Patents

Literature

119 results about "Acetone / Ethanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acetone–butanol–ethanol (ABE) fermentation is a process that uses bacterial fermentation to produce acetone, n-Butanol, and ethanol from carbohydrates such as starch and glucose.

Method for preparing granulating auxiliary agent for processing plastic

InactiveCN101235162ADepressed maximum melting pointGood dispersionGranulation by material expressionAdjuvantRoom temperature

The invention relates to a preparation method of granulating agent for plastic processing, in particular to a preparation method of granulating anti-oxidant for metaformaldehyde processing. The granulating agent is composed of anti-oxidant, common stabilizer, acid absorber and lubricant. The preparation method comprises mixing the powder agents aforementioned uniformly, using acetone alcohol and water as adjuvants, adding at least one adjuvant into the uniform powder agent, using twin-screw extruder to extrude and granulate at room temperature, drying to obtain granulating agent. The agent has high rigidity and non dust generation in carriage and transmission. The granulating agent has significant alloying effect, which can be used in metaformaldehyde resin to obtain lower yellow index, higher thermal decomposition temperature, higher product thermal stability and better application effect than the metaformaldehyde resin applied with powder agent.

Owner:SICHUAN UNIV

Method for extracting cellulose in one step

InactiveCN102251424AImprove qualityReduce concentrationPaper material treatmentOrganosolvPotassium hydroxide

Owner:ZHEJIANG SCI-TECH UNIV +1

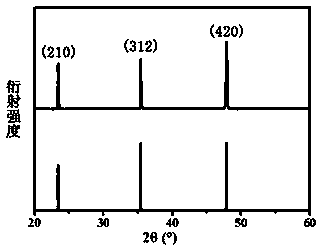

Preparation method of perovskite single crystals

ActiveCN110699745AEasy to prepareLow operational difficultyPolycrystalline material growthFrom normal temperature solutionsPhysical chemistrySingle crystal

The invention discloses a preparation method of perovskite single crystals. The perovskite single crystals are CsPbBr3 perovskite single crystals or CsPb2Br5 perovskite single crystals, and the perovskite single crystals are in the shape of sheet or rod. A preparation method comprises the following steps: cleaning a single crystal growth substrate, wherein respectively carrying out ultrasonic treatment on the substrate for 15-30 minutes with acetone, 70%-80% ethanol and deionized water, taking out the substrate, and drying the substrate in a drying oven overnight to obtain a single crystal growth substrate; preparing a perovskite precursor solution, wherein dissolving CsBr and PbBr2 in hydrobromic acid or dimethyl sulfoxide according to the proportion of 1 / 1-1 / 4, controlling the concentration of CsBr to be 0.06 mol / L to 0.3 mol / L, the concentration of PbBr2 to be 0.06 mol / L to 0.3 mol / L, and obtaining a perovskite precursor solution; and preparing the perovskite single crystals, namelypreheating the perovskite precursor solution to 80-95 DEG C, dripping the perovskite precursor solution on the substrate, and removing the solvent to obtain the perovskite single crystals. The methodis simple to operate and low in operation process difficulty, and the components and morphology of the perovskite single crystals are adjustable.

Owner:SOUTHEAST UNIV

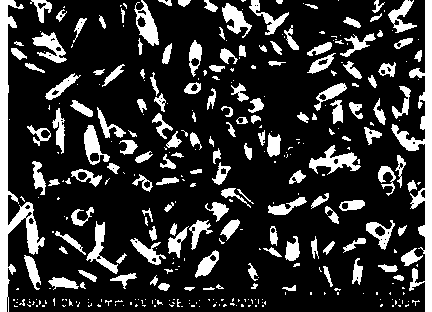

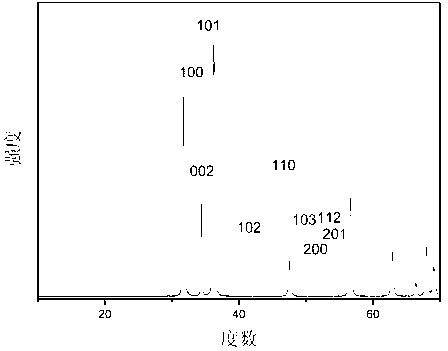

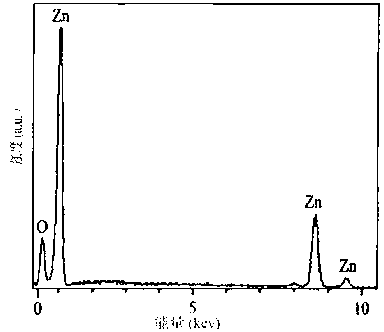

Preparation method of zinc oxide nanotube array

InactiveCN103101961AEasy post-processingThe synthesis method is simpleZinc oxides/hydroxidesDecorative surface effectsHexamethylenetetramineNitrogen gas

The invention provides a preparation method of a zinc oxide nanotube array. The method is characterized by comprising the following steps: cutting a base material into a certain size, and respectively subjecting the base material to ultrasonic treatment in acetone and ethanol for 15min, and taking out the base material and then drying with nitrogen; putting cleaned base material in UV and ozone for 15min to remove the organic substances on the surface; preparing a reaction solution by respectively preparing a zinc salt solution with concentration of 0.01-0.1M and an ammonia solution, a sodium hydroxide solution or a methenamine solution with a concentration of 0.01-0.1M, and mixing the two solution according to a volume ratio of 1:1-5:1; placing the treated base material into the prepared solution, and sealing; placing a sealing bottle containing the reaction solution and the base material in an oven, reacting at 70-105 DEG C for 5-20h, taking out the sample, naturally cooling to room temperature, conducting rinsing with deionized water and performing drying to obtain the zinc oxide nanotube array. The preparation method has the advantages of simple process and flow, good ZnO nanotube array product with uniform thickness, low cost, strong repeatability and synthesis in a large amount.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

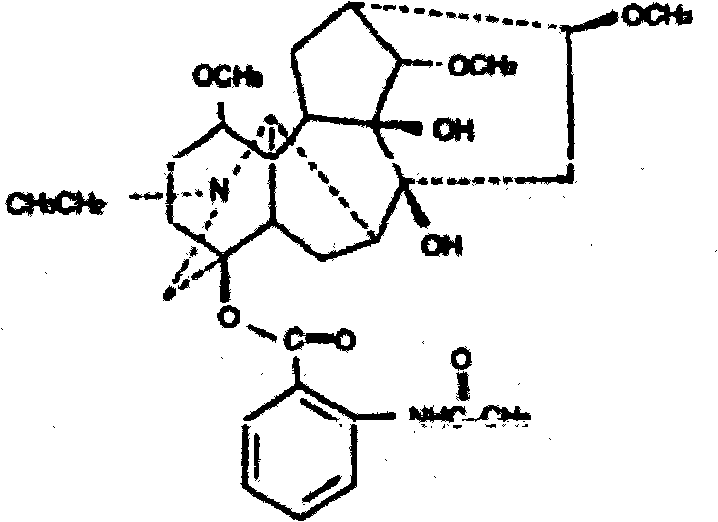

Separation and purification method for lappaconitine

The invention relates to a separation and purification method for lappaconitine, which is used for preparing high-purity lappaconitine by integrating a solvent extraction-ion resin column-alumina column-recrystallization method and comprises the following steps: ultrasonically extracting the lappaconitine by utilizing ethanol, dissolving the concentrated lappaconitine by utilizing 1% of hydrochloric acid, adding cation exchange resins in a countercurrent mode, carrying out acid elution, regulating the pH value to neutral and desalting, wherein a column chromatography adopts a short and thick column; a filler is alumina; a mobile phase is the ethanol; and a recrystallization solvent is acetone-ethanol (the ratio is 1 to 1). The separation and purification method has the advantages of obvious reduction of organic solvents, in particular to toxic solvents, low cost, high yield, short production period and easy industrialization.

Owner:NANJING ZELANG MEDICAL TECH

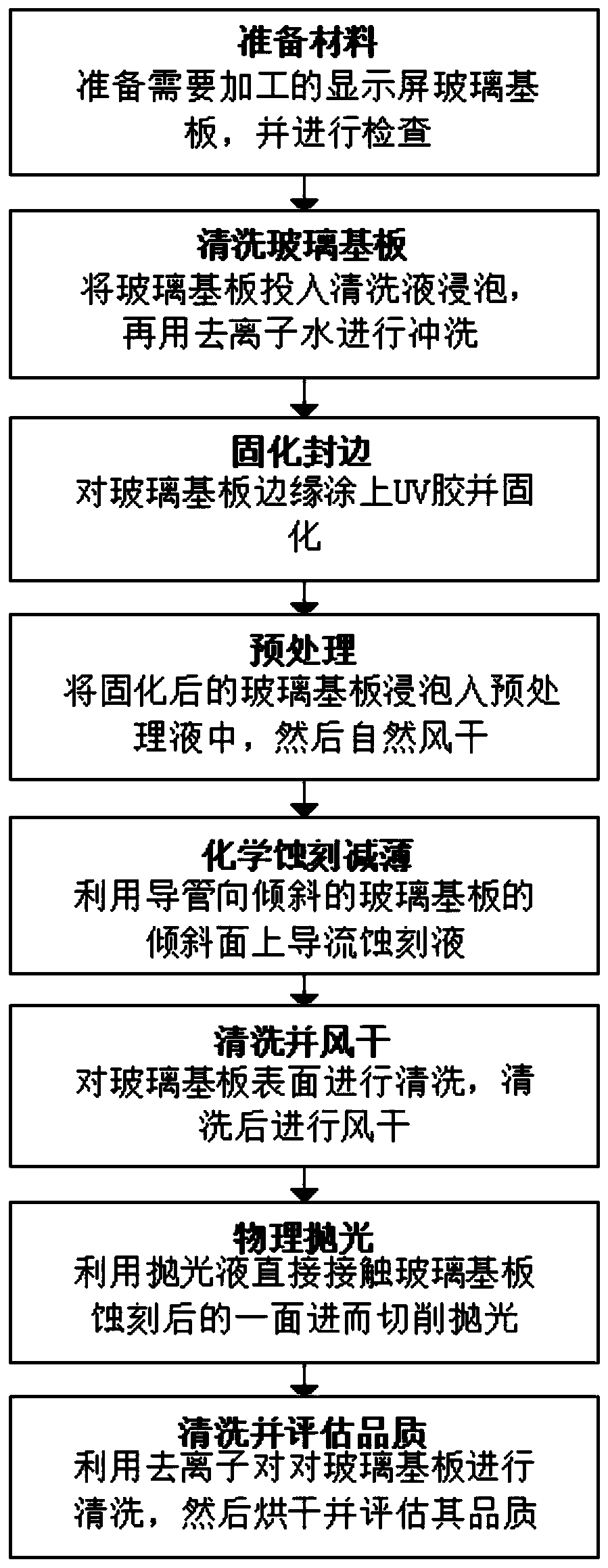

Single-sided thinning treatment method for liquid crystal display screen

InactiveCN111362585AAvoid crackingHigh viscosityOrganic non-surface-active detergent compositionsSurface treatment compositionsSodium bicarbonateEtching

The invention discloses a single-side thinning treatment method for a liquid crystal display screen. The single-side thinning treatment method comprises the following steps of material preparation, glass substrate cleaning, curing and edge sealing, pretreatment, chemical etching and thinning, cleaning and air drying, physical polishing, cleaning and quality evaluation. According to the invention,cleaning liquid prepared from acetone, ethanol and pure water is used for cleaning a glass substrate so as to remove dust and grease; the glass substrate is soaked with a prepared pretreatment solution, tiny concave points on the surface of the glass are filled with sodium hydroxide and sodium bicarbonate, and the sodium hydroxide and sodium bicarbonate are combined with silicon-oxygen bonds on the surface of the glass, so the glass substrate is prevented from generating cracks in subsequent processing; sodium perchlorate and disodium ethylenediaminetetraacetate in a thinning etching solutionare matched with pyrethroid and hydrogen peroxide, so the viscosity of the thinning etching solution is increased, which is beneficial for realizing uniform etching and reducing the generation of concave-convex points; and meanwhile, the glass substrate obliquely leans against the interior of the etching groove in the etching process, and single-face processing is facilitated through circulating waterfall type flow guide of the thinning etching solution.

Owner:滁州东盛电子科技有限公司

Preparation method of crystal-non-crystal metal oxide composite gas-sensitive material

InactiveCN104048996ASimple preparation processImprove stabilityMaterial analysis by electric/magnetic meansChlorobenzeneOxide composite

The invention provides a preparation method of a composite gas-sensitive material having high sensitivity, high selectivity and high stability and belongs to the field of functional materials. The invention mainly relates to a preparation method of a crystal-non-crystal metal oxide composite gas-sensitive material. The crystal-non-crystal metal oxide composite gas-sensitive material has high sensitivity to organic volatile compounds such as acetone, ethanol, 2-chloroethanol, chlorobenzene and formaldehyde, and has good heat stability and good selectivity. The preparation method has simple processes.

Owner:UNIV OF JINAN

Method for producing acetone, ethanol and butanol by taking straw as raw material

ActiveCN102876736ARelieve stressAvoid detoxification processBiofuelsMicroorganism based processesMicroorganismEnzymatic hydrolysis

The invention relates to a method for producing acetone, ethanol and butanol by taking the straw as the raw material, which is characterized in that: FeSO4.7H2O is added to the straw as the raw material. The process comprises the pretreatment of the straw, the enzymatic hydrolysis of the straw, the preparation of the fermentation medium, the preparation of acetone, ethanol and butanol fermentation microorganism seed liquid and fermentation. Because the straw is used for producing the acetone, ethanol and butanol, and the FeSO4.7H2O is added singly to promote the fermentation, the solvent yield and the production efficiency are improved, the production cost is reduced, and the production process is simplified.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

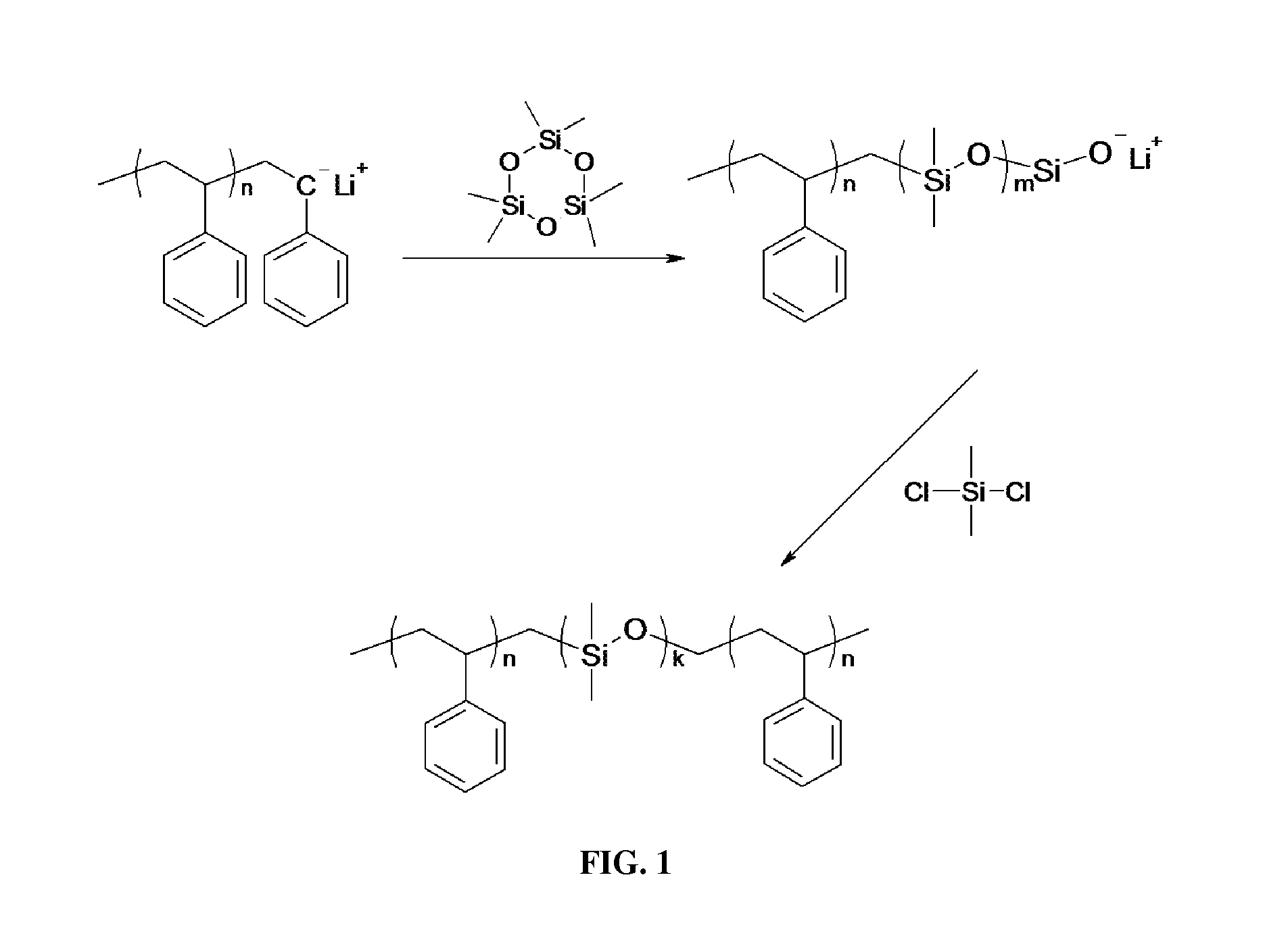

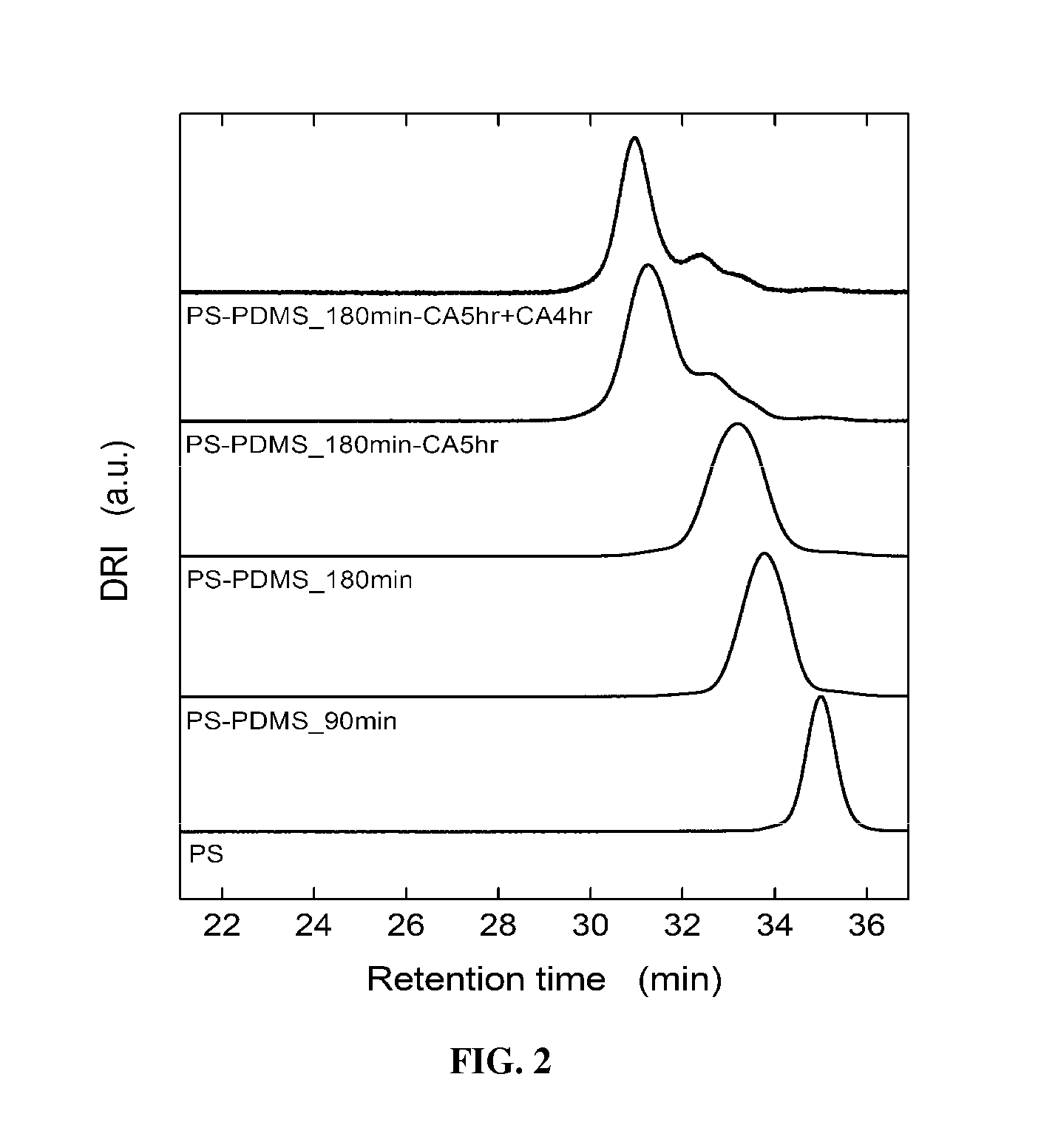

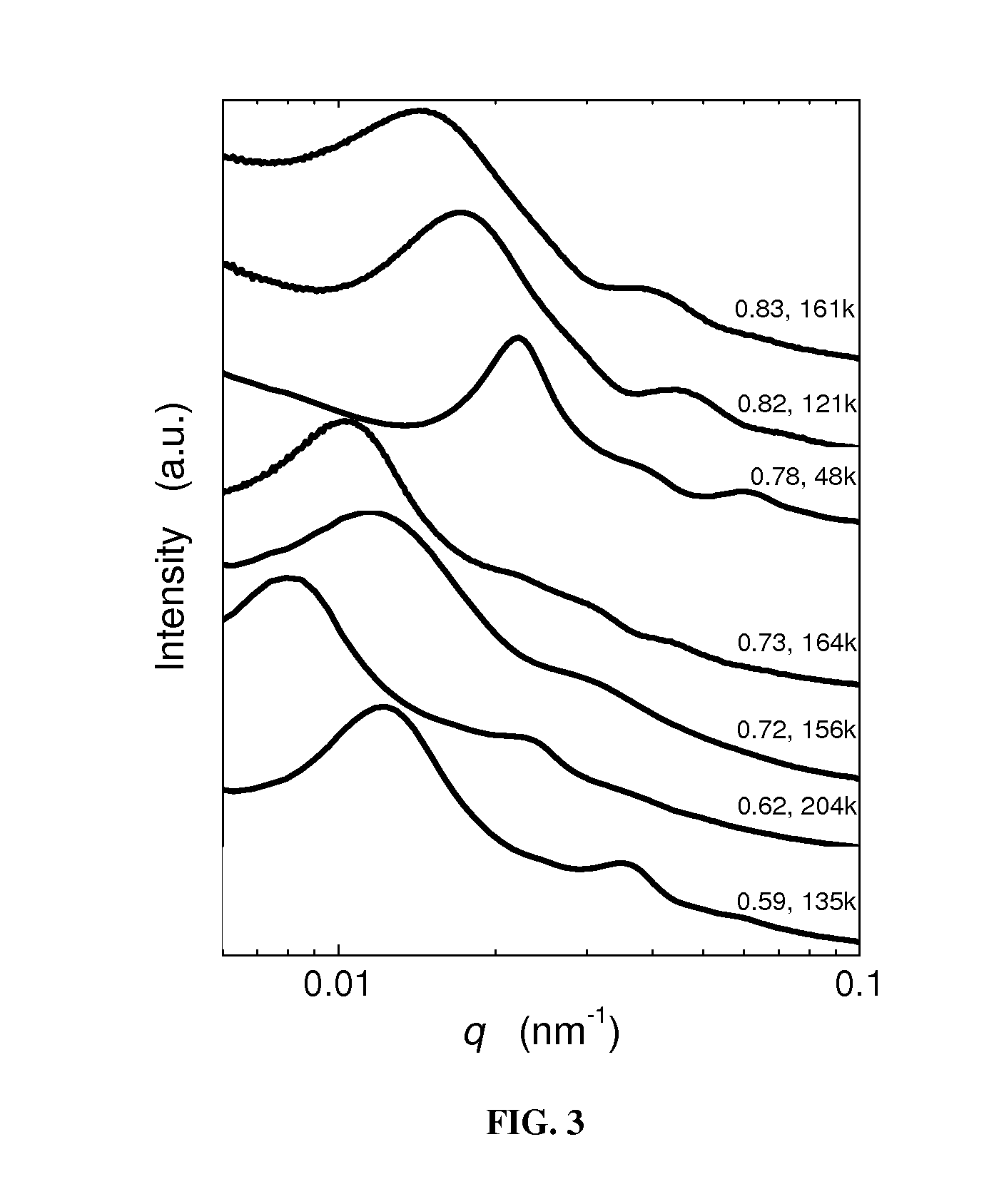

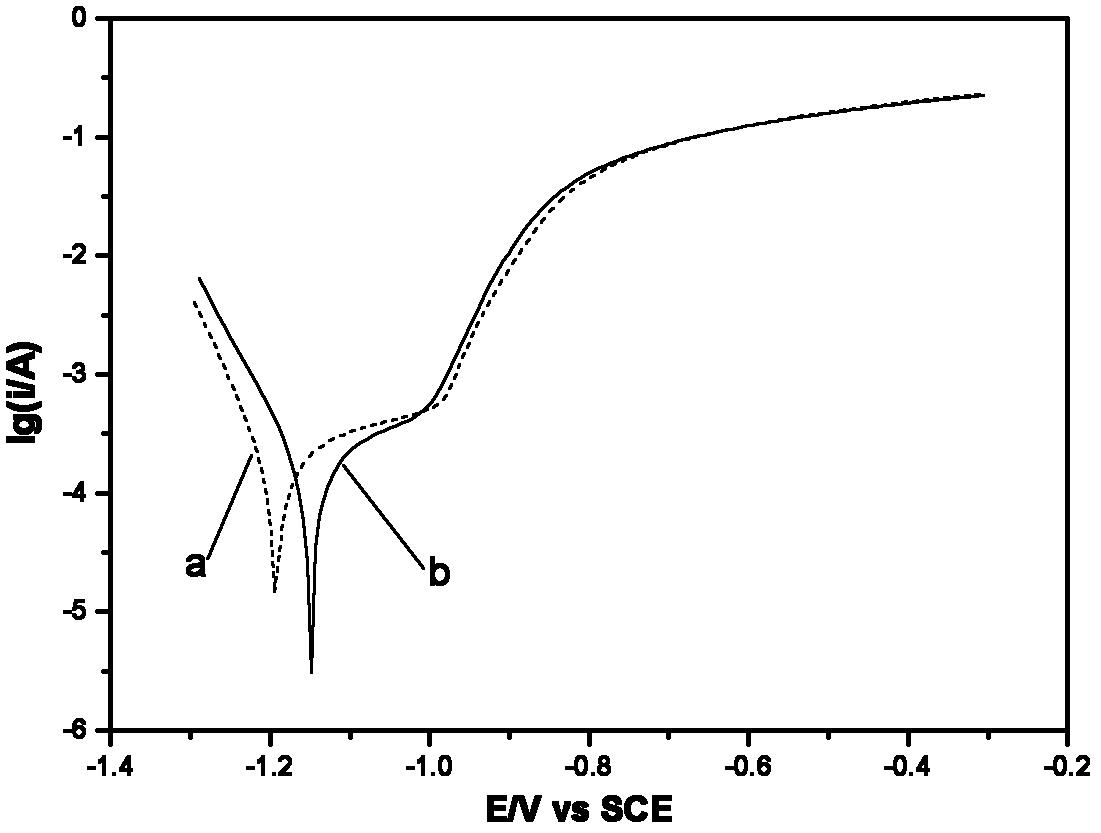

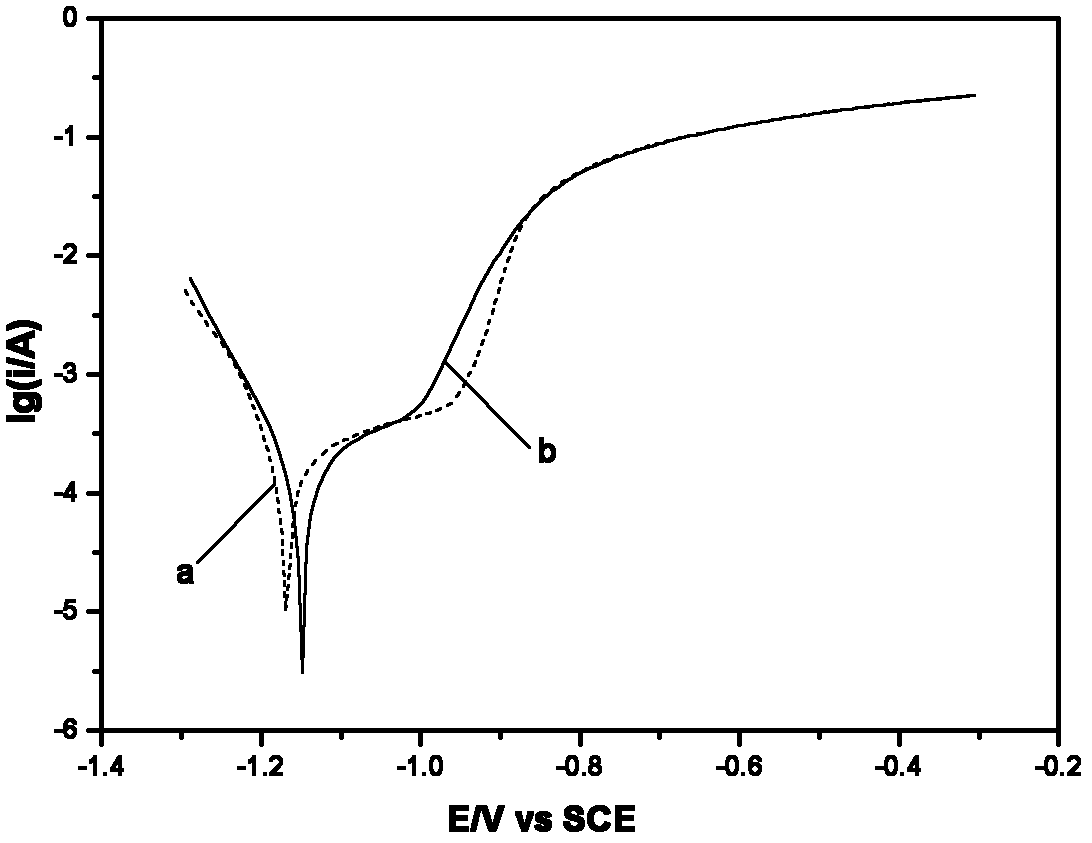

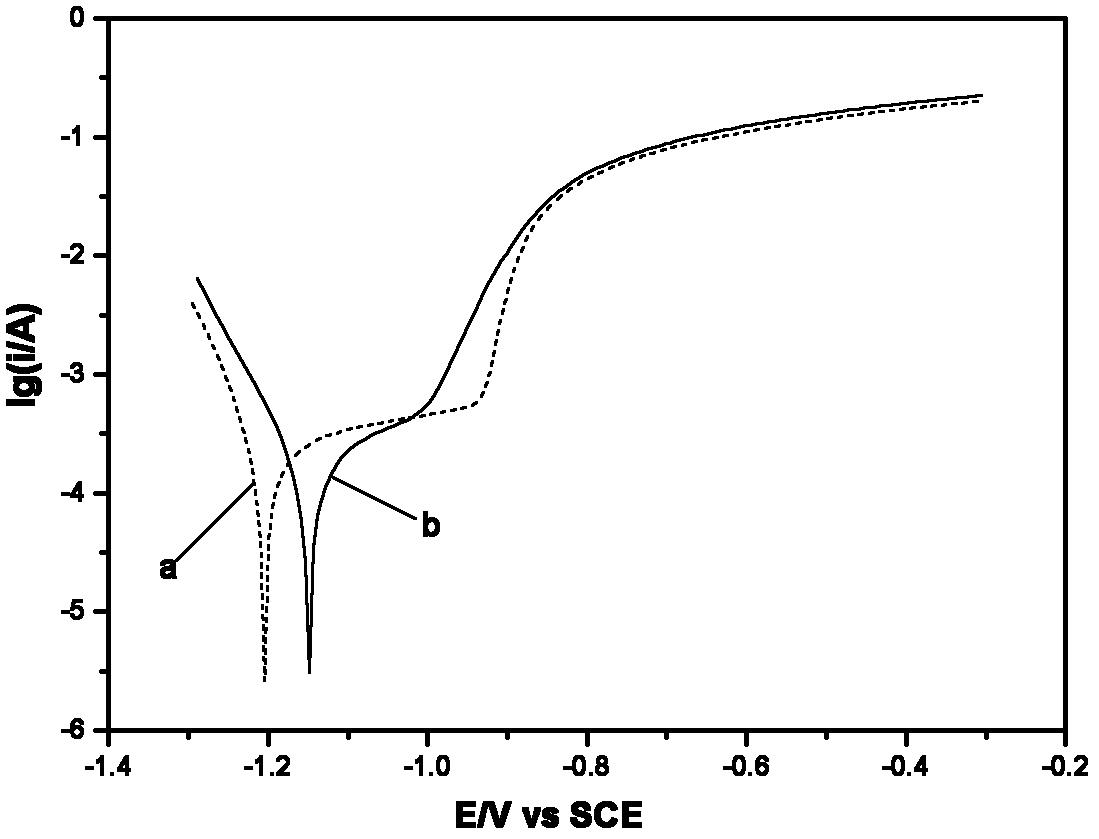

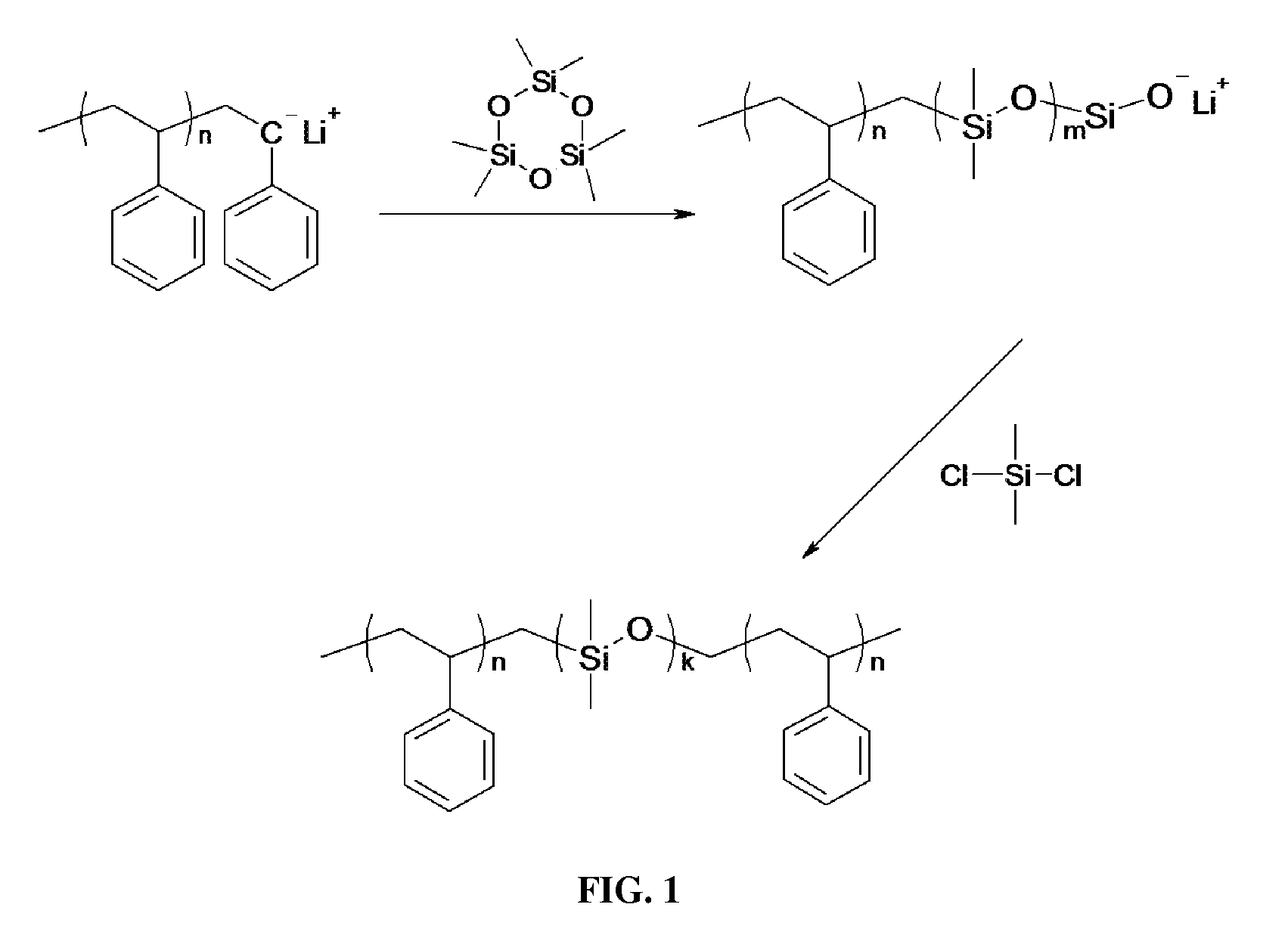

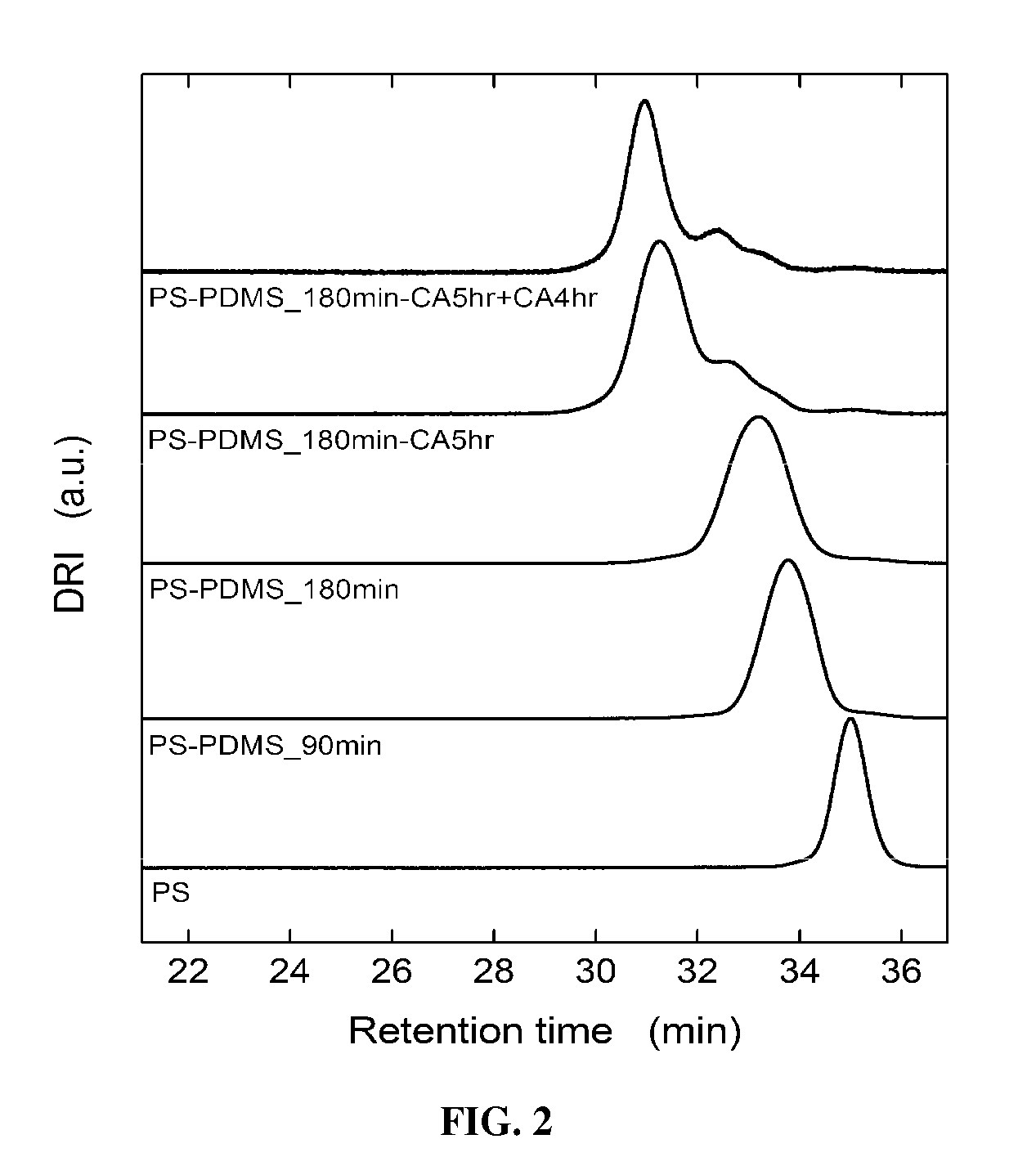

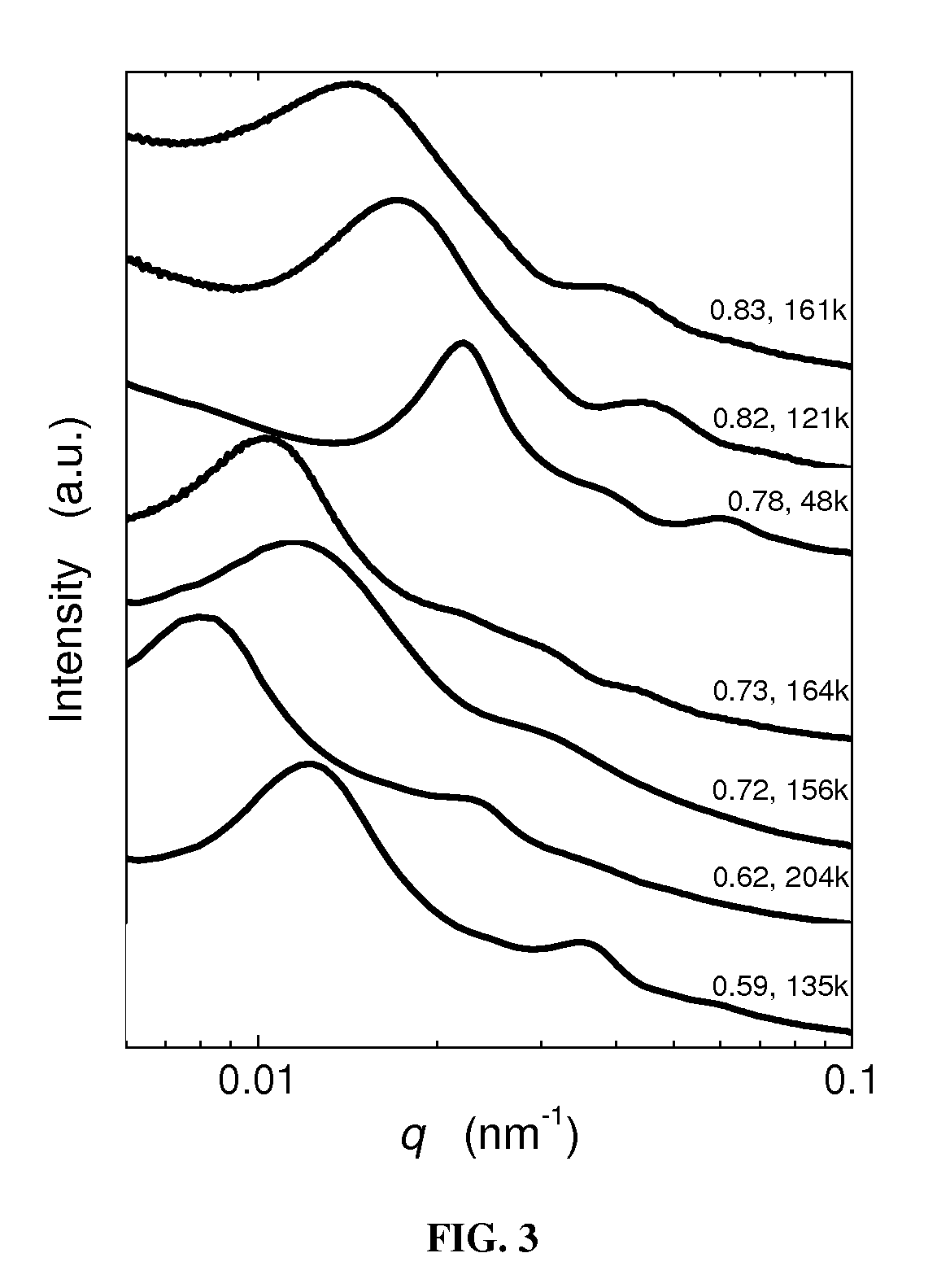

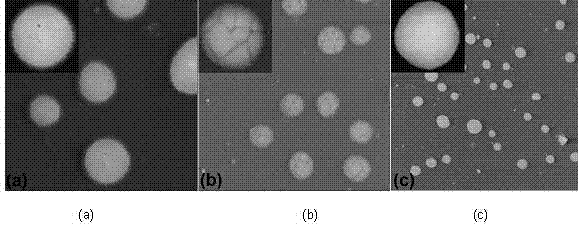

Styrene-siloxane triblock copolymers as membranes for selective transport of alcohols and other organic compounds in aqueous mixtures

The present disclosure relates to high molecular weight polystyrene-polydialkylsiloxane-polystyrene (“SDS”) triblock copolymer compositions and methods of separating one or more organic compounds from an aqueous solution using membranes derived from SDS triblock copolymers. The methods may be used to separate the one or more organic compounds from an aqueous solution produced in a fermentation process. In some embodiments, the one or more organic compounds include an alcohol, such as, for example, ethanol. In other embodiments, the one or more organic compounds include acetone. In other embodiments, the one or more organic compounds include acetone, ethanol, and n-butanol produced in an acetone-ethanol-n-butanol (ABE) fermentation process. In other embodiments, the one or more organic compounds include one or more byproducts produced in a fermentation process.

Owner:RGT UNIV OF CALIFORNIA

Additive for chloride zincification and preparation method and application thereof

The invention discloses an additive for chloride zincification and a preparation method and application of the additive. The method comprises the following steps: allowing an esterification reaction between alkylphenol polyoxyethylene and a phosphorylated reagent at a molar ratio of 1:(1-1.5) to obtain a condensation product, adjusting the pH value of the product to neutrality, mixing with a surfactant, and then mixing with benzylidene acetone ethanol solution to obtain the additive for chloride zincification, wherein the final concentration of benzylidene acetone is 10-30g / L, the final concentration of the surfactant is 100-150g / L, and the final concentration of the condensation product is 100-130g / L. The preparation method of the addtive for chloride zincification provided in the invention is simple and easy to operate and environment-friendly; the obtained additive is non-toxic, easy to biodegrade, green and environment-friendily, makes the chloride zincification process simple and convenient to operate, reduces the foam produced in a plating solution effectively, and reduces the comprehensive cost; and the obtained plating coat is not only uniform and bright, but also has good corrosion resistance.

Owner:SOUTH CHINA NORMAL UNIVERSITY

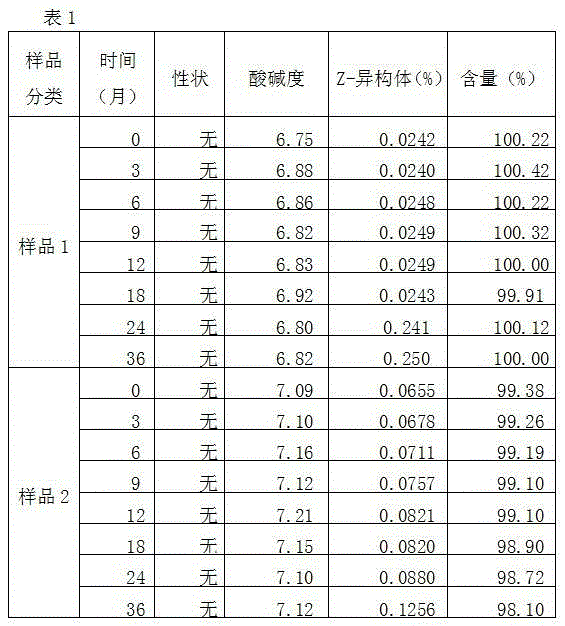

Tranexamic acid injection and preparation method of same

The invention provides a tranexamic acid injection and a preparation method of the same. In the preparation technology, the added active carbon for needles is preprocessed as follows: washing the active carbon for needles with acetone, alcohol and edetic acid water solution, and drying to remove residual metals and other impurities in the added active carbon for needles. The preprocessed active carbon for needles is used for preparing the tranexamic acid injection, thus, the generation of impurity-Z-isomer can be reduced, and the quality of the tranexamic acid injection is guaranteed.

Owner:SHANXI PUDE PHARMA CO LTD

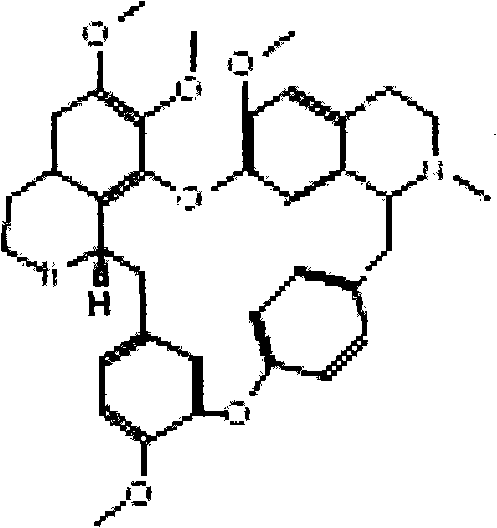

Method for extracting tetrandrine

InactiveCN101955486AEasy to separateGood removal effectOrganic chemistryHigh concentrationTetrandrine

The invention relates to a method for extracting tetrandrine. The method comprises the following steps of: adding alkali into high-concentration ethanol for extracting, dissolving with an acid, separating with D732 macroporous cation exchange resin, extracting with toluene, and alternately crystallizing with acetone ethanol to obtain the product. The method of the invention for producing tetrandrine has the advantages of simple operation, low cost and high purity of the product.

Owner:NANJING ZELANG MEDICAL TECH

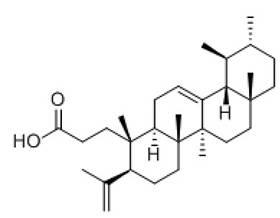

Method for purifying roburic acid

InactiveCN102329225AEasy to oozeHigh extraction rateCarboxylic compound separation/purificationWater bathsGradient elution

The invention discloses a method for purifying roburic acid, which comprises the following steps: (1) taking the raw material large leaf gentian root, drying, pulverizing, soaking in an enzyme solution, carrying out water bath enzymolysis, and sufficiently stirring; (2) filtering, extracting the filter residue with 5-10 times of ethanol water solution 2-3 times, merging the extracting solutions, and concentrating under reduced pressure to obtain an extract; (3) passing the extract through macroporous adsorbent resin columns, eluting with ethanol water solution, and collecting the eluate; (4) recycling ethanol from the eluate under reduced pressure, extracting by ethyl acetate, concentrating the extracting liquid, passing the extracting liquid through silica gel columns, carrying out cyclohexane-ethanol gradient elution, carrying out TLC (thin layer chromatography) tracking and monitoring, and collecting the roburic acid fraction; and (5) concentrating the roburic acid fraction under reduced pressure to small volume, standing to crystallize, and carrying out methanol / petroleum ether-acetone ethanol recrystallization. The invention is simple to operate, has the advantages of high product yield and low cost, and is suitable for large-scale production.

Owner:苏州宝泽堂医药科技有限公司

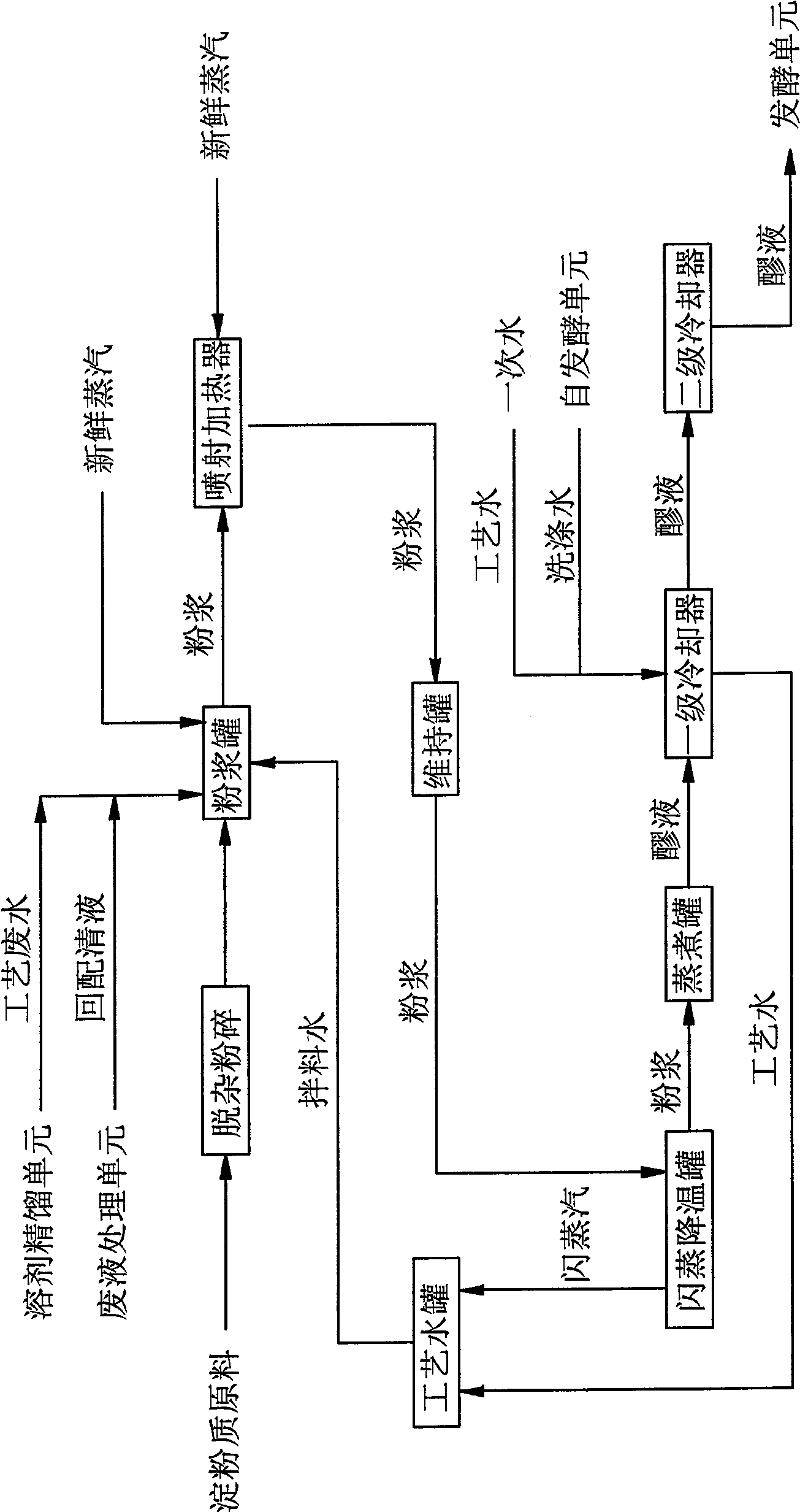

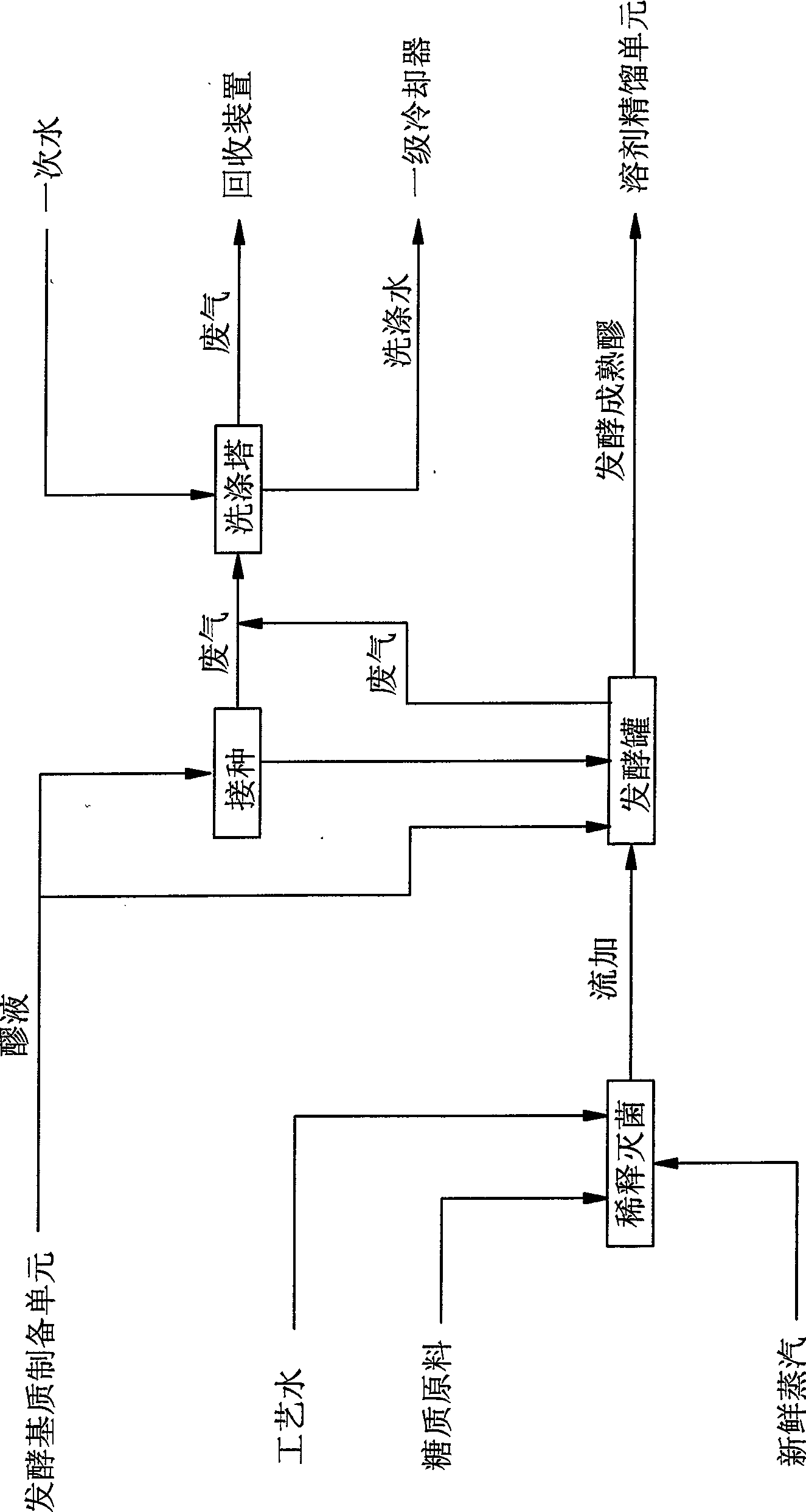

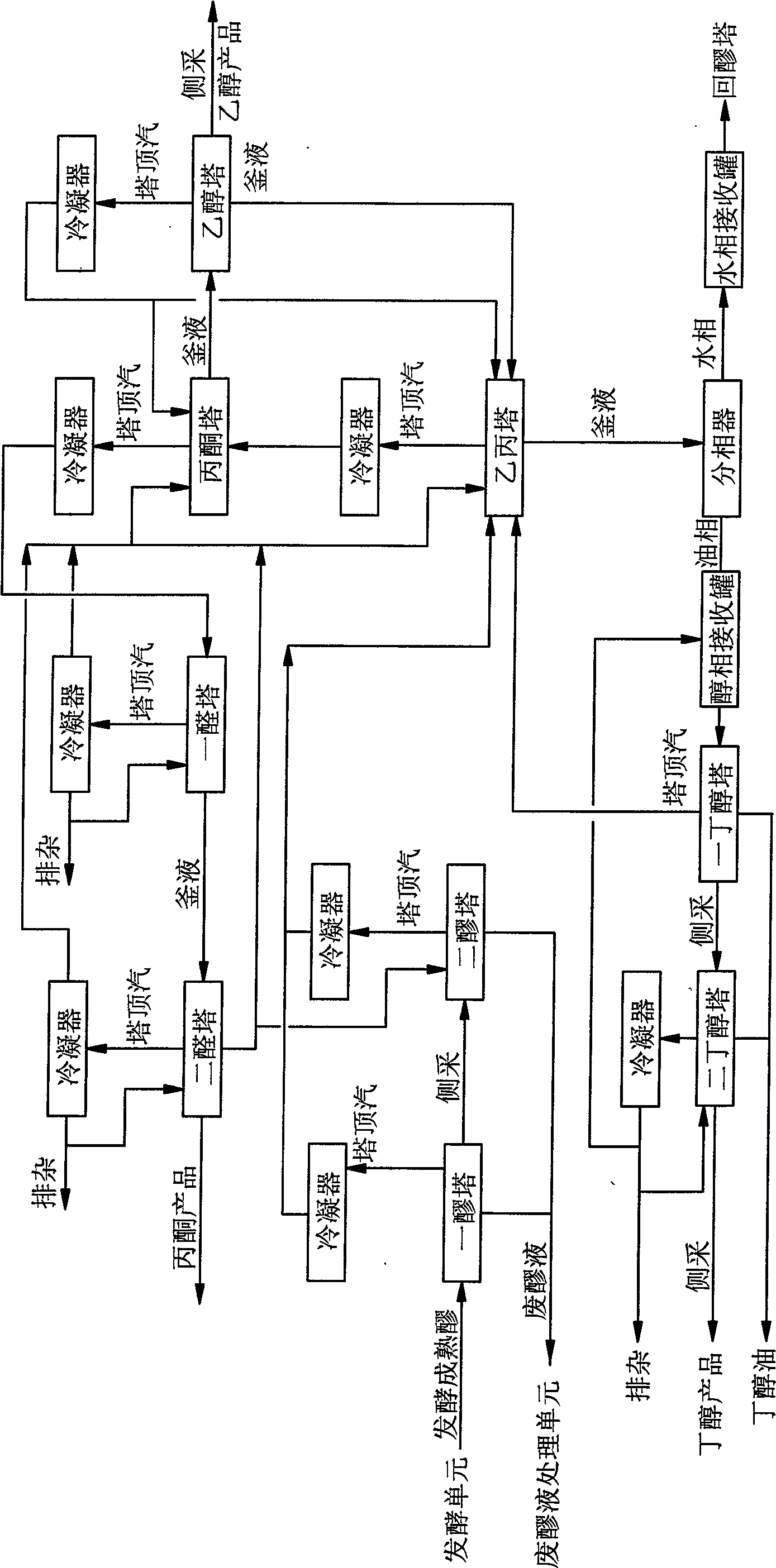

Method and apparatus for producing biological butanol

ActiveCN101497555AReduce energy consumptionReduce manufacturing costFermentationHydroxy compound separation/purificationSolventFermentation

The invention relates to a method and equipment for producing bio-butanol. The equipment comprises four production units, namely fermentation substrate preparation, fermentation, solvent rectification and waste mash treatment, wherein the rectification unit comprises beer columns, an ethylene-propylene tower, a butanol tower, an acetone tower, an aldehyde-removing tower and an ethanol tower, and comprises the following process flow: mature mash feed is delivered into a beer column I, is extracted from the side of the beer column I to enter a beer column II, and crude solvents with water content of between 30 and 80 percent extracted from the top of the beer column I and the beer column II are both delivered to the ethylene-propylene tower to be further rectified; the material is produced into crude butanol and mixture of acetone, ethanol and water through the ethylene-propylene tower; the crude butanol is refined into a butanol finished product through the butanol tower; the mixture of acetone, ethanol and water is produced into crude acetone and crude ethanol through the acetone tower; the crude acetone is refined into an acetone finished product through the aldehyde-removing tower; and the crude ethanol is refined into an ethanol finished product through the ethanol tower. The method and the equipment can effectively reduce material consumption and energy consumption in the process for producing the bio-butanol, reduce quantity of wastewater effluent in the production process, and improve market competitiveness of the bio-butanol product.

Owner:TIANJIN UNIV

Improved radix sophorae flavescentis thin-layer chromatography identification method

ActiveCN103245754AUniform and clear colorSimple and fast operationComponent separationSophocarpidinePotassium iodine

The invention discloses an improved radix sophorae flavescentis thin-layer chromatography identification method. In comparison with the thin-layer chromatography identification method specified under a radix sophorae flavescentis item of Chinese Pharmacopoeia 2010, the method has been improved in the following aspects: (1) the test solution is prepared by an ultrasonic method from a soaking method; the amount of thin layer plates is reduced to be one from two, and three components of sophocarpidine, oxymatrine and sophoridine are unfolded on the same thin layer plate; (3) the amount of developing solvents is reduced to be two from three, that is methylbenzene-acetone-ethanol-ammonia water (6:8:2:0.28), methanol-chloroform (1.6:10); and (4) developing by a single color agent: bismuth potassium iodide-0.6mol / L hydrochloric acid (1:1). The method is simple to operate, time-saving, low in cost and good in separation effect and developing effect, the result can be easily judged and the color agent can be stored for a long time. A system suitability study proves that the method has favorable repeatability, sensitivity and developing stability, and is suitable for radix sophorae flavescentis thin-layer chromatography identification.

Owner:SOUTHWEST UNIVERSITY

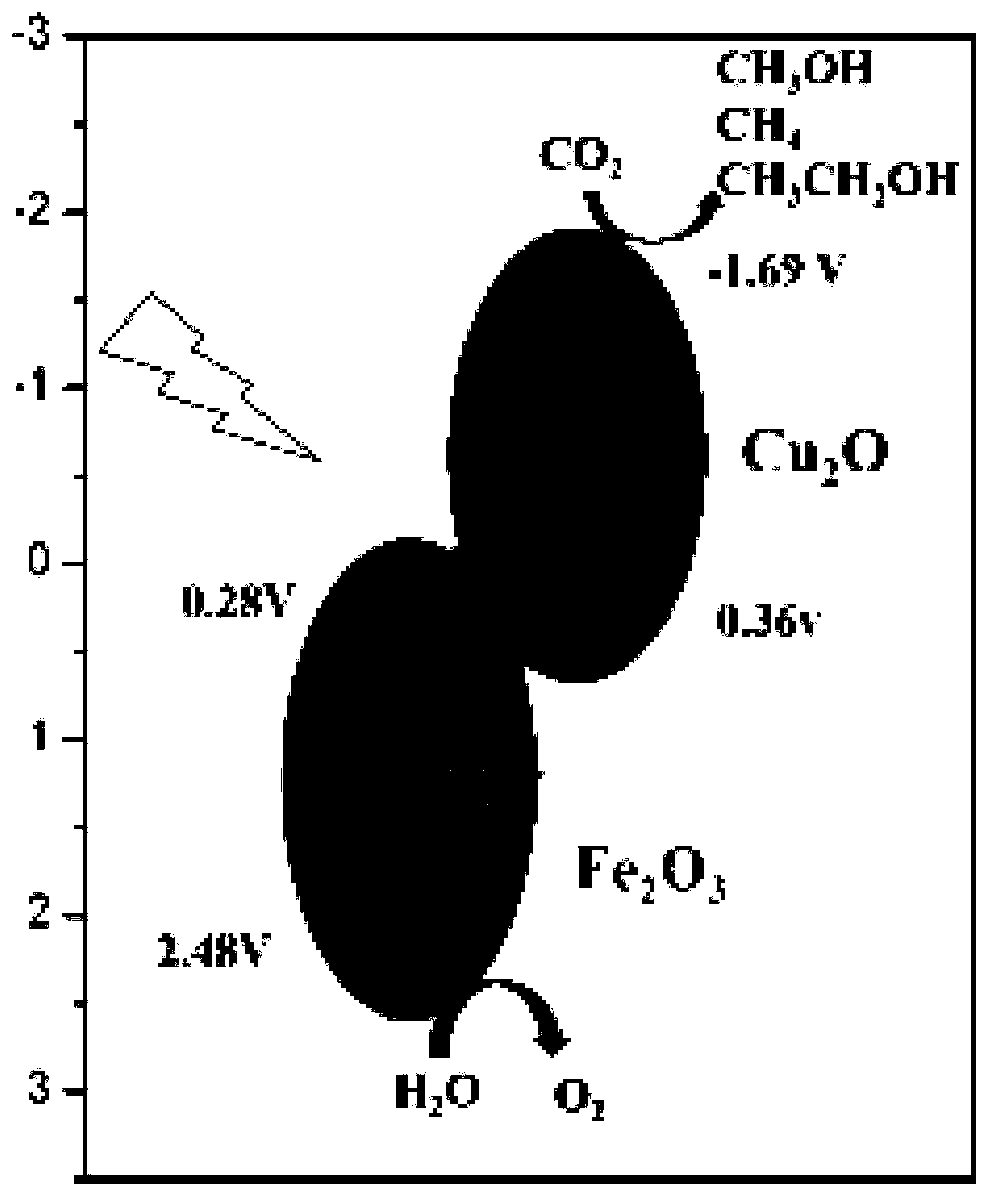

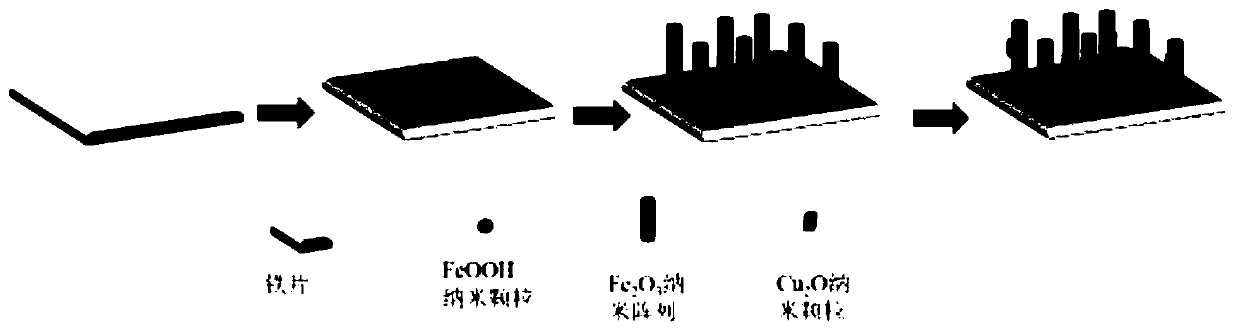

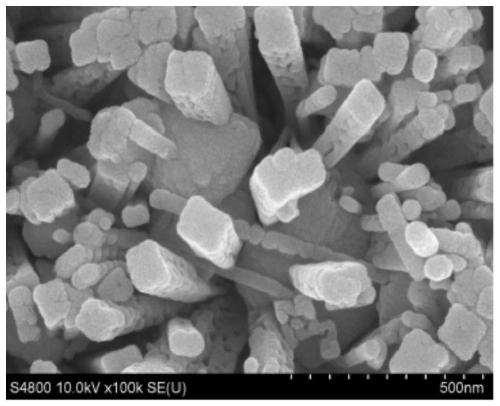

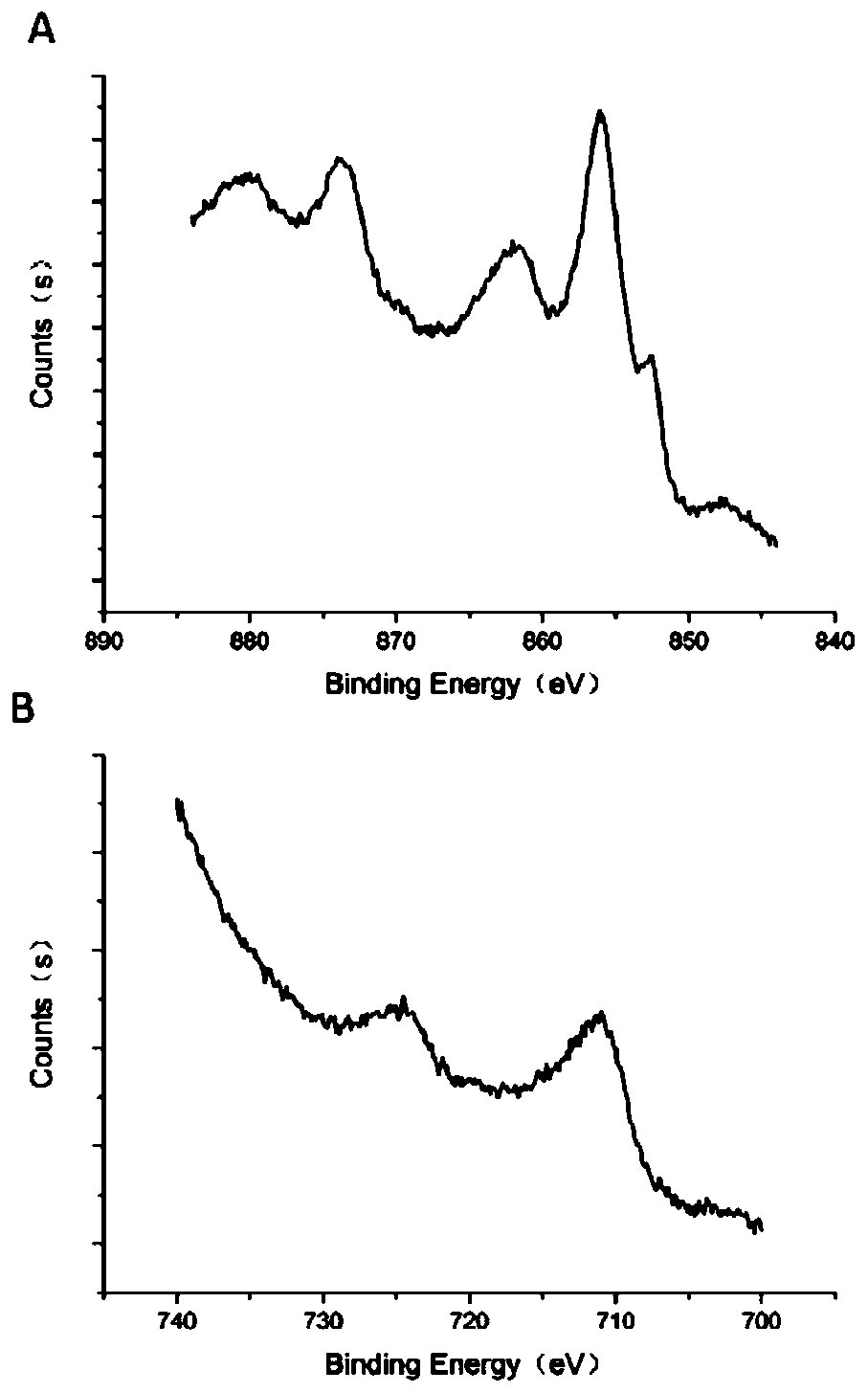

Preparation method of iron oxide/cuprous oxide photoelectric film

PendingCN111545204AFacilitate the realization of restorationFacilitate the realization of decompositionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsElectrolytic agentOverpotential

The invention discloses a preparation method of an iron oxide / cuprous oxide photoelectric film, which is characterized by comprising the following steps: respectively carrying out ultrasonic treatmenton an iron sheet in acetone, ethanol and deionized water, and then carrying out electric etching in ammonia water; immersing an iron sheet in the Fe < 3 + > precursor solution, carrying out hydrothermal film-forming reaction, and then calcining at a constant temperature to obtain an iron sheet to which a Fe2O3 film is attached; and taking the precursor solution of Cu < 2 + > as an electrolyte, carrying out electro-deposition, taking the obtained iron sheet as a cathode, taking a platinum wire as a counter electrode and taking an Ag / AgCl electrode as a reference electrode, and carrying out constant-voltage electro-deposition on the Fe2O3 film of the obtained iron sheet in a water bath. According to the present invention, by forming the Z-scheme, the separation of the photo-induced electrons and the photo-induced holes is promoted, such that the film has the low overpotential of 230 mV at the temperature of 10 mA.cm <-2 >, the carbon dioxide conversion efficiency can achieve 16.92% at most, and the water photolysis speed can achieve 120 mmol / L.h at most.

Owner:SHANGHAI INST OF TECH

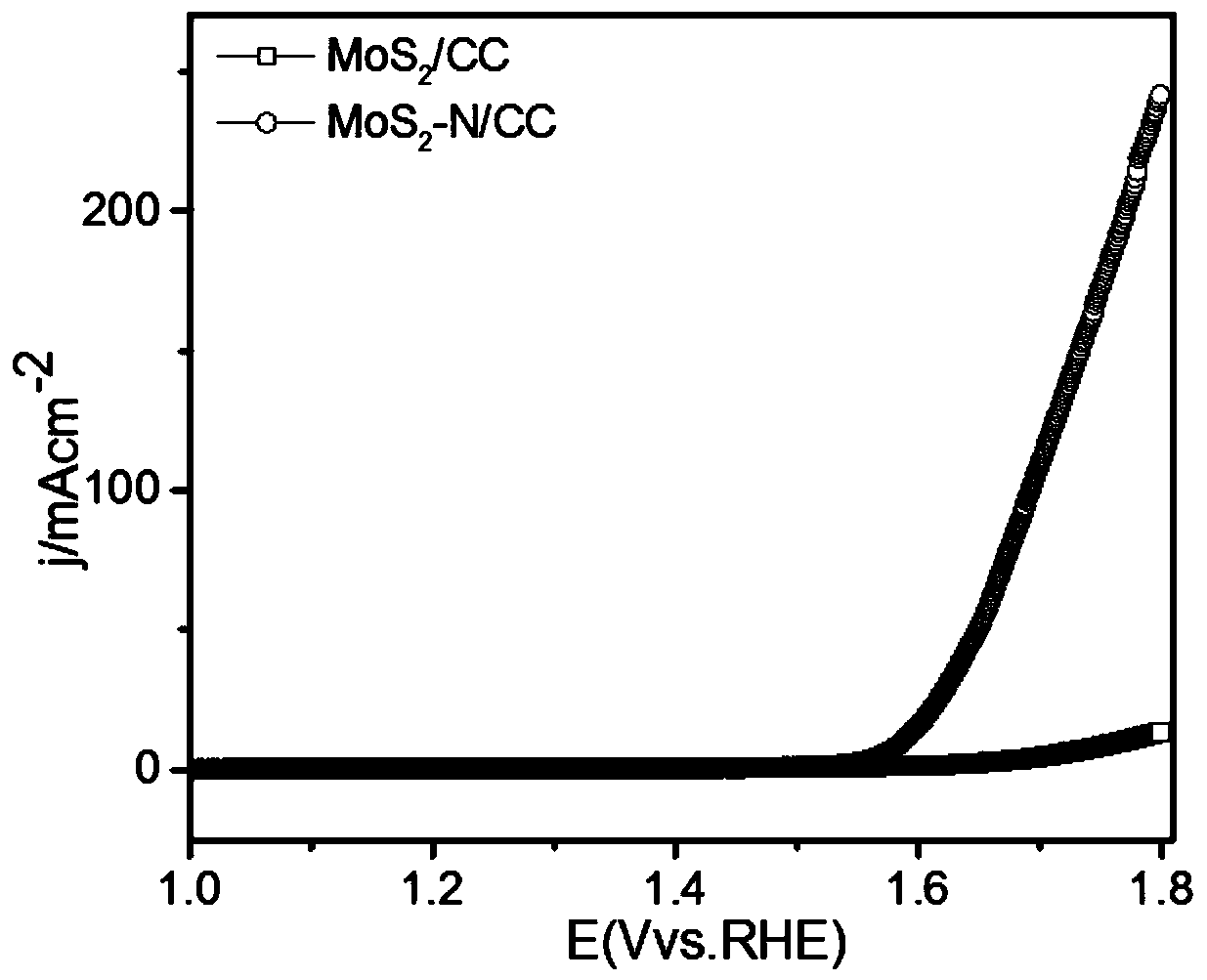

Preparation and application of heteroatom nitrogen surface modified MoS2 nano-material

ActiveCN110787820ALow priceSimple reaction conditionsPhysical/chemical process catalystsCell electrodesPtru catalystThiourea

Belonging to the technical field of electro-catalytic material synthesis, the invention discloses preparation and application of a heteroatom nitrogen surface modified MoS2 nano-material. The preparedcatalyst has excellent electrocatalytic oxygen evolution performance. The preparation process comprises the steps of: (1) carrying out ultrasonic treatment on carbon cloth (3*3cm) in acetone, ethanoland water respectively for 10min; (2) mixing ammonium molybdate and thiourea uniformly in proportion in water, carrying out high-temperature reaction with clean carbon cloth in a reaction kettle, then performing cooling to room temperature, washing the carbon cloth with ethanol and water in sequence, and performing drying; and (3) putting the MoS2 nanosheet obtained in step (2) and ammonia waterinto a reaction kettle, and carrying out high-temperature reaction for a certain period of time to obtain the heteroatom nitrogen modified MoS2 nano-material. The catalyst obtained by the invention shows excellent electrocatalytic performance, and the preparation process is simple and low in cost, and is suitable for large-scale production.

Owner:QINGDAO UNIV OF SCI & TECH

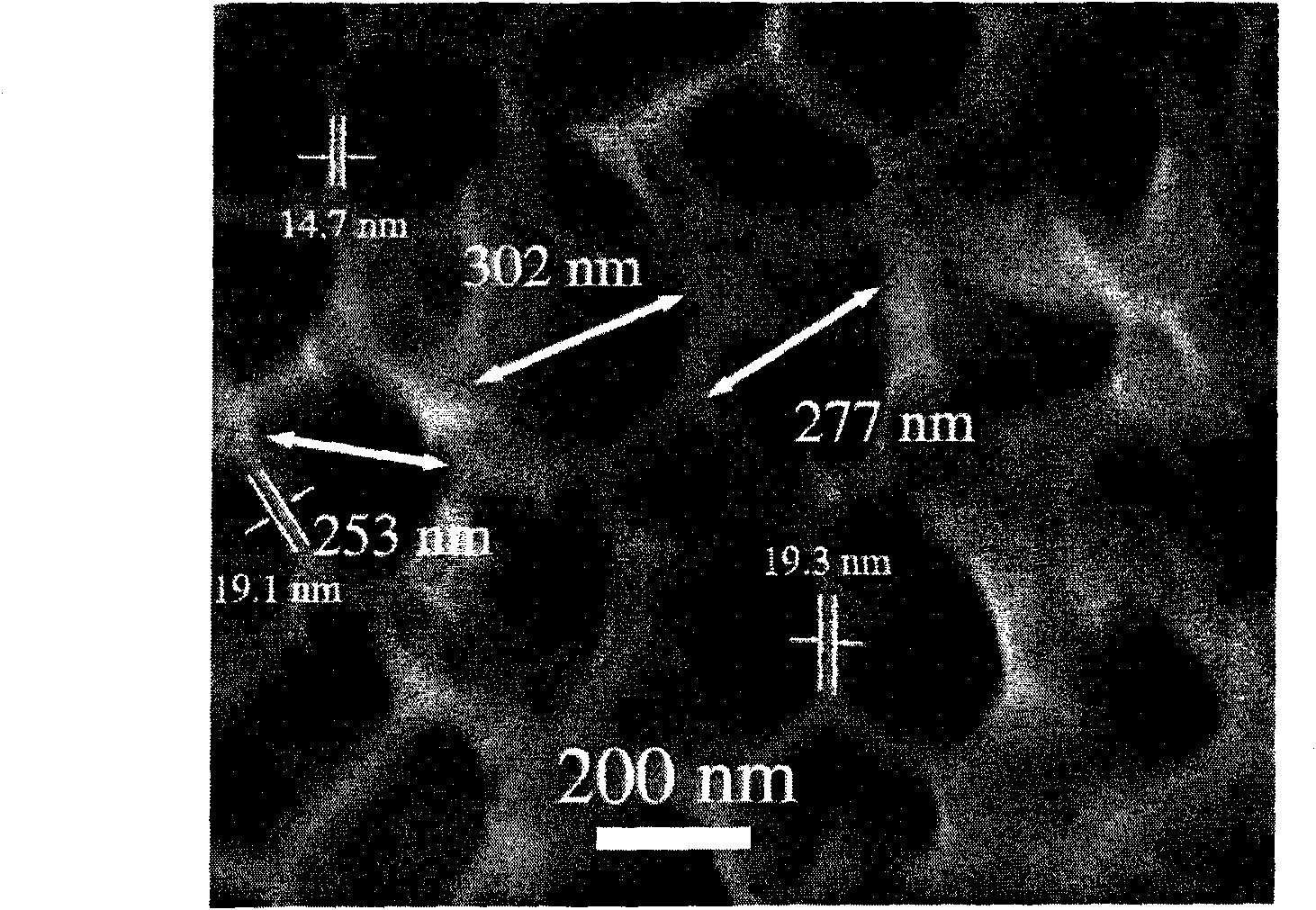

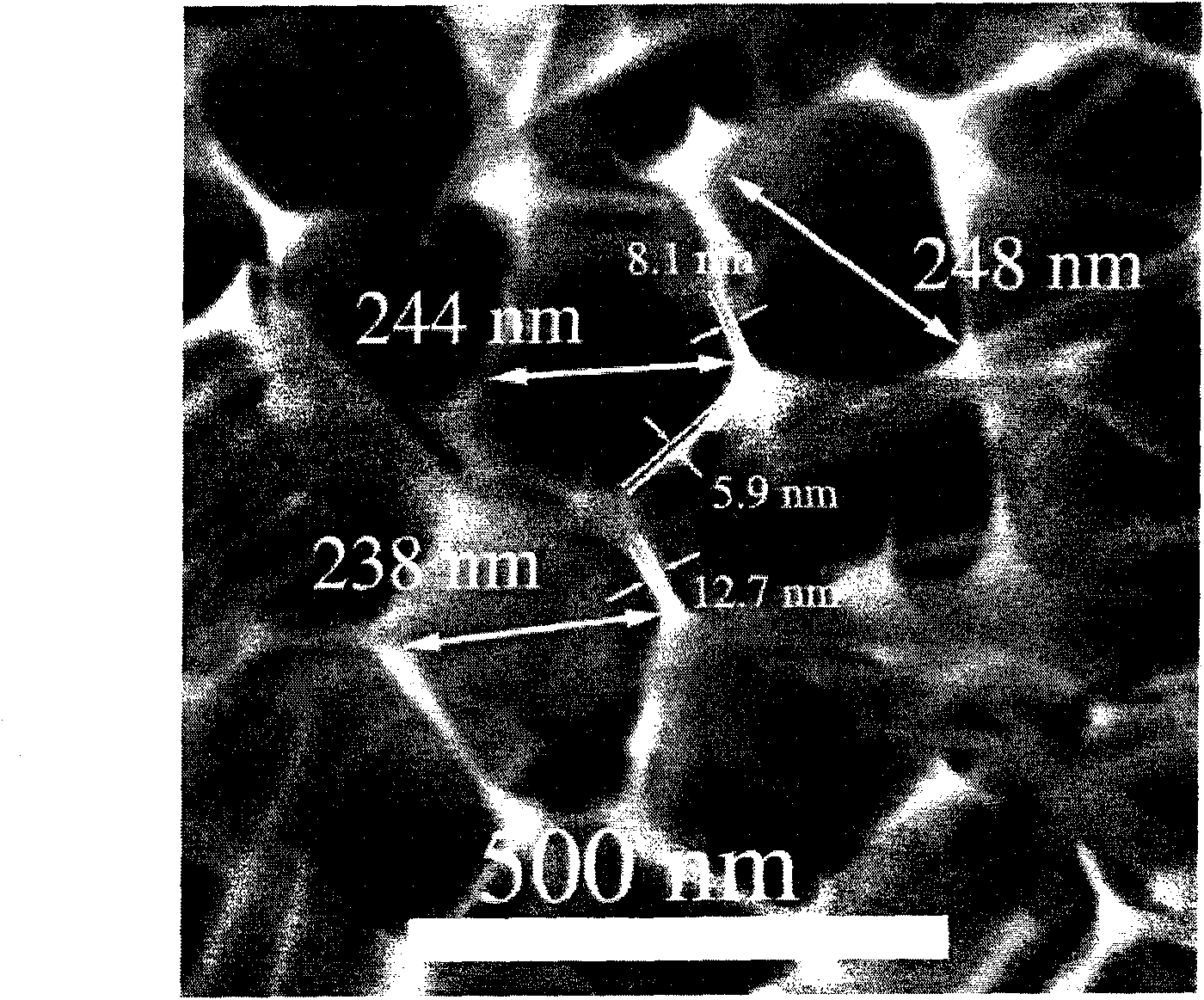

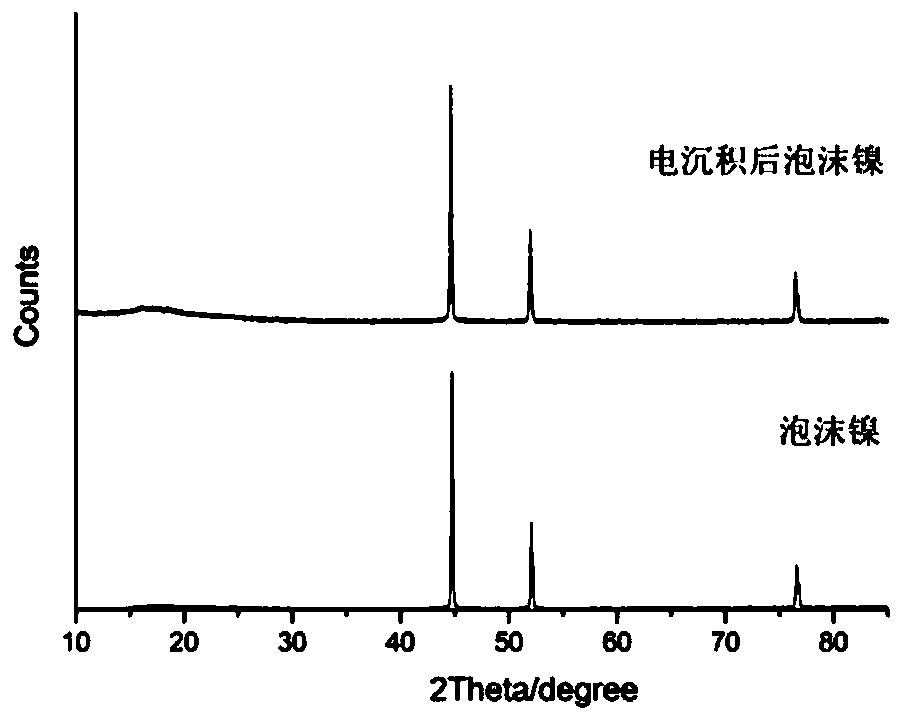

Large-aperture thin-wall anodized aluminum film and preparation method thereof

A large-aperture thin-wall anodized aluminum film is characterized by 200-300 nanometers of aperture and 5-20 nanometers of wall thickness. The preparation method of the film comprises the steps of: ultrasonic washing an aluminum sheet for 10 minutes sequentially by using acetone, ethanol and high purity water to remove superficial lipin and smudge; placing the washed aluminum sheet in 5 mass percent of sodium hydroxide solution for reacting for 30 minutes to remove oxide layers on the surface of the aluminum sheet; then placing the aluminum sheet obtained from step (1) in 1-10 mass percent of phosphoric acid solution, anodizing for 1 minute to 1 hour under 40-160V of voltage, later lowering the voltage to be 10-120V and continuously anodizing for 10 minutes to 10 hours, and finally finishing the preparation of the large-aperture thin-wall anodized aluminum film.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

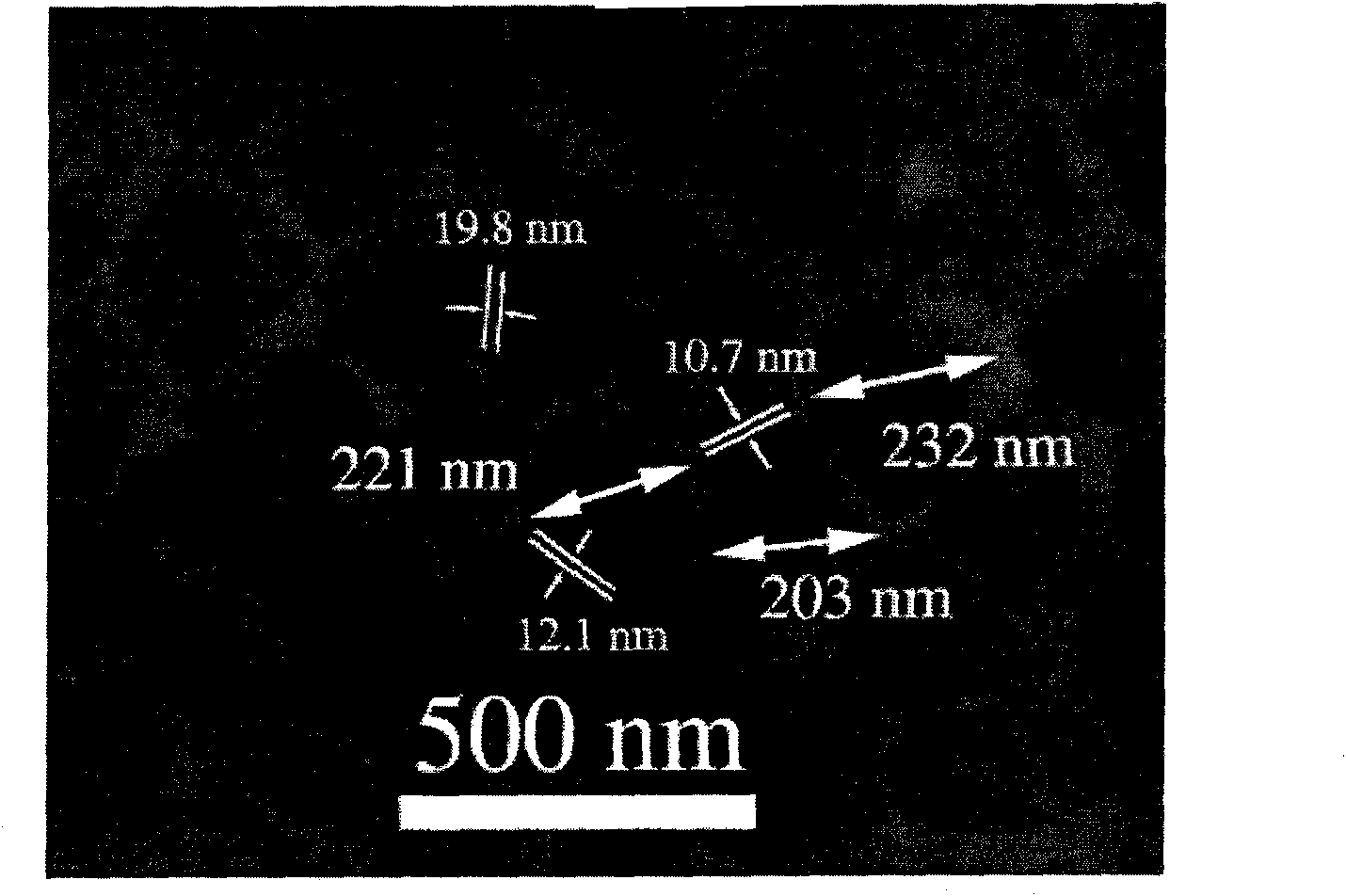

Ni-Fe catalyst, and preparation method and application thereof

ActiveCN111569884AImprove performanceEfficient electrolyzed waterElectrode shape/formsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystElectrolysis

The invention discloses a preparation method of a Ni-Fe catalyst. The preparation method comprises the following steps: 1, cutting a foamed nickel substrate and carbon paper, cleaning the foamed nickel substrate and the carbon paper with acetone, ethanol and deionized water in sequence, and conducting drying for later use; 2, respectively preparing a ferric nitrate solution and a nickel nitrate solution for later use; 3, respectively adding the ferric nitrate solution and the nickel nitrate solution in the step 2 into ethylene glycol, then adding deionized water and ammonium fluoride, and carrying out ultrasonic dispersion to form a uniform precursor solution; 4, taking clean foamed nickel as a cathode and carbon paper as an anode, putting the cathode and the anode into the precursor solution having been preheated to 40 DEG C, and conducting standing; step 5, keeping the cathode and the anode fixed, applying voltage to two ends by using a voltage-stabilized power supply, and maintaining the voltage for 5 minutes; and step 6, taking down foamed nickel deposited with a black catalyst, soaking the foamed nickel in absolute ethyl alcohol for cleaning, taking out the foamed nickel, anddrying the foamed nickel to obtain the NiFe catalyst. The prepared NiFe catalyst is excellent in water electrolysis performance, simple in preparation method and low in cost, and has excellent industrialization prospects.

Owner:SHANGHAI TECH UNIV

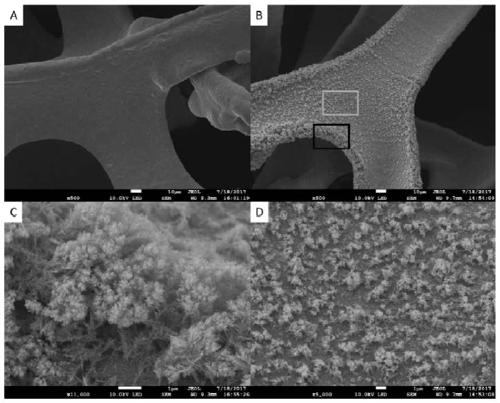

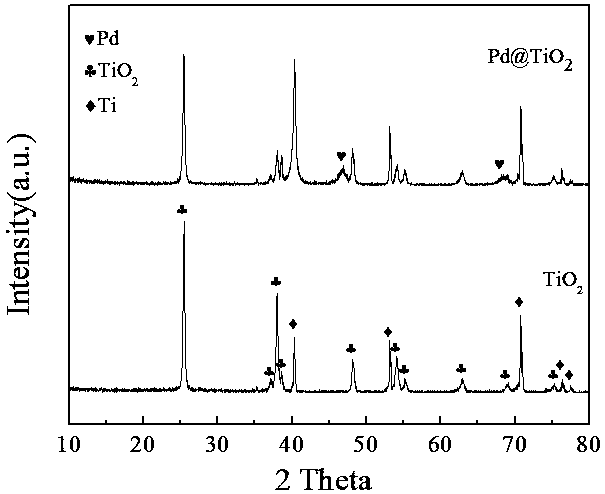

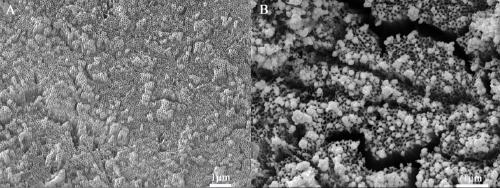

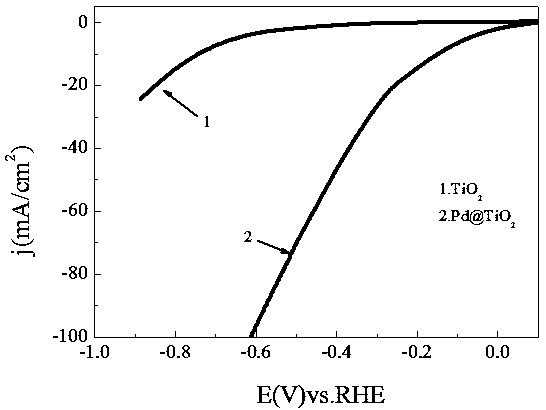

Preparation and application of Pd/TiO2 hydrogen evolution catalyst

PendingCN111097408ARegular shapeEvenly distributedCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsElectrolytic agentTio2 nanotube

The invention discloses preparation and application of a Pd / TiO2 hydrogen evolution catalyst, which comprises the following steps: 1) cutting a titanium sheet with the thickness of 1mm into titanium sheets with the size of 10mm * 15mm, sequentially carrying out ultrasonic treatment in acetone (CH3COCH3), ethanol (C2H6O) and water (H2O) respectively for 10min, and airing in air; 2) polishing the air-dried titanium sheet in a polishing solution for 30 seconds, quickly cleaning the titanium sheet with water, and drying the titanium sheet in a drying oven of 60 DEG C for 10 hours after cleaning, the polishing solution being composed of nitric acid (HNO3), hydrofluoric acid (HF) and water (H2O) in a ratio of 4: 1: 5 (V: V: V); (3) reacting in an electrolyte of ethylene glycol (C2H6O2) and 3vol%water of 0.5 wt% ammonium fluoride (NH4F) under the condition of 50V voltage for 2 hours, obtaining a TiO2 nanotube after the reaction is finished, cleaning and drying, and annealing at 500 DEG C for2 hours; 4) depositing for 15 minutes under the current density of 20 mA / cm < 2 > in an electrolyte consisting of 1 mM of palladium chloride (PdCl2) and 0.1 M of sodium chloride (NaCl) to obtain Pd / TiO2; and 5) carrying out a hydrogen evolution electrochemical test. The overpotential of Pd / TiO2 prepared by the method provided by the invention in a hydrogen evolution reaction is positively shiftedby 588 mV compared with the overpotential (j = 10mA / cm < 2 >) of the TiO2 nanotube.

Owner:SOUTHWEST UNIVERSITY

Carbon deposit cleaning agent and its application in reproduction of carbon deposit deactivation catalyst

ActiveCN1768959AReduce carbon depositionLow toxicityCatalyst regeneration/reactivationHydrocarbon oil crackingBurning outBenzene

The invention discloses a carbon build-up cleaning agent and its use in the regeneration process of devitalized catalyst, the carbon build-up cleaning agent comprises the following components: acetic ether 5-95 v%, acetone 5-95 v%, ethanol 0-90 v%, benzene 0-90 v%. The carbon build-up cleaning agent can be used for catalysts with appreciable heat release during regeneration, especially for devitalized hydrogenation catalyst and methane aromatization catalyst requiring oxidation burning-out for carbon build-up cleaning.

Owner:CHINA PETROLEUM & CHEM CORP +1

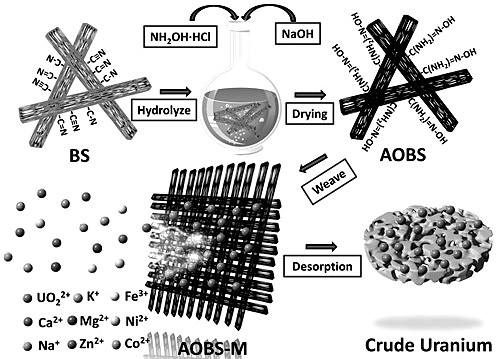

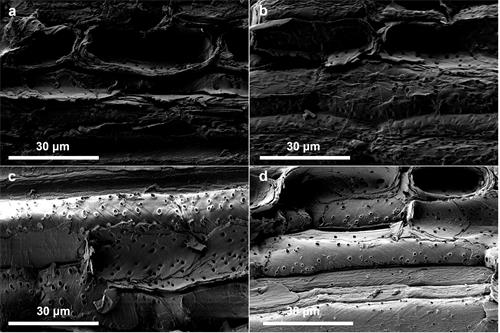

Knittable seawater uranium extraction adsorption material and flexible regulation and control preparation method thereof

ActiveCN113231038ALower synthesis costEasy to operateOther chemical processesSeawater treatmentPhysical chemistryHydroxylation

The invention discloses a knittable seawater uranium extraction adsorption material and a flexible regulation and control preparation method thereof, and relates to the technical field of adsorption materials, in particular to a knittable seawater uranium extraction material and a flexible regulation and control preparation method thereof. The preparation method comprises the following steps: carrying out ultrasonic treatment on the bamboo splits by using acetone, ethanol and deionized water, selecting H2O2 as a solvent, carrying out hydroxylation treatment on the bamboo splits by using a hydrothermal method, and finally carrying out amidoximation reaction by using an alkaline solution of NH2OH.HCl to prepare the amidoximated bamboo splits. The method is simple in preparation operation and low in cost, and a macroscopic large-area formed adsorption material can be built. Besides, oxime nitrogen, amino nitrogen and oxime oxygen in the amidoxime functional group can be subjected to chemical coordination with uranyl ions, so the selectivity of the bamboo splits to the uranyl ions is effectively improved, and the effect of specifically capturing the uranyl ions is achieved.

Owner:HARBIN ENG UNIV

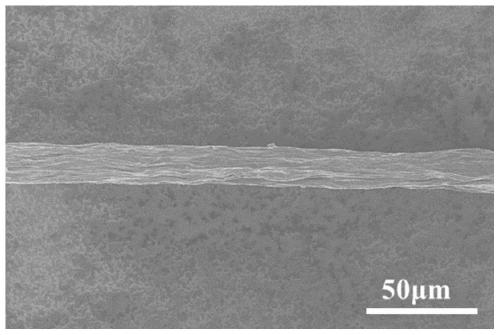

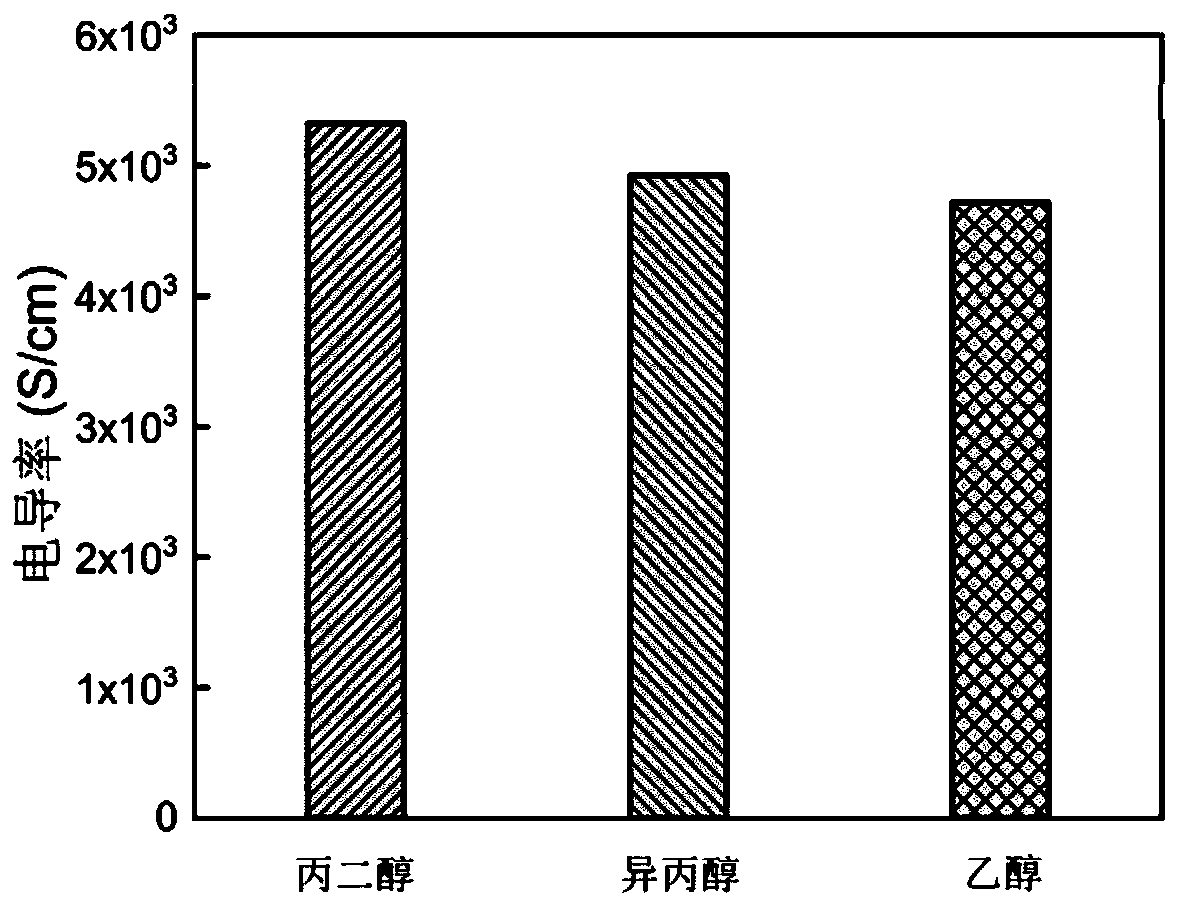

Carbon nano-based fiber as well as preparation method and application thereof

InactiveCN111334897AGood dispersionReduce the impactElectroconductive/antistatic filament manufactureFiberSpinning

The invention discloses a carbon nano-based fiber as well as a preparation method and an application thereof. The preparation method comprises the following steps of providing a carbon nano tube dispersion liquid comprising a carbon nano tube and a dispersant, wherein the content of the carbon nano tube in the carbon nano tube dispersion liquid is 1.01-3wt%; and taking the carbon nano tube dispersion liquid as a spinning liquid, injecting the spinning liquid into coagulating bath by adopting a wet spinning technology, thereby obtaining the carbon nano-based fibers, wherein the coagulating bathcomprises an organic solvent and / or an organic solvent and water mixed solution, and the organic solvent comprises acetone, ethanol, isopropanol, ethylene glycol, 1, 2-propylene glycol and the like.According to the preparation method, the use of strong acid for treatment of the carbon nano tube is avoided, and influence to the intrinsic structure of the carbon nano tube is reduced; meanwhile, through coagulating liquid ingredient and proportion control, preparation and performance regulation of different microcosmic structure carbon nano-based fibers is realized, and in addition, the prepared carbon nano-based fiber has relatively high conductivity and mechanical performance, can be used for the fields of fiber-like energy storage devices, wires, sensing and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Styrene-siloxane triblock copolymers as membranes for selective transport of alcohols and other organic compounds in aqueous mixtures

The present disclosure relates to high molecular weight polystyrene-polydialkylsiloxane-polystyrene (“SDS”) triblock copolymer compositions and methods of separating one or more organic compounds from an aqueous solution using membranes derived from SDS triblock copolymers. The methods may be used to separate the one or more organic compounds from an aqueous solution produced in a fermentation process. In some embodiments, the one or more organic compounds include an alcohol, such as, for example, ethanol. In other embodiments, the one or more organic compounds include acetone. In other embodiments, the one or more organic compounds include acetone, ethanol, and n-butanol produced in an acetone-ethanol-n-butanol (ABE) fermentation process. In other embodiments, the one or more organic compounds include one or more byproducts produced in a fermentation process.

Owner:RGT UNIV OF CALIFORNIA

Preparing method for micro-nano organic ferroelectric particles

InactiveCN103483746AParticle Size ControlSimple preparation processFerroelectric polymersPolymer science

The invention relates to a preparing method for micro-nano organic ferroelectric particles. The method includes the following steps: adding second solvents (water, acetone and ethanol) of appropriate amount in a methyl ethyl ketone solution of a ferroelectric polymer, and uniformly mixing; coating the surface of a clean substrate with the mixed solution; obtaining the micro-nano ferroelectric polymer particles after the solvents are evaporated. Through adjusting the mass concentration of the ferroelectric polymer solution and selecting the second solvents, the ferroelectric particles with different particle diameters can be obtained; according to the invention, the preparing technology is simple, the micro-nano ferroelectric polymer particles can be prepared through mixing the two kinds of solvents, and the particle diameter of the micro-nano ferroelectric polymer particles can be adjusted and controlled through adjusting the volume ratio of the two kinds of solvents and the mass concentration of the ferroelectric polymer particles.

Owner:FUDAN UNIV

Fast sieving method for dihydropyridine blood-pressure lowering compound mixed in Chinese medicinal herb blood-pressure lowering product

ActiveCN101666757ALow costEasy to operateMaterial analysis by observing effect on chemical indicatorNifedipineDihydropyridine

The invention relates to a fast sieving method for a dihydropyridine blood-pressure lowering compound mixed in a Chinese medicinal herb blood-pressure lowering product. The fast sieving method comprises the following steps of: (1) sampling, crushing, adding acetone-ethanol solution with volume ratio to a sample of equal to 5 : 1 and mass of 5 times to 10 times of the sample, shaking for dissolution, filtering and keeping filtering solution; (2) taking out 1ml of the filtering solution obtained from step (1), adding with 3 drops to 5 drops of potassium hydroxide-ethanol solution with mass concentration of equal to 2 percent to 3 percent, shaking evening and observing the change of color; in the case that the solution is changed into reddish-brown, which shows the dihydropyridine blood-pressure reducing compound is doped in the sample; and the dihydropyridine blood-pressure reducing compound is one or more than two of nifedipine, nitrendipine and nimodipine. The invention also disclosesa special kit for applying the method and the kit comprises the acetone-ethanol solution with volume ratio of 5 to 1 and the potassium hydroxide-ethanol solution with mass concentration of equal to 2percent to 3 percent. The sieving method is characterized by fastness, low cost, simple operation and the like.

Owner:广东省药品检验所

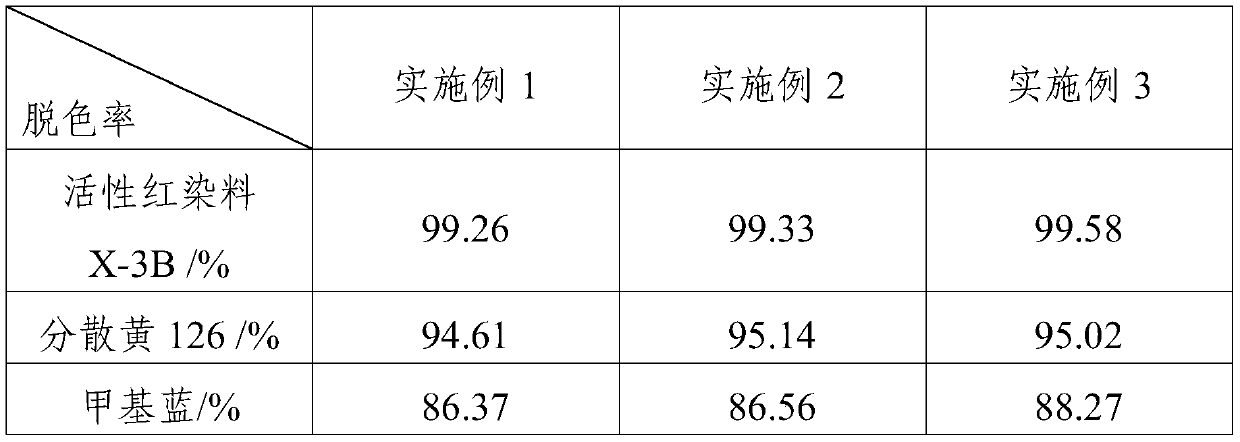

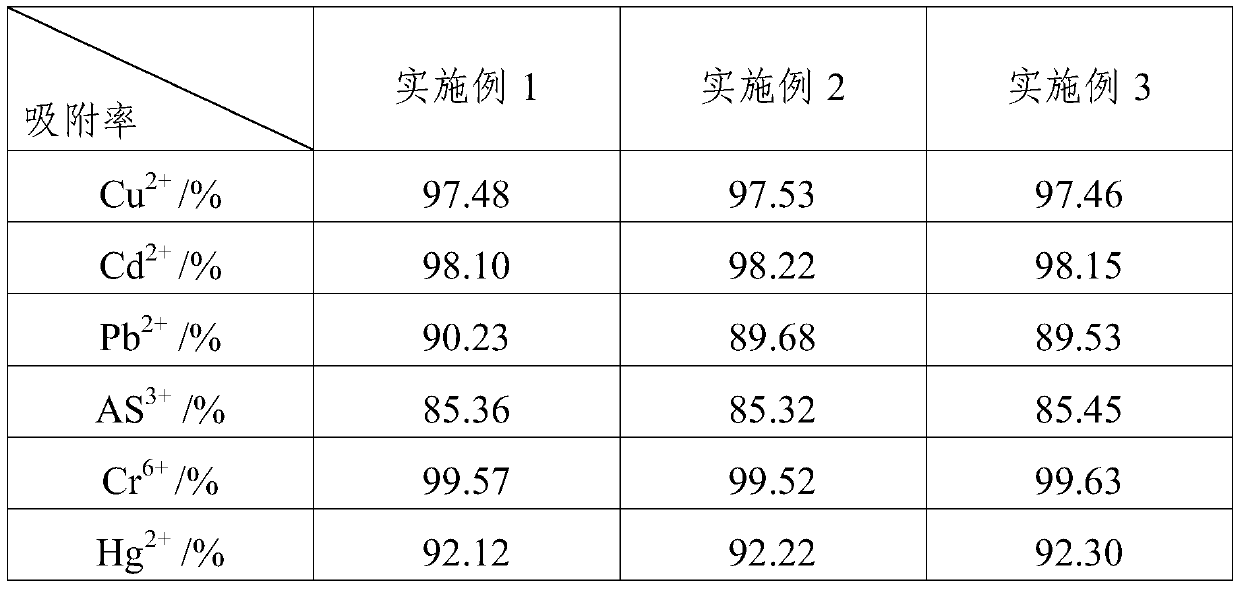

Preparation method for hydrophobic associated amphoteric flocculant used for industrial wastewater treatment

InactiveCN111087058AIncrease loadHigh degree of polymerizationWater/sewage treatment by flocculation/precipitationMeth-Industrial waste water

The invention provides a preparation method for a hydrophobic associated amphoteric flocculant used for industrial wastewater treatment, and relates to the technical field of sewage treatment engineering. The preparation method comprises the following steps: preparing modified montmorillonite; adding dodecafluoroheptyl perfluorooctylethyl acrylate and an emulsifier into deionized water, then adding acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, itaconic acid and dimethyl diallyl ammonium chloride, adding triethylamine to adjust the pH value of a system to be neutral, introducing nitrogen to remove oxygen, then adding an initiator, carrying out a heat preservation reaction for 8-12 h, carrying out drying to remove water, carrying out grinding and crushing, adding an obtained powderinto an acetone / ethanol mixed solution, and carrying out heating reflux purification for 10-15 h so as to obtain a mixed powder; and dispersing nanometer silicon dioxide with a proper amount of anhydrous butanone, then adding dispersed nanometer silicon dioxide into a polyacrylate emulsion, carrying out high-speed shearing dispersion, adding the above-mentioned mixed powder, carrying out drying ata temperature of 120-130 DEG C, and immersing an obtained material into an isopropanol solution of fluorosilane for 40-50 min. The hydrophobic associated amphoteric flocculant provided by the invention has good adsorption effect on dyes and heavy metal elements in industrial wastewater and can be used for treating the industrial wastewater.

Owner:安徽掌榕网科技有限公司

Method for extracting chlorophyll and aromatic oil from leaves of Zanthoxylum bungeanum

ActiveCN110483532AEfficient extractionReduce usageOrganic chemistryEssential-oils/perfumesZanthoxylum bungeanumOrganic solvent

The invention discloses a method for extracting chlorophyll and aromatic oil from leaves of Zanthoxylum bungeanum. The method comprises the following steps: picking fresh leaves of Zanthoxylum bungeanum; grinding the leaves into slurry; filtering the slurry to respectively obtain a first filtrate and first filter dregs; adding ethanol into the first filter dregs, then performing filtration to obtain a second filtrate and second filter dregs; mixing the first filtrate and the second filtrate to obtain a mixed filtrate; adsorbing chlorophyll in the mixed filtrate by utilizing an adsorption column, with the mixed filtrate adsorbed by the adsorption column being Zanthoxylum bungeanum leaf juice, and eluting the adsorption column to extract the chlorophyll; distilling the Zanthoxylum bungeanumleaf juice to obtain an oil-water mixture; storing the oil-water mixture in a sealedpool, and uniformly and continuously injecting air into the sealed pool; transferring the sealed oil-water mixture into an oil-water separator, and obtaining aromatic oil in a high-speed centrifugal state; and adding an acetone-ethanol mixed solution into the second filter dregs, uniformly stirring the mixture, filtering the mixture to obtain a filtrate, and concentrating the filtrate to recover acetone and ethanol and to obtain chlorophyll. The use amount of the organic solvent is reduced.

Owner:卓士鸿

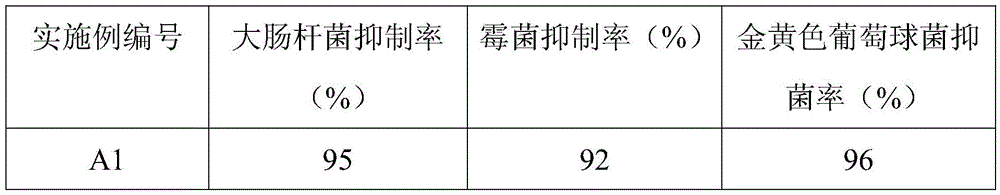

Antibacterial watercolor and preparation method thereof

The invention discloses antibacterial watercolor and a preparation method thereof. The preparation method comprises the following steps: mixing rare-earth, cyclohexanol, 8-carboxylquinoline and cyclohexane, sufficiently stirring for 15-25 minutes, and adding sodium m-carboxy benzoate to obtain a micro-emulsion M; adding tetra-n-butyl titanate into the micro-emulsion M, sufficiently stirring, centrifuging for 3-5 times, alternately washing with an acetone-ethanol mixed liquid and deionized water, drying, and grinding powder to obtain antibacterial powder N; and mixing epoxy resin, sodium benzoate, aluminum silicate, packing and a colorant, heating in water bath, adding the prepared antibacterial powder N, and performing ultrasonic dispersion to obtain the antibacterial watercolor. According to the antibacterial watercolor, the problem that mould easily grows on the surface of the traditional watercolor in a humid environment can be solved.

Owner:FOSHAN JUCHENG BIOCHEM TECH RES & DEV CO LTD

Freckle-removing and depression-relieving composition and preparation method thereof

ActiveCN112870290AObvious freckle removal effectRelieve anxietyOrganic active ingredientsNervous disorderFormularyTremella

The invention relates to the field of freckle-removing products, in particular to a freckle-removing and depression-relieving composition suitable for lying-in women and the application thereof. The freckle-removing and depression-relieving composition is prepared from rose, tremella polysaccharide, radix ophiopogonis and folic acid, the principle of dialectical treatment of traditional Chinese medicine is followed, and all the medicines in the formula supplement one another. The preparation method comprises the following steps: extracting volatile oil from rose and radix ophiopogonis by a steam distillation method, and carrying out inclusion; adding acetone-ethanol aqueous solution with certain concentration into filtered dregs, extracting, concentrating and drying to obtain dry paste powder, mixing the dry paste powder, volatile oil clathrate compound, tremella polysaccharide and folic acid, and the freckle-removing composition has obvious effects of removing freckles, relieving anxiety and improving sleep, and is safe and reliable.

Owner:JIANCHANGBANG CHINESE HERBAL MEDICINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com