Preparation method of anti-ultraviolet and moisture-permeable composite fabric

A composite fabric, anti-ultraviolet technology, applied in the directions of light-resistant fibers, fiber processing, textiles and papermaking, etc., can solve the problems of poor moisture permeability of fabrics, achieve high-efficiency anti-ultraviolet application, enhance anti-ultraviolet performance, and enhance composite degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

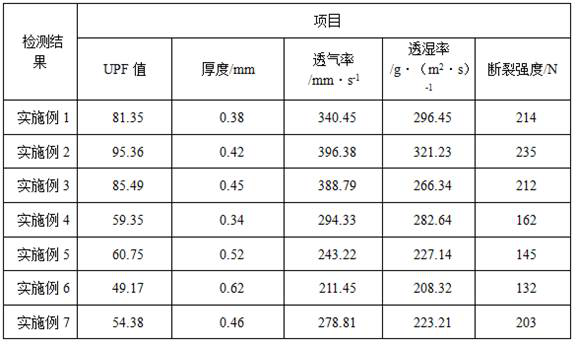

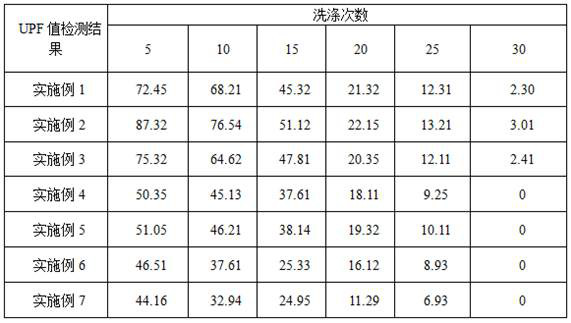

Examples

Embodiment 1

[0032] Take the composite fabric co-spun with spandex and cotton fiber, add 100g of pretreatment solution, place the composite fabric in the pretreatment solution, soak it at 60°C for 5 minutes, shake it, wash it with water, and dry it to get the fabric to be treated.

[0033] Weigh 10 g of deionized water, 80 g of 10% sodium hydroxide solution and 0.01 g of accelerator 1227 into a flask, stir and disperse to prepare a pretreatment solution.

[0034] Weigh 1g of chitosan, disperse in 40g of hydrochloric acid solution, after stirring, add 20g of hydrogen peroxide aqueous solution, heat in 300W microwave for 1min, cool at room temperature to obtain acid solution, adjust the acid solution to weak alkalinity, and suction filter to obtain The solid was washed until neutral, and vacuum freeze-dried to obtain a dry product.

[0035] Weigh 30g of water-based polyurethane, add 500g of deionized water, stir and disperse to obtain a polyurethane solution; take 3g of the dried product and...

Embodiment 2

[0041] Take the composite fabric co-spun with spandex and cotton fiber, add 120g of pretreatment solution, place the composite fabric in the pretreatment solution, soak it at 70°C for 10 minutes, shake it, wash it with water, and dry it to get the fabric to be treated.

[0042] Weigh 15g of deionized water, 100g of 15% sodium hydroxide solution and 0.05g of Accelerator 1227 into a flask, stir and disperse to prepare a pretreatment solution.

[0043] Weigh 2g of chitosan, disperse in 50g of hydrochloric acid solution, after stirring, add 30g of hydrogen peroxide aqueous solution, heat in 400W microwave for 3min, cool at room temperature to get acid solution; adjust the acid solution to weak alkaline, filter with suction A solid was obtained, washed until neutral, and vacuum freeze-dried to obtain a dry product.

[0044] Weigh 45g of water-based polyurethane, add 750g of deionized water, stir and disperse to obtain a polyurethane solution; mix 3g of solid chitosan with 700g of h...

Embodiment 3

[0050] Take the composite fabric co-spun with spandex and cotton fiber, add 150g of pretreatment solution, place the composite fabric in the pretreatment solution, soak it at 80°C for 15 minutes, shake it, wash it with water, and dry it to get the fabric to be treated.

[0051] Weigh 20g of deionized water, 120g of 20% sodium hydroxide solution and 0.1g of accelerator 1227 into a flask, stir and disperse to prepare a pretreatment solution.

[0052] Weigh 5g of chitosan, disperse in 60g of hydrochloric acid solution, after stirring, add 40g of hydrogen peroxide aqueous solution, heat in 500W microwave for 6min, cool at room temperature to obtain acid solution, adjust the acid solution to weak alkaline, and suction filter to obtain The solid was washed until neutral, and vacuum freeze-dried to obtain a dry product.

[0053] Weigh 60g of water-based polyurethane, add 1000g of deionized water, stir and disperse to obtain a polyurethane solution; take 3g of solid chitosan and 1000g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com