A packaging front panel and a preparation process thereof

A preparation process and front plate technology, which is applied in the field of solar cell packaging components, can solve the problems of complex packaging process, low yield rate, and expensive fluorine film, and achieve the effects of simple process steps, improved wear resistance, and dense coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

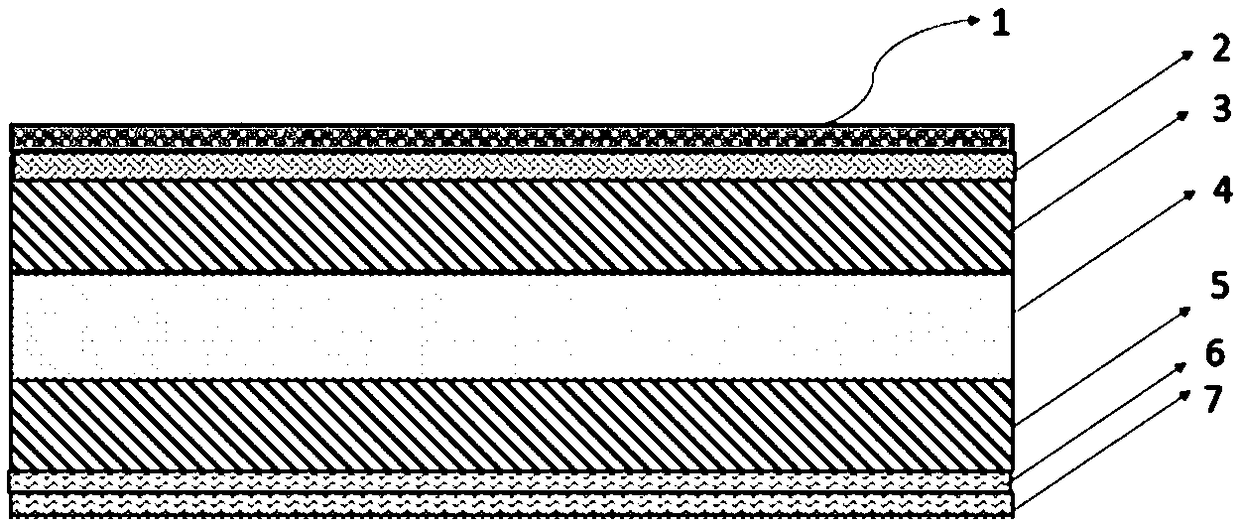

[0042] In this embodiment, the encapsulation front plate is composed of a composite film tightly covering the upper surface of the solar cell module, which is composed of multi-layer films. Wherein, 1 is an anti-sticking coating, the thickness is preferably 1-10um, more preferably 3-8um, more preferably 5um, which is distributed on the upper surface of the composite film of the front plate of the package, with anti-sticking, dustproof, self- Cleaning effect; 2 is frosted anti-aging coating, the thickness is preferably 1-10um, more preferably 3-8um, more preferably 5um, the specific composition of this layer preferably contains organic or inorganic frosted particles, for example, organic particles choose PMMA , PBMA, PDMS, the inorganic particles are SiO 2 、Al 2 o 3 , ZrO 2 , more preferably contains an anti-aging agent, and this layer has wear-resistant, scratch-resistant, and aging-resistant effects; 3 is the first film substrate layer, the thickness is preferably 50-200um...

Embodiment 2

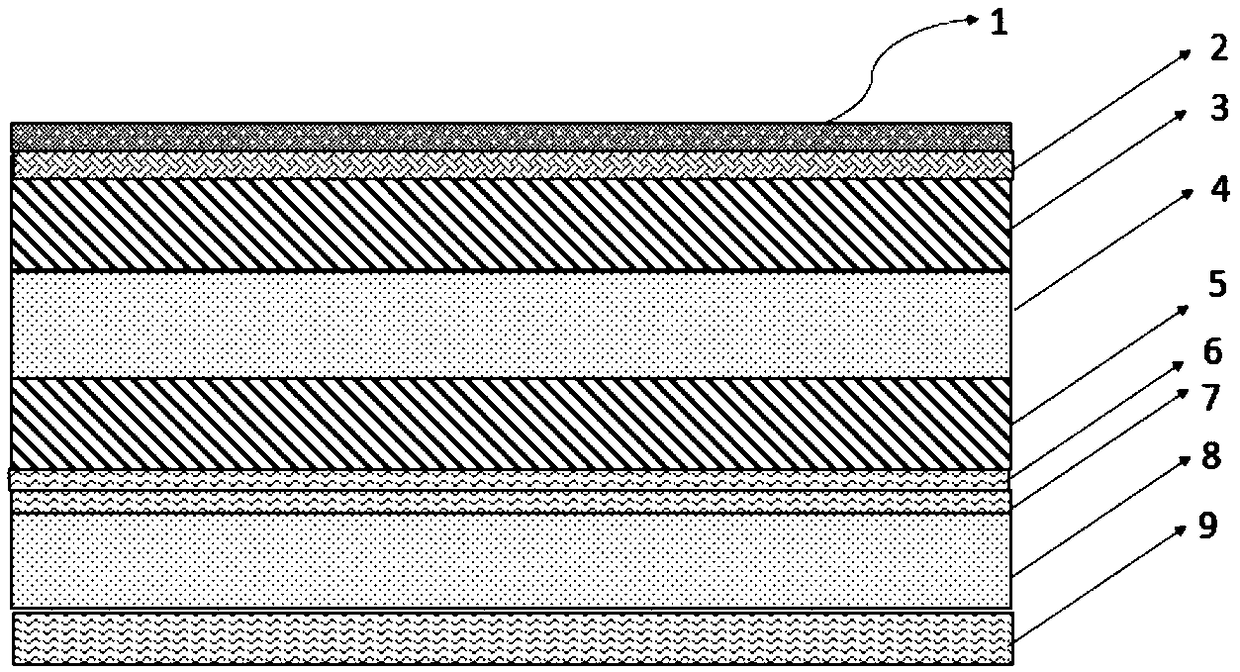

[0052] In order to further adjust and optimize the structure and comprehensive performance of the flexible solar cell encapsulation front plate of the present invention, this embodiment 2 makes the following improvements to the structure and its preparation process on the basis of the encapsulation front plate in embodiment 1. Preferably, on the basis of the packaging front panel of Embodiment 1, the lower surface of the water vapor barrier layer 7 is compounded with the second adhesive film layer 8 .

[0053] More preferably, the lower surface of the second adhesive film layer 8 is compounded with a PE protective film 9 .

[0054] In this embodiment, the conceiver designed the water vapor barrier layer 7 so that it does not directly cover and contact with the solar battery module, and there is a layer of adhesive film 8 in between. On the one hand, it can prevent the water and gas generated by the battery module from damaging the water vapor barrier layer. On the other hand, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com