Ultra-light-color high-stability hydrogenated terpene-phenol resin and preparation method thereof

A technology of hydrogenated terpene phenol resin and terpene phenol resin, which is applied in the field of ultra-light color and high stability hydrogenated terpene phenol resin and its preparation, can solve the problems of low stability and weather resistance, dark color, etc., and achieve improved stability Sexuality, the effect of preventing the color from darkening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

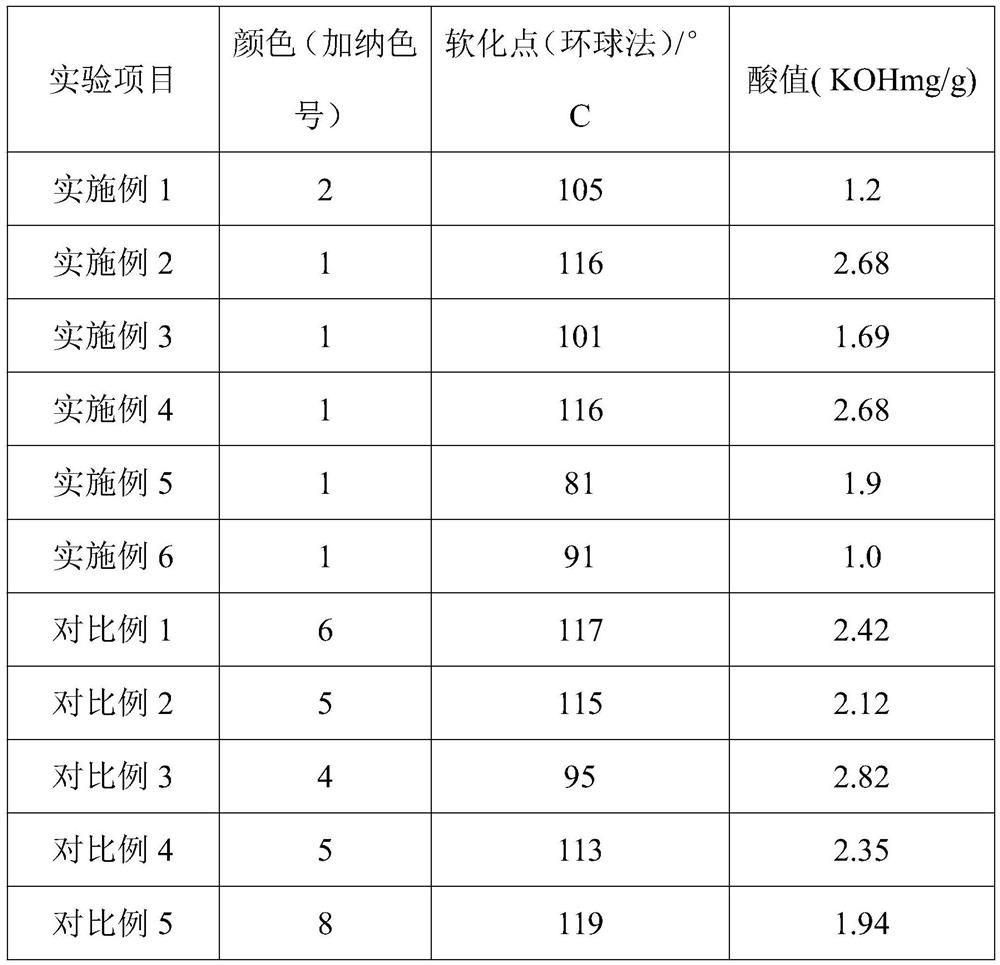

Examples

Embodiment 1

[0025] A preparation method of ultra-light-colored high-stability hydrogenated terpene phenol resin, comprising the following steps:

[0026] S1: pulverize the terpene phenol resin to obtain a pulverized terpene phenol resin;

[0027] S2: add solvent, catalyzer, catalyst carrier, stabilizer by mass ratio to terpene phenol resin pulverized material, the mass ratio of described terpene phenol resin pulverized material, solvent, catalyst, catalyst carrier, stabilizer is 1:1: 0.04:0.05:0.01, then pass in hydrogen with a pressure of 10MPa, heat up to 210°C, and react for 8h to obtain a melt after the reaction; the solvent is turpentine; the catalyst is ZrCl 4 , BiCl 3 , Ni metal catalyst is composed of 1:3:2 by mass ratio; the catalyst carrier is zeolite, TiO 2 It is composed of 2:5 by mass ratio; the stabilizer is composed of hypophosphorous acid, thiourea, antioxidant 300, and triphenyl phosphite by mass ratio of 2:5:2:4;

[0028] S3: then pressure relief, cooling, discharging...

Embodiment 2

[0031] A preparation method of ultra-light-colored high-stability hydrogenated terpene phenol resin, comprising the following steps:

[0032] S1: pulverize the terpene phenol resin to obtain a pulverized terpene phenol resin;

[0033] S2: add solvent, catalyst, catalyst carrier, stabilizer by mass ratio to the pulverized terpene phenol resin, and the mass ratio of the pulverized terpene phenol resin, solvent, catalyst, catalyst carrier, and stabilizer is 1:2: 0.02:0.008:0.004, then pass in hydrogen with a pressure of 20MPa, heat up to 230°C, and react for 8h to obtain a melt after the reaction; the solvent is turpentine; the catalyst is ZrCl 4 , BiCl 3 , Ni metal catalyst is composed by mass ratio of 2:5:1; the catalyst carrier is zeolite, TiO 2 It is composed of 3:4 by mass ratio; the stabilizer is composed of hypophosphorous acid, thiourea, antioxidant 300, and triphenyl phosphite by mass ratio of 1:3:3:2;

[0034] S3: then pressure relief, cooling, discharging, filtering...

Embodiment 3

[0037] A preparation method of ultra-light-colored high-stability hydrogenated terpene phenol resin, comprising the following steps:

[0038] S1: pulverize the terpene phenol resin to obtain a pulverized terpene phenol resin;

[0039] S2: add solvent, catalyst, catalyst carrier, stabilizer by mass ratio to the terpene phenol resin pulverized material, the mass ratio of described terpene phenol resin pulverized material, solvent, catalyst, catalyst carrier, stabilizer is 1:1: 0.06:0.02:0.08, then pass in hydrogen with a pressure of 20MPa, heat up to 220°C, and react for 3h to obtain a melt after the reaction; the solvent is turpentine; the catalyst is ZrCl 4 , BiCl 3 , Ni metal catalyst is composed of 3:2:2 by mass ratio; the catalyst carrier is zeolite, TiO 2 It is composed of 2:5 by mass ratio; the stabilizer is composed of hypophosphorous acid, thiourea, antioxidant 300, and triphenyl phosphite by mass ratio of 3:4:3:2;

[0040] S3: then pressure relief, cooling, discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com