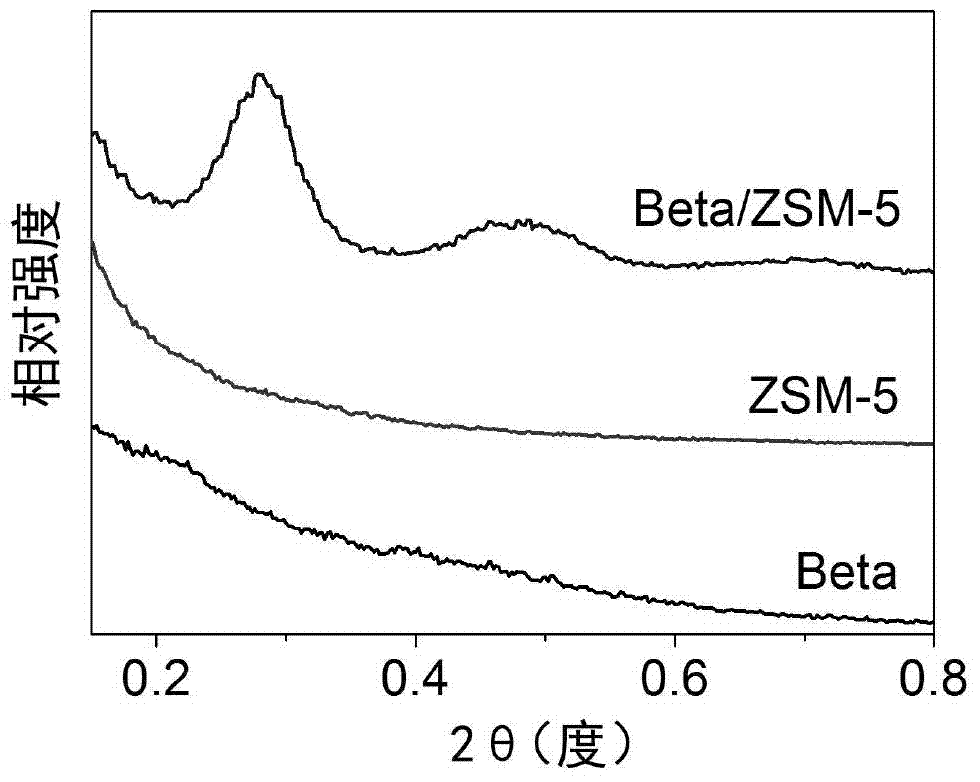

Beta/ZSM - 5 nano composite molecular sieves and preparation method thereof

A ZSM-5, nanocomposite technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of uneven distribution of Beta and ZSM-5 crystal phases, low degree of molecular sieve compounding, and preparation. Harsh conditions and other problems, to achieve the effects of controllable morphology and mesoporous structure, improved catalytic activity and selectivity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Taking mesoporous carbon with a three-dimensional ordered mesoporous structure as a hard template mesoporous carbon with a mesopore diameter of 40nm as an example, the method for preparing Beta / ZSM-5 nanocomposite molecular sieves is realized by the following steps:

[0034] (1) Weigh 0.05g of sodium hydroxide and dissolve it in 6.75g of tetraethylammonium hydroxide (abbreviation: (TEA) 2 (2, 35wt% aqueous solution), add 8.925g silica sol (containing 30wt% silica aqueous solution) dropwise, stir until the silica sol dissolves completely under room temperature conditions, add 0.185g aluminum isopropoxide (98wt%), wherein silica sol SiO 2 In terms of aluminum isopropoxide as Al 2 o3 Calculate, so that the molar ratio of each material is: SiO 2 :Al 2 o 3 : (TEA) 2 O: Na 2 O: H 2 O=25:0.25:9:0.35:330, stirring continuously at room temperature for 12 hours; filtering with a syringe filter with a filtration precision of 200 nm to obtain a clear Beta zeolite growth solu...

Embodiment 2

[0042] Taking mesoporous carbon with three-dimensional ordered mesoporous structure as hard template mesoporous carbon with mesoporous structure, the mesopore diameter is 20nm as an example, the method for preparing Beta / ZSM-5 nanocomposite molecular sieve is realized by the following steps:

[0043] (1) Weigh 0.05g sodium hydroxide and dissolve in 6.75g tetraethylammonium hydroxide (35wt% aqueous solution, called for short (TEA) 2 O); add 8.925g silica sol (containing 30wt% SiO 2 aqueous solution), stirring at room temperature until the silica sol is completely dissolved, adding 0.185g aluminum isopropoxide (98wt%), wherein the silica sol is made of SiO 2 In terms of aluminum isopropoxide as Al 2 o 3 Calculate, so that the molar ratio of each material is: SiO 2 :Al 2 o 3 : (TEA) 2 O: Na 2 O: H 2 O=25:0.25:9:0.15:330, stirring continuously at room temperature for 12 hours; filtering with a syringe filter with a filtration precision of 200 nm to obtain a clear Beta zeol...

Embodiment 3

[0051] Taking mesoporous carbon with a three-dimensional ordered mesoporous structure as a hard template mesoporous carbon with mesoporous structure, and the mesopore diameter is 10nm as an example, the method for preparing Beta / ZSM-5 nanocomposite molecular sieve is realized by the following steps:

[0052] (1) Weigh 0.05g of sodium hydroxide and dissolve it in 12.62g of tetraethylammonium hydroxide (abbreviation: (TEA) 2 (2, 35wt% aqueous solution), add 5g white carbon black, stir under room temperature until completely dissolving; Add 0.087g aluminum isopropoxide (98wt%), wherein white carbon black is SiO 2 In terms of aluminum isopropoxide as Al 2 o 3 Calculate, so that the molar ratio of each material is: SiO 2 :Al 2 o 3 : (TEA) 2 O: Na 2 O: H 2 O=20:0.1:7.2:0.3:110, stirring continuously for 10 hours at room temperature; filtering with a syringe filter with a filtration precision of 450 nm to obtain a clear Beta zeolite growth solution.

[0053] (2) Weigh 0.5g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com