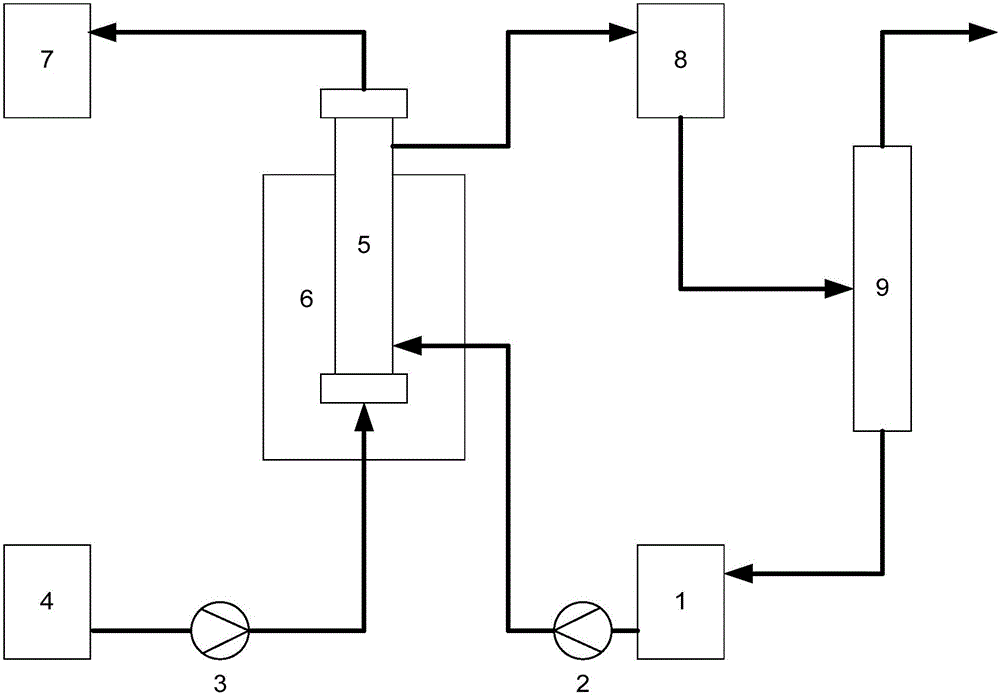

Particle controllable preparation method and device based on ultrasonic auxiliary continuous anti-solvent film dialysis process

An ultrasonic-assisted, anti-solvent technology, applied in the field of continuous controllable preparation of particles, can solve the problems of particle agglomeration and uneven particle size, and achieve the effects of improving dispersibility, reducing residues and good dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11

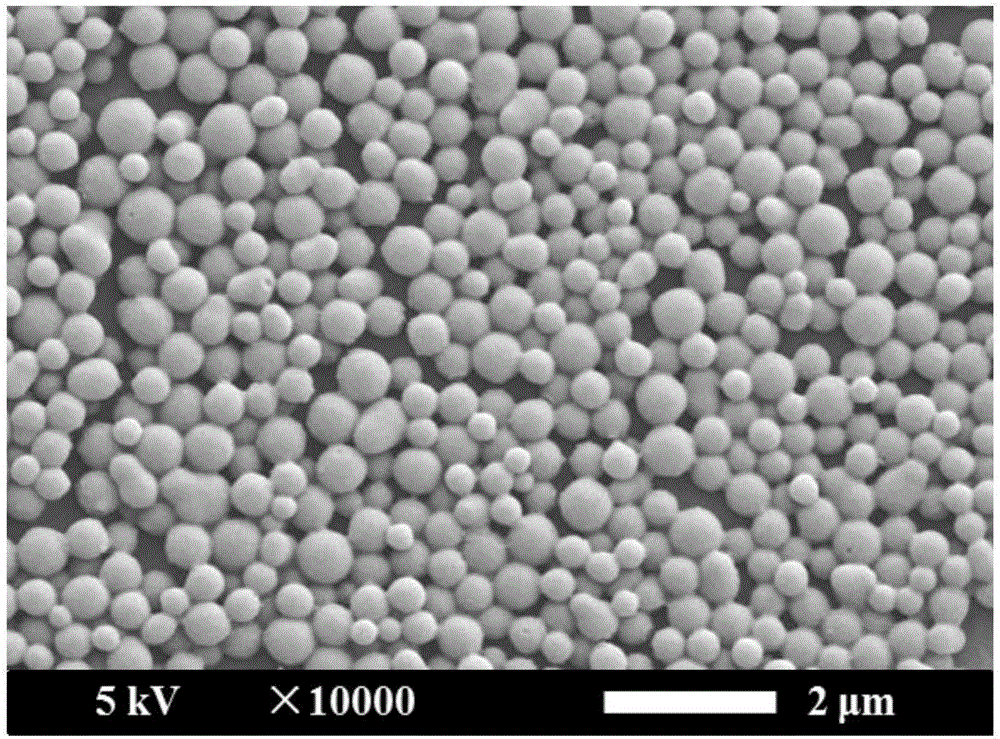

[0046] A preparation method of zein microspheres, comprising the following steps:

[0047] (1) Prepare ethanol solvents with different volume fractions according to Table 1, and place them in the second sealed container 4; select ethanol solvents with different volume fractions according to Table 1, and prepare 250 mL of zein solutions with different concentrations for use.

[0048] (2) Ultrapure water is used as an anti-solvent, placed in the first sealed container 1; the ultrapure water enters the shell side of the membrane module 5 through the first peristaltic pump 2, and the flow rate is the shell side flow rate corresponding to Examples 1-11 in Table 1.

[0049] (3) Step (1) The ethanol solvent placed in the second sealed container 4 passes through the second peristaltic pump 3 into the tube side of the membrane module 5, and the flow rate is the tube side flow rate corresponding to Examples 1-11 in Table 1.

[0050] (4) Turn on the ultrasonic generator 6, and set the ul...

Embodiment 13~22

[0062] A preparation method for curcumin granules, comprising the following steps:

[0063] (1) Configure ethanol solvents with different volume fractions according to Table 2, and place them in the second sealed container 4; select ethanol solvents with different volume fractions according to Table 2, and prepare 250 mL of curcumin solutions with different concentrations for subsequent use.

[0064] (2) Ultrapure water is used as an anti-solvent, placed in the first sealed container 1; the ultrapure water enters the shell side of the membrane module 5 through the first peristaltic pump 2, and the flow rate is the shell side flow rate corresponding to Examples 13-22 in Table 2.

[0065] (3) Step (1) The ethanol solvent placed in the second sealed container 4 passes through the second peristaltic pump 3 into the tube side of the membrane module 5, and the flow rate is the tube side flow rate corresponding to Examples 13-22 in Table 2.

[0066] (4) Turn on the ultrasonic generat...

Embodiment 24~29

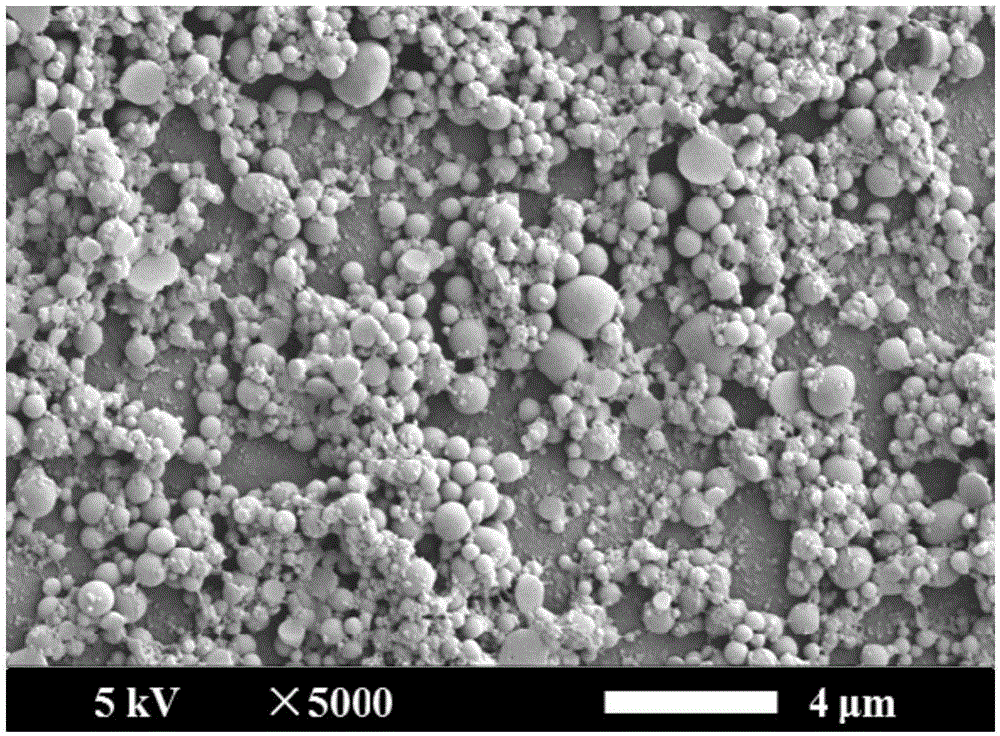

[0079] A preparation method of zein microspheres loaded with curcumin, comprising the following steps:

[0080] (1) Prepare ethanol solvents with different volume fractions according to Table 3, and place them in the second sealed container 4; select ethanol solvents with different volume fractions according to Table 3, and prepare 250 mL of zein solutions with different concentrations for use.

[0081] (2) According to Table 3, the curcumin powder was dispersed into the zein solution according to different drug loading ratios to prepare a raw material solution for use.

[0082] (3) Ultrapure water is used as an anti-solvent, placed in the first sealed container 1; the ultrapure water enters the shell side of the membrane module 5 through the first peristaltic pump 2, and the flow rate is the shell side flow rate corresponding to Examples 24-29 in Table 3.

[0083] (4) Step (1) The ethanol solvent placed in the second sealed container 4 passes through the second peristaltic pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com