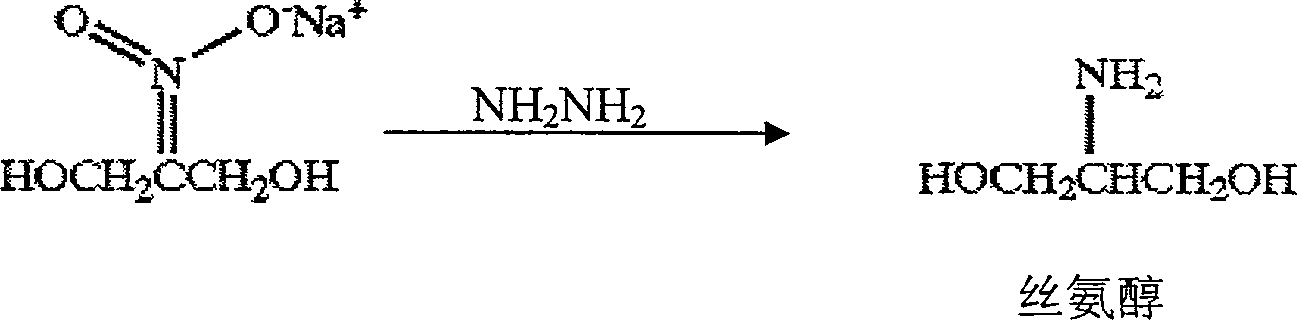

Preparation method of serinol

A technology for serinol and propylene glycol sodium salt, which is applied in the field of preparing serinol by reduction reaction, can solve the problems of large investment and high pressure in industrialized production equipment, and achieve the effects of avoiding high-pressure catalytic hydrogenation, easy operation and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Add 150mL of water and 20g of 2-nitro-1,3-propanediol sodium salt into a 250mL three-necked flask, adjust the pH value to 5-7 with concentrated sulfuric acid, add 0.1g of 10% palladium / carbon catalyst, and raise the internal temperature to 85°C , 12.2 mL of 80% hydrazine hydrate was added dropwise under stirring, and stirring was continued for 2 hours after the addition, and filtered, and the yield of serinol was 95.8%.

Embodiment 2

[0019] The reaction medium is ethanol, the reaction temperature is 75° C., the other conditions are the same as in Example 1, and the yield of serinol is 85.6%.

Embodiment 3

[0021] The reaction medium is methanol, the reaction temperature is 50° C., the other conditions are the same as in Example 1, and the yield of serinol is 45.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com