Carbon-silicon composite material, and preparation method and application thereof

A technology of silicon composite materials and composite materials, applied in nanotechnology for materials and surface science, active material electrodes, electrical components, etc., can solve the problems of high volume expansion rate, uniform distribution, and degradation of cycle performance of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] (1) Get 120g ferric chloride hexahydrate, 75mL concentrated hydrochloric acid and add 1725mL deionized water and fully stir until clarification prepares ferric chloride solution, then add 60g polyethylene glycol and fully stir until dissolved to obtain polyethylene glycol and ferric chloride Dispersions.

[0063] (2) Take 900g of natural flake graphite and add it to the dispersion liquid obtained in step (1) to fully infiltrate it, stir it evenly, and then dry it to obtain a base material for catalytic metal surface interface modification.

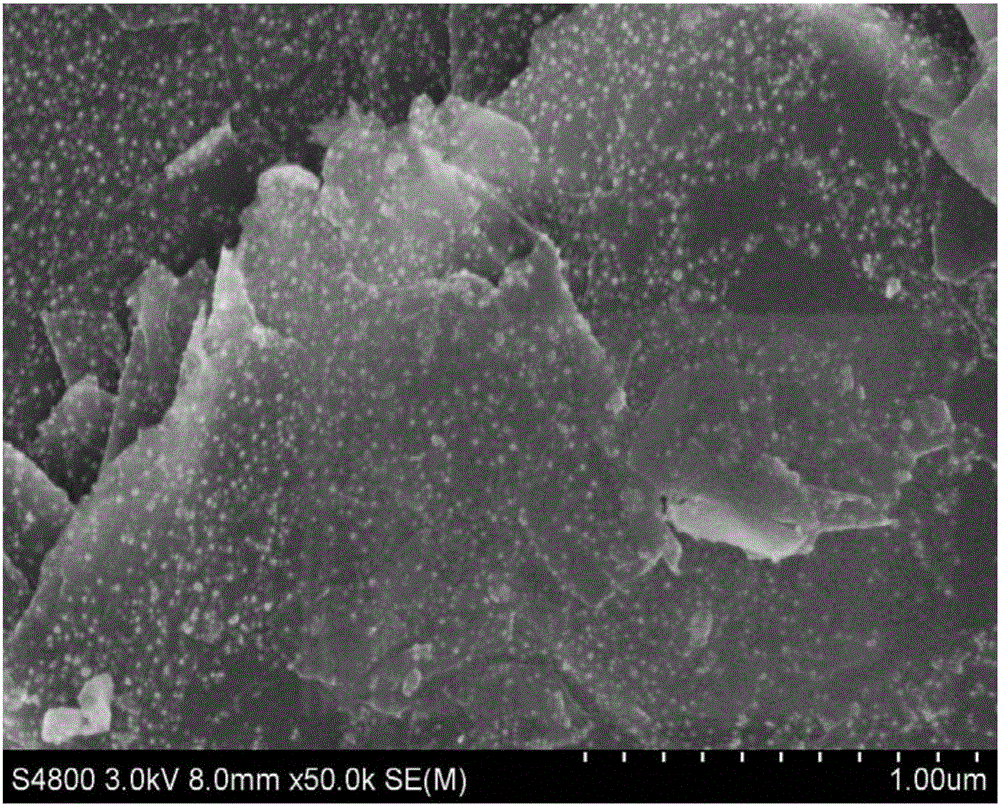

[0064] (3) Add the base material modified by the catalytic metal surface interface in step (2) into a rotary CVD furnace, heat to 750°C under the protection of nitrogen, and then use nitrogen at a flow rate of 3.5L / min as a carrier gas, and use 5L / min The speed of min is passed through the heated and vaporized trichlorosilane, and the carbon-silicon composite material is obtained after reacting for 3 hours.

[0065] (4) The carbon-...

Embodiment 2

[0074] (1) Take 201g of copper chloride dihydrate and 75mL of concentrated hydrochloric acid and add 1725mL of deionized water to fully stir until clarified to prepare a copper chloride solution, then add 20g of glucose and fully stir until dissolved to obtain a dispersion of glucose and copper chloride.

[0075] (2) Take 900g of natural spherical graphite and add it to the dispersion obtained in step (1) to fully infiltrate it, stir it evenly, and then dry it to obtain a base material for catalytic metal surface interface modification.

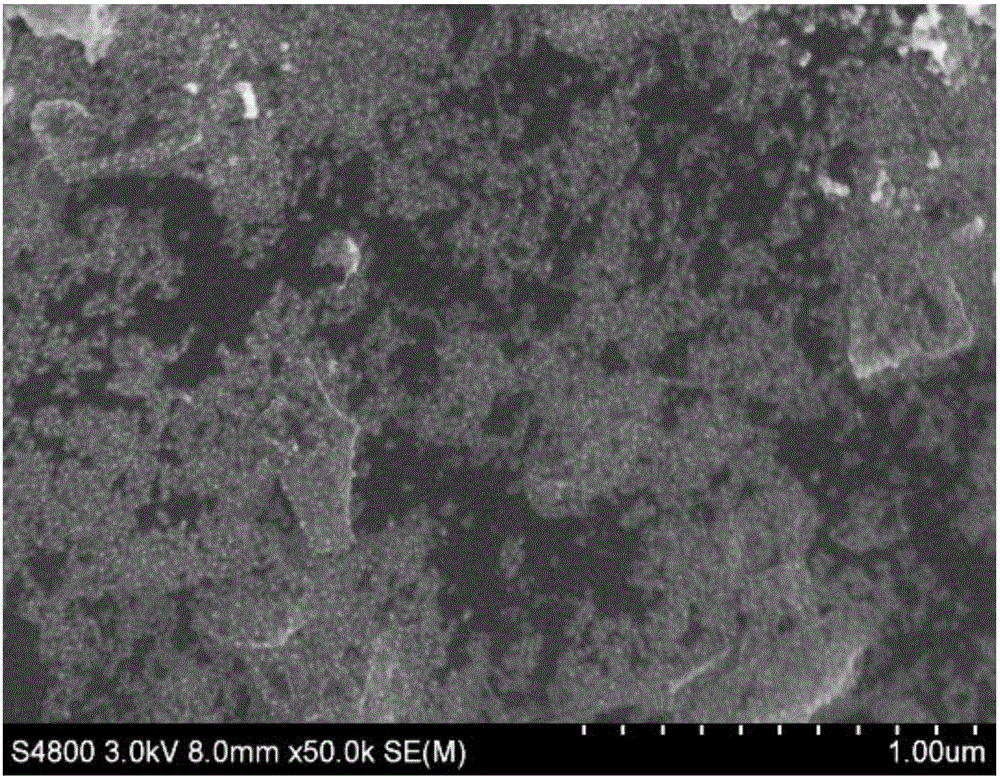

[0076] (3) Add the substrate material modified by the catalytic metal surface interface in step (2) into a rotary CVD furnace, heat it to 550°C under the protection of argon, and then use nitrogen at a flow rate of 3.5L / min as a carrier gas, and use 5L A certain amount of monosilane was introduced at a speed of 1 / min, and the carbon-silicon composite material was obtained after 1.5 hours of reaction.

[0077] (4) The carbon-silicon composite ...

Embodiment 3

[0085] (1) Add 202g of copper acetate monohydrate and 25mL of concentrated hydrochloric acid into 1350mL of deionized water and stir until clarified to prepare a copper acetate solution, then add 20g of polyvinylpyrrolidone and stir until dissolved to obtain a dispersion of polyvinylpyrrolidone and copper acetate.

[0086] (2) Take 900g of conductive graphite and add it to the dispersion liquid obtained in step (1) to fully infiltrate it, stir it evenly, and then dry it to obtain a base material for catalytic metal surface interface modification.

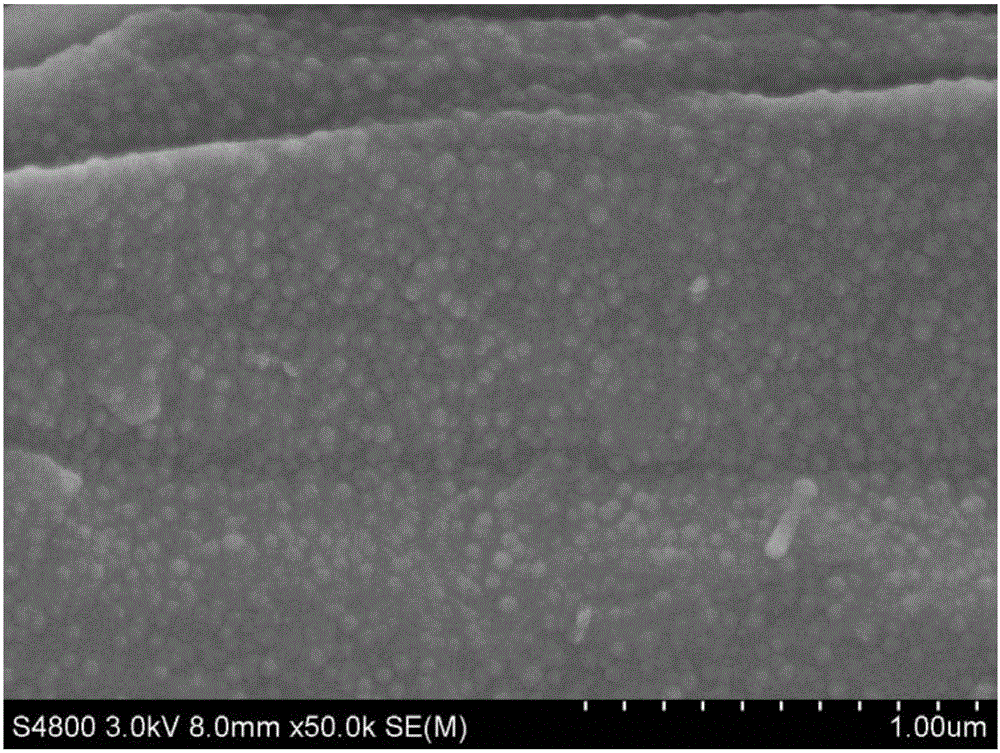

[0087] (3) Add the base material modified by the catalytic metal surface interface in step (2) into a rotary CVD furnace, heat it to 550°C under the protection of argon, and then use nitrogen at a flow rate of 3.5L / min as a carrier gas to A certain amount of monosilane was introduced at a rate of 6 L / min, and a carbon-silicon composite material was obtained after 3 hours of reaction.

[0088] (4) Adopt asphalt as binder to carry out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com