Equipment and method for processing gas absorbed by film

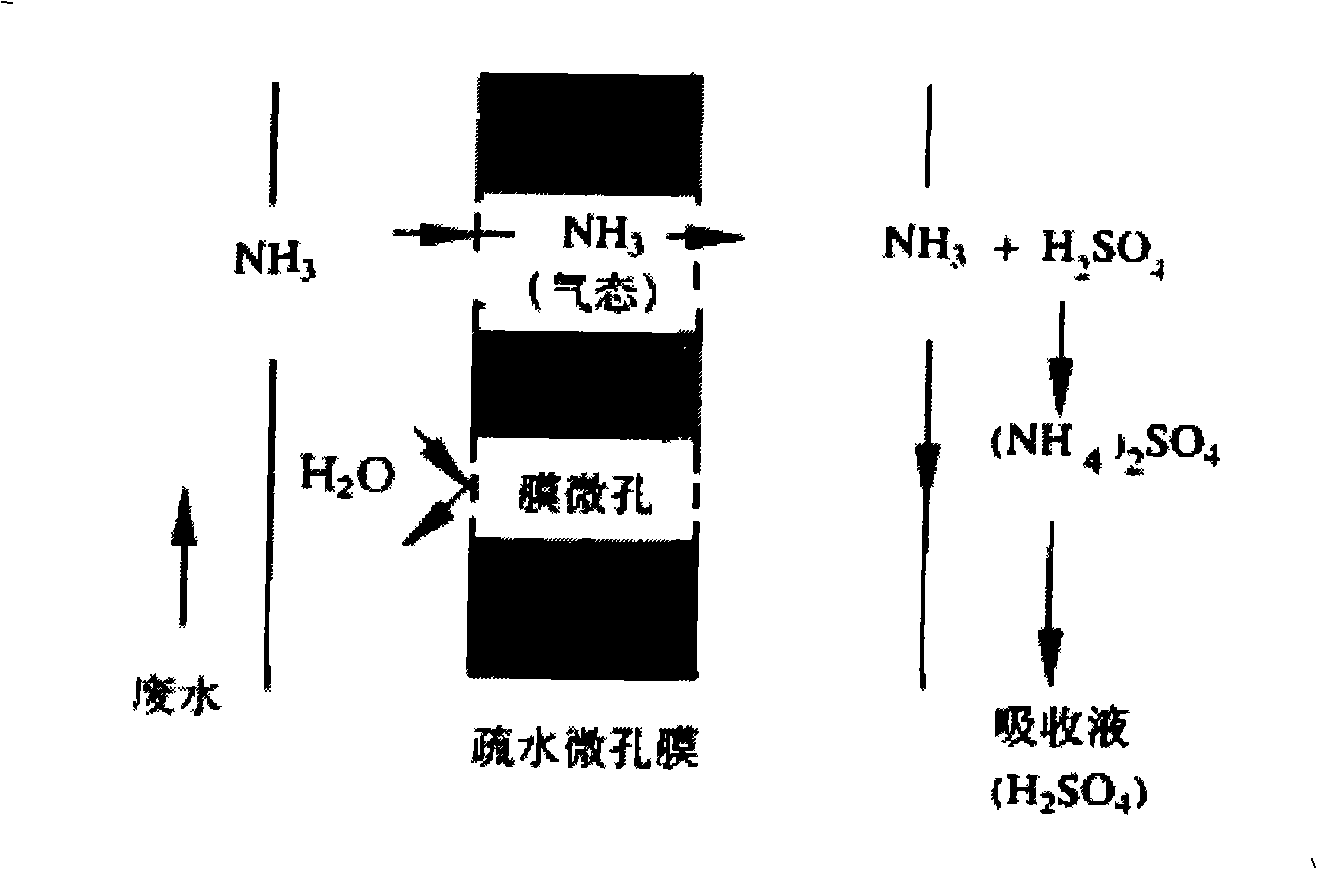

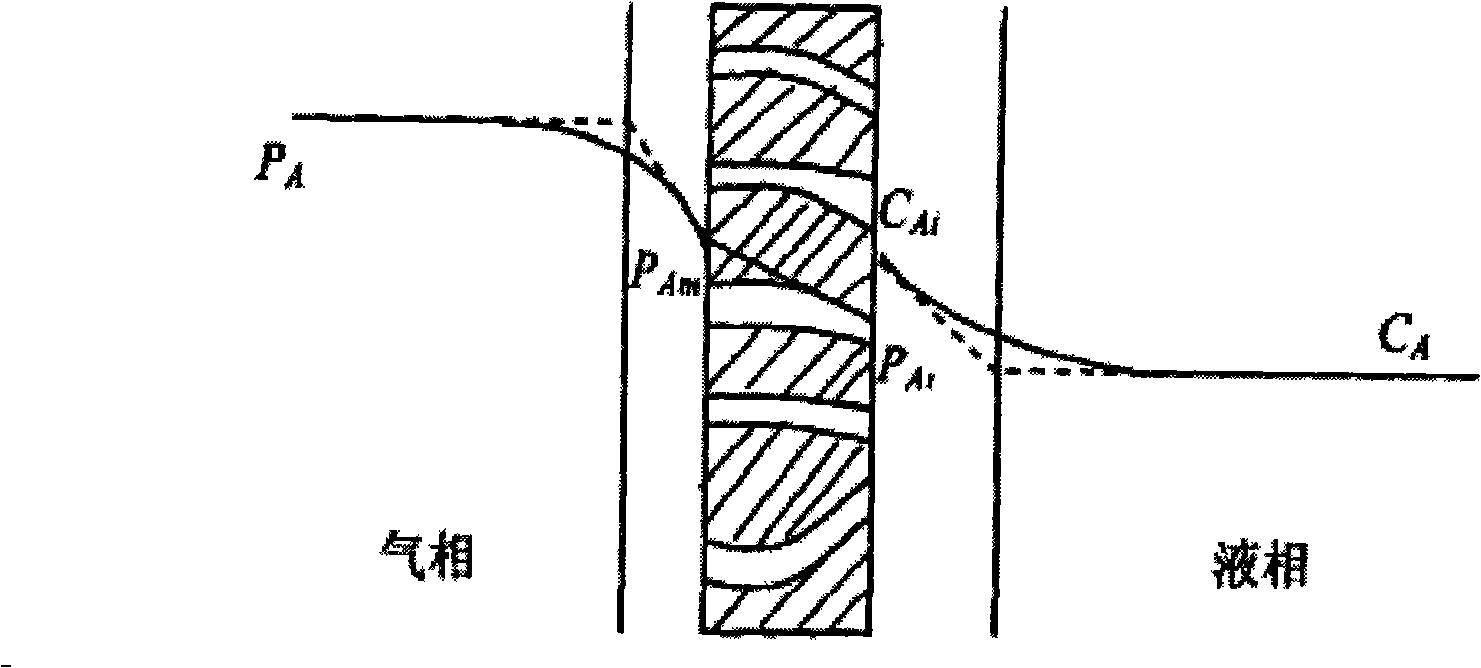

A gas treatment and membrane absorption technology, applied in separation methods, chemical instruments and methods, and pervaporation, etc., can solve problems affecting mass transfer efficiency, uneven distribution of shell-side fluids, and uneven distribution of shell-side fluids, etc. The effect of large contact area of membrane, control of membrane fouling, and reduction of concentration polarization and temperature difference polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

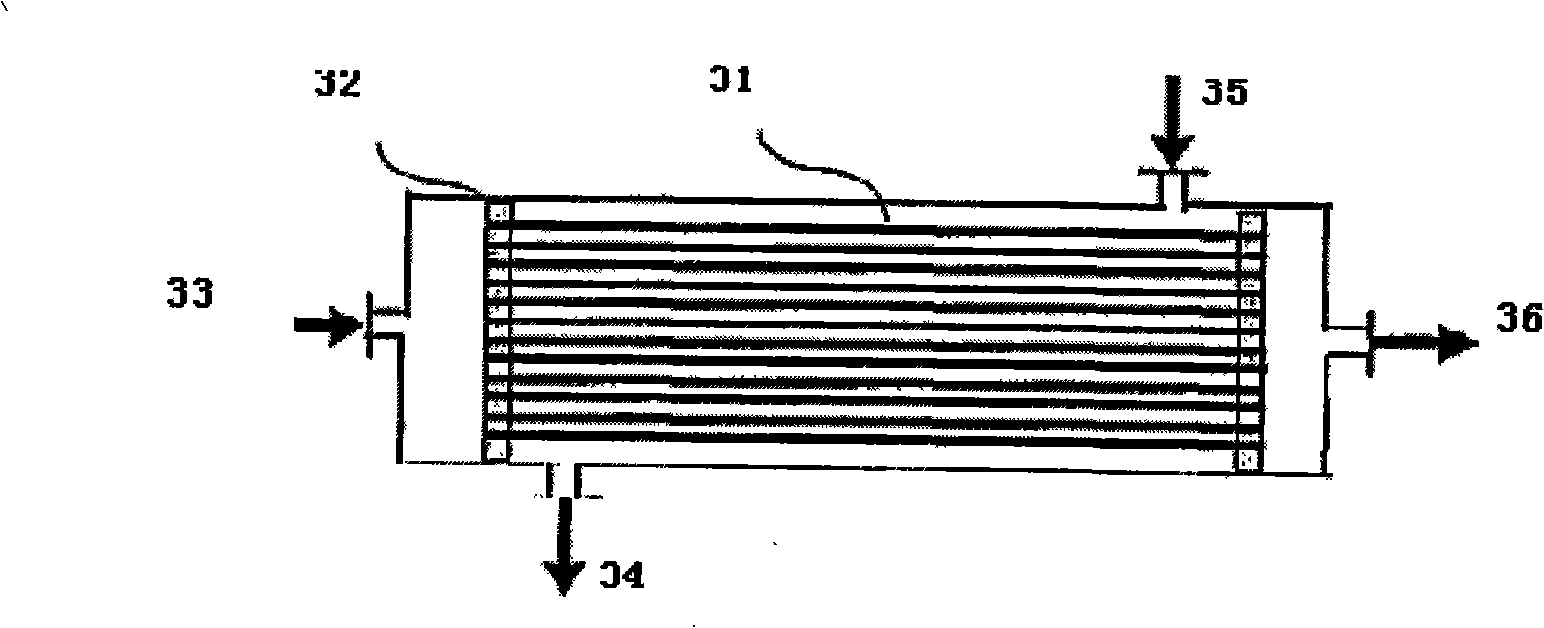

[0041] Such as Figure 4 , the membrane absorption device of the present invention comprises: reaction tank 2, the feed liquid inlet 1 that is arranged on the reaction tank 2, air inlet 9, the submerged hydrophobic hollow fiber membrane gas-liquid separator 3 that is arranged in the reaction tank 2, is arranged on The perforated aeration tube 4 for controlling membrane pollution at the lower part of the separator 3, the absorption liquid container 5 arranged outside the reaction tank, and the negative pressure pump 6 is arranged behind the outlet 5 of the absorption liquid container, which adopts negative pressure suction to absorb the gas It is introduced into the absorption liquid container 5 for absorption and collection. Alternatively, compressed air is blown through the perforated aeration tube 4 to sweep the absorbed gas through the membrane and enter the absorption liquid container 5 for absorption and collection. During compressed air purging, the negative pressure pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com