Nano-composite catalyst and preparation method thereof

A nanocomposite and catalyst technology, applied in the field of catalysis, can solve the problems of poor catalytic performance and low degree of nanocomposite, and achieve the effects of high degree of recombination, improved atom utilization rate, and high-efficiency catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of nanocomposite catalyst provided by the invention, its concrete steps are as follows:

[0025] Step 1: preparing non-stoichiometric or stoichiometric composite oxides by sol-gel method, impregnation method, Penichi method, co-precipitation method, deposition precipitation method, etc.;

[0026] Step 2: Put the composite oxide prepared in step 1 into a U-shaped tube, add a reducing agent, and reduce the composite oxide lattice or the first type of metal ion doped in the lattice at 500°C-1000°C in an inert reducing atmosphere , the reduction time is 0.5h-1h, and the nano-metal particles containing the first type of metal are obtained;

[0027] Step 3: Soak the reduced nanometer metal particles in the nitrate solution containing the second type of metal ions, filter after 0.5h-24h, wash with water, dry, and roast to obtain a nanocomposite catalyst;

[0028] The first type of metal is one or more of Co, Ni, Cu, Bi, and the second type of metal is o...

Embodiment 1

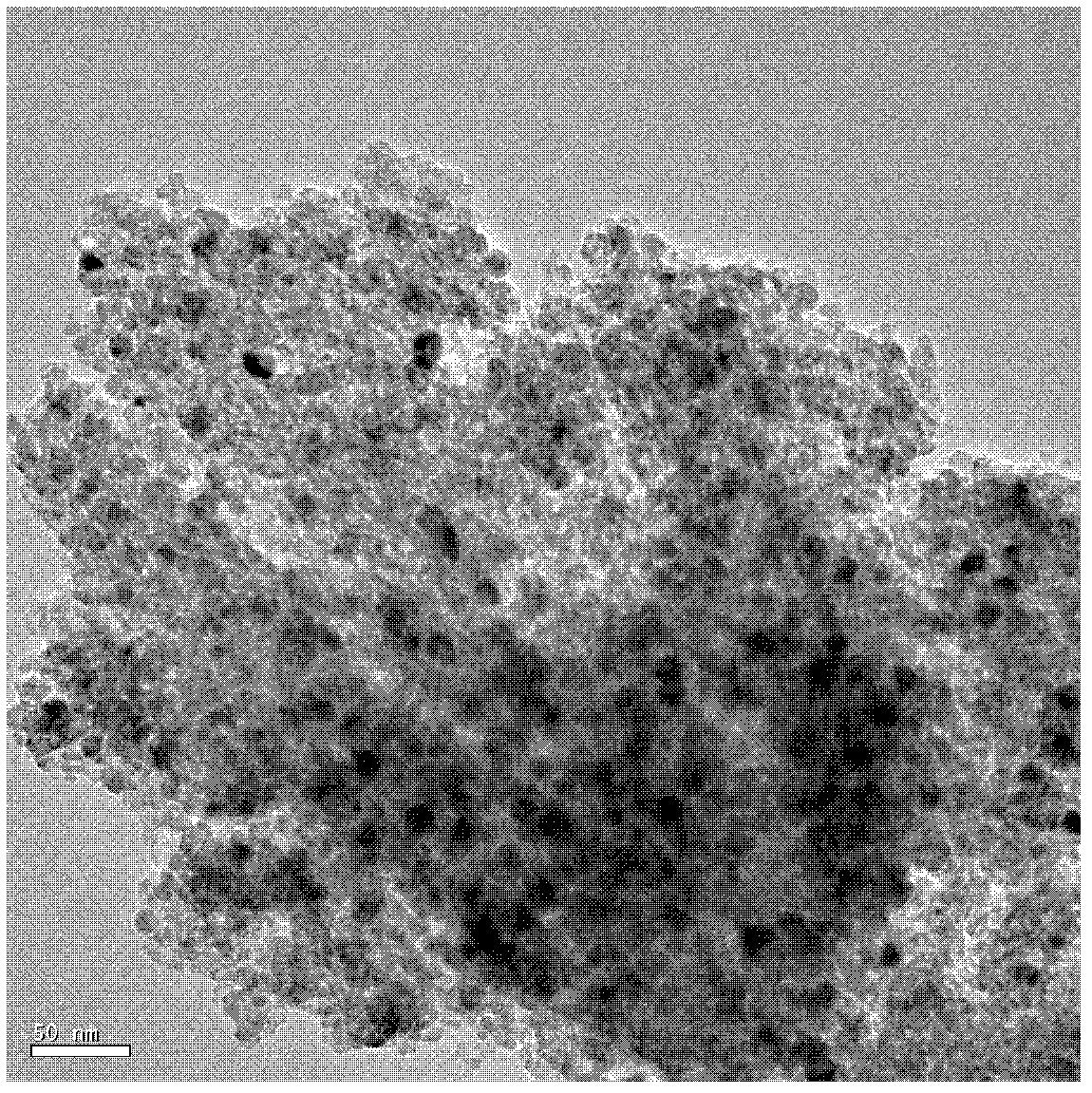

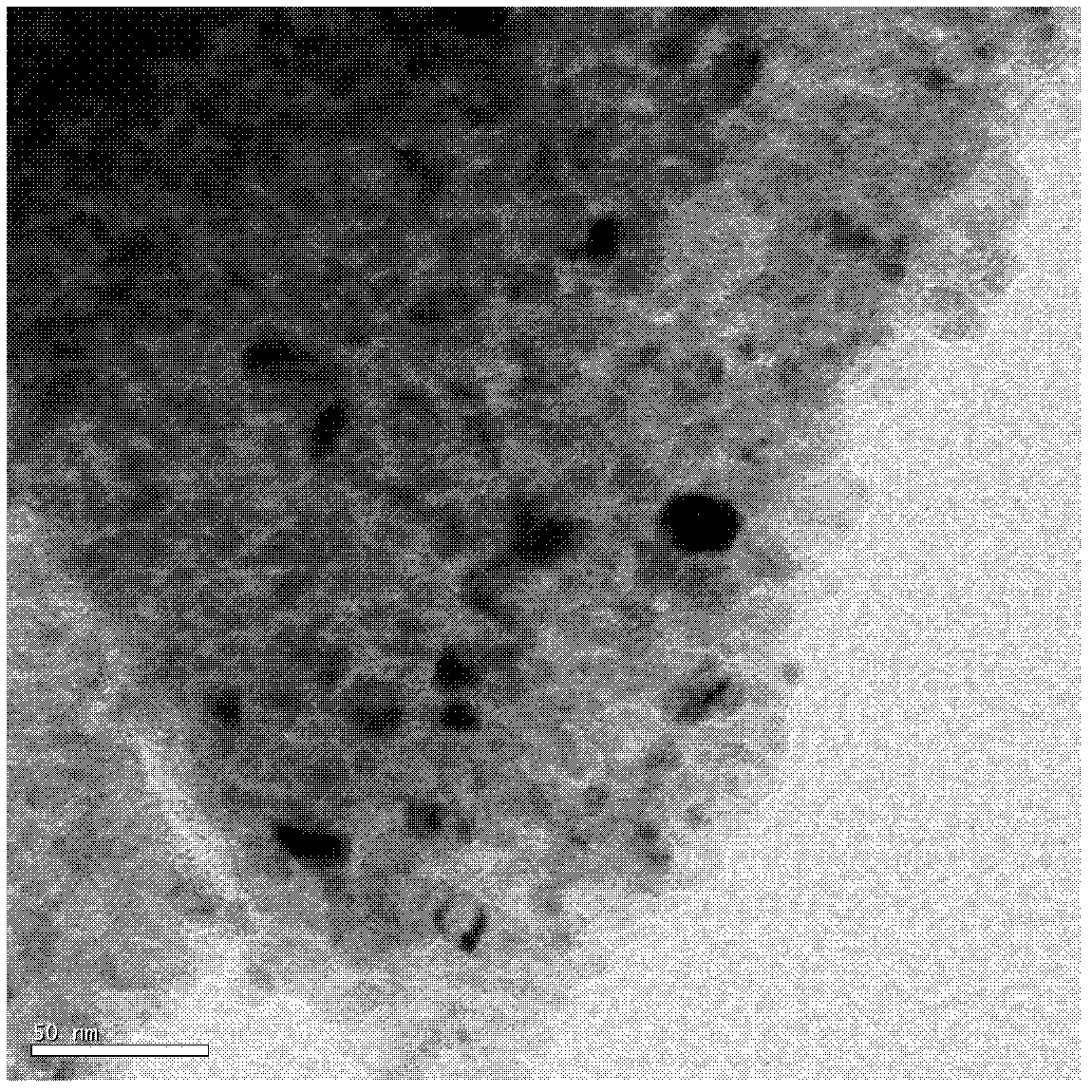

[0034] Weigh 0.01mol of aluminum isopropoxide (2.04g) and dissolve it in 180ml of water, stir to dissolve at 80°C, then add 1.5ml of concentrated nitric acid, heat to 90°C and keep for 3h to obtain a clear aluminum sol. Add 0.001mol nickel nitrate (0.291g) to the above aluminum sol, stir for 2h, then evaporate to the gel point at 100°C. The resulting gel was dried under vacuum at 100°C overnight, and then calcined at 700°C for 4 hours to obtain non-stoichiometric NiAl 2 o 4 spinel carrier. Weigh 2.5g of the carrier and put it into a U-shaped tube, 5%H 2 / Ar atmosphere at 750°C-1000°C for 1h, cooled to room temperature under the protection of reducing atmosphere, and immersed the reduced sample in 10ml 0.43mol / L Pd(NO 3 ) 2 solution, filtered after 0.5h, washed with water, dried and calcined to obtain Catalyst 1. Finally, the catalyst is pressed into tablets, ground, and sieved to obtain 40-80 mesh particles for later use. The obtained sample NiAl 2 o 4 , Pd / Ni-Al 2 o ...

Embodiment 2

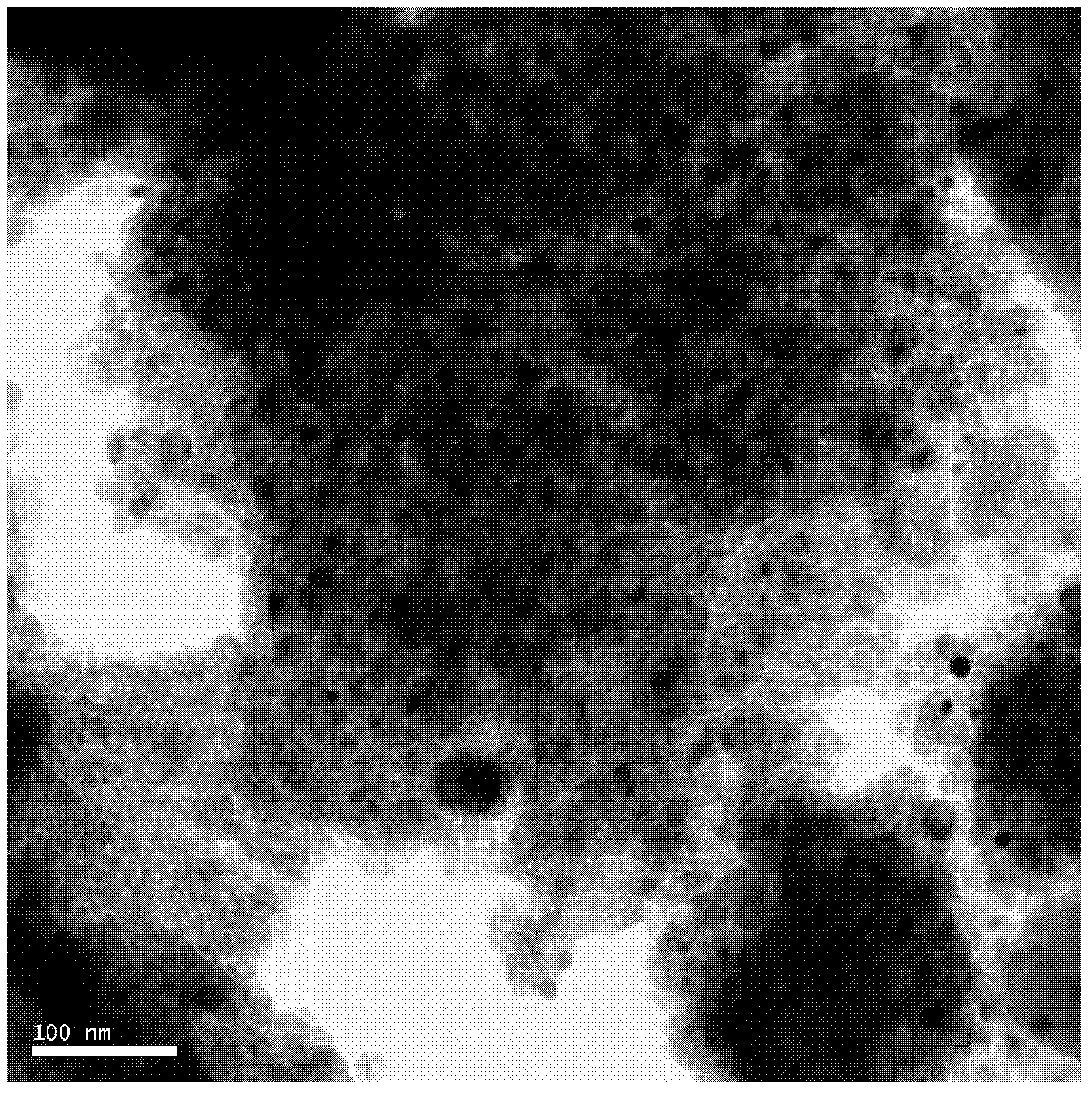

[0036]0.01 mol of aluminum nitrate (3.75 g) and 0.01 mol of nickel nitrate (2.91 g) were weighed and dissolved in 250 ml of water. Then add 3.00 g of urea to the above solution. After the urea is completely dissolved, start heating to 95°C-100°C, and heat and stir at this temperature until evaporated to dryness. The obtained samples were dried overnight at 110°C and calcined in air at 800°C for 4 hours to obtain a stoichiometric ratio of NiAl 2 o 4 spinel carrier. Weigh 2.5g NiAl 2 o 4 Put into U-shaped tube, 5%H 2 / Ar atmosphere at 750°C-1000°C for 1h, cooled to room temperature under the protection of reducing atmosphere, and immersed the reduced sample in 10ml 0.43mol / L Pd(NO 3 ) 2 solution, filtered after 1h, washed with water, dried and calcined to obtain Catalyst 2. Finally, the catalyst is pressed into tablets, ground, and sieved to obtain 40-80 mesh particles for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com