Preparing method for micro-nano organic ferroelectric particles

The technology of organic iron and electric particles is applied in the field of preparation of micro-nano-sized organic ferroelectric particles, which can solve the problems of corrosion, difficult processing and preparation of micro-nano-scale ferroelectric polymer structures, and achieve the effect of simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] This example illustrates that the adjustment of the particle size of organic ferroelectric particles can be realized by adjusting the volume ratio of the two solvents in the mixed solution. Proceed as follows:

[0018] 1) Prepare 10ml of butanone solution of P(VDF-TrFE) ferroelectric polymer, the mass concentration is 1.0%.

[0019] 2) Measure 2ml of methyl ethyl ketone solution and place them in three clean beakers respectively. Select acetone as the second solvent. The volume ratios of acetone are 1:6, 1:15 and 1:55, respectively. Sonicate for 5 min to ensure that the solvent is well mixed.

[0020] 3) The mixed solution was drip-coated on a clean glass slide, and after the solvent was completely evaporated, the geometric structure of the formed ferroelectric particles was observed with an atomic force microscope.

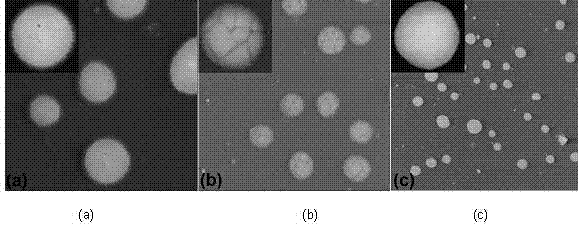

[0021] figure 1 The atomic force microscope images showed that with the increase of acetone content in the mixed solution, the particle size of organi...

Embodiment 2

[0023] This example illustrates that both deionized water and ethanol can be used as the second solvent to realize the preparation of micro-nano-sized ferroelectric particles. Proceed as follows:

[0024] 1) Prepare 10ml of butanone solution of P(VDF-TrFE) ferroelectric polymer, the mass concentration is 1.0%.

[0025] 2) Measure 2ml of methyl ethyl ketone solution and place them in two clean beakers, and select ethanol and deionized water as the second solvent. Add deionized water (butanone:water=1:0.8) and ethanol (butanone:ethanol=1:20) into the two beakers respectively and mix well.

[0026] 3) The mixed solution was drip-coated on a clean glass slide, and after the solvent was completely evaporated, the geometric structure of the formed ferroelectric particles was observed with an atomic force microscope.

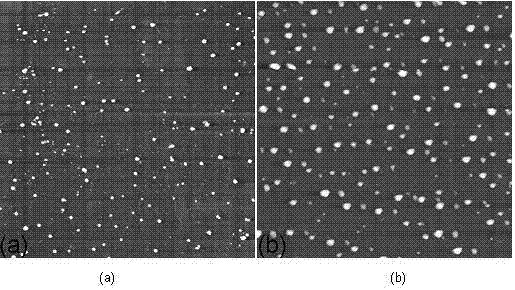

[0027] figure 2 The atomic force microscope image shows that the ferroelectric particles obtained from the butanone / ethanol mixed solution have a particle size of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com