A method for preparing an optical fiber preform and drawing an optical fiber

An optical fiber preform and preform technology, which is applied to glass manufacturing equipment, manufacturing tools, etc., can solve the problem of high process cost, maintenance cost and environmental protection treatment cost, high complexity of preform mainstream technology, and strict requirements for equipment, process and environmental protection. and other problems, to achieve the effect of reducing comprehensive production costs, excellent product performance, and obvious cost advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

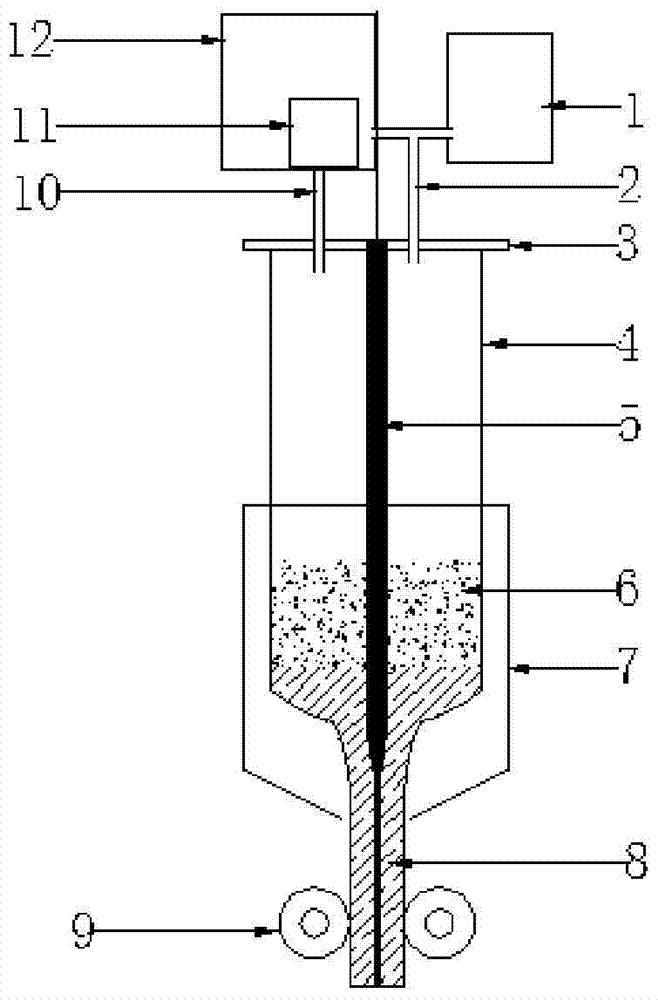

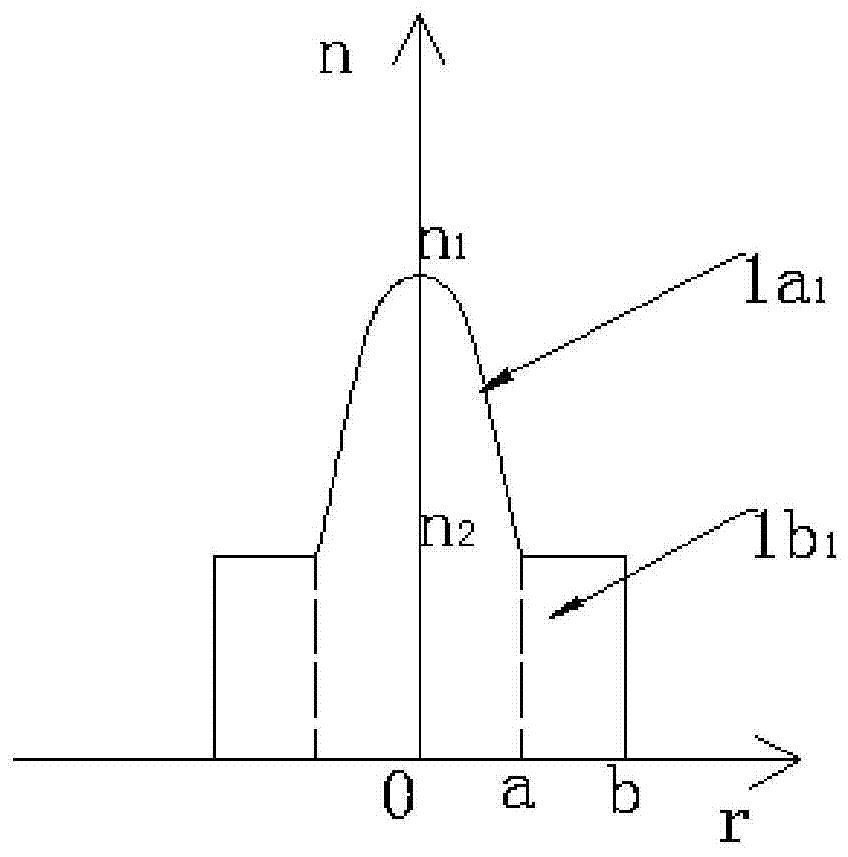

[0040] Example 1: Using an electric heating furnace device as a heat source, arranging a core containing SiO in a quartz tube 2 Department of glass rod (cross-sectional structure such as figure 2 , 1a 1 —Multimode core layer, n 1 —Refractive index of the multimode core layer, 1b 1 — multimode optical cladding, n 2—refractive index of the multimode optical cladding), length 1000mm, diameter 50mm, after welding the rod is assembled and fixed vertically into the quartz tube and kept coaxial, the height of the quartz tube is 1200mm, diameter 120mm, wall thickness 5mm, installed on the top It is best to have a high temperature resistant sealing device with a quartz sand discharge port and a vacuum port, close the quartz sand discharge port, and vacuum to 4mbar.

[0041] Start the quartz sand automatic feeding system, fill the 100 mesh to 300 mesh quartz sand material with a purity of 99.999% or more into the aforementioned quartz tube container at a predetermined height of 200...

example 2

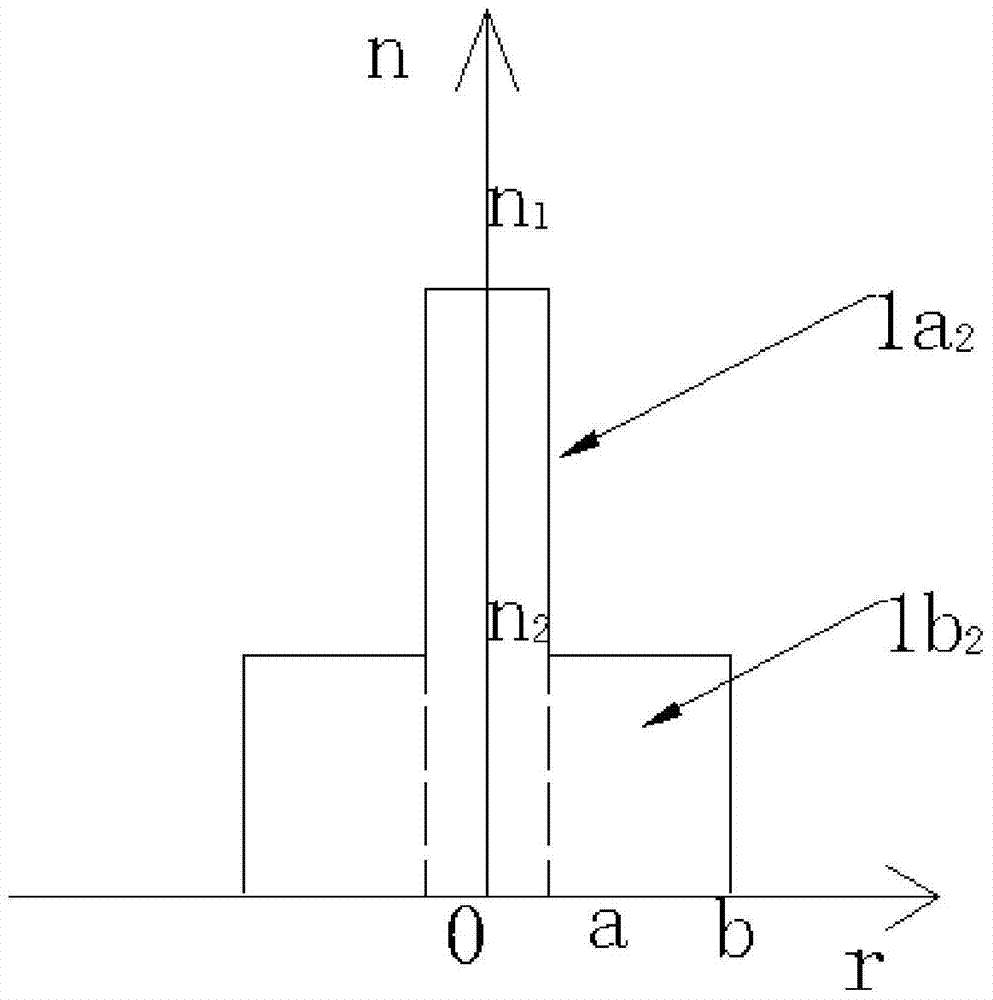

[0044] Example 2: Using a heating furnace device as a heat source, arranging a core containing SiO2 in a quartz tube container 2 Department of glass rod (cross-sectional structure such as image 3 , 1a 2 —Single-mode core layer, n 1 —Refractive index of the single-mode core layer, 1b 2 — single-mode optical cladding, n 2 —refractive index of single-mode optical cladding), length 1500mm, diameter 40mm, after welding the rods are assembled and fixed vertically into the quartz tube and kept coaxial, the height of the quartz tube is 1700mm, diameter 210mm, wall thickness 5mm, installed on the top It is best to have a high temperature resistant sealing device with a quartz sand discharge port and a vacuum port, close the quartz sand discharge port, and vacuum to 9mbar.

[0045] Start the quartz sand automatic feeding system, fill the 100 mesh to 300 mesh quartz sand material with a purity of 99.999% or more into the aforementioned quartz tube container at a predetermined height...

example 3

[0048] Example 3: Using the heating furnace device as the heat source, disposing SiO for the core in the quartz tube container 2 Glass rod (cross-sectional structure such as Figure 4 , 1a 3 —Pure SiO 2 core layer, n 1 —Pure SiO 2 Refractive index of the core, 1b 3 — SiO doped with F 2 Optical cladding, n 2 — SiO doped with F 2 Refractive index of the optical cladding), length 1500mm, diameter 10mm, after welding the rods are assembled and fixed vertically into the quartz tube and kept coaxial, the height of the quartz tube is 700mm, the diameter is 170mm, and the wall thickness is 5mm. The high-temperature-resistant vacuum plug of the quartz sand discharge port and the vacuum port, close the quartz sand discharge port, and vacuum to 7mbar.

[0049] Start the quartz sand automatic feeding system, fill the 100 mesh-300 mesh doped F element quartz sand mixture into the aforementioned quartz tube container at a predetermined height of 300mm, and start heating and melting....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com