Eprinomectin refining method

A technology of acetamido abamectin and a refining method, which is applied in the field of refining acetamido abamectin, can solve the problems of high solvent residue and low product purity, and achieves the advantages of reducing environmental pollution, improving purity and reducing dosage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

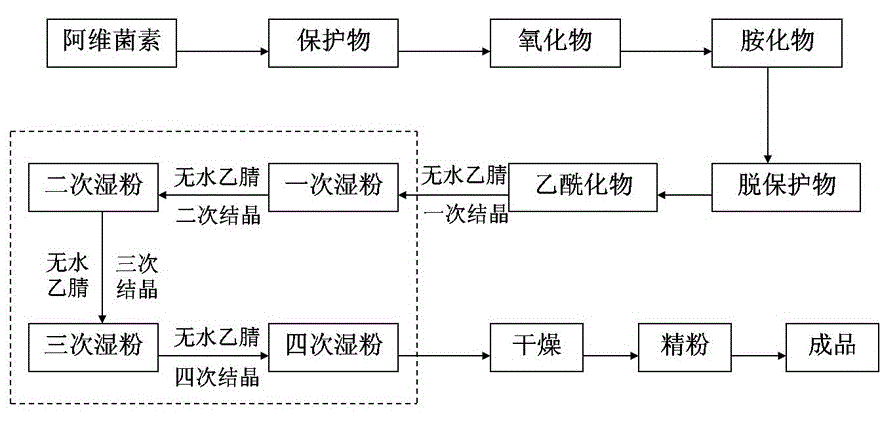

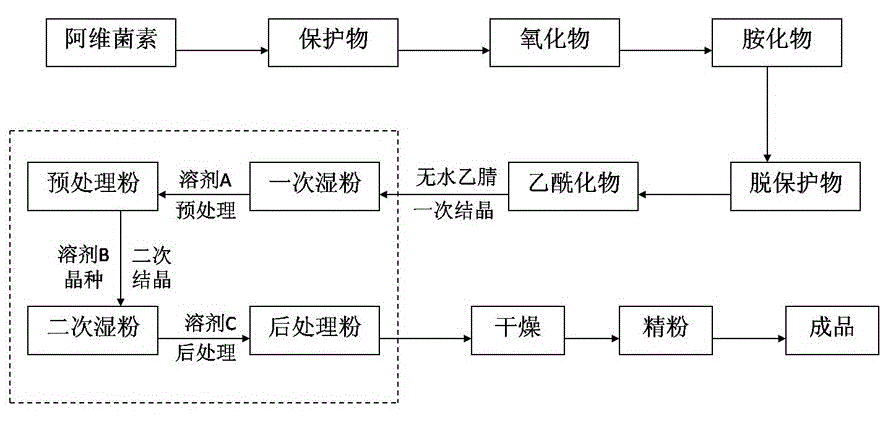

Method used

Image

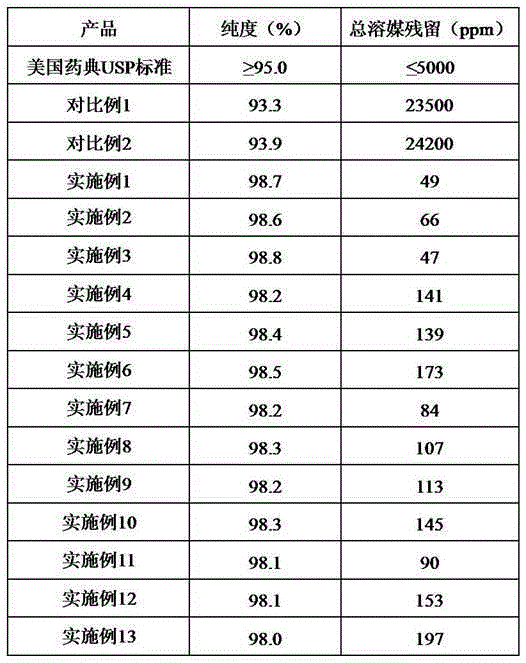

Examples

Embodiment 1

[0027] Take 100g of acetamidoabamectin primary wet powder, add it to 800ml of mixed solvent A composed of (v / v) 80% n-hexane and 20% ethyl acetate, fully stir, and separate solid and liquid to obtain acetamidoabamectin 98g of mycetin pretreatment powder, then heated and dissolved in 250ml of mixed solvent B composed of (v / v) 30% ethanol, 40% acetone, and 30% water, and added 0.5g of acetamidoabamectin crystals at 70°C Seed, cooling crystallization, solid-liquid separation, obtain acetamidoabamectin secondary wet powder 81g, then add it in the 800ml ether, fully stir, solid-liquid separation, obtain acetamidoabamectin post-treatment powder 78g, At 65° C., vacuum-dried for 5 hours to obtain 57 g of acetamidoabamectin fine powder.

Embodiment 2

[0029] Take 100g of acetamidoabamectin primary wet powder, add it to 700ml of mixed solvent A composed of (v / v) 80% n-hexane and 20% ethyl acetate, fully stir, and separate solid and liquid to obtain acetamidoabamectin 96g of mycetin pretreatment powder, then heated and dissolved in 300ml of mixed solvent B composed of (v / v) 30% ethanol, 40% acetone, and 30% water, and added 0.5g of acetamidoabamectin crystals at 65°C Seed, cooling crystallization, solid-liquid separation, obtain acetamidoabamectin secondary wet powder 78g, then add it in the 700ml ether, fully stir, solid-liquid separation, obtain acetamidoabamectin post-treatment powder 75g, At 65° C., vacuum-dried for 5 hours to obtain 54 g of acetamidoabamectin fine powder.

Embodiment 3

[0031] Take 100g of acetaminobamectin primary wet powder, add it to 900ml of mixed solvent A composed of (v / v) 80% n-hexane and 20% ethyl acetate, fully stir, and separate solid and liquid to obtain acetamidobamectin 92g of mycetin pretreatment powder, then heated and dissolved in 500ml of mixed solvent B composed of (v / v) 30% ethanol, 40% acetone, and 30% water, and added 0.5g of acetamidoabamectin crystals at 75°C Seed, cooling crystallization, solid-liquid separation, obtain acetamidoabamectin secondary wet powder 80g, then add it in 900ml ether, fully stir, solid-liquid separation, obtain acetamidoabamectin post-treatment powder 77g, At 65° C., vacuum-dried for 5 hours to obtain 56 g of acetamidoabamectin fine powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com