Method for preparing phthalocyanine film

A phthalocyanine and thin film technology, applied in the field of preparation of phthalocyanine thin films, achieves the effects of high efficiency, less time-consuming, and easy large-scale industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

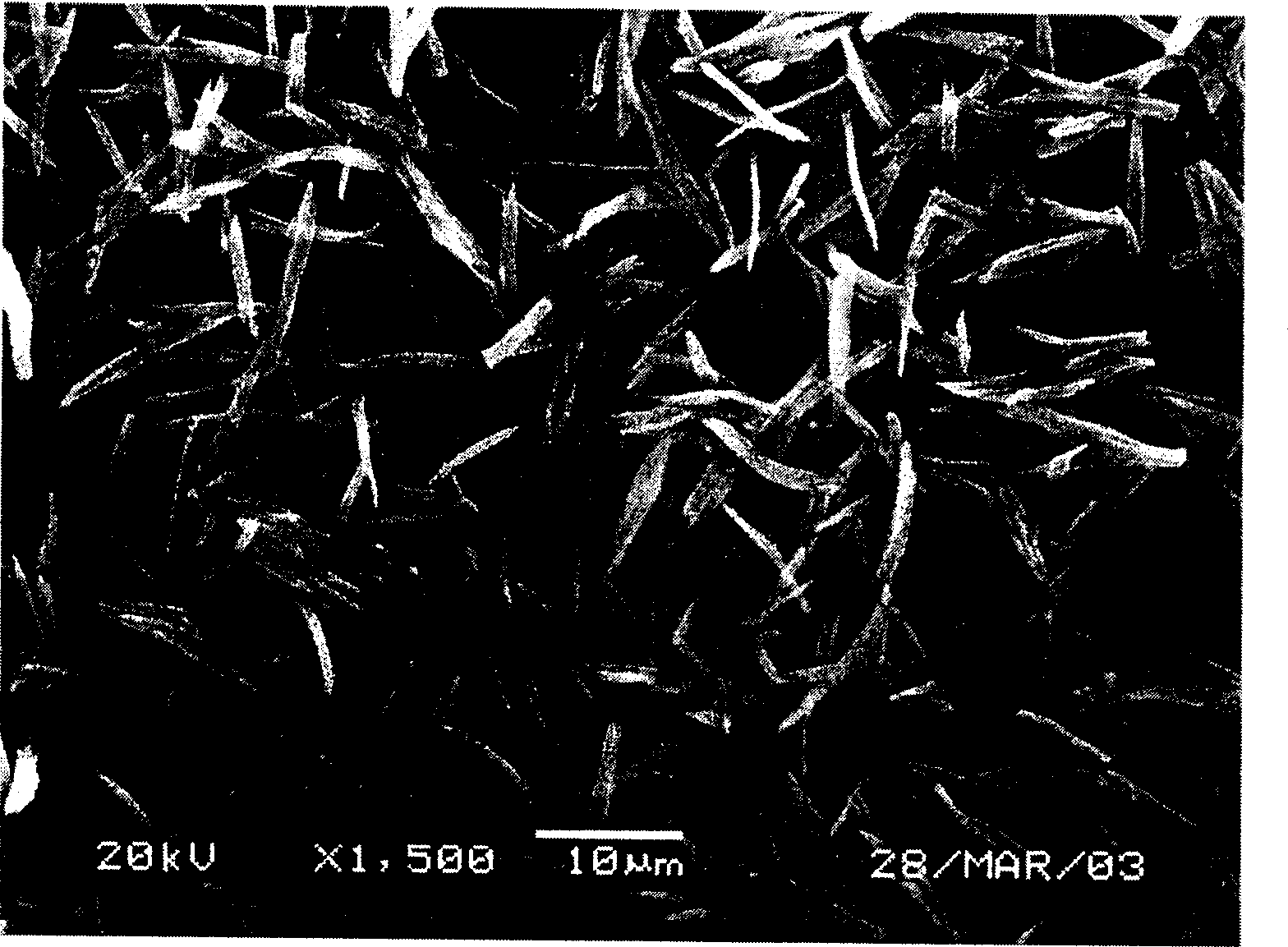

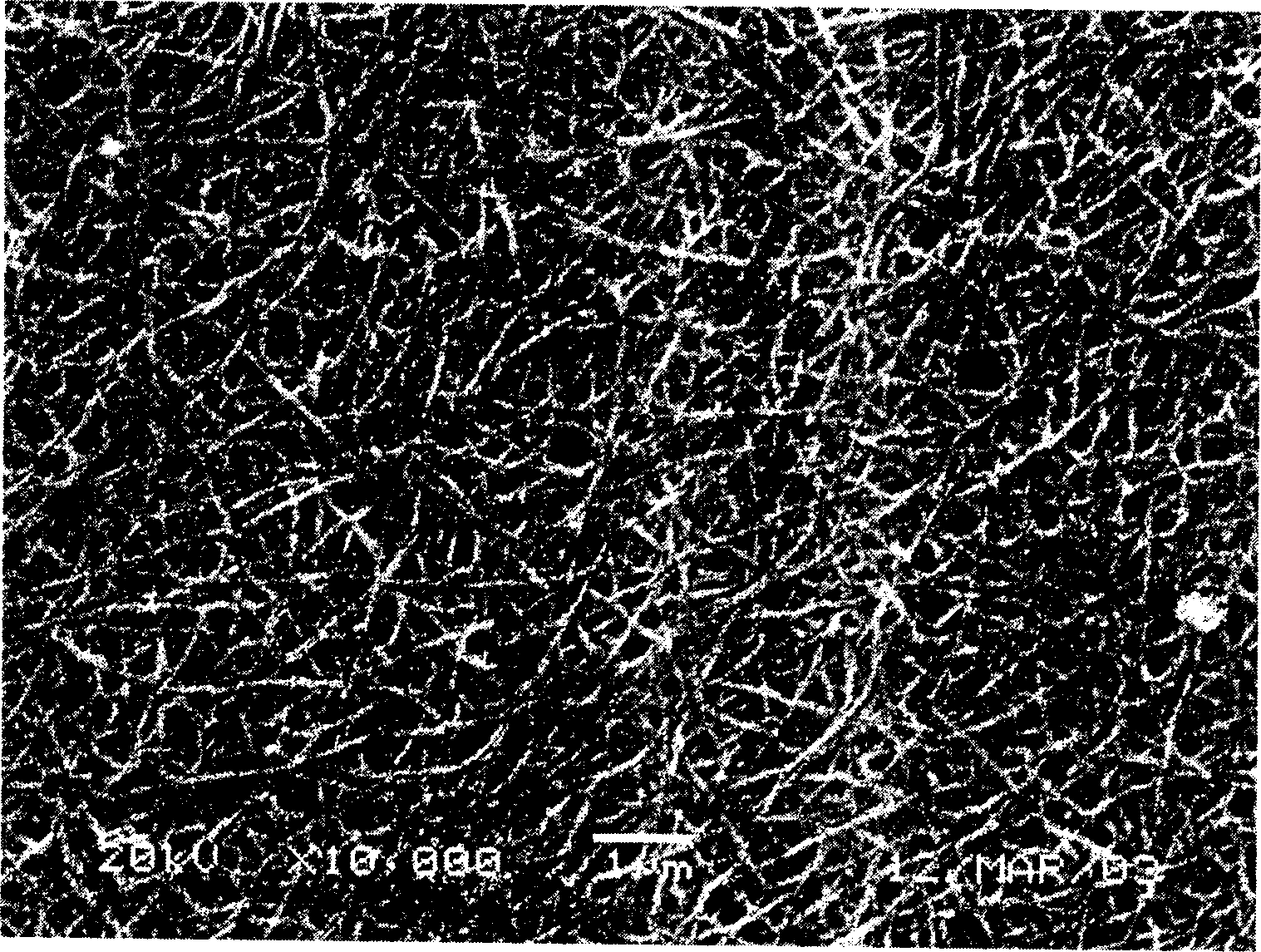

Image

Examples

Embodiment 1

[0023] Add 1 mg of titanyl phthalocyanine to 20ml of benzenesulfonic acid, heat and stir for 10 minutes, put the clean aluminum sheet into the phthalocyanine solution, and use the electric field and magnetic field together for 20 minutes. Take out the aluminum sheet in a vacuum oven at 100°C (vacuum Bake at -700mmHg) for one hour and take it out to obtain a phthalocyanine film.

Embodiment 2

[0025] Add 5 mg of titanyl phthalocyanine to 30ml of mixed solvent of benzenesulfonic acid and toluene (volume ratio is 10:1), heat and stir for 30 minutes, put the clean ITO glass into the phthalocyanine solution, apply an electrostatic field for 1 minute, and take it out The ITO glass was baked in a vacuum oven (vacuum degree of -700 mmHg) at 100°C for one hour and taken out to obtain a phthalocyanine film.

Embodiment 3

[0027] Add 1 mg of bisphthalocyanine erbium to 20ml N,N'-dimethylacetamide, heat and stir for 10 minutes, put the clean aluminum sheet into the phthalocyanine solution, perform electrophoresis for 20 minutes, take out the aluminum sheet in a vacuum oven at 30°C Bake in a medium (vacuum degree of -750mmHg) for one hour and take it out to obtain a phthalocyanine film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com