Vinasse porous carbon/cobalt-nickel hydroxide electrode material and preparation process thereof

A technology of cobalt-nickel hydroxide and electrode materials, which is applied in the manufacture of hybrid/electric double-layer capacitors and electrodes of hybrid capacitors, can solve the problems of poor conductivity, poor conductivity, and expensive graphene, and achieve good rate performance, The effect of high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Material product preparation:

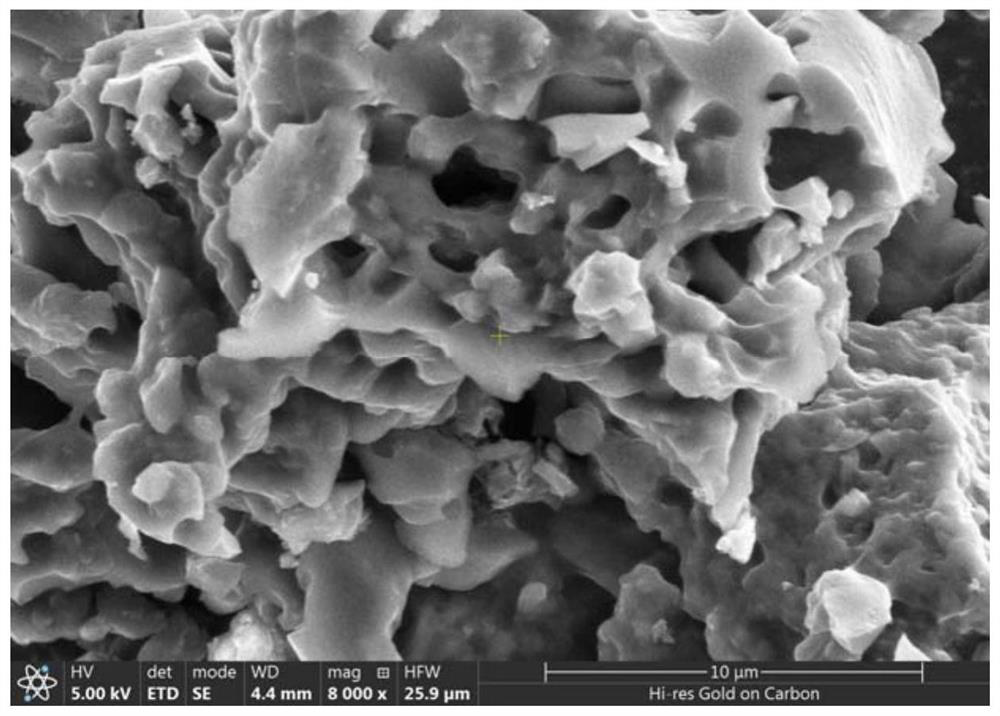

[0036] (1) Preparation of distiller's grain porous carbon: After drying, grinding and crushing distiller's grains, pre-carbonize to obtain a carbon precursor. The pre-carbonization temperature is 500°C, and the pre-carbonization time is 2h. Mix and grind at a ratio of 1:4, and calcinate the ground powder at a temperature of 700°C for 2 hours, then wash, filter, dry, and grind to obtain distiller’s grain porous carbon.

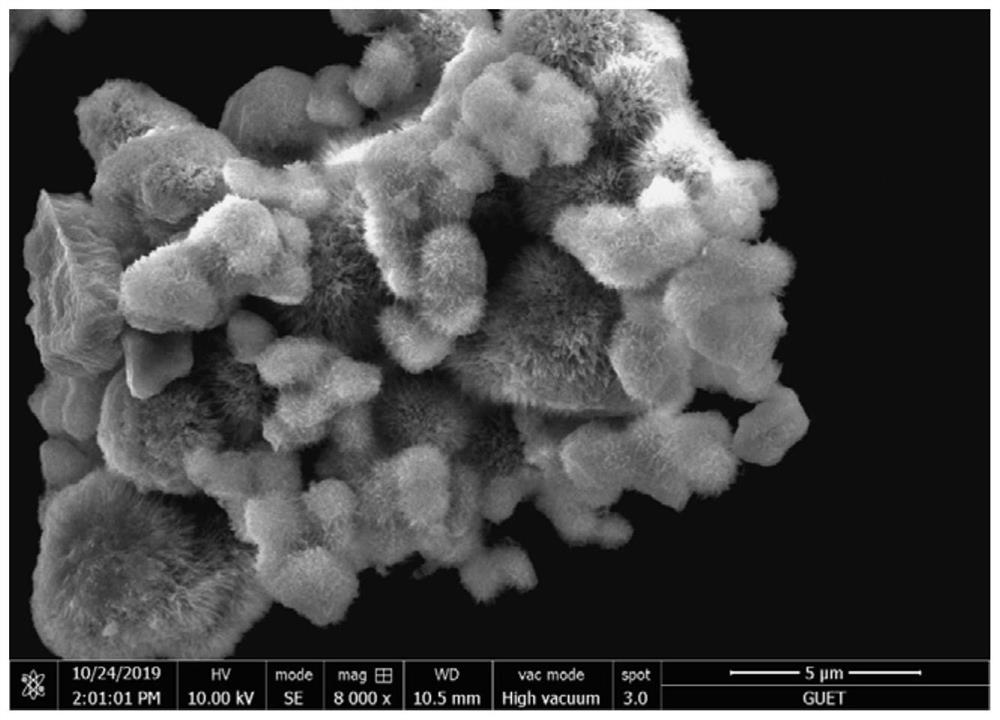

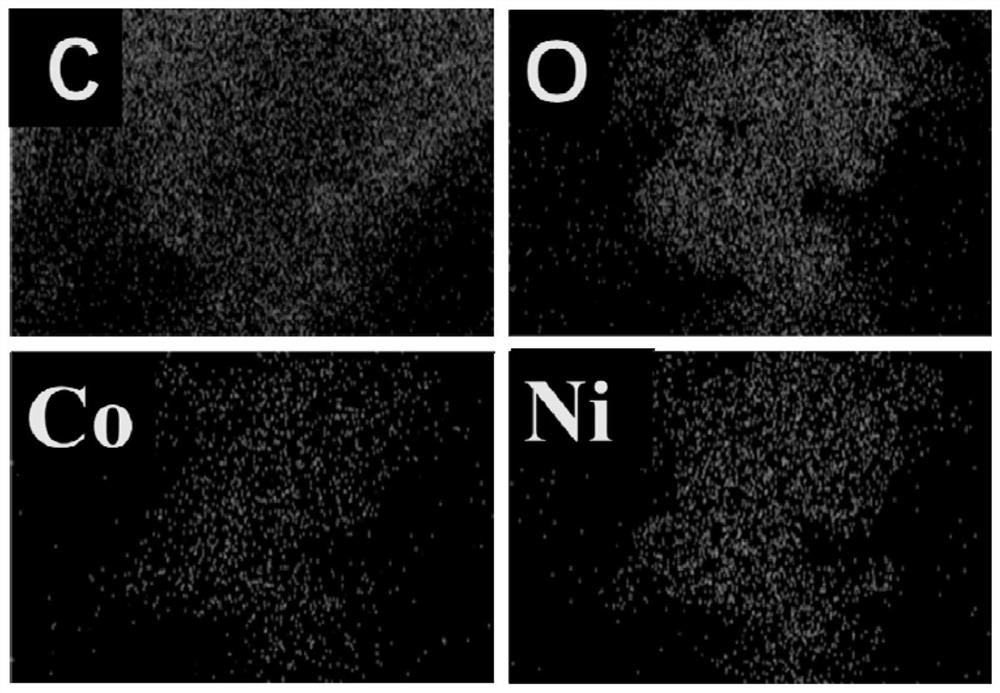

[0037] (2) Distiller's grain porous carbon / cobalt-nickel hydroxide electrode material: First, weigh 0.03 g of the prepared distiller's grain porous carbon into a beaker, then weigh 0.4 g of cobalt nitrate hexahydrate, 0.8 g of nickel nitrate hexahydrate, and 0.5 g of urea. g, polyvinylpyrrolidone 0.1g, respectively added to a beaker, then poured into 50ml of deionized water, ultrasonically stirred at room temperature until completely dissolved and mixed evenly, then transferred to a reaction kettle, and carried out hydroth...

Embodiment 2

[0045] Comparative analysis of electrochemical properties of distiller's grain porous carbon / cobalt-nickel hydroxide composites under different cobalt-nickel mass ratios (the mass ratio of distiller's grain porous carbon to cobalt nitrate hexahydrate, nickel nitrate hexahydrate, urea and polyvinylpyrrolidone is 0.3: 4:4:5:1)

[0046] The steps not specified in the specific steps are the same as the preparation method of Example 1, the difference is that the quality of the specific distiller's grain porous carbon is 0.03g, the quality of cobalt nitrate hexahydrate is 0.4g, and the quality of nickel nitrate hexahydrate is 0.4g. The quality that takes is 0.4g, urea 0.5g, polyvinylpyrrolidone 0.1g, carries out electrochemical test to the composite material prepared in embodiment 2, and test method is identical with embodiment 1, and test result is as follows Figure 7 , Figure 8 As shown, there is still an obvious redox peak at 20mV s-1, which proves its good rate performance, b...

Embodiment 3

[0048] Comparative analysis of electrochemical properties of distiller's grain porous carbon / cobalt-nickel hydroxide composites under different cobalt-nickel mass ratios (the mass ratio of distiller's grain porous carbon to cobalt nitrate hexahydrate, nickel nitrate hexahydrate, urea and polyvinylpyrrolidone is 0.3: 4:12:5:1)

[0049] The steps not specified in the specific steps are the same as the preparation method of Example 1, the difference is that the quality of the specific distiller's grain porous carbon is 0.03g, the quality of cobalt nitrate hexahydrate is 0.4g, and the quality of nickel nitrate hexahydrate is 0.4g. The quality that takes is 1.2g, urea 0.5g, polyvinylpyrrolidone 0.1g, carries out electrochemical test to the composite material prepared in embodiment 3, and test method is identical with embodiment 1, and test result is as follows Figure 9 , Figure 10 As shown, it can be seen from the figure that there are still obvious redox peaks, and its specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com