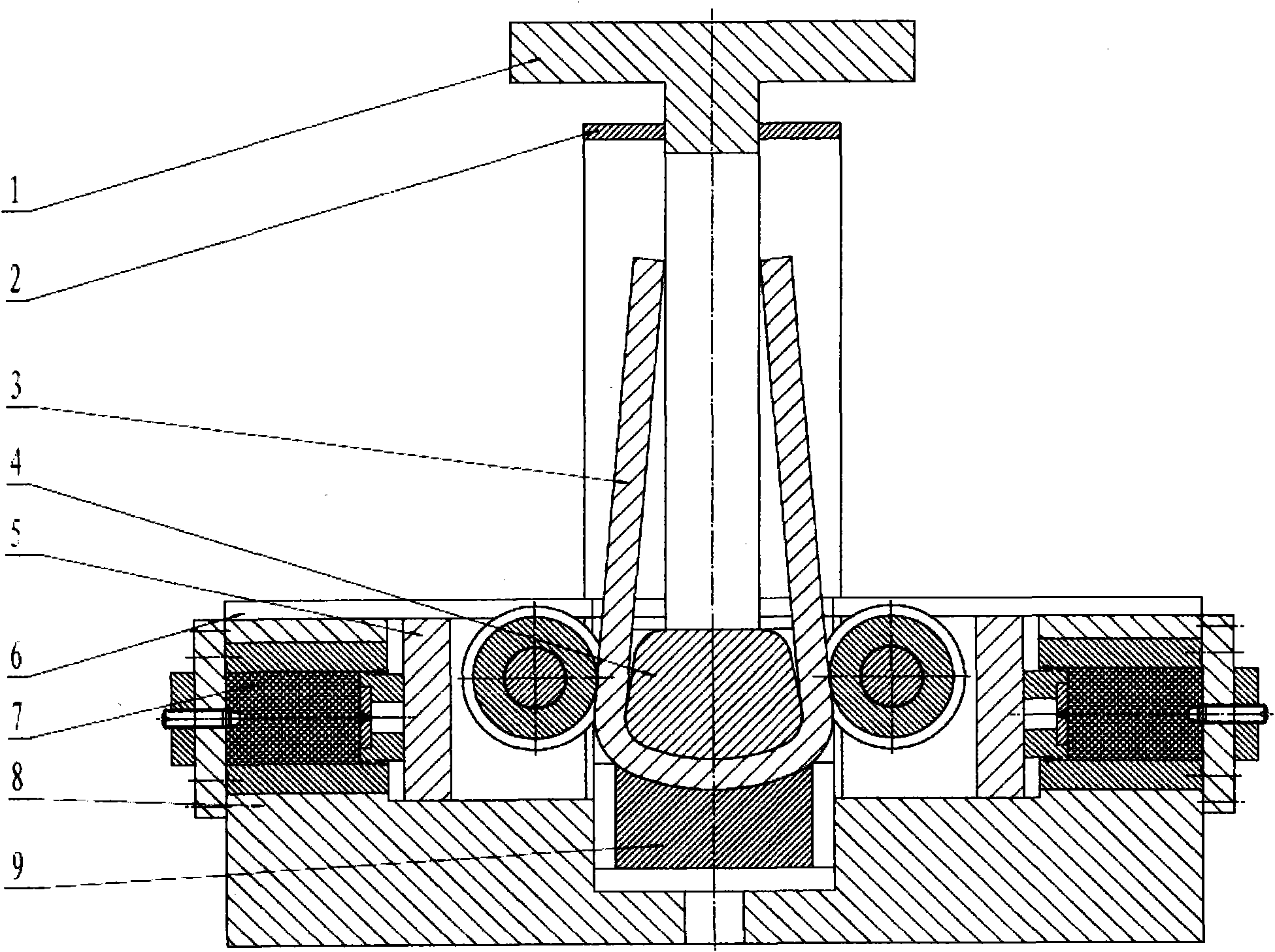

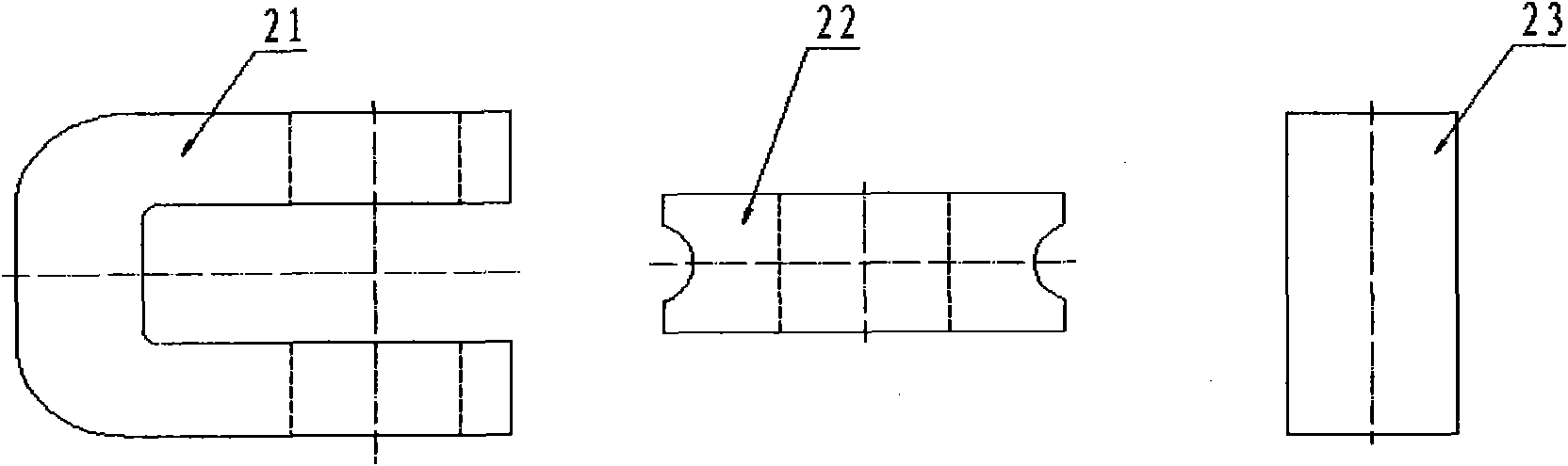

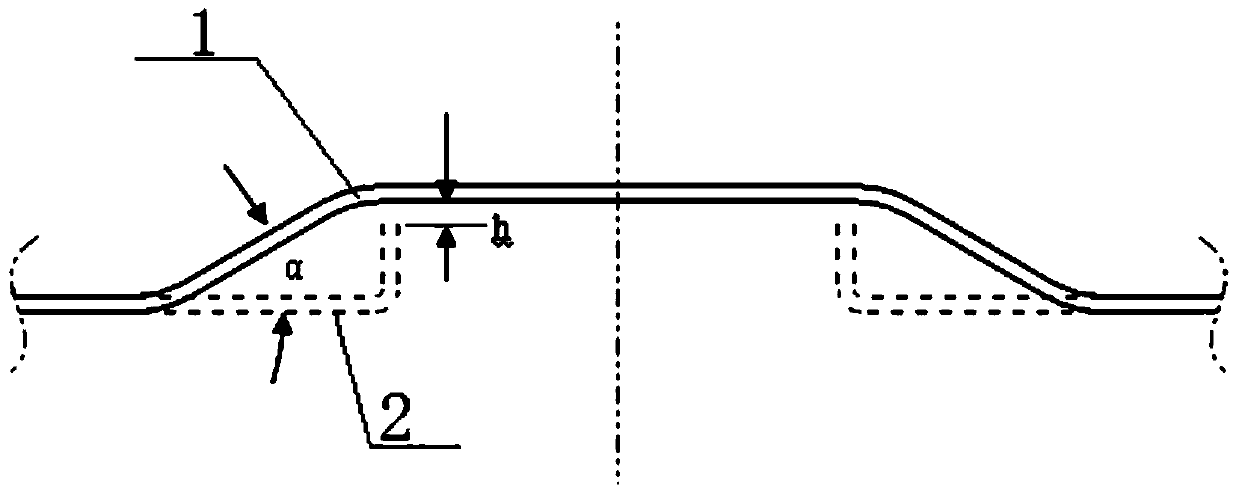

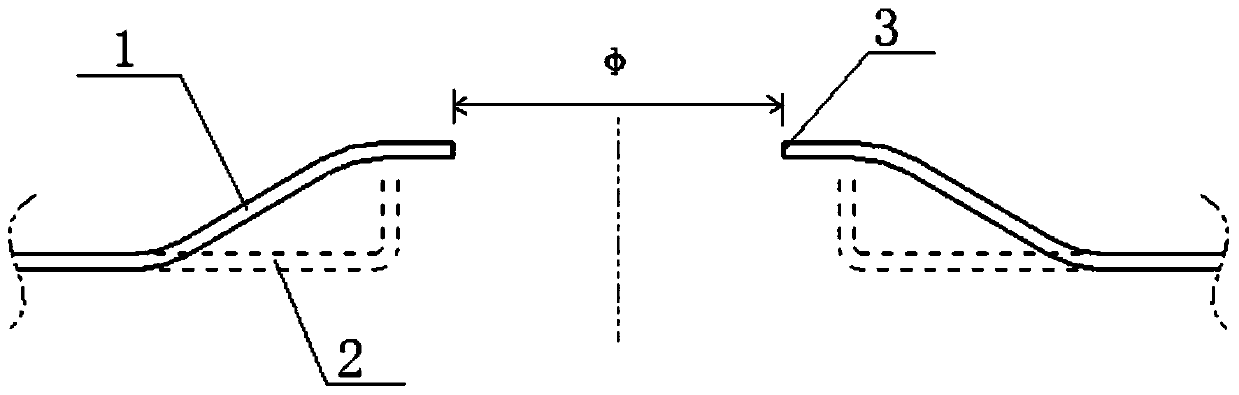

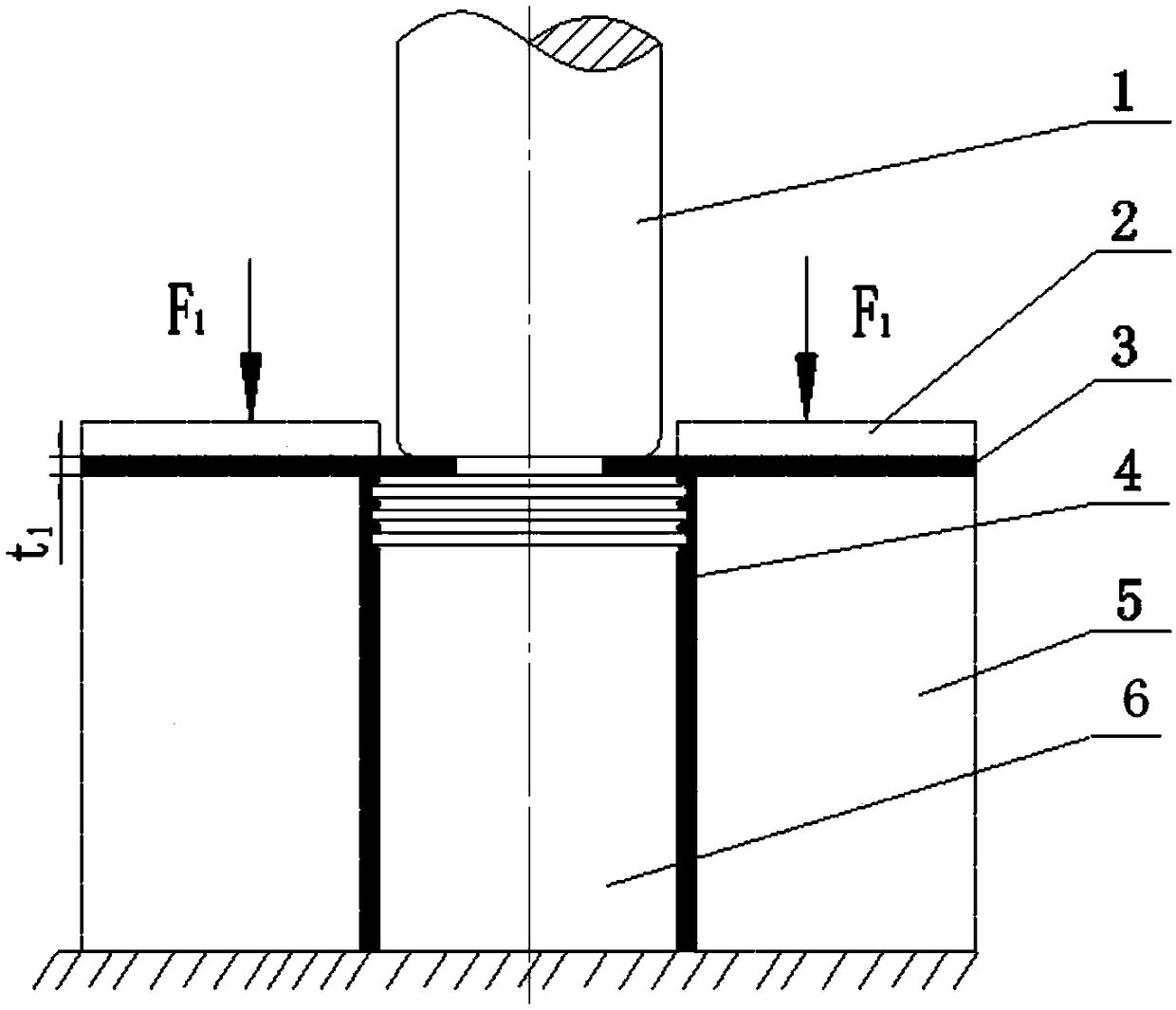

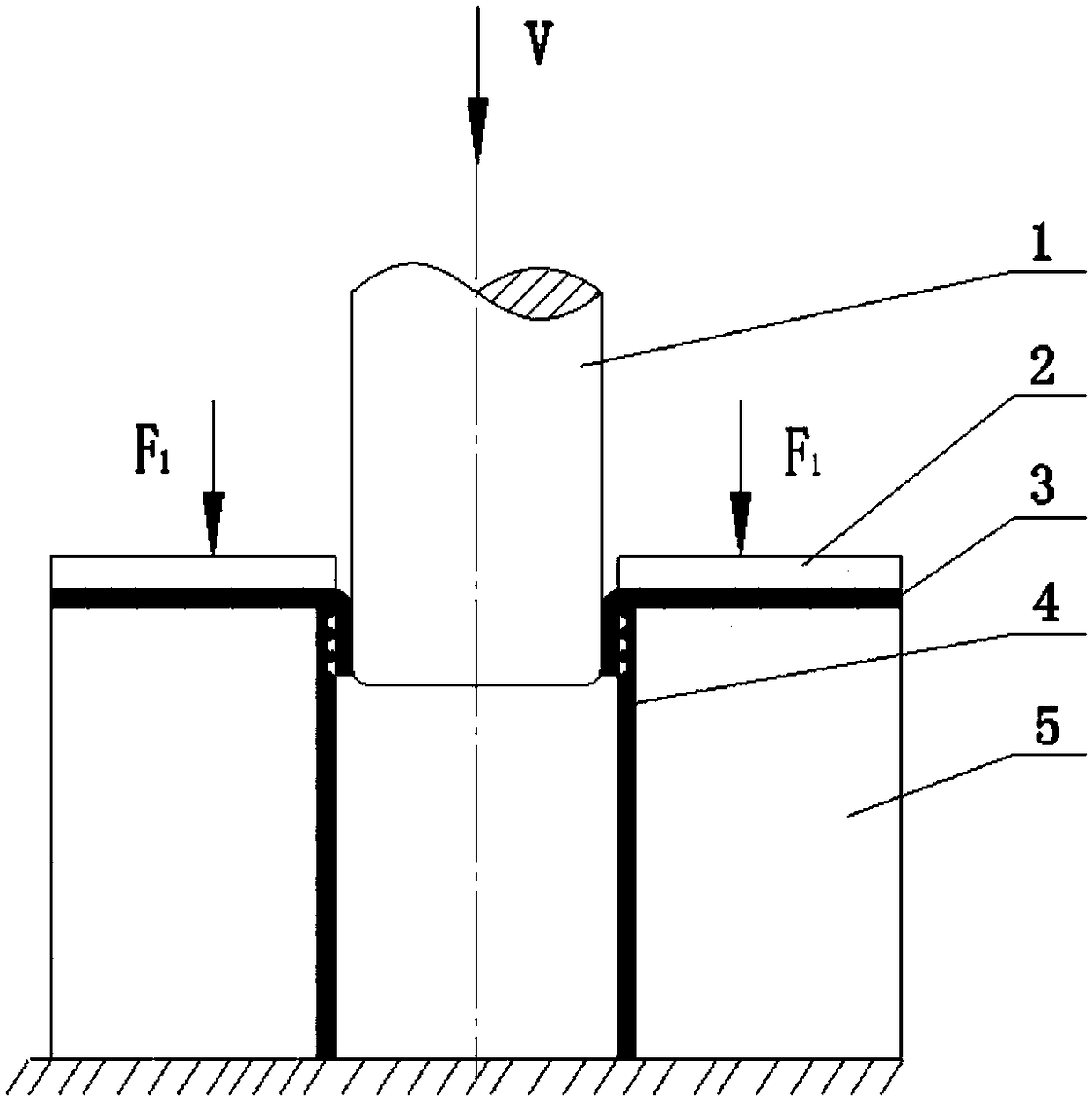

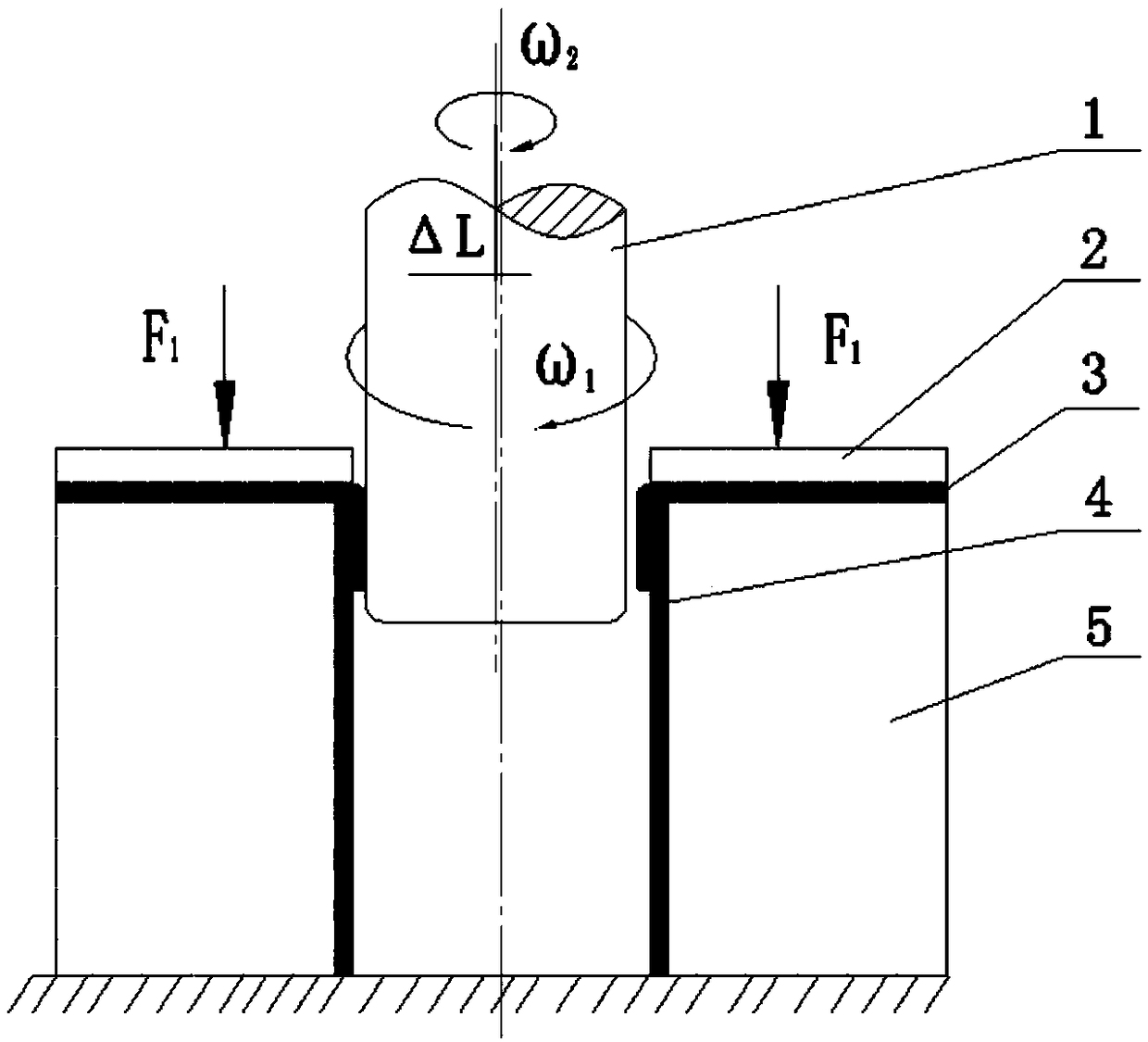

Moving die compressive stress decomposing and forming method, volume spring and U-shaped bolt composite bending die

InactiveCN101856693ALarge bending forceIncrease bending forceShaping toolsMultiple spring combinationsEngineeringHardness

The invention relates to a moving die compressive stress decomposing and forming method, a volume spring and a U-shaped bolt composite bending die. Aiming at the problems that under cold pressing, with the 1-2mm large tolerance range of the forging stock thickness of a U-shaped bolt, the rebound of the U-shaped bolt can not be finished in an one-step forming way when a clearance between a convex die and a concave die of a bending die is large, and the die is easy to crush and break open when the clearance is small, and the production efficiency is low, accordingly, a forming die structure of the convex die and the moving concave die under a required clearance state that the clearance between the convex die and the concave die is 1-5 less than the foraging stock thickness is adopted, wherein the convex die is an original rigid-fixed convex die; the moving concave die is a dynamic compressive stress retractable concave die which is formed in such a way that an original concave die is correspondingly separated and guided to limit connection and then is in retractable connection with the volume spring fixedly arranged at the outer side; the volume spring realizes the rebound by compressing the volume of fluid and solid contained and sealed by a metal shell; and the U-shaped bolt composite bending die is obtained by adopting the structure of the convex die and the moving concave die as well as the application of the volume spring, therefore, the aim of controlling rebound bending by the spring is achieved by adopting one-step bending forming compounding with hardness and softness.

Owner:李义

Method for producing hollow microsphere modified fluoro-silicone emulsion and outer wall heat-insulating coating thereof

ActiveCN101805433AGood weather resistanceImprove performanceReflecting/signal paintsMicrosphereSolvent

The invention relates to a building outer wall heat-insulating coating, in particular to a method for producing hollow microsphere modified fluoro-silicone emulsion and outer wall heat-insulating coating thereof. Hollow microspheres are added into aqueous solution containing vinylsilane coupling agent and uniformly stirred, so that hollow microsphere dispersion with the solid content of 20 percent to 60 percent is produced, and the hollow microsphere dispersion, deionized water, buffer and emulsifier are uniformly mixed and then added with fluorin, silicon acrylate mixed monomer and initiator to carry out reaction, so that the hollow microsphere modified fluoro-silicone emulsion is produced. The hollow microsphere modified fluoro-silicone emulsion is uniformly mixed with bactericide, dispersing agent, wetting agent, cosolvent and defoamer and then added with thickening agent, so that the outer wall heat-insulating coating is produced. The outer wall heat-insulating coating has the advantages of excellent comprehensive performance, outstanding heat-insulating, stain-resistant and weather-resistant properties and convenient construction, and therefore has a broad market prospect.

Owner:武汉双虎涂料股份有限公司

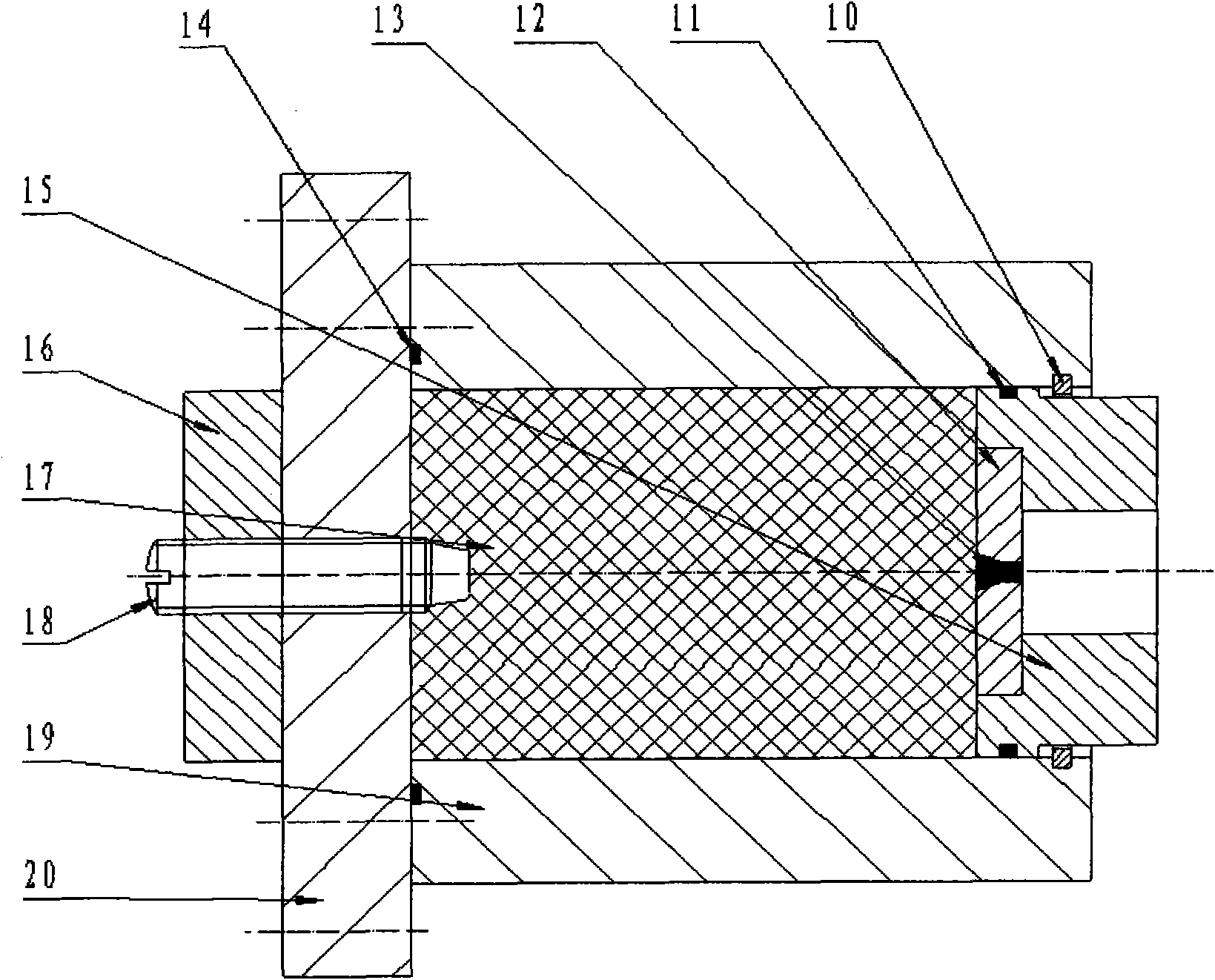

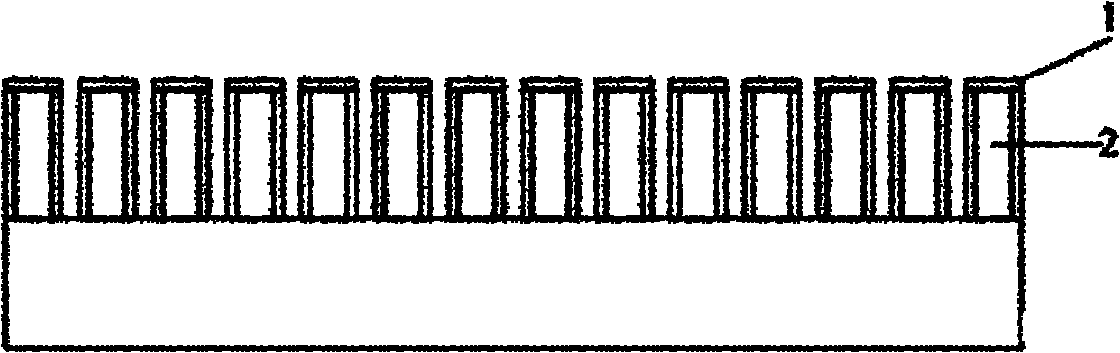

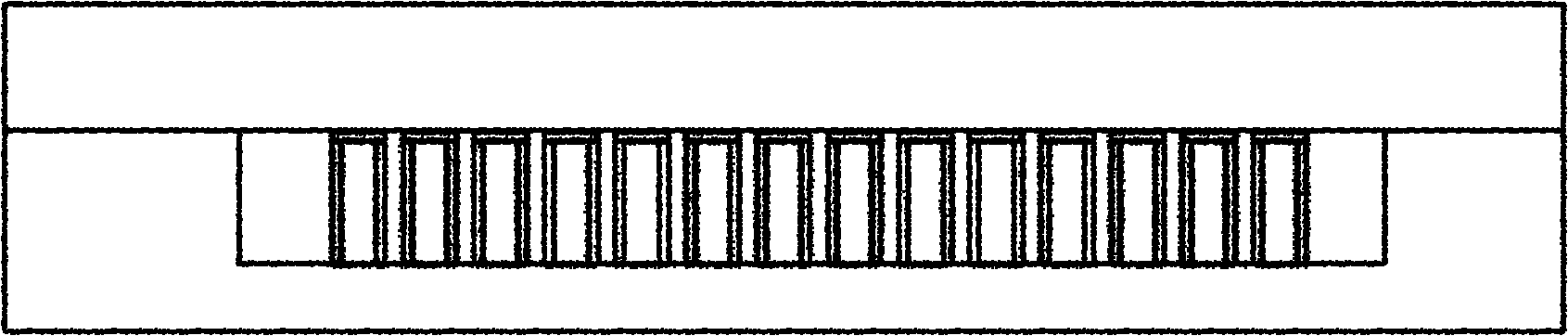

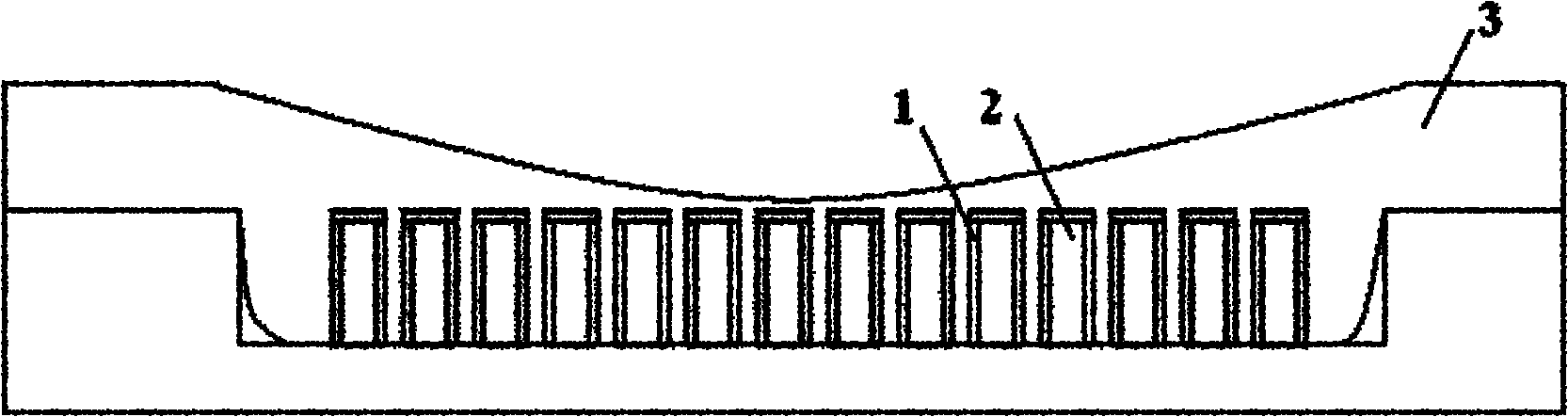

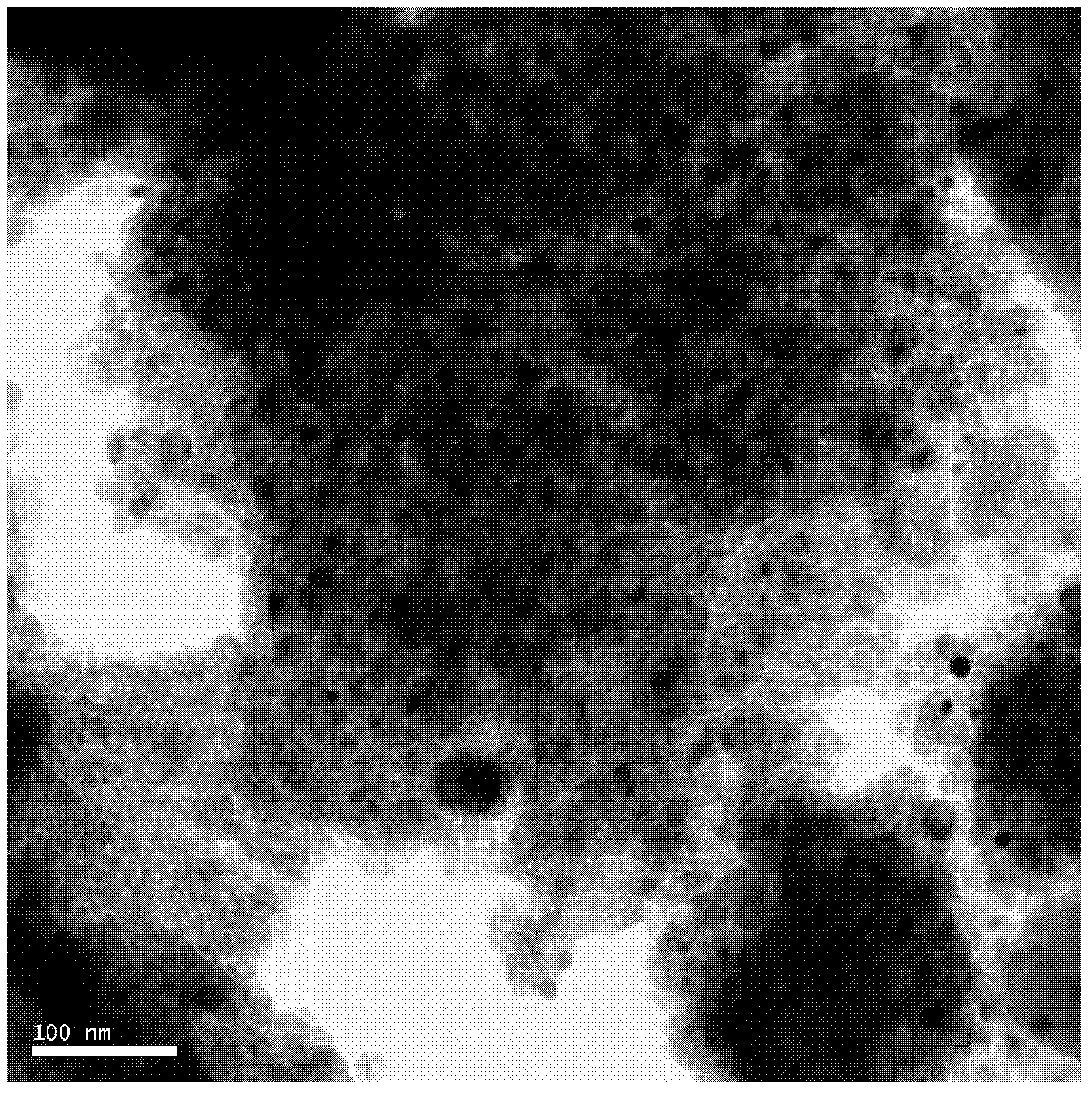

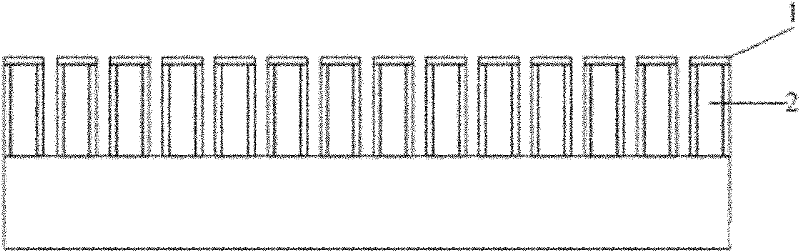

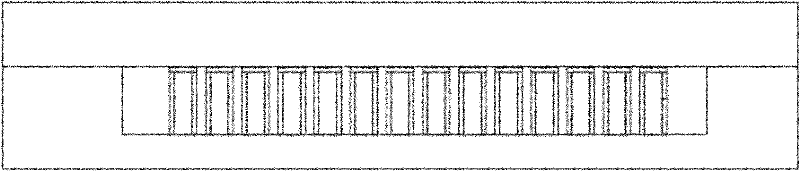

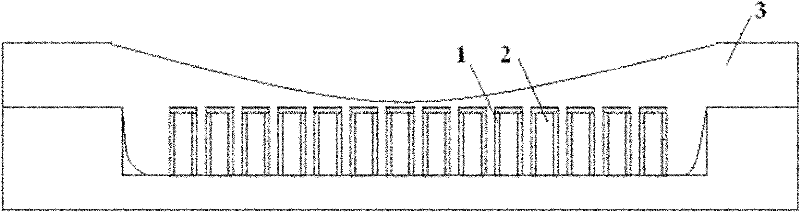

Preparation method for high-density interposer for microelectronic system-in-package

ActiveCN102070120AImprove reliabilitySmall coefficient of thermal expansionDecorative surface effectsChemical vapor deposition coatingThermal dilatationElectrical conductor

The invention discloses a preparation method for a high-density interposer for microelectronic system-in-package. The preparation method comprises the following steps of: 1, preparing a drectionally growing carbon nanotube bundle array, wherein the diameter of each carbon nanotube bundle is 0.5 to 30 microns, the gap of the carbon nanotube bundle is 0.8 to 100 microns, and the carbon nanotube bundle is 40 to 500 microns long; 2, depositing metal tungsten on the surface of the drectionally growing carbon nanotube bundle so as to form a conductor array; 3, melting borosilicate glass and compounding the melted borosilicate glass with the conductor array so as to form a compound body; and 4, grinding the upper surface and the lower surface of the formed compound body so as to expose the end of the carbon nanotube bundle deposited with the metal tungsten, and obtaining the high-density interposer for the system-in-package. The material adopted by the preparation method has low thermal expansivity and the process method is low in time consumption, so the prepared high-density interposer has the advantages of high density, high reliability and low cost.

Owner:SOUTHEAST UNIV

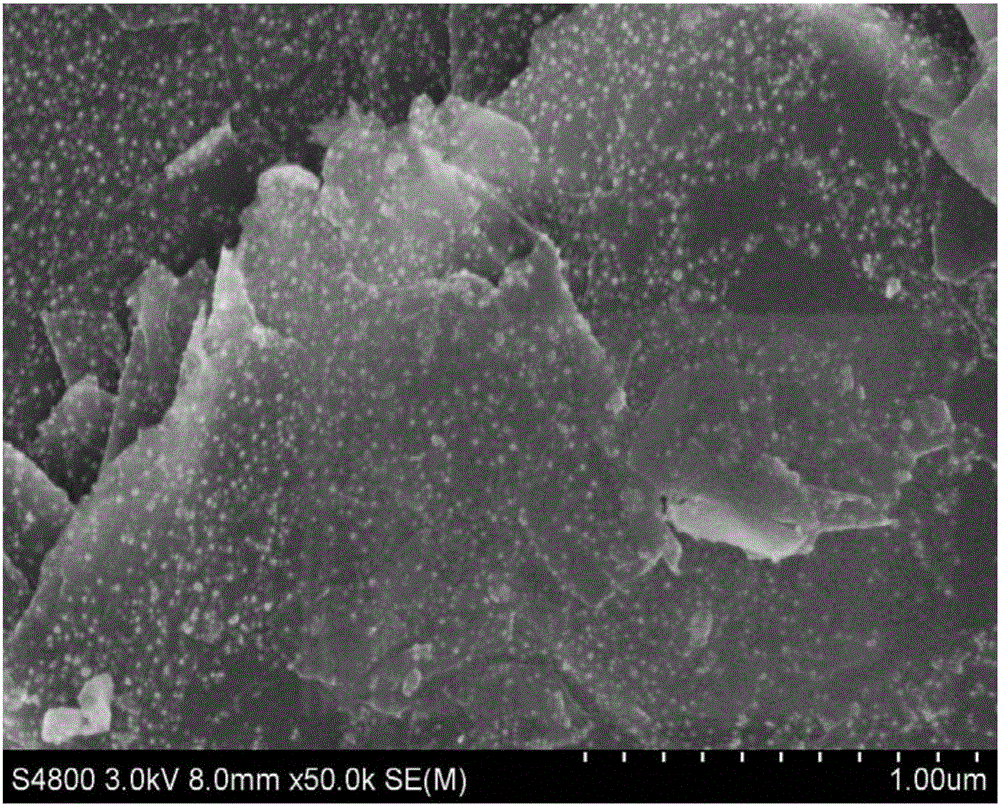

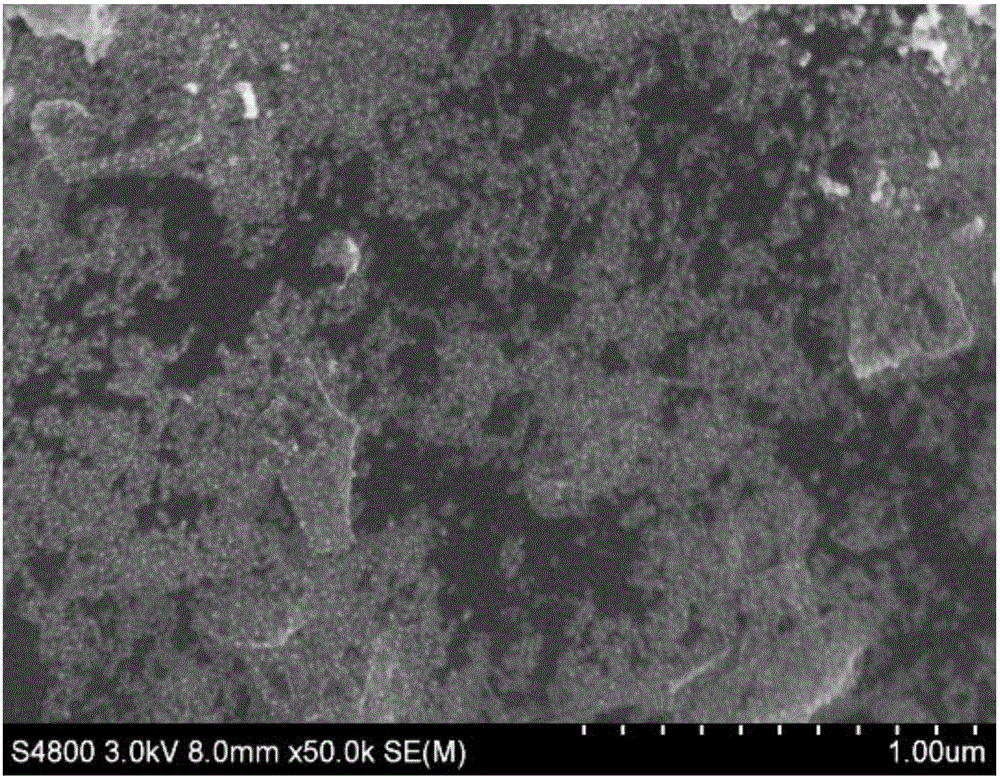

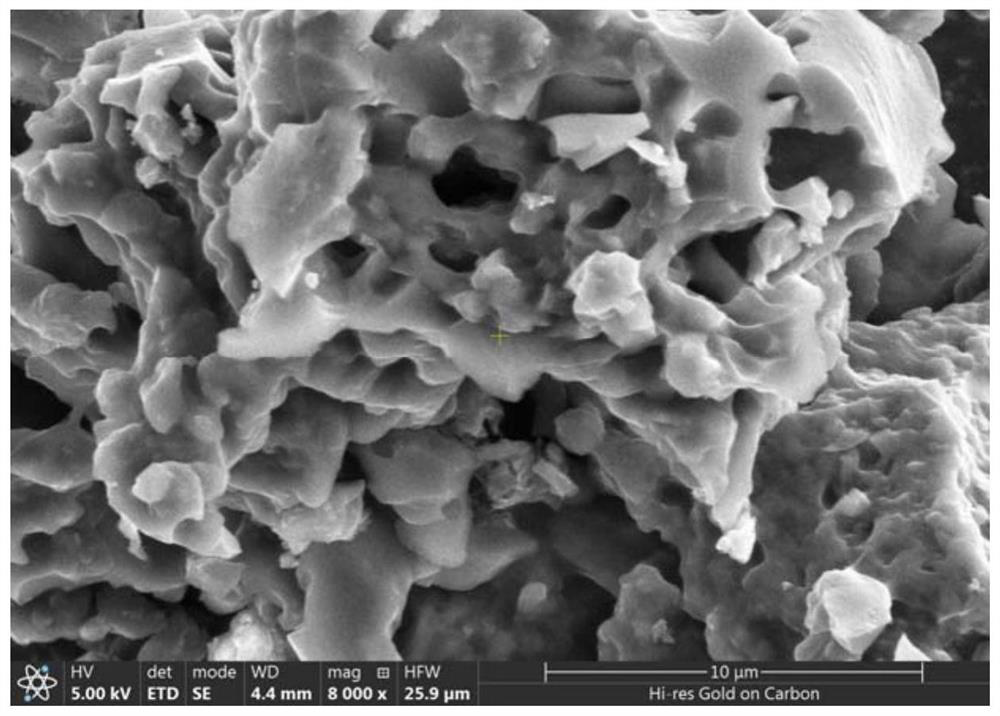

Carbon-silicon composite material, and preparation method and application thereof

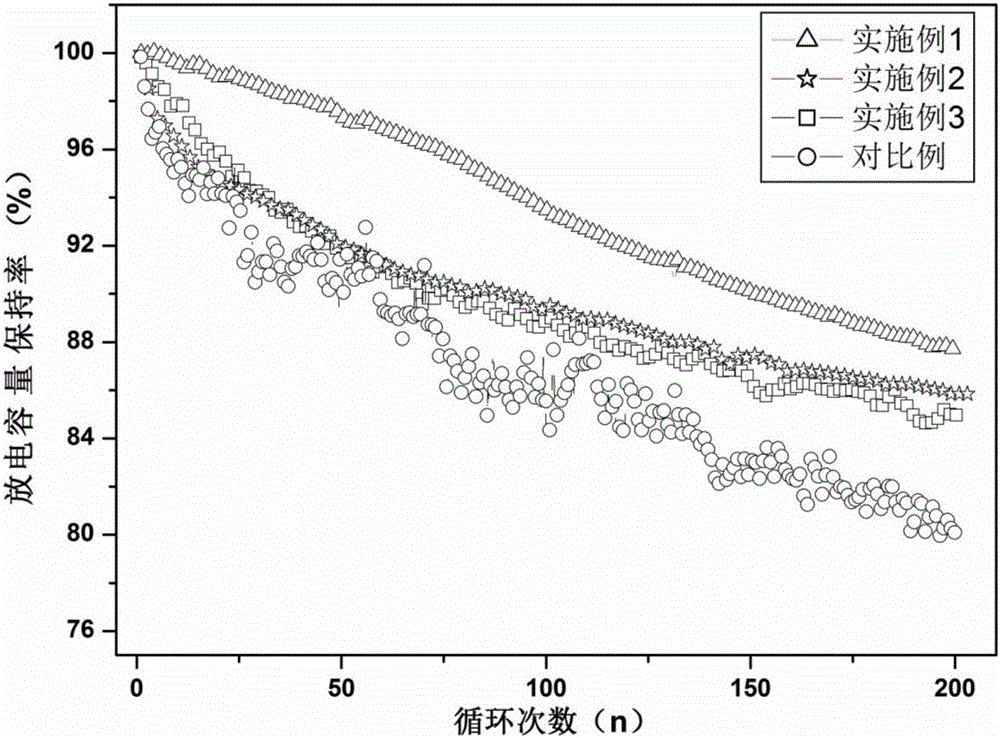

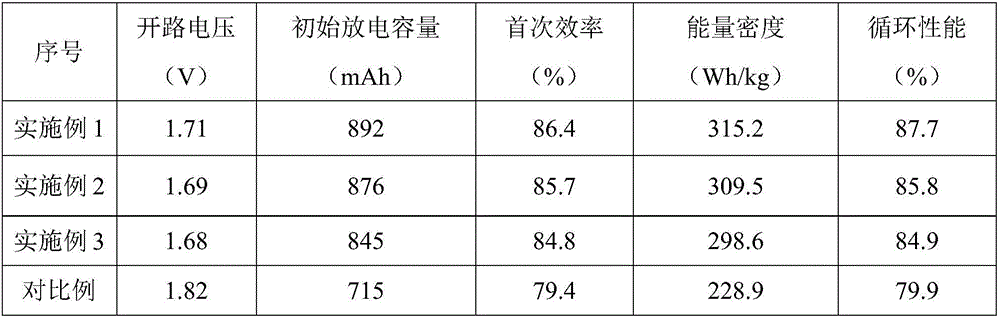

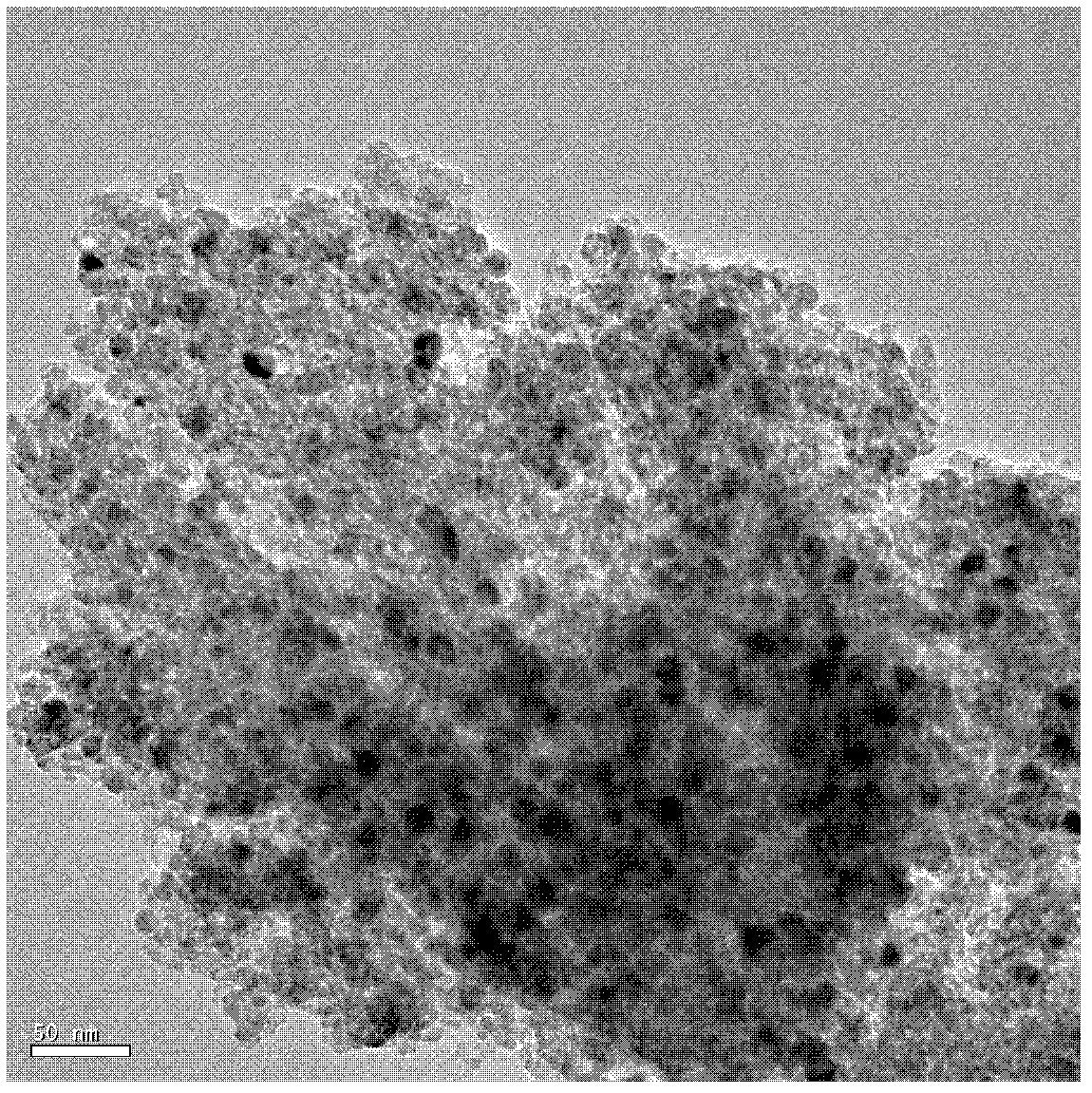

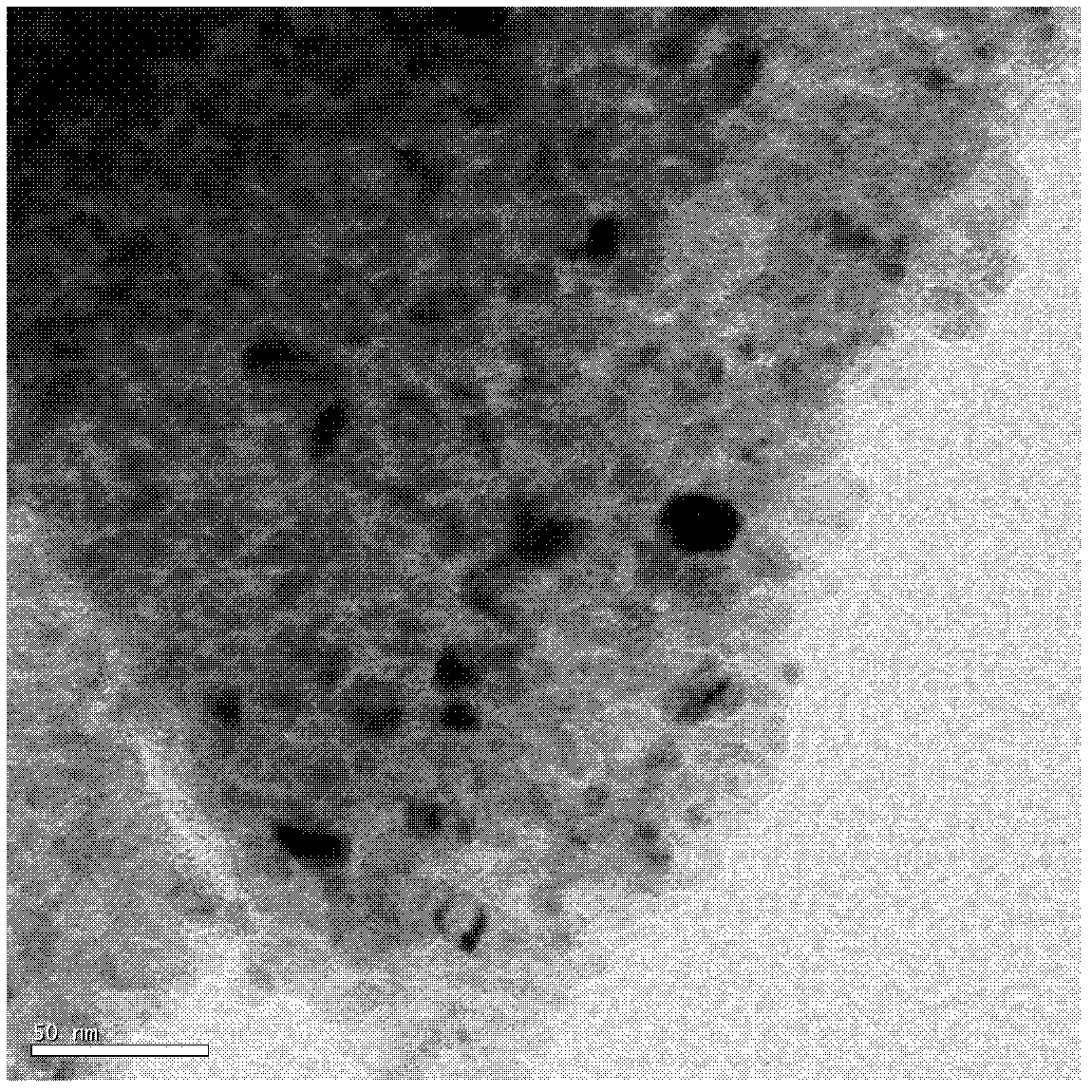

InactiveCN106848268ATightly boundHigh degree of compoundMaterial nanotechnologySecondary cellsReaction temperatureCatalytic decomposition

The invention relates to a carbon-silicon composite material, a preparation method thereof and an application in a lithium ion battery. The carbon-silicon composite material provided by the invention comprises a carbon substrate, a catalyst and nanometer silicon grains and / or a silicon film uniformly attached to the carbon substrate. The method comprises the following steps: 1) preparing dispersion liquid of an organic additive and the catalyst; 2) uniformly mixing the carbon substrate with the dispersion liquid and then drying, thereby modifying the surface interface of the carbon substrate with the catalyst; and 3) transferring the carbon substrate modified with the catalyst into a CVD furnace, increasing the temperature under a protective atmosphere till reaching the reaction temperature, then introducing a silicon source for reacting, and uniformly attaching the nanometer silicon grains and / or the silicon film generated by catalytic decomposition to the surface interface of the carbon substrate, thereby obtaining the carbon-silicon composite material. The method provided by the invention has easiness in large-scale preparation; the silicon carbon compounding degree of the product is high; and the carbon-silicon composite material is an excellent negative electrode material for the lithium ion battery.

Owner:BTR NEW MATERIAL GRP CO LTD

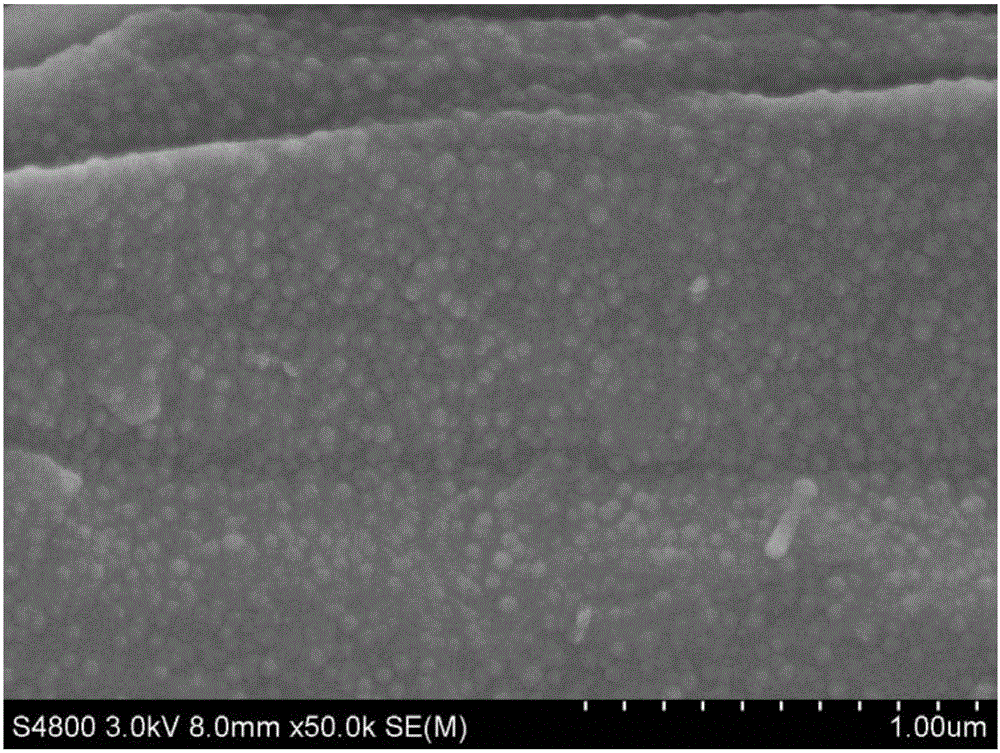

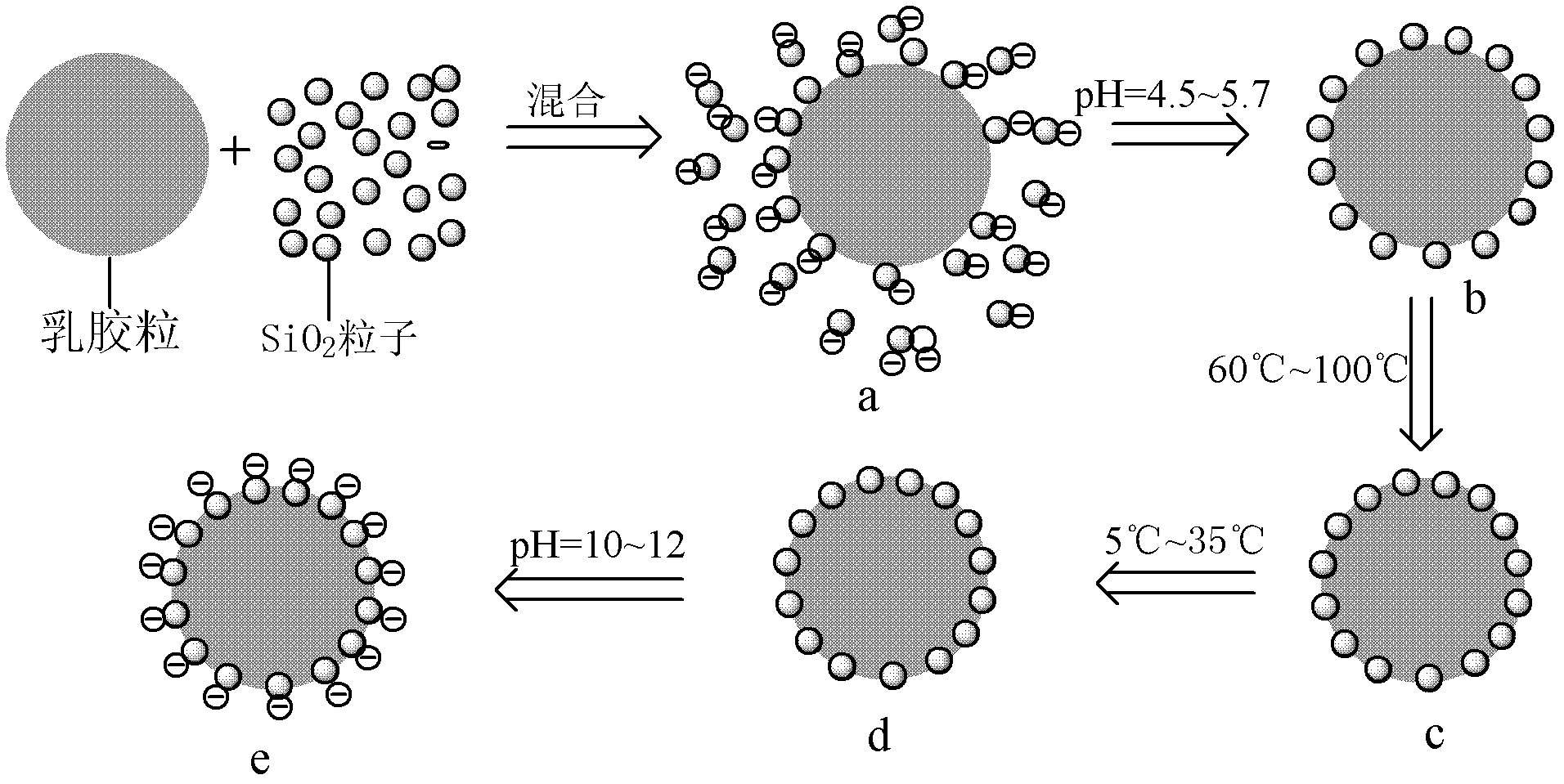

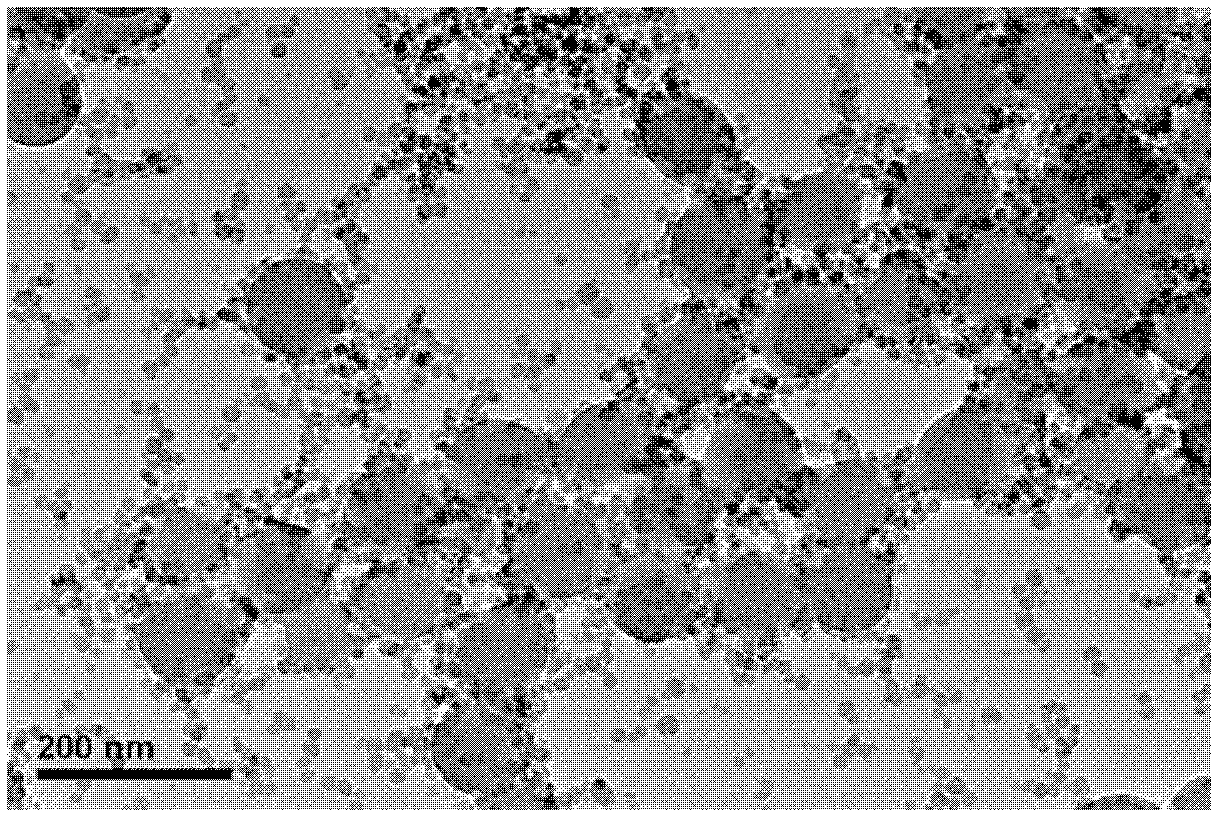

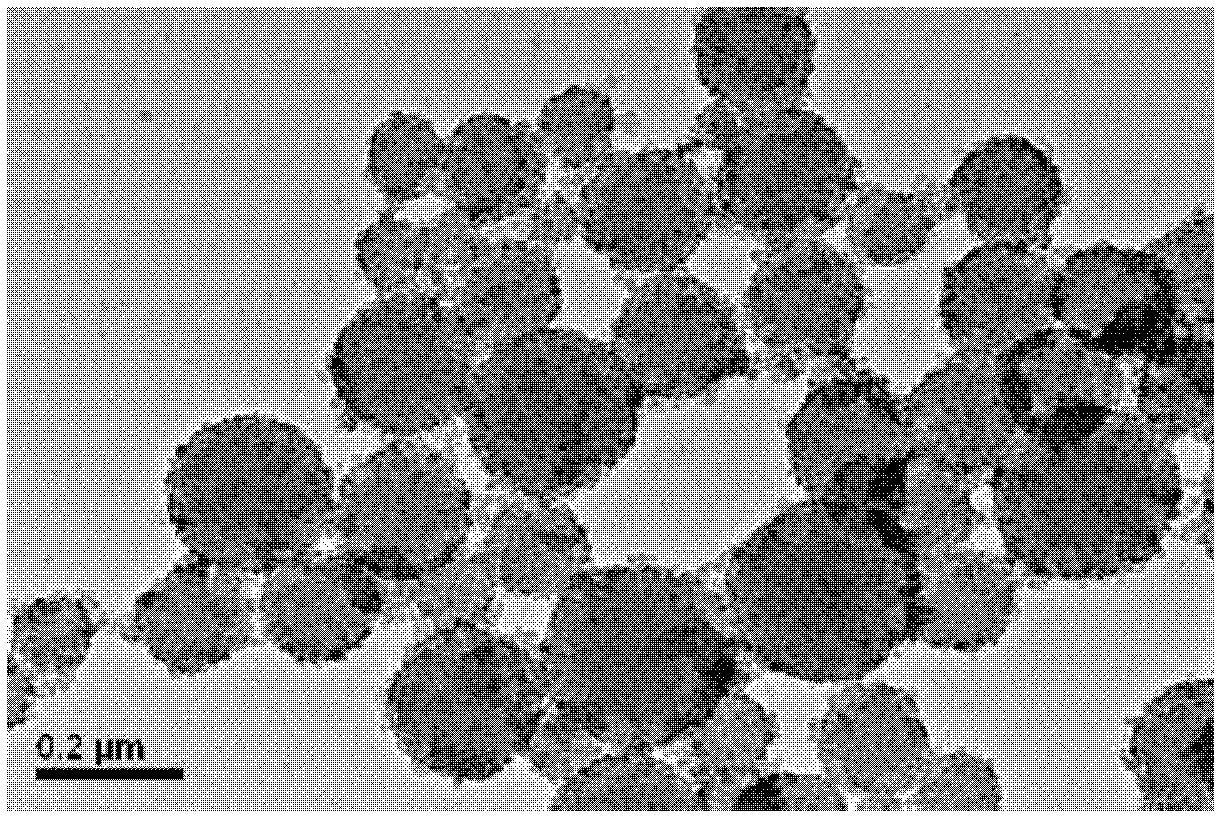

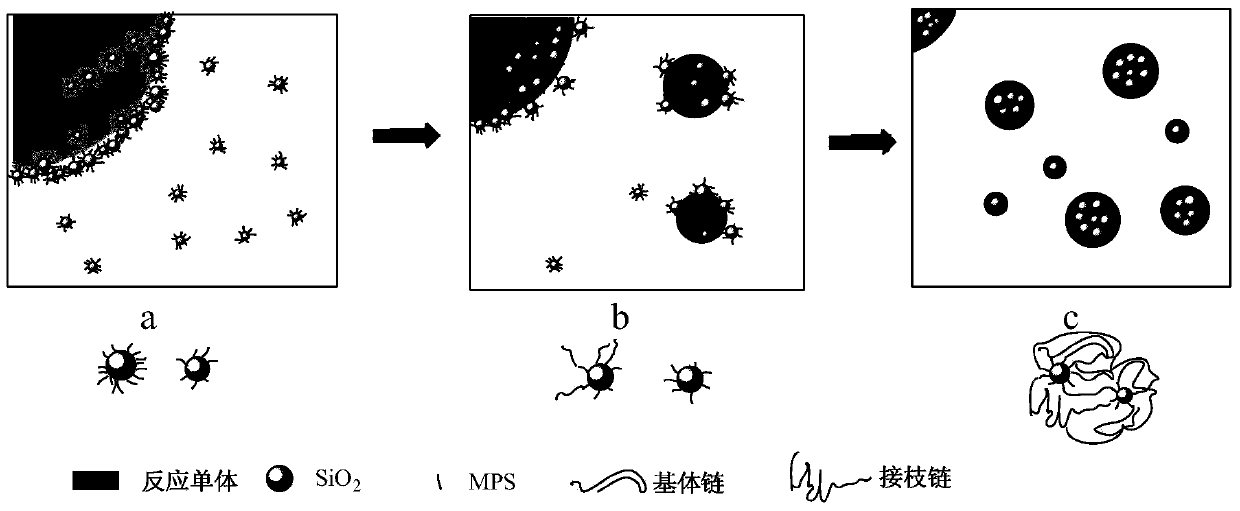

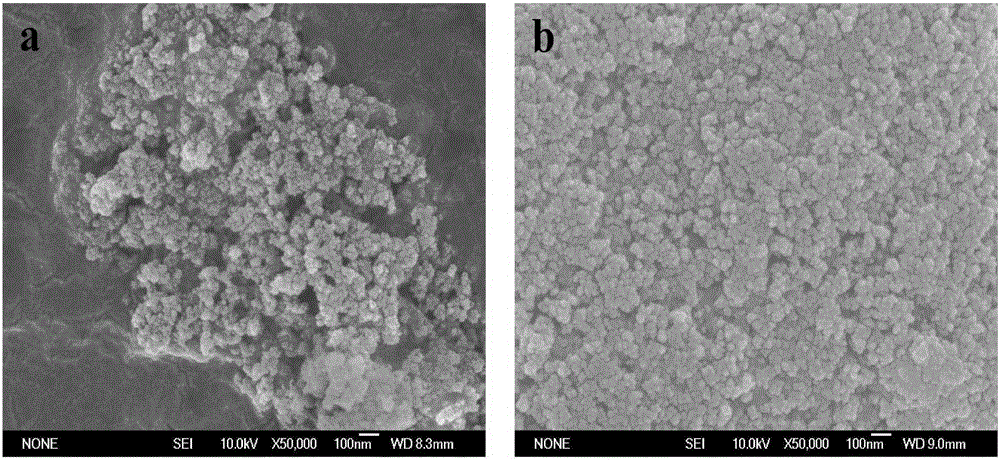

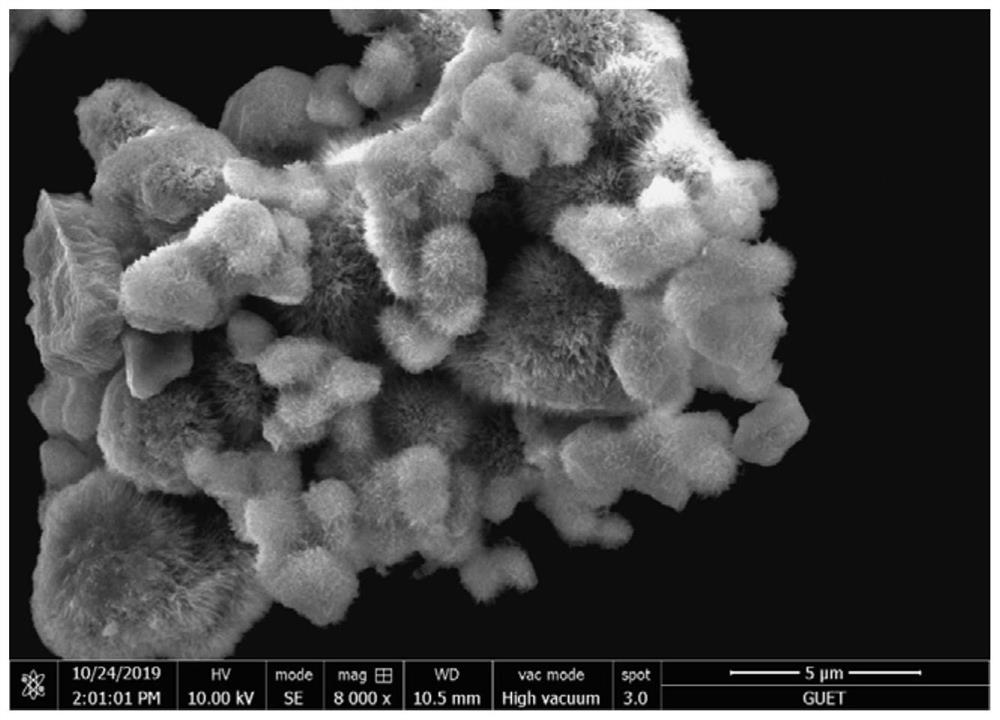

Preparation method of strawberry-shaped organic-inorganic nanometer composite microsphere

ActiveCN102430372AMature technologyLow costMicroballoon preparationMicrocapsule preparationSilica particleMicrosphere

The invention discloses a preparation method of a strawberry-shaped organic-inorganic nanometer composite microsphere. The preparation method comprises the following steps: 1, adding a silica colloid to a styrene acrylate copolymer latex drop by drop under stirring, and adding an acid drop by drop to adjust the pH value of the obtained material to 4.5-5.7 to form a blending system; 2, heating theblending system to 60-100DEG C under stirring, and continuously stirring for 0.5-3.0h under the shearing effect to obtain an organic-inorganic nanometer composite latex system; 3, cooling the organic-inorganic nanometer composite latex system, and adding an alkali drop by drop to adjust the pH value of the latex system to 10-12 to obtain the firmly-combined stably-dispersed strawberry-shaped organic-inorganic nanometer composite microsphere with the surface embedded with small silica particles. The preparation method has the advantages of wide resource and easy availableness of raw materials,simple preparation technology, good latex particle controllability, and wide adjustable range of the particle size of the composite microsphere. The strawberry-shaped organic-inorganic nanometer composite microsphere prepared with the method, which has the advantages of high composite degree, good structure firmness and stable placement, can be applied to the fields of coatings, rubbers, plastics, the biology and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Transition metal oxide/binary carbon network positive electrode composite material and aluminum-ion battery

ActiveCN106129374AImprove structural stabilityImprove cycle performanceCell electrodesSecondary cellsAluminum IonGas phase

The invention relates to a transition metal oxide / binary carbon network positive electrode composite material and an aluminum-ion battery. Preparation of the positive electrode composite material comprises the steps of (1) adding a catalyst and a citric acid to water for mixing to obtain a catalyst precursor solution; (2) soaking a transition metal oxide into the catalyst precursor solution and carrying out separating and drying to obtain a transition metal oxide / catalyst precursor composite material; and (3) preparing a transition metal oxide / carbon nanotube composite material through chemical vapor deposition, soaking the transition metal oxide / carbon nanotube composite material into a graphene oxide dispersion liquid, carrying out separating and drying to obtain the transition metal oxide / carbon nanotube / graphene oxide composite material and then carrying out reductive heat treatment to obtain the transition metal oxide / binary carbon network positive electrode composite material. According to the positive electrode composite material provided by the invention, a binary carbon network coats the surface of the transition metal oxide, so that the conductivity and the structure stability of the positive electrode material are improved; the cycle performance of the electrode material is improved; and the transition metal oxide / binary carbon network positive electrode composite material can be applied to preparation of the high-performance aluminum-ion battery.

Owner:深圳博磊达新能源科技有限公司 +1

Nano-composite catalyst and preparation method thereof

ActiveCN102626641AHigh degree of compoundReduce dosageMetal/metal-oxides/metal-hydroxide catalystsDecompositionSurface-active agents

The invention provides a nano-composite catalyst and a preparation method thereof, belongs to the technical field of catalyzing, and solves the problem that the conventional load nano-composite oxide catalyst is low in nano-composite degree, and poor in catalyzing performance. The nano-composite catalyst is obtained by the flowing steps based on the condition that a surface-active agent is not used: firstly, reducing composite oxide crystal lattices or first metal ions mixed in the crystal lattices so as to obtain nano-metal granules containing first metal; and then introducing second metal into the surface of the first metal by Galvanic substitution reaction so as to obtain the nano-composite catalyst. Compared with the conventional catalyst, the nano-composite catalyst has more efficient catalyzing performance when being used for catalytic reaction of VOC (volatile organic compound) removal, automobile tail gas purification, formaldehyde removal, methane combustion, hydrogenation, hydrogenolysis, ammonia synthesis, ammonia decomposition, hydrocarbon synthesis, hydroformylation and the like.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

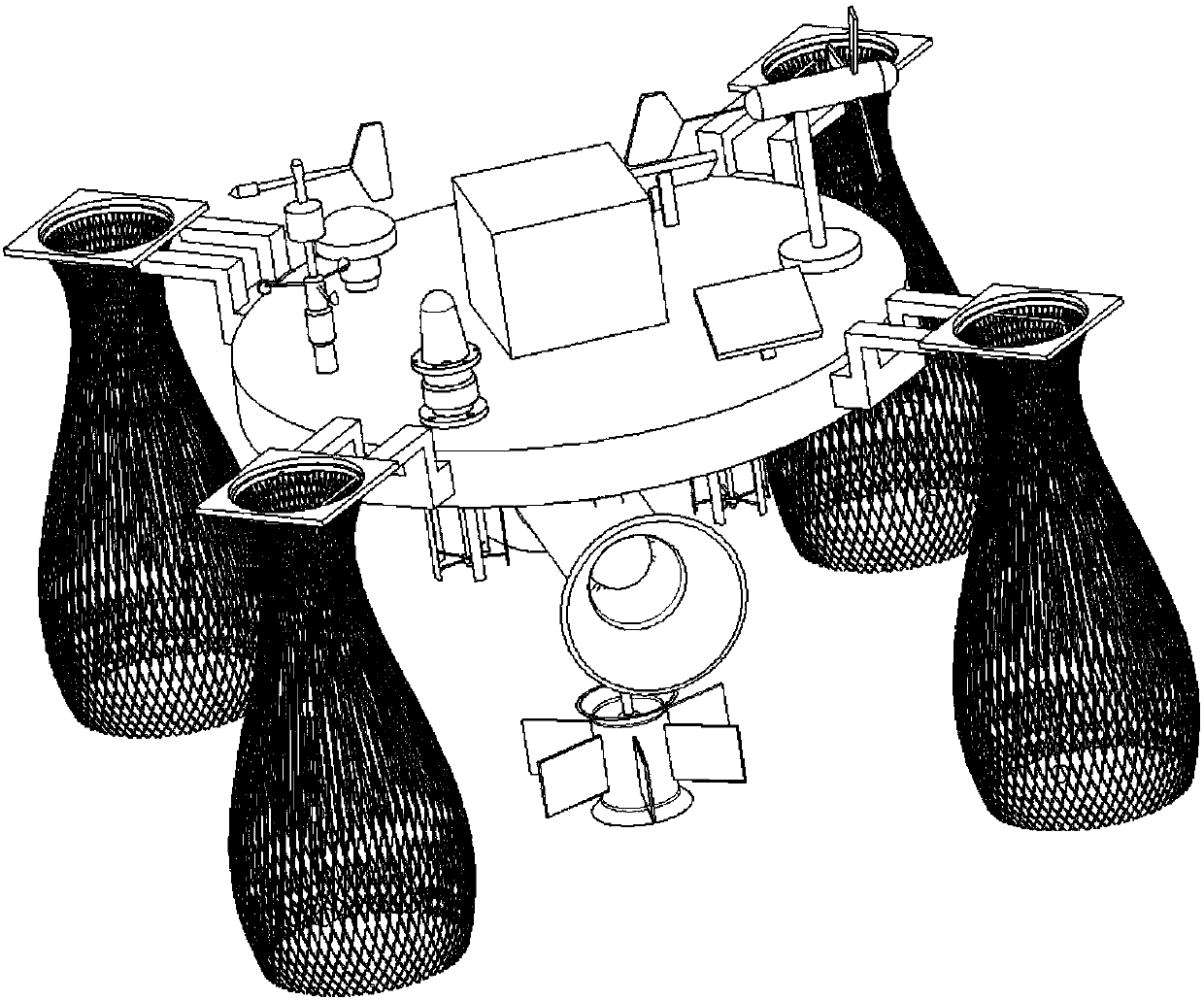

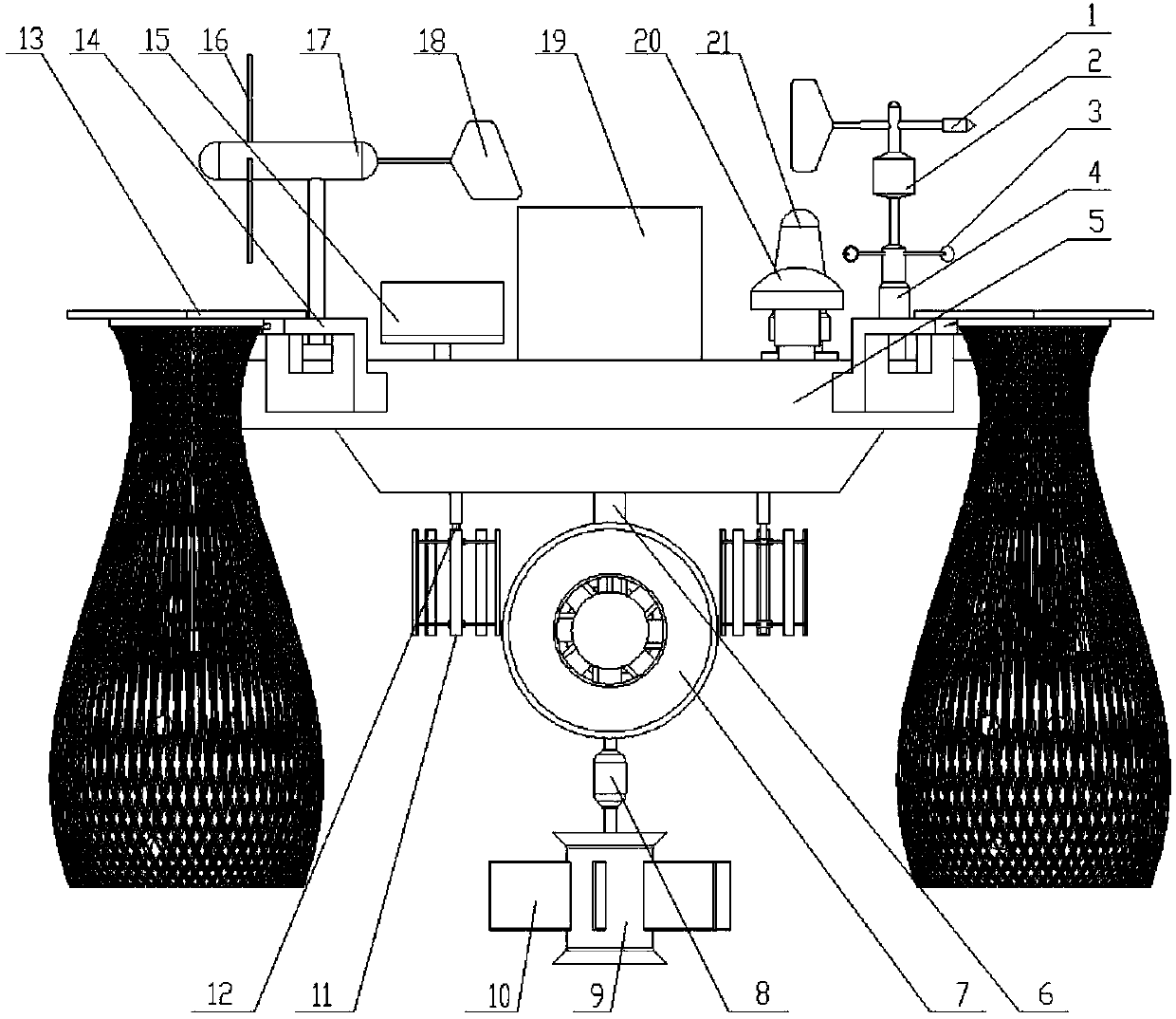

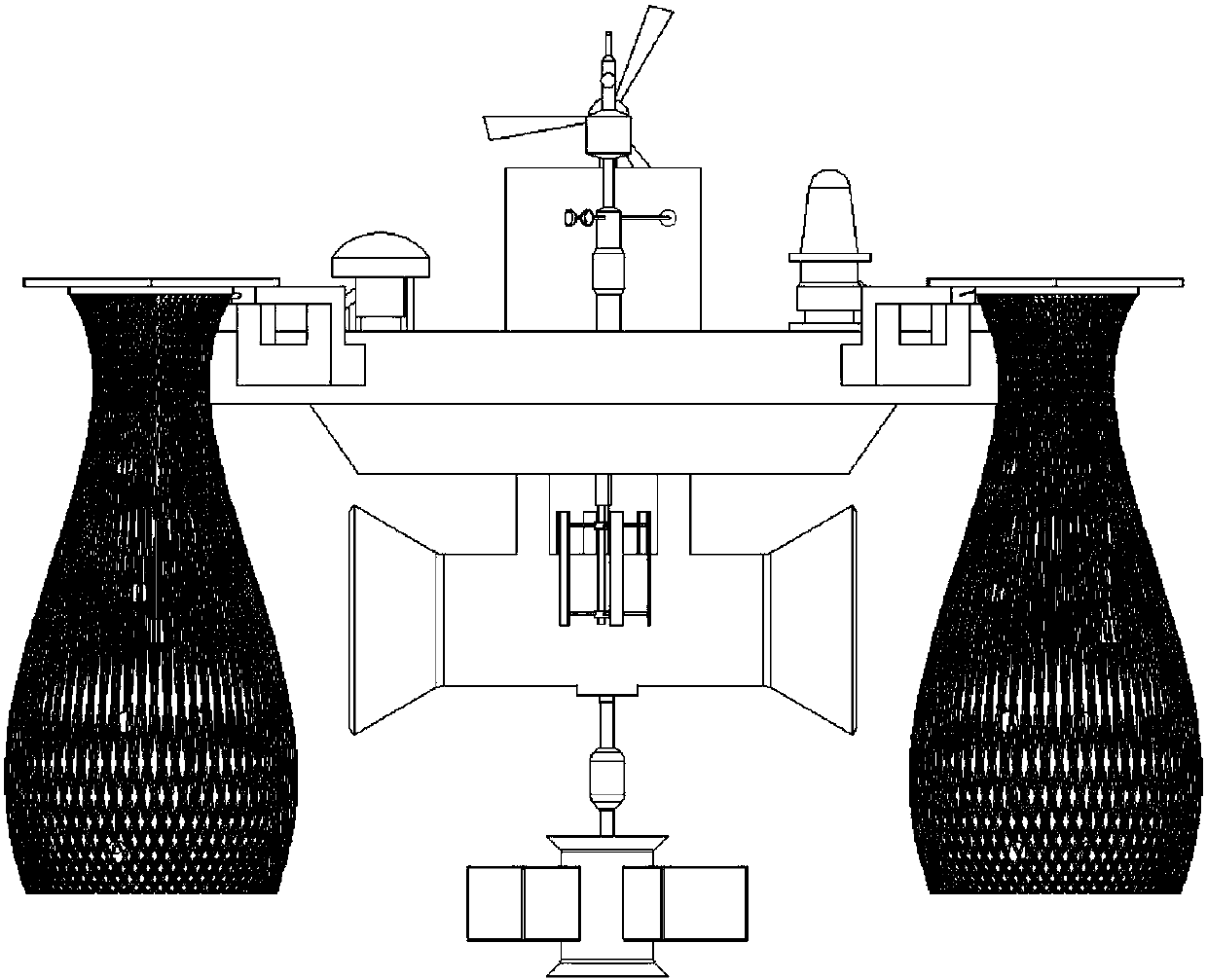

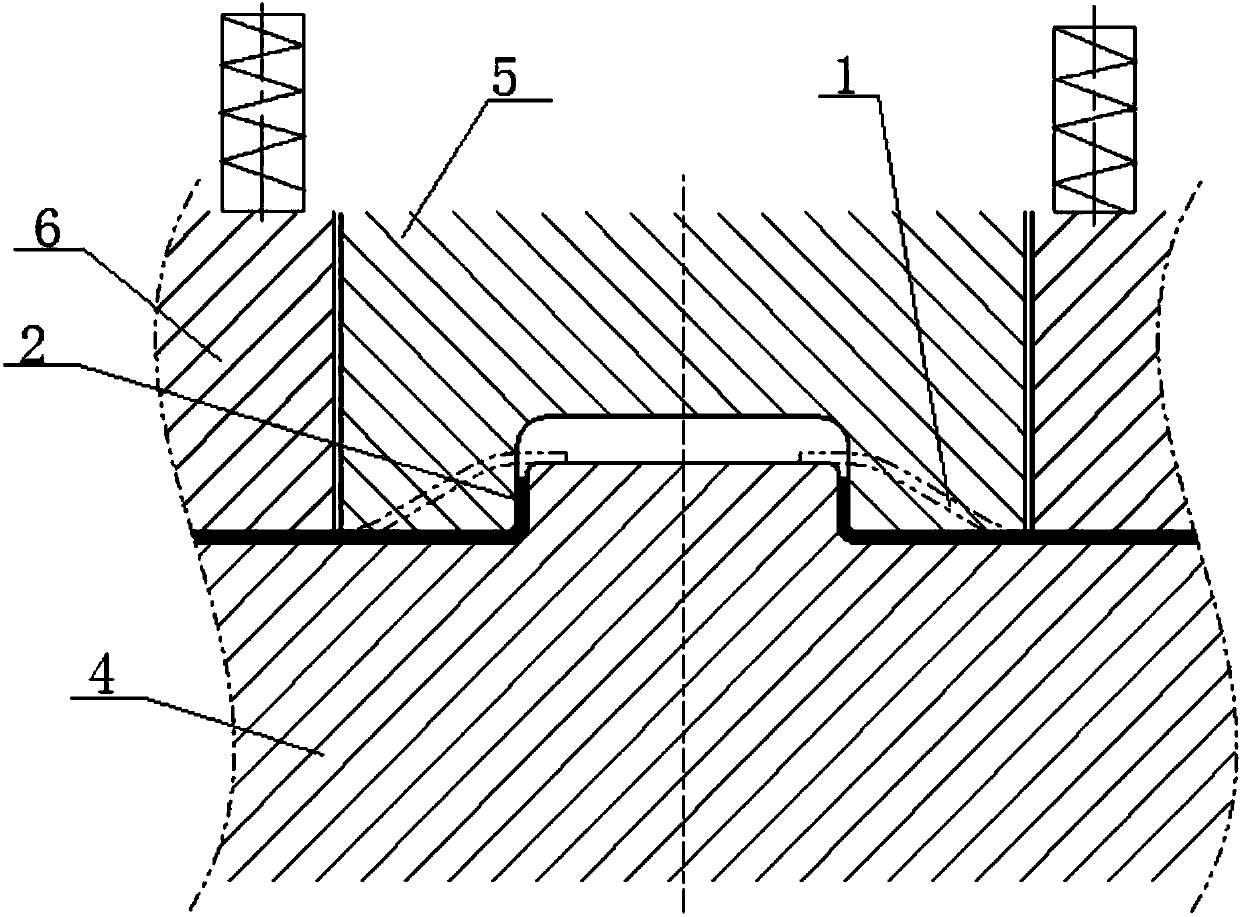

Multi-energy integrated type self-powered breeding platform

ActiveCN108050016AAchieve integrationSelf-poweredPhotovoltaic supportsWind motor controlOxygen sensorWater flow

The invention relates to a multi-energy integrated type self-powered breeding platform. An impact type turbine power generation device is fixed to the lower side of a floating body. An oscillating float type turbine power generation device is fixedly arranged on the lower side of the impact type turbine power generation device. An electric energy storage cabinet is connected with an oscillating float type turbine generator. A vertical-axis tidal current energy power generation device is fixedly arranged on the lower portion of the floating body. A windward wind power generation device is fixedly arranged on the upper side of the floating body. The electric energy storage cabinet is connected with an electric energy processing cabinet. The impact type turbine power generation device, the vertical-axis tidal current energy power generation device and the windward type wind power generation device are connected with the electric energy processing cabinet. A net cage group comprises a plurality of net cages fixed to the periphery of the floating body. A rope is led out from each net cage sleeve, and a temperature sensor, a water flow sensor, a dissolved oxygen sensor and an image-texttransmitting device are evenly distributed on each rope. The multi-energy integrated type self-powered breeding platform is high in function compounding degree and ingenious in design.

Owner:SHANGHAI OCEAN UNIV

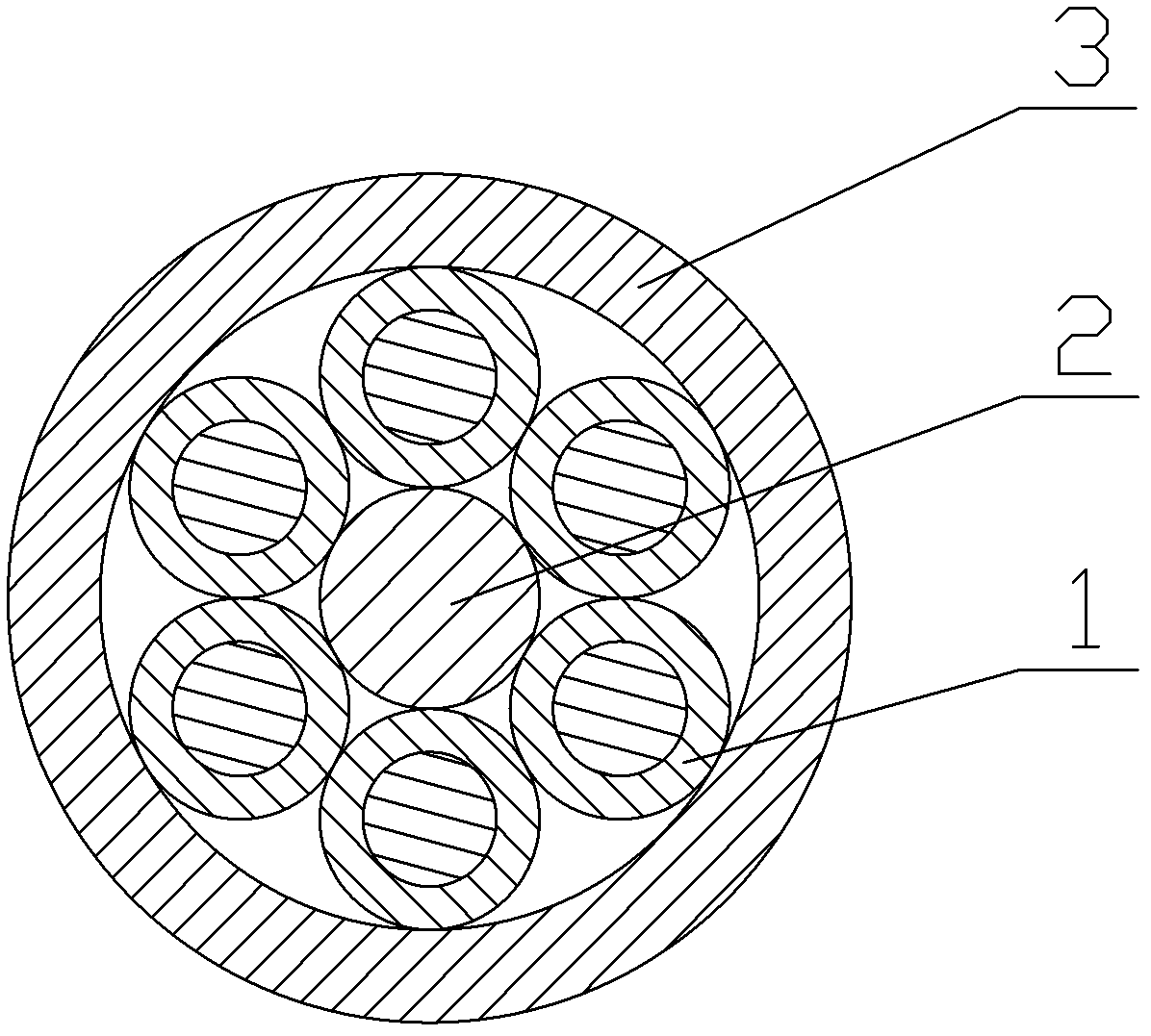

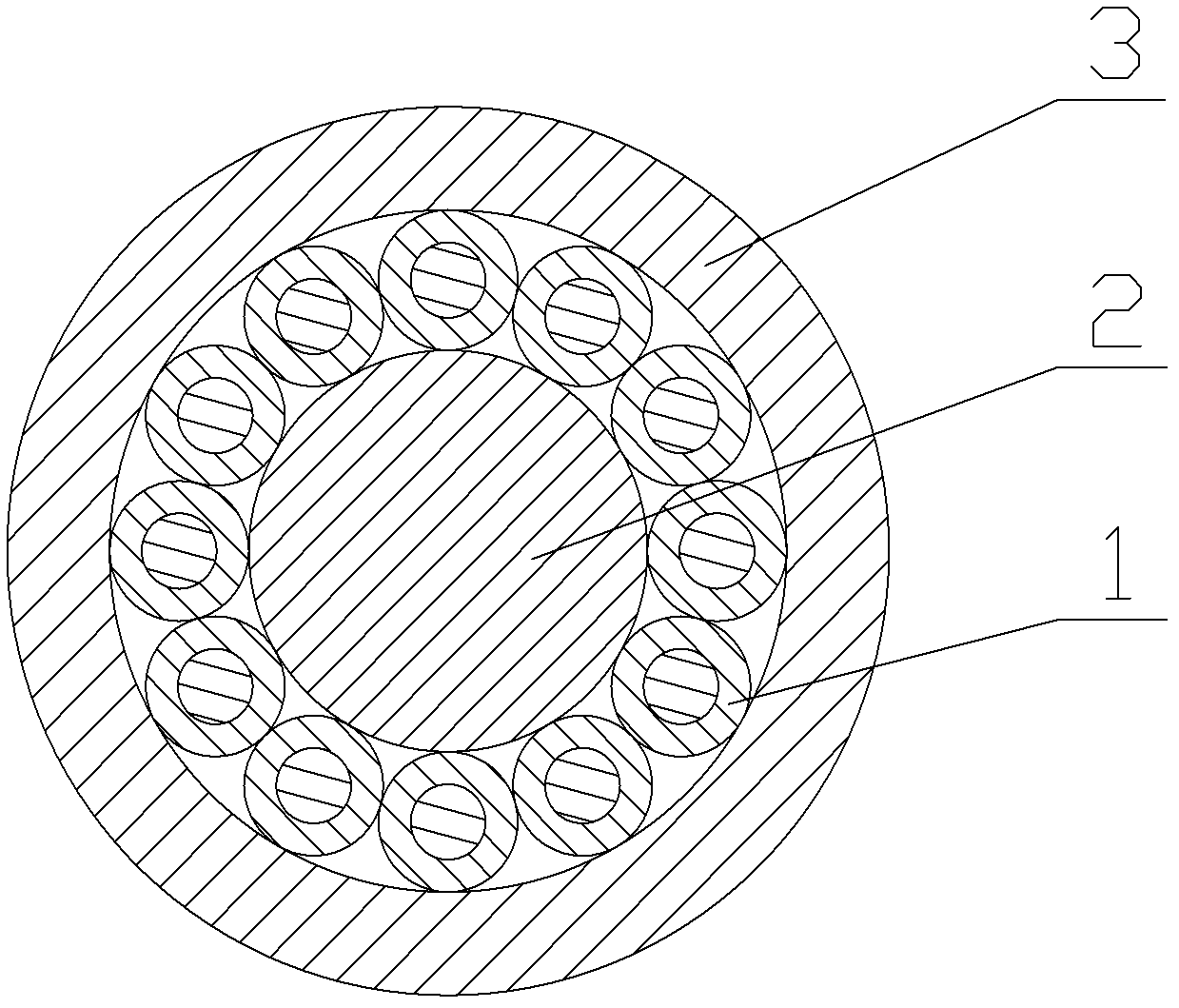

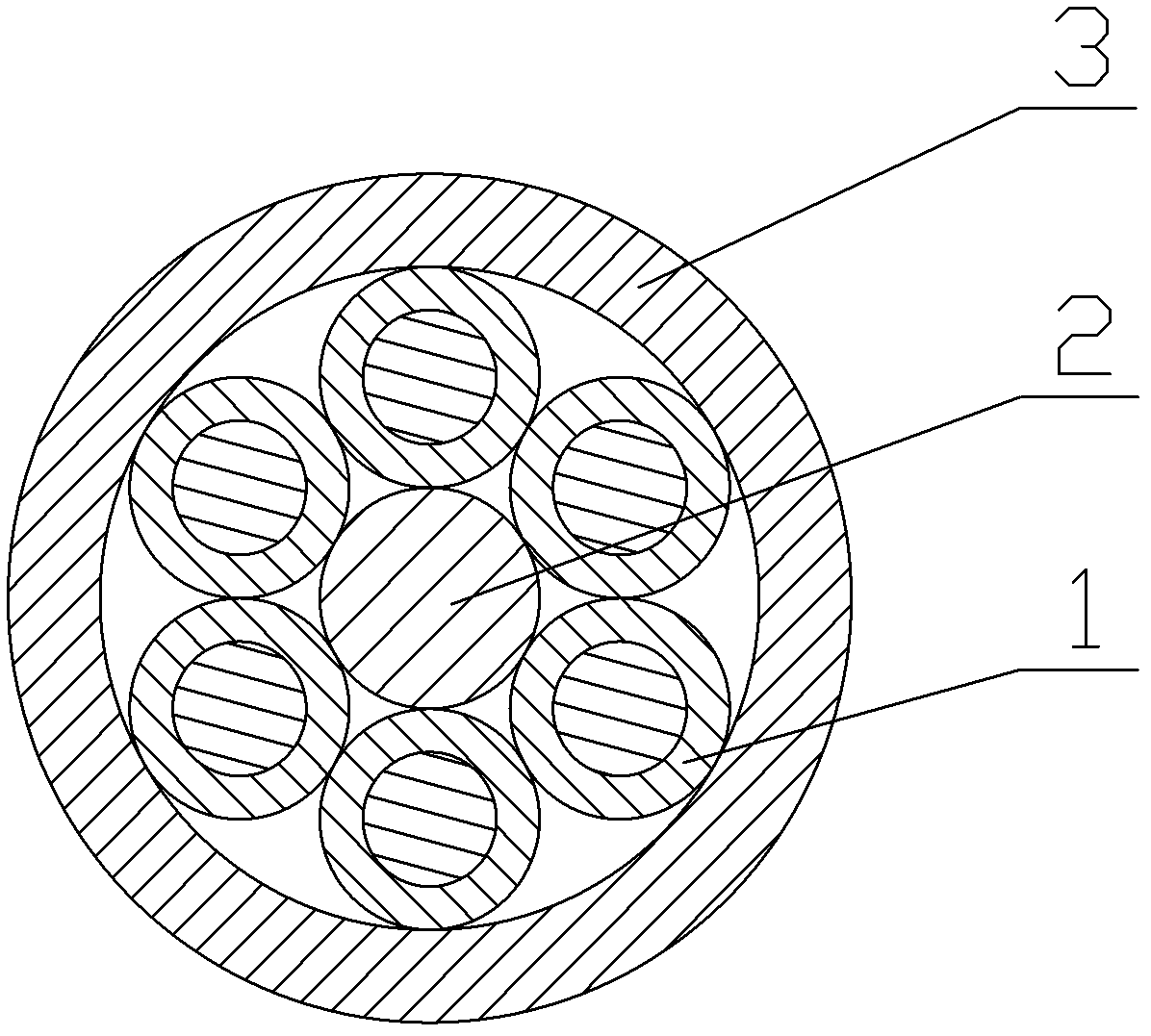

Preparation method of multi-core MgB2 superconducting wire

ActiveCN102522153AHigh degree of compoundHigh densitySuperconductors/hyperconductorsSuperconductor devicesSwagingUltimate tensile strength

The invention discloses a preparation method of a multi-core MgB2 superconducting wire. The method comprises: first, precursor power is prepared; second, the precursor power is placed in a Ta tube to prepare a tubulation complex; third, groove rolling is carried out on a single core wire; fourth, a NbTi / Cu composite rod and a plurality of single core wires are placed in an oxygen-free copper tubefor assembling so as to obtain a secondary composite rod; fifth, rotary swaging and drawing are carried out on the secondary composite rod, groove rolling is carried out and rotary swaging and drawing are carried out again, so that a multi-core wire is obtained; and sixth, heat treatment is carried out on the multi-core wire to obtain a multi-core MgB2 superconducting wire. According to the invention, processes of rotary swaging, drawing and groove rolling are combined and employed; therefore, not only is density of the multi-core wire improved, but also connectivity between crystal grains can be improved; it is beneficial to prepare a multi-core MgB2 superconducting wire with high performances; and the prepared wire has high mechanical strength and can bear great stress and strain without obvious reduction of the superconductive current carrying performance, so that a superconducting wire practical requirement can be well met.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Preparation method of pomegranate-shaped organic-inorganic nano-composite microspheres

The invention discloses a preparation method of pomegranate-shaped organic-inorganic nano-composite microspheres, which comprises the following steps: mixing an aqueous dispersion solution of silicon dioxide modified by proper amount of double-bond silane coupling agent in a coupling method with a phenylpropyl monomer, anionic emulsifier, non-anionic emulsifier and water, and stirring simply, so that a milky emulsified liquid is obtained; adding initiator to perform emulsion polymerization in the presence of silicon dioxide, so that the pomegranate-shaped organic-inorganic nano-composite microspheres with multiple silicon dioxide particles wrapped in phenylpropyl emulsion particles are obtained finally and are stably dispersed in the emulsified liquid. The preparation method has the advantages that the sources of the raw materials are extensive, the raw materials are easy to obtain, the preparation process is simple, and moreover, in the prepared pomegranate-shaped organic-inorganic nano-composite microspheres, the wrapping rate of silicon dioxide is high, the structure is neat and the placement stability is good. The adhesion property and the film forming performance of the composite microsphere particles are adjustable, the adhesive force and the transparency of the corresponding glue film are good, and the organic-inorganic nano-composite microspheres can be applied to the fields of coating, textile, rubber, plastics, biology, medicine and the like.

Owner:杭州华利实业集团有限公司

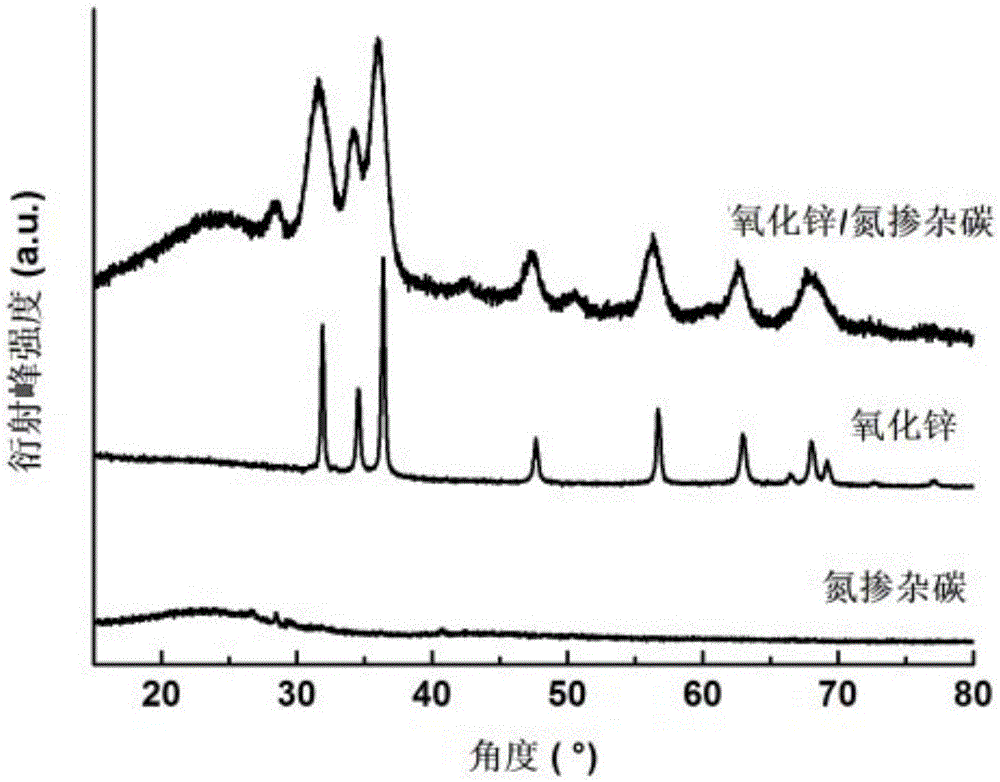

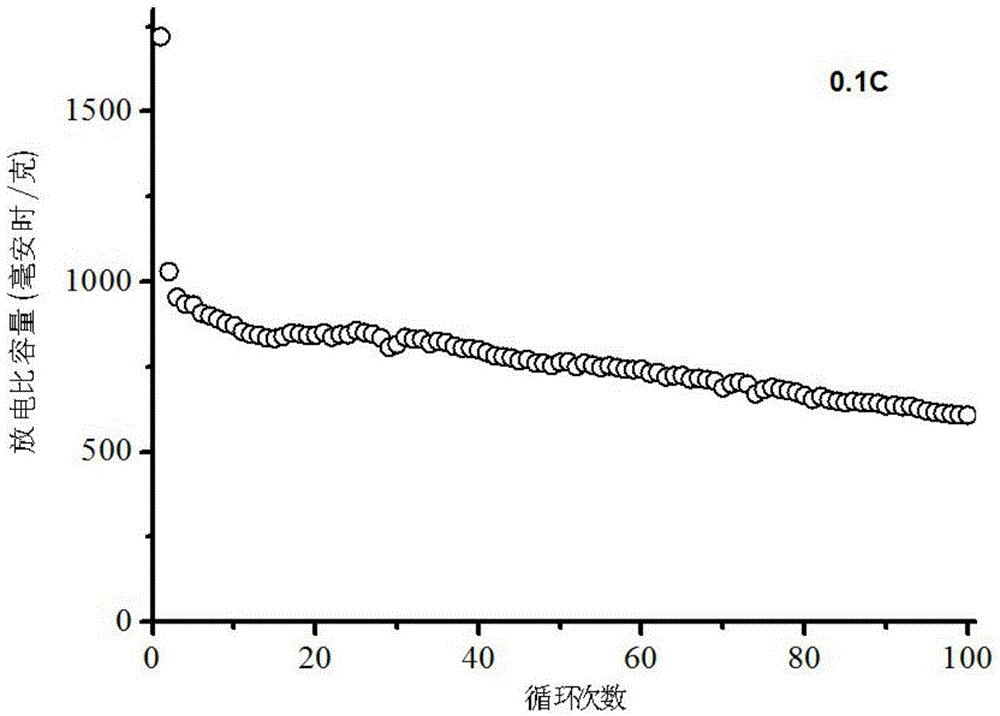

Preparation method of zinc oxide/nitrogen-doped carbon composite material capable of being used for lithium ion battery negative electrode

ActiveCN105591090AImprove conductivityImprove electrochemical performanceCell electrodesSecondary cellsCarbon compositesPolypyrrole

The invention provides a preparation method of a zinc oxide / nitrogen-doped carbon composite material capable of being used for a lithium ion battery negative cathode. The method is applied to low-temperature polymerization reaction to prepare polypyrrole, then polypyrrole is prepared into nitrogen-doped carbon, and then the zinc oxide / nitrogen-doped carbon composite material is prepared through a sol-gel method. Compared with other carbon materials, nitrogen elements in nitrogen-doped carbon can change distribution of electron cloud around carbon atoms, agglomeration of the carbon atoms is effectively prevented, and compared with other common carbon materials, the nitrogen-doped carbon composite material has more excellent electrical conductivity and chemical stability.

Owner:SYNERGY INNOVATION INST OF GDUT HEYUAN

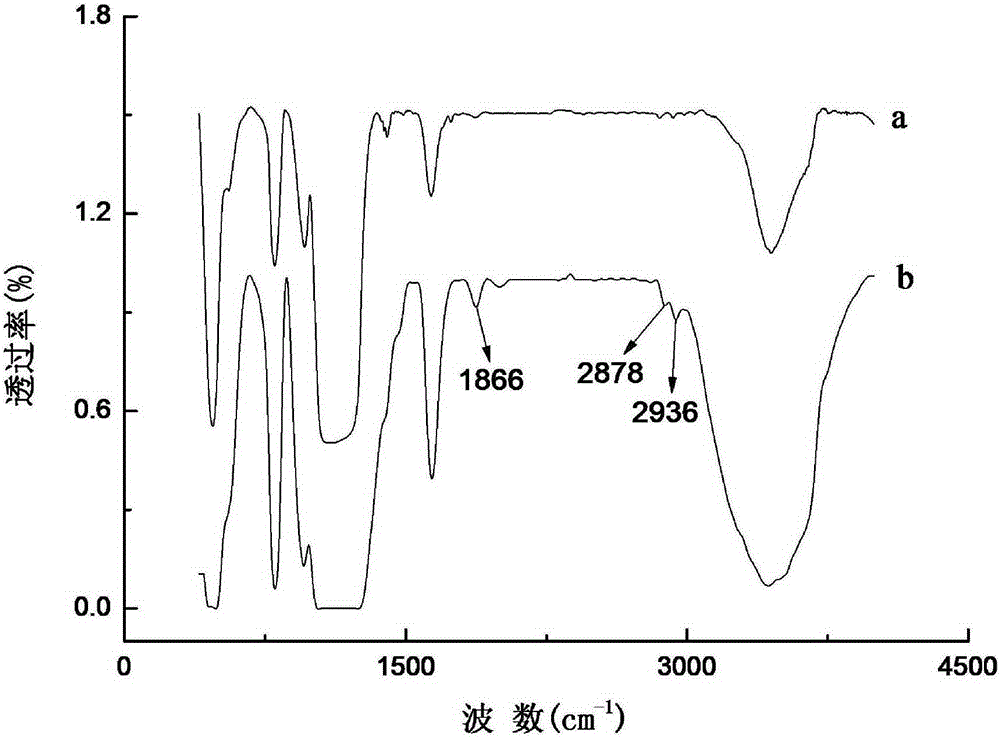

A kind of surface graft modification method of silicon dioxide

InactiveCN104312215BHigh purityHigh degree of compoundMaterial nanotechnologyPigment treatment with organosilicon compoundsFiberAntioxidant

The invention relates to a silicon dioxide surface grafting modification method, and aims at insufficient atomic coordination number on silicon dioxide surface, high surface energy and easy agglomeration. An epoxy silane coupling agent and ammonia water react on the silicon dioxide surface in an alkaline environment to improve the dispersibility and compatibility with polymer; the silicon dioxide surface is subjected to grafting modification with a hindered amine antioxidant; the grafting modified silicon dioxide is nano powder particles with diameter no more than 30 nm; and the the purity of product is high up to 97.6%. the preparation process has advanced strict process and accurate data; the grafting modified silicon dioxide can be used as the additive for polyphenylene sulfide composite material, can well improve and the dispersibility and compatibility with polyphenylene sulfide matrix, and can improve processability and thermal oxidation resistance performance in fiber preparation and application.

Owner:TAIYUAN UNIV OF TECH

Molding and stamping technology of upward flanging hole in car floor part

ActiveCN103624145AHigh degree of composite mold structureImprove production tact and efficiencyFlangingEngineering

The invention discloses a molding and stamping technology of an upward flanging hole in a car floor part. The technology comprises the following steps that (1), drawing is carried out, wherein a panel veneer is drawn and molded to form a boss; (2), punching is carried out, wherein a bottom hole is punched out in the top face of the boss; (3), downward shaping is carried out; (4), trimming is carried out, wherein the trimming is finished on the same mould with the downward shaping procedure. According to the molding and stamping technology of the upward flanging hole in the car floor part, the upward flanging is changed into the downward shaping through the drawing molding, a shaping male mould and a material pressing board are located on an upper mould, a shaping female mould is located on a lower mould, as the shaping female mould is of a fixed structure, the mould structure replaces a traditional lower mould movable structure with the fixed structure of the lower mould, the fixed lower mould structure can be compounded with other trimming structures, the flanging procedure and other trimming procedures are finished on the same mould, a set of mould is omitted compared with a traditional technology, the compound degree of the mould structure is high, and therefore the production efficiency is improved, and the production cost is lowered.

Owner:DONGFENG MOTOR CORP HUBEI

Preparation method for high-density interposer for microelectronic system-in-package

ActiveCN102070120BImprove reliabilitySmall coefficient of thermal expansionDecorative surface effectsSemiconductor/solid-state device manufacturingThermal dilatationElectrical conductor

The invention discloses a preparation method for a high-density interposer for microelectronic system-in-package. The preparation method comprises the following steps of: 1, preparing a drectionally growing carbon nanotube bundle array, wherein the diameter of each carbon nanotube bundle is 0.5 to 30 microns, the gap of the carbon nanotube bundle is 0.8 to 100 microns, and the carbon nanotube bundle is 40 to 500 microns long; 2, depositing metal tungsten on the surface of the drectionally growing carbon nanotube bundle so as to form a conductor array; 3, melting borosilicate glass and compounding the melted borosilicate glass with the conductor array so as to form a compound body; and 4, grinding the upper surface and the lower surface of the formed compound body so as to expose the end of the carbon nanotube bundle deposited with the metal tungsten, and obtaining the high-density interposer for the system-in-package. The material adopted by the preparation method has low thermal expansivity and the process method is low in time consumption, so the prepared high-density interposer has the advantages of high density, high reliability and low cost.

Owner:SOUTHEAST UNIV

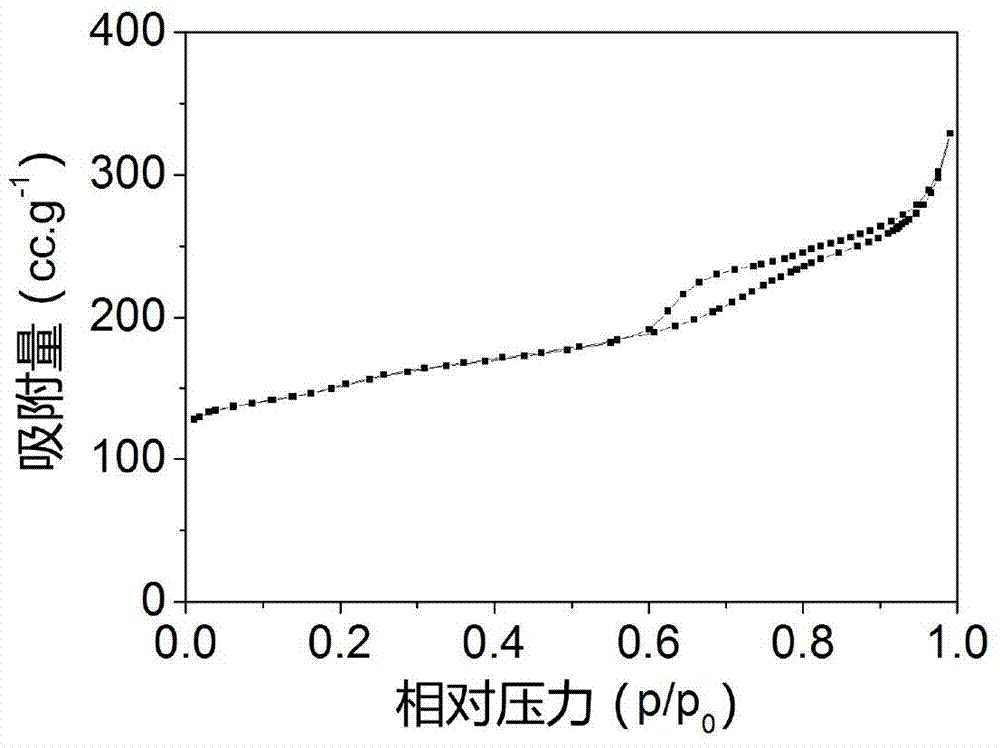

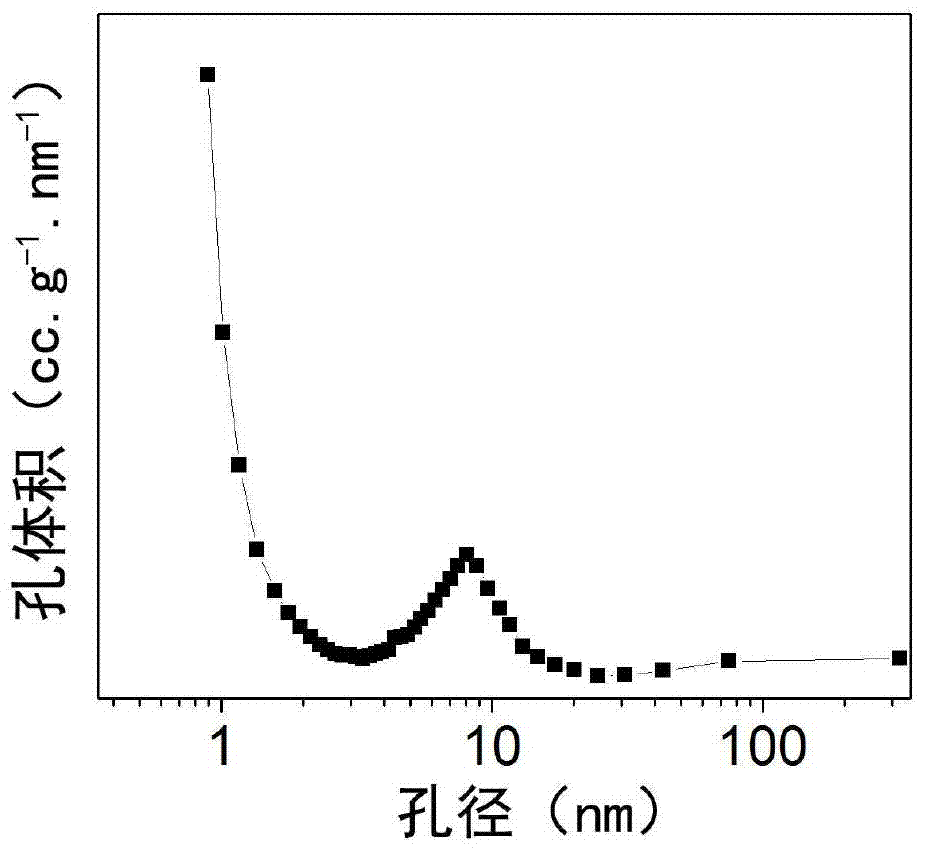

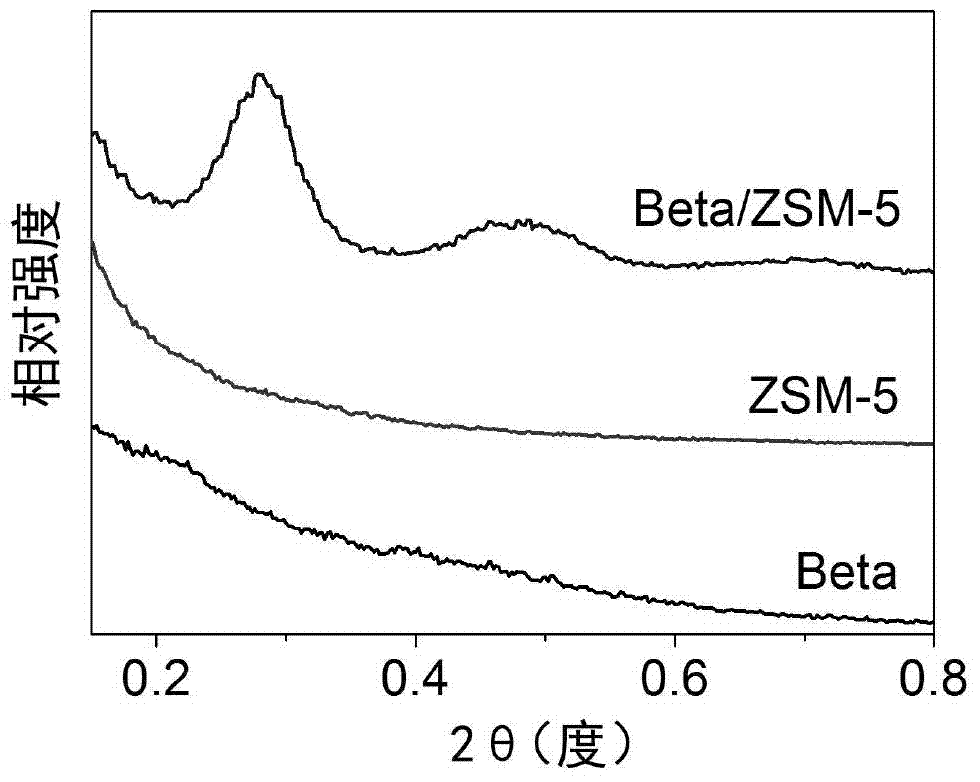

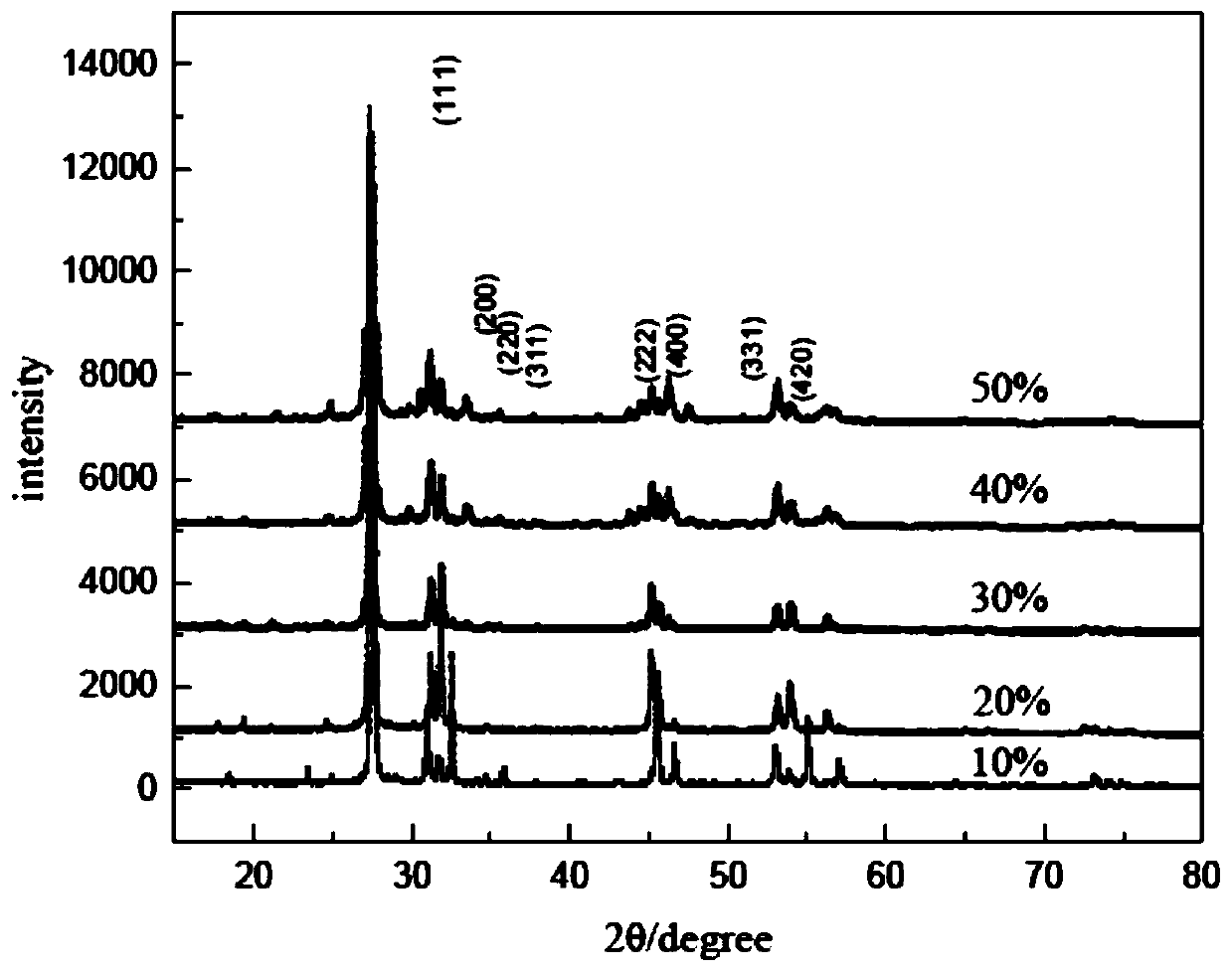

Beta/ZSM - 5 nano composite molecular sieves and preparation method thereof

InactiveCN104843730AHigh degree of compoundHigh crystallinityMaterial nanotechnologyCrystalline aluminosilicate zeolitesMolecular sieveMaterials preparation

The invention relates to a Beta / ZSM - 5 nano composite molecular sieves and preparation method thereof, which belongs to molecular sieve catalytic materials preparation area. The Beta / ZSM - 5 nano composite molecular sieves is a composite zeolite with medium and micro double holes and neat structure which is parallel arranged on nanoscale of beta zeolite and ZSM - 5 zeolite particles. The space of the parallel arrangement of beta zeolite and ZSM - 5 zeolite particles is medium hole. The Beta / ZSM - 5 nano composite molecular sieves is high in compound degree and good in crystallinity, and the micro hole passing path in unit volume is shortened. The mass transfer resistance of macromolecule catalytic reaction is reduced. The match of acid sites and micro hole structure of the two zeolites is realized. The catalytic activity and selectivity of the objective product is increased. The preparation method is easy. An ordered mesoporous carbon is used as hard template, and the removal of calcine is easy. The morphology and medium hole structure of the composite molecular sieves is controllable, the operation is convenient and the reproducibility is high.

Owner:NORTHWEST UNIV(CN)

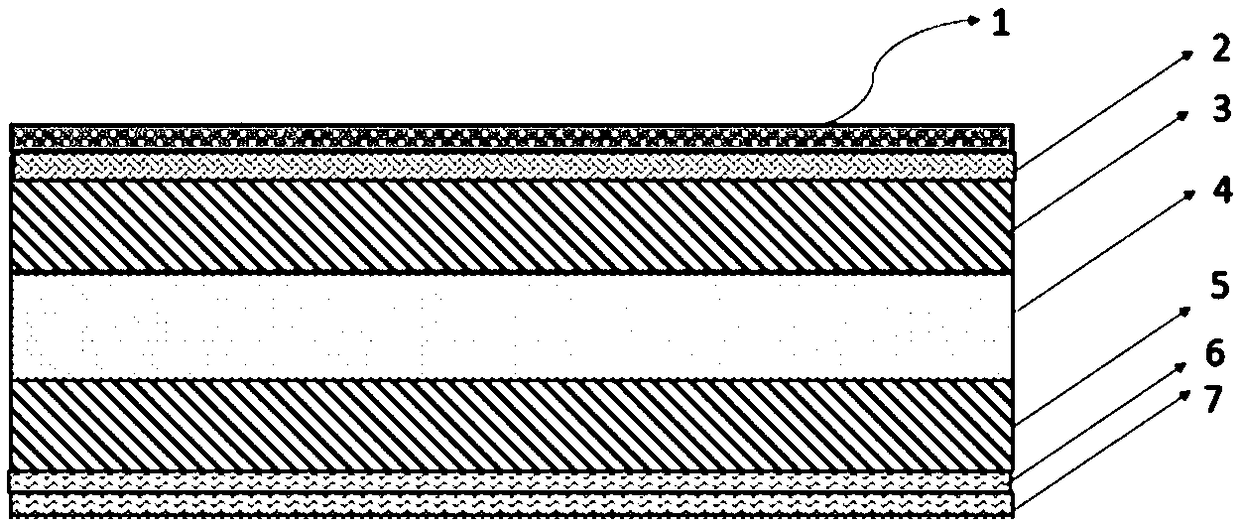

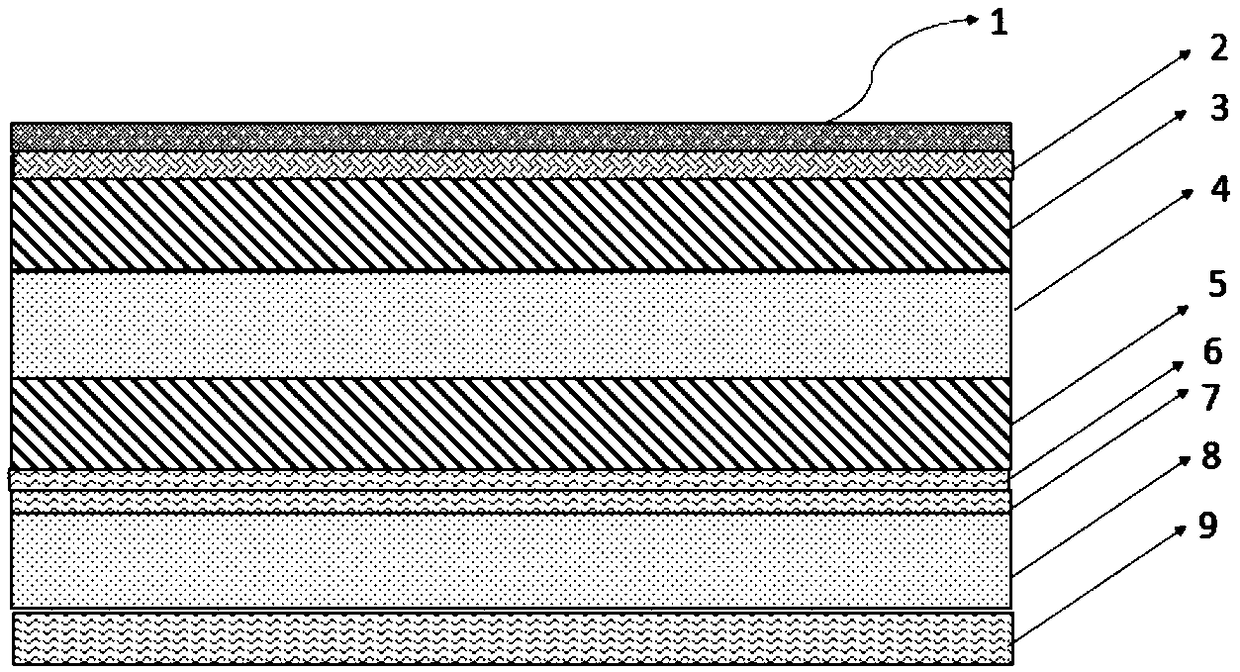

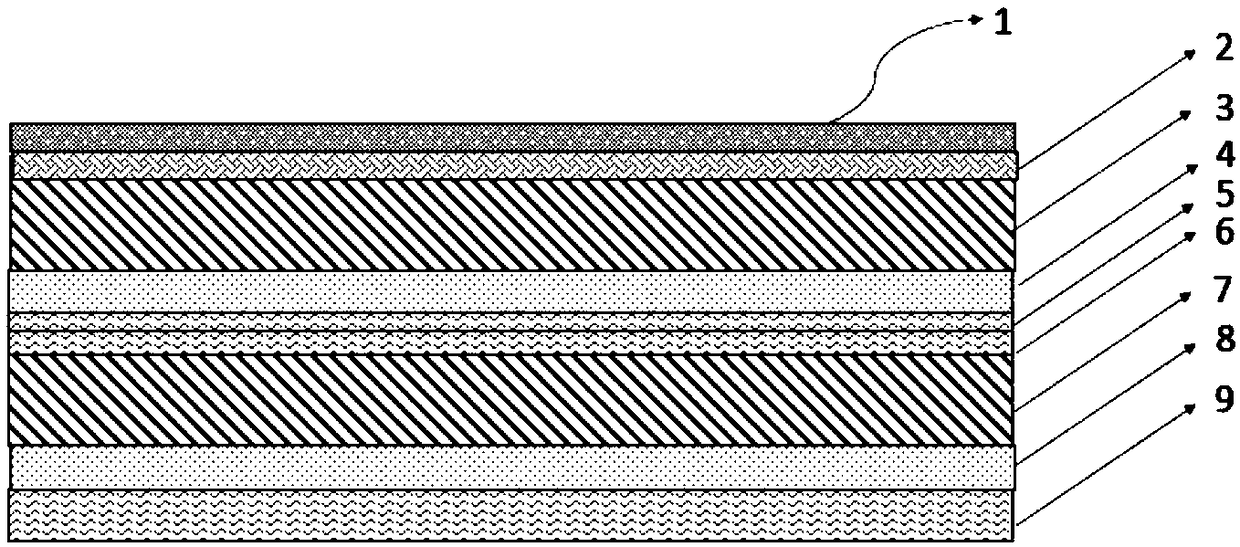

A packaging front panel and a preparation process thereof

PendingCN109087963AImprove scratch resistanceImprove aging resistancePhotovoltaic energy generationSemiconductor devicesComposite filmWater vapor

The invention provides an packaging front panel and a preparation process thereof, wherein the packaging front panel is a composite film bonded on the upper surface of a solar cell module, and the composite film comprises an anti-adhesion coating, an abrasive anti-aging layer, a first thin film base material layer, a first adhesive film layer, a second thin film base material layer, a modified undercoat layer and a water vapor barrier layer from top to bottom. The packaging front panel of the invention can meet the requirements of lower water vapor transmission rate and lower service life of mobile energy sources (less than 5 years), meanwhile, the surface of the flexible front panel is anti-fingerprint and anti-scratch, the packaging process is simple and efficient, and the material and process cost are low.

Owner:DONGJUN NEW ENERGY CO LTD

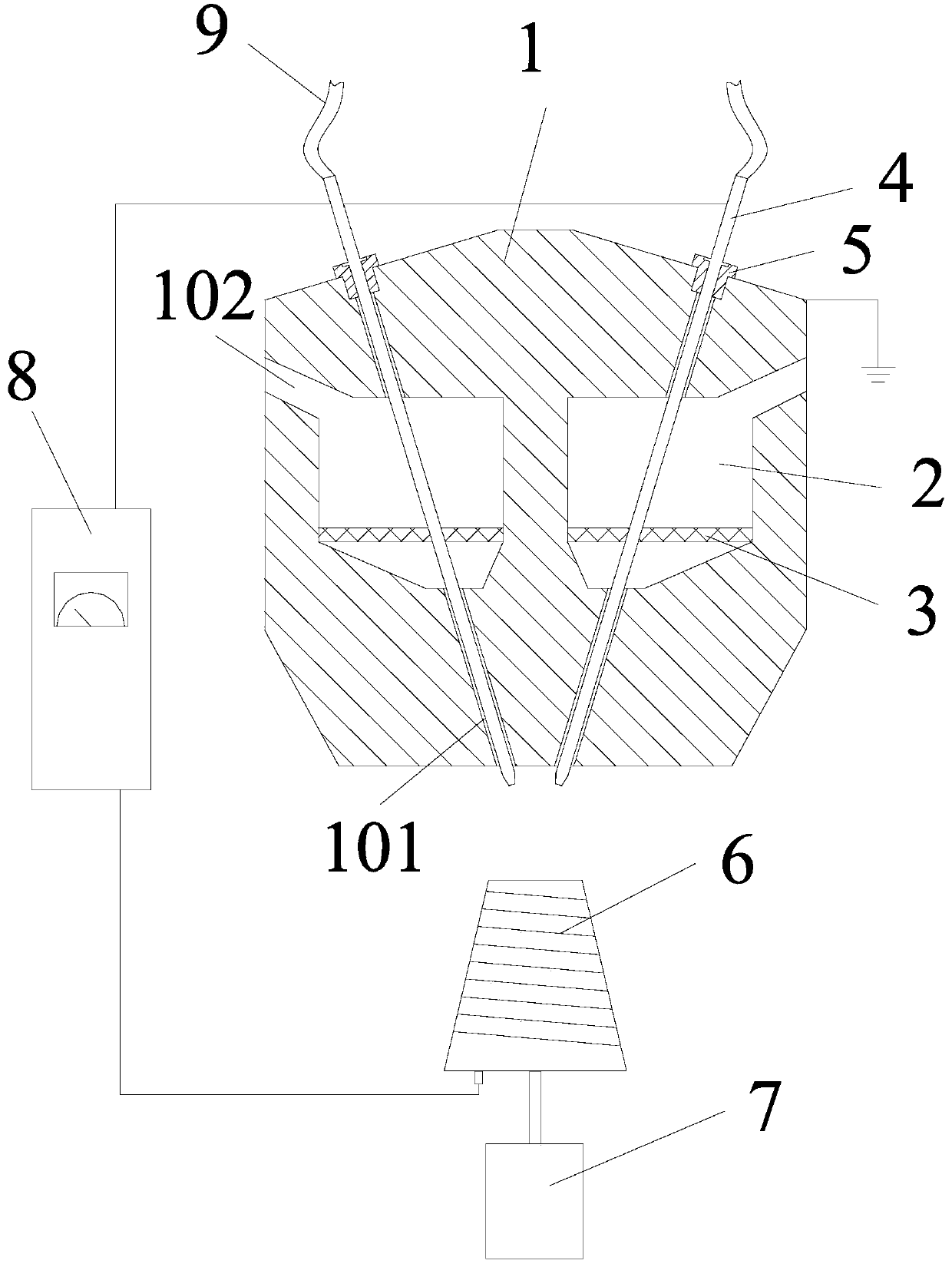

Composite polypropylene fiber spinning device and preparation method thereof

ActiveCN110468459AHigh degree of compoundEasy to wrapFilament/thread formingConjugated synthetic polymer artificial filamentsEngineeringHigh voltage

The invention relates to the technical field of polypropylene fibers, in particular to a composite polypropylene fiber spinning device and a process thereof.The device comprises a housing, filter chambers, a strainer, a needle tube, a locking ring, a cone curling drum, a motor and a high-voltage electrostatic generator; the interior of the housing is symmetrically provided with two filter chambersand two inclined through holes, the inclined through holes pass through the filter chambers and through the whole housing, the two sides of the housing are provided with feeding holes, and the strainer is located at the bottoms of the filter chambers; and the needle tube perforates in the inclined through holes and both ends of the needle tube extend outside the housing.The invention has the following benefits: the produced composite polypropylene fibers are allowed to have a high compounding degree; the spinning device in the invention may not only prepare composite polypropylene but also prepare single-component polypropylene fibers; the inclination of the needle tube makes the distance of molten polypropylene flowing outside the housing from the housing is short so that the molten polypropylene may be compositely wound better; and the cone curling drum allows composite polypropylene fibers to be wound better without being scattered outside.

Owner:福建闽瑞新合纤股份有限公司

Vinasse porous carbon/cobalt-nickel hydroxide electrode material and preparation process thereof

ActiveCN112289591AHigh specific capacityGood magnification performanceHybrid capacitor electrodesHybrid/EDL manufacturePoly ethyleneCOBALTOUS NITRATE HEXAHYDRATE

The invention provides a vinasse porous carbon / cobalt-nickel hydroxide electrode material and a preparation process thereof. The material is a vinasse porous carbon / cobalt-nickel hydroxide electrode material obtained by taking vinasse porous carbon as a substrate and loading cobalt and nickel elements on the surface of the vinasse porous carbon in a CoNiLDH form. The process comprises the following steps: carbonizing vinasse to obtain vinasse porous carbon, carrying out hydrothermal reaction on the vinasse porous carbon, cobalt nitrate hexahydrate, nickel nitrate hexahydrate, urea and polyvinylpyrrolidone, and finally, carrying out suction filtration, washing and drying to obtain the product. The prepared composite material is good in stability, high in compounding degree and high in specific capacity and rate capability, meanwhile, the substrate carbon material is from vinasse, the raw materials are wide in source and low in price, and the vinasse is turned into wealth.

Owner:GUILIN UNIV OF ELECTRONIC TECH

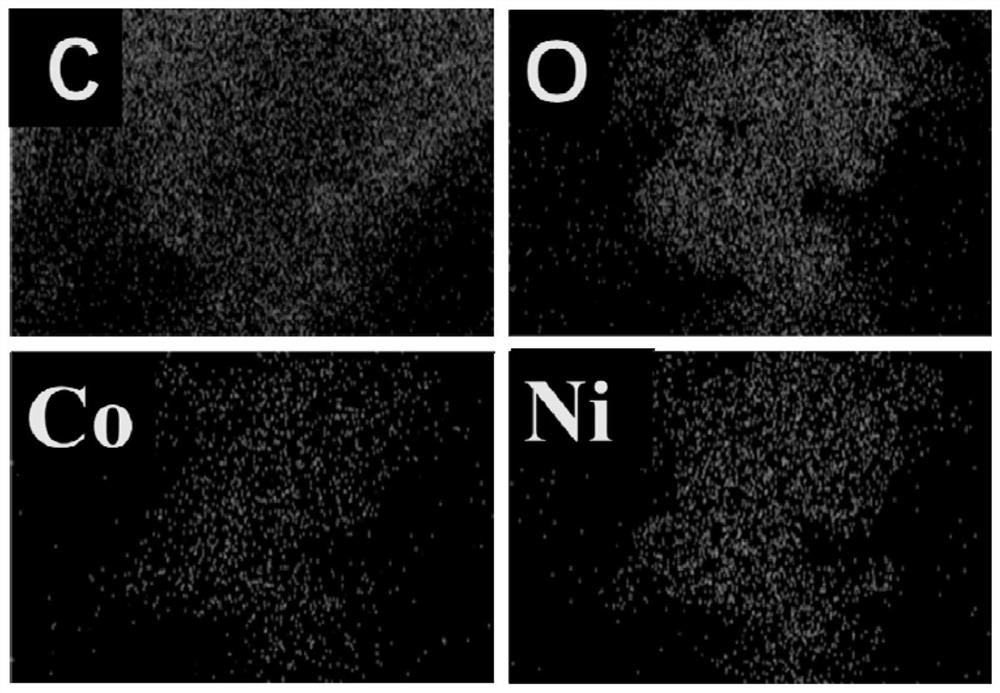

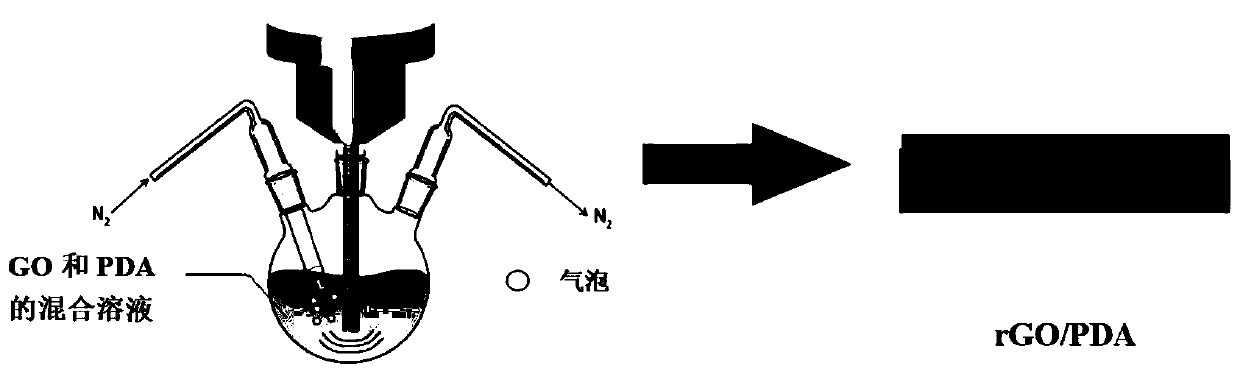

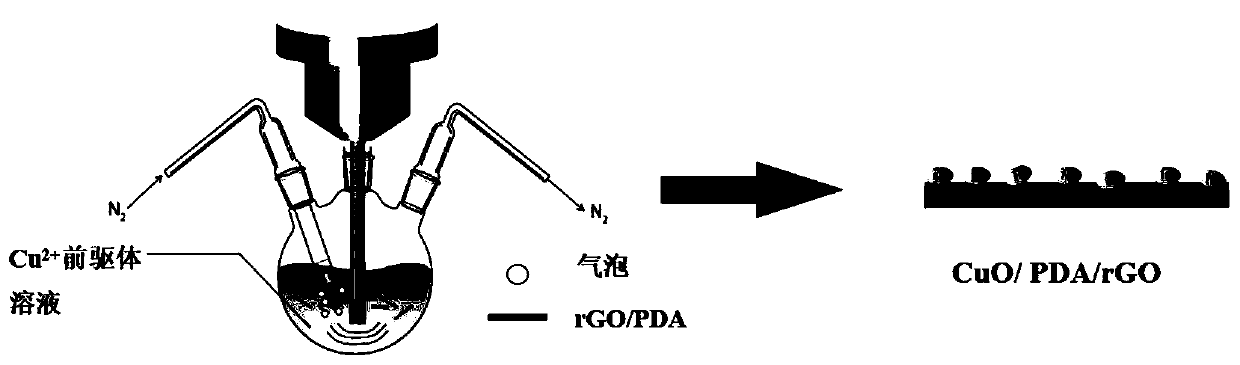

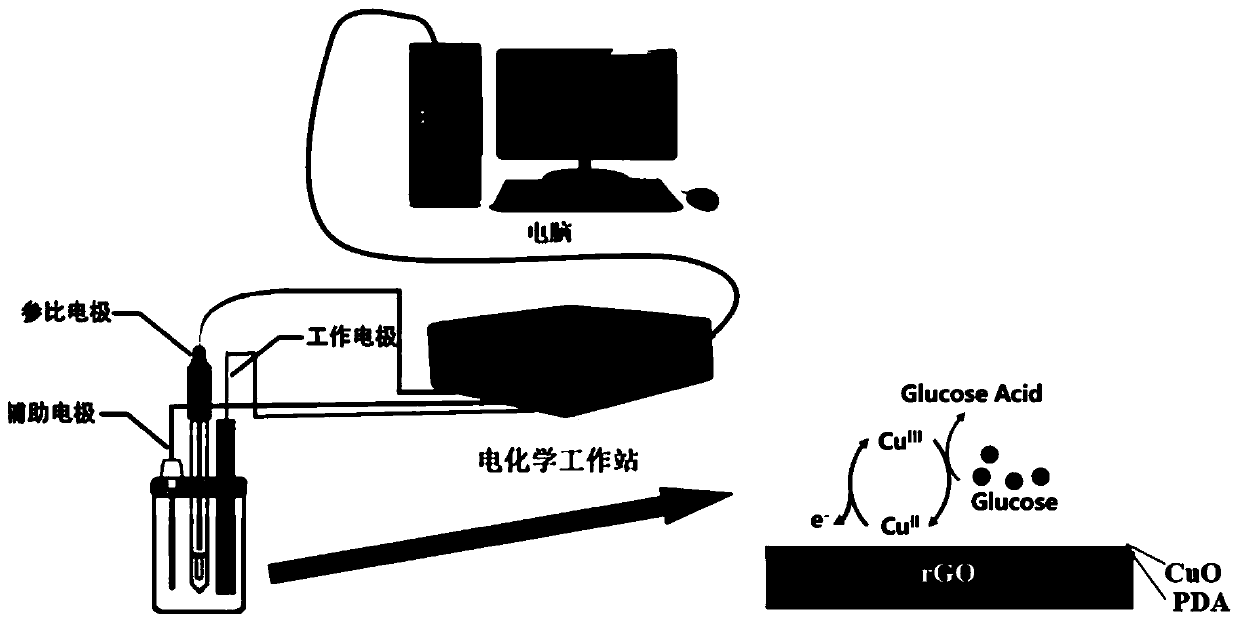

Method for preparing copper oxide/polydopamine/reduced graphene oxide CuO/PDA/rGO

InactiveCN110183850AEfficient preparationImprove conductivityMaterial analysis by electric/magnetic meansFreeze-dryingCopper oxide

The invention relates to a method for preparing copper oxide / polydopamine / reduced graphene oxide CuO / PDA / rGO. The method comprises the following steps: firstly, by taking DA (dopamine) as a reducing agent and graphene oxide as a raw material, regulating and controlling process conditions such as the ratio and the reaction time of the raw materials by using an ultrasonic chemical method, so as to prepare rGO / PDA with good conductivity; and by taking rGO / PDA as a conductive substrate, respectively developing two preparation methods for preparing CuO / rGO / PDA by using a one-step method and a two-step method, wherein the two-step method comprises steps of cleaning and freeze-drying the prepared rGO / PDA, mixing the rGO / PDA with a copper salt precursor of a certain ratio, and preparing the CuO / PDA / rGO by regulating and controlling ultrasonic process conditions; and the one-step method comprises steps of directly mixing a copper salt precursor solution with a reaction liquid of the rGO / PDA, and preparing the CuO / PDA / rGO by controlling the ultrasonic process conditions.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method and device for plastically connecting metal pipes and plates with one another

ActiveCN109261816AFast plastic connectionEfficient plastic connectionShaping toolsFriction effectHigh volume manufacturing

The invention discloses a method and a device for plastically connecting metal pipes and plates with one another, and belongs to the technical field of material connection. The device comprises a maledie, an edge pressing ring and a female die. The device and the method have the advantages that the pipes and the plates which are required to be connected with one another are prefabricated, then the pipes can be placed in the female die, the plates can be clamped by the female die and the edge pressing ring, the male die can revolve at the high speeds and can rotate along the axes of the pipesat the low speeds, and the plasticity of the pipes can be enhanced by the aid of friction effects; plastic deformation portions of the plates can be promoted by rolling of the male die to flow into annular grooves of the pipes, and accordingly the pipes and the plates can be quickly and efficiently plastically connected with one another in a green manner; the device is high in production efficiency, low in cost and suitable for mass production and is environmentally friendly; plastic forming modes are adopted by the method for connecting the metal pipes and the plates with one another by the aid of the device, the annular grooves are filled with materials for the plates, connectors are good in quality, high tensile stress can be borne, and the problem of difficulty in connecting plate metal with heterogeneous pipes difficult to weld can be solved by the aid of the method and the device.

Owner:SHAANXI UNIV OF SCI & TECH

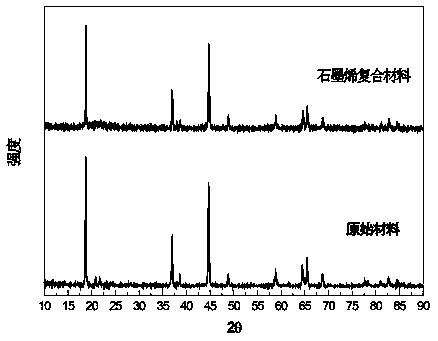

Method for preparing graphene composite lithium-rich positive electrode material through solvent-assisted reducing agent method

InactiveCN108832086AHigh purityHigh degree of compoundSecondary cellsPositive electrodesCvd grapheneSolvent

The invention belongs to the technical field of lithium ion battery material and graphene composite material preparation, and specifically discloses a method for preparing a graphene composite lithium-rich positive electrode material through a solvent-assisted reducing agent method. The method comprises the following steps: (1) preparing a lithium-rich positive electrode material: taking an Ni-Co-Mn metal salt solution, sodium carbonate and an ammonia water solution into a reaction still to perform a coprecipitation reaction, cleaning and drying a precipitate, and after adding a lithium salt for ball-milling, carrying out high-temperature calcinations for several hours to obtain the lithium-rich positive electrode material; and (2) preparing a composite material: after dissolving oxidizedgraphene into a solvent, adding a reducing agent and the lithium-rich positive electrode material, and dropwise adding ammonia water to react so as to obtain the graphene composite lithium-rich positive electrode material. The graphene prepared in the invention is higher in purity and high in composition degree with the lithium-rich positive electrode material, the electronic conductivity of the material is improved through high conductivity and a special two-dimensional netted transmission structure, the polarization is reduced, and the rate capability and cycle performance of the lithium-rich positive electrode material are obviously improved.

Owner:SHANDONG UNIV OF TECH

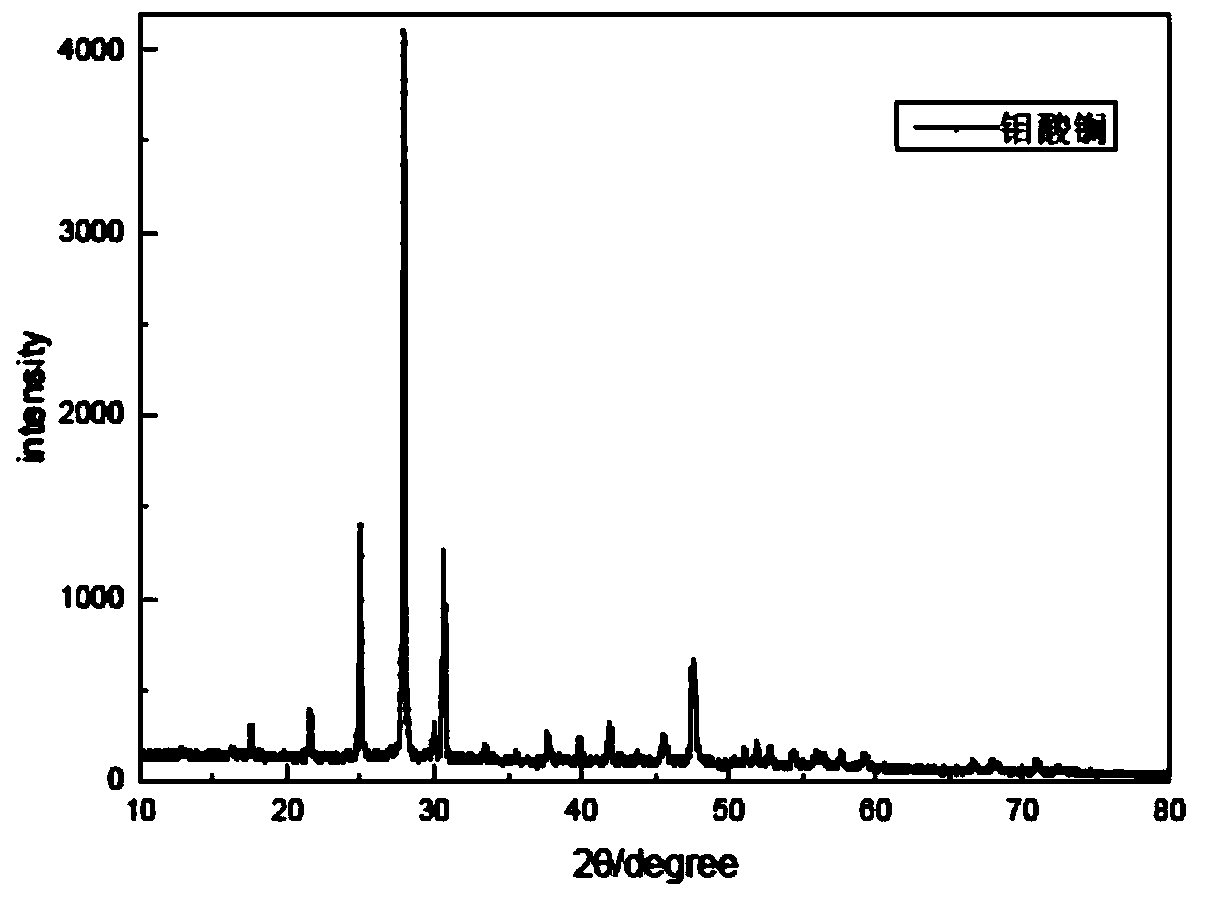

Method for preparing bismuth oxide-lanthanum molybdate composite electrolyte by sol-gel self-combustion method

ActiveCN110224167ANo distractionXRD image is goodFuel cellsComposite electrolytesComposite electrolyteHYDROSOL

The invention relates to the technical field of solid electrolyte material preparation, in particular to a method for preparing bismuth oxide-lanthanum molybdate composite electrolyte by a sol-gel self-combustion method. The method comprises the following steps that acidifying is carried out on a mixed solution of lanthanum nitrate and ammonium molybdate by using ethylene glycol, and then stirringand heating are performed to carry out sol-gel reaction to prepare lanthanum molybdate coarse powder; the lanthanum molybdate powder is purified by a self-combustion method, the lanthanum molybdate coarse powder is placed in a crucible to be placed into a muffle furnace for sintering; and solid-phase compounding is carried out on lanthanum molybdate and bismuth oxide, and steps of grinding, tabletting, and finally sintering are carried out to prepare the bismuth oxide-lanthanum molybdate composite electrolyte. When the bismuth oxide and lanthanum molybdate composite electrolyte with the doping ratio of 20% is sintered to 800 DEG C, the absorption peak of the bismuth oxide completely covers the absorption peaks of the lanthanum molybdate, and the composite degree is very high. The researchalso provides important experimental data for research and practical application of bismuth oxide.

Owner:HEFEI UNIV

Preparation method of titanium dioxide fiber modified phenolic resin thermal insulation material

The invention provides a titanium dioxide fiber modified phenolic resin thermal insulation material. Raw materials of the thermal insulation material comprise raw materials for preparing phenolic resin, and titanium dioxide fibers, and the raw materials of the thermal insulation material are uniformly mixed, polymerized and molded to prepare the resin. Impact experiments show that the titanium dioxide fibers added according to the fiber reinforcement principle improve the strength of the phenolic resin thermal insulation material and degrade the indoor environment, so the requirements of environmentally friendly buildings are met.

Owner:铜仁市万山区建辉新型环保建材有限公司

Method for preparing environment-friendly type organosilicon modified acrylic ester binding agent

InactiveCN101423735BPromote environmental protectionImprove stabilityFibre treatmentEster polymer adhesivesPolymer scienceAdhesive

The invention relates to a method for preparing an environment-friendly silicone-modified acrylate adhesive. Raw materials of the preparation method comprise a basic monomer, a modified monomer and an auxiliary agent, wherein the basic monomer comprises a hard monomer, a soft monomer and a crosslinking monomer; the modified monomer comprises a silane monomer, a coupling agent and inorganic nano-powder; the crosslinking monomer is glycidyl acrylate or glycidyl methacrylate; and the grain diameter of the inorganic nano-powder is less than 80 nanometers. In the preparation method, the crosslinking monomer adopts the glycidyl acrylate or the glycidyl methacrylate so as to be environment-friendly. The product prepared by the method is a nanometer / silicone double-modified molecular composite polymer material. The molecular composite material is combined with the advantages of two polymer materials, namely silicone and polyacrylic ester and an inorganic nanometer material, and has better performance and broad application.

Owner:WUHAN TEXTILE UNIV

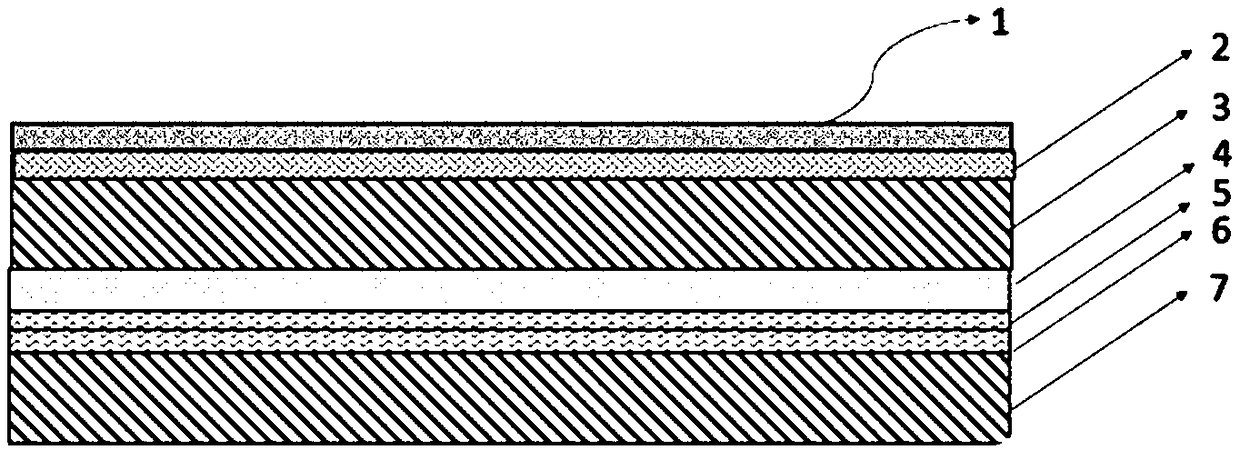

A packaging front panel and a preparation process thereof

PendingCN109087962AThe process steps are simpleClean thoroughlyPhotovoltaic energy generationSemiconductor devicesComposite filmWater vapor

The invention provides an packaging front panel and a preparation process thereof, wherein the packaging front panel is a composite film bonded on the upper surface of a solar cell module, and is characterized in that the composite film comprises an anti-adhesion coating, a frosted anti-aging layer, a first thin film base material layer, a first adhesive layer and a water vapor barrier layer fromtop to bottom. The packaging front panel of the invention can meet the requirements of lower water vapor transmission rate and lower service life (less than five years) of mobile energy sources, meanwhile, the flexible front panel has fingerprint-proof and scratch-resistant surface, simple and efficient packaging process, and low material and process cost. The package front board is lighter, thinner, softer than the traditional front board, lower material cost and simpler process.

Owner:DONGJUN NEW ENERGY CO LTD

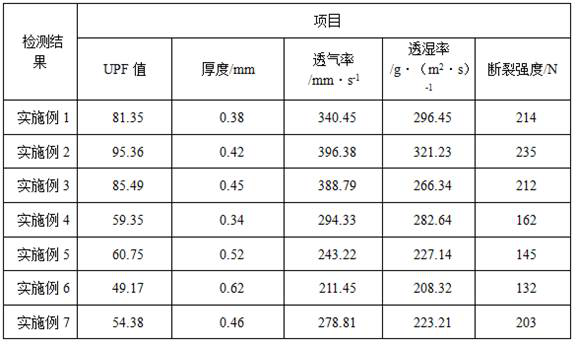

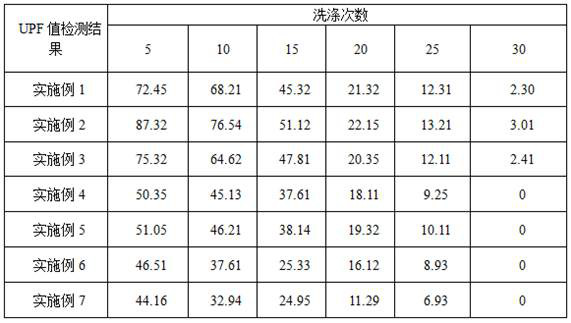

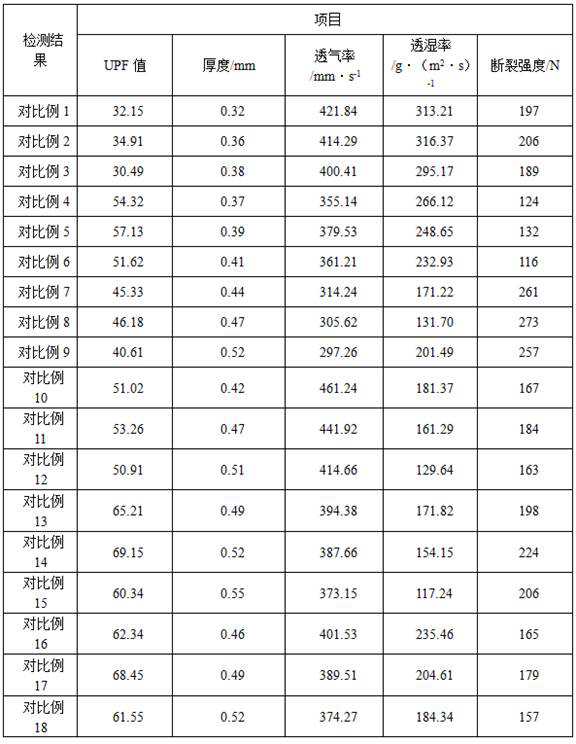

Preparation method of anti-ultraviolet and moisture-permeable composite fabric

ActiveCN113235289AImproves UV resistanceGood moisture permeabilityLight resistant fibresPolymer scienceLithium chloride

The invention relates to the field of textile materials, and particularly discloses a preparation method of an anti-ultraviolet and moisture-permeable composite fabric. The preparation method of the anti-ultraviolet and moisture-permeable composite fabric comprises the following steps of S1, taking a composite fabric formed by co-spinning polyurethane and cotton fibers, dipping the composite fabric in a pretreatment solution, carrying out an oscillation reaction, and performing washing with water and and drying to obtain a to-be-treated fabric; S2, taking 40-60 parts by weight of an anti-ultraviolet finishing agent, 10-30 parts by weight of a moisture-permeable finishing agent, 1-10 parts by weight of polyethylene glycol 200, 0.5-2 parts by weight of lithium chloride and 10-15 parts by weight of deionized water, stirring and dispersing the anti-ultraviolet finishing agent, the moisture-permeable finishing agent and the polyethylene glycol 200 firstly, performing heat-preservation stirring, adding the lithium chloride and the deionized water, and performing stirring to obtain a composite finishing agent; S3, putting the to-be-treated fabric into a composite finishing agent solution, carrying out padding treatment, and taking out a finished fabric; and S4, enabling the finished fabric to be pre-baked, baked, washed and naturally aired, so that the anti-ultraviolet moisture-permeable composite fabric is obtained. The anti-ultraviolet and moisture-permeable composite fabric has the advantages of being excellent in anti-ultraviolet performance, elasticity and moisture permeability.

Owner:杭州超峰布艺有限公司

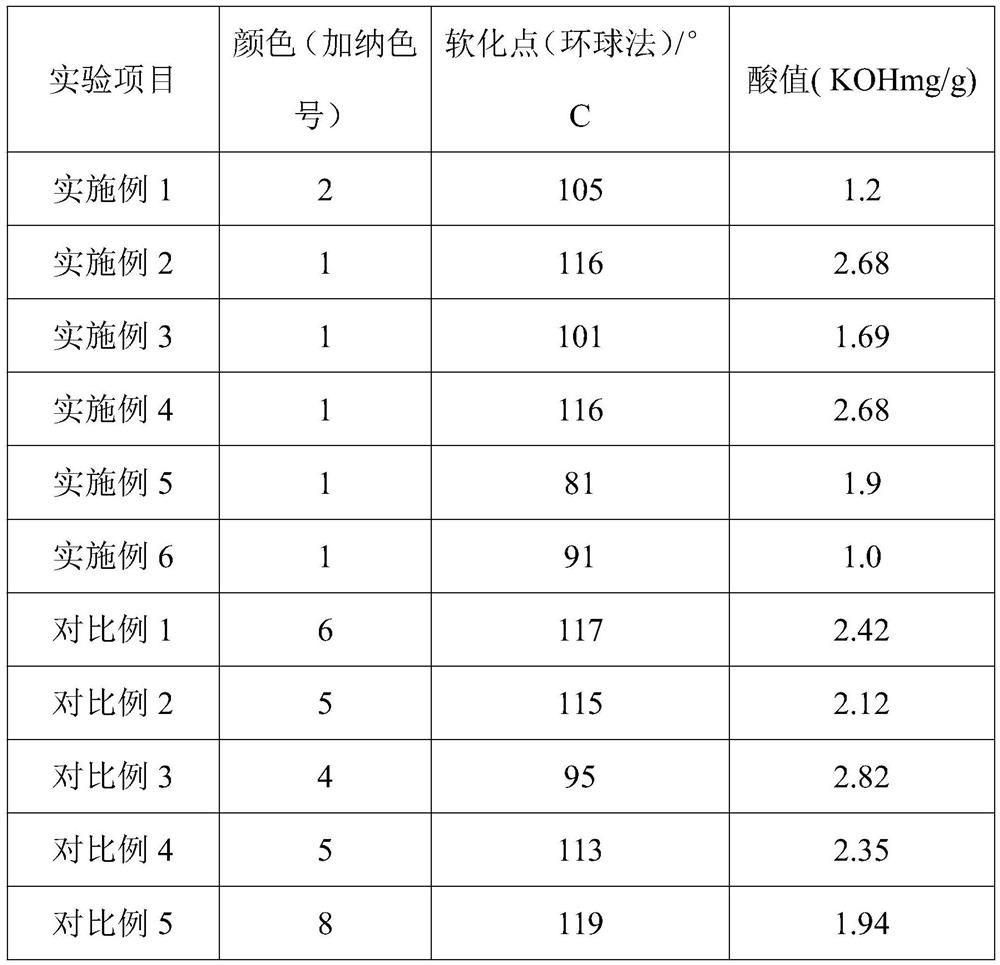

Ultra-light-color high-stability hydrogenated terpene-phenol resin and preparation method thereof

The invention discloses a preparation method of ultra-light-color high-stability hydrogenated terpene-phenolic resin, which comprises the following steps: S1, pulverizing terpene-phenolic resin to obtain pulverized terpene-phenolic resin; s2, a solvent, a catalyst, a catalyst carrier and a stabilizer are added into the crushed terpene-phenol resin, then hydrogen is introduced, the hydrogen pressure is 10-30 MPa, the temperature is increased to 210-240 DEG C, a reaction is conducted for 2.5-8 h, and a post-reaction melt is prepared; s3, releasing the pressure, cooling, discharging, and filtering to remove the catalyst, the catalyst carrier and the stabilizer; and S4, distilling the filtered product to remove the solvent, thereby obtaining the ultra-light-color high-stability hydrogenated terpene-phenol resin. The terpene-phenolic resin prepared by the method is light in color and luster, good in stability and weather resistance, simple in preparation step and green, environment-friendly and pollution-free in preparation process.

Owner:广西鼎弘树脂有限公司

Modified phenolic resin thermal insulation material

InactiveCN108752854AQuality improvementHigh degree of compoundThermal insulationUltimate tensile strength

The invention provides a modified phenolic resin thermal insulation material. Raw materials of the thermal insulation material comprise raw materials for preparing phenolic resin, and modified seashell powder, and the raw materials of the thermal insulation material are uniformly mixed, polymerized and molded to prepare the resin. Impact experiments show that the addition of the modified seashellpowder improves the strength of the phenolic resin thermal insulation material, and meets requirements of environmentally friendly buildings.

Owner:铜仁市万山区建辉新型环保建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com