Metallic electrolytic cell and metal electrolysis process

A technology of metal electrolysis and electrolytic cell, which is applied in the field of metal electrolysis process and metal electrolytic cell, and can solve problems such as cell voltage increasing production energy consumption, product quality declining, and affecting anode slime settlement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The core of the present invention is to provide a metal electrolytic cell with reduced concentration polarization. Another core of the present invention is to provide a metal electrolysis process.

[0037]In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

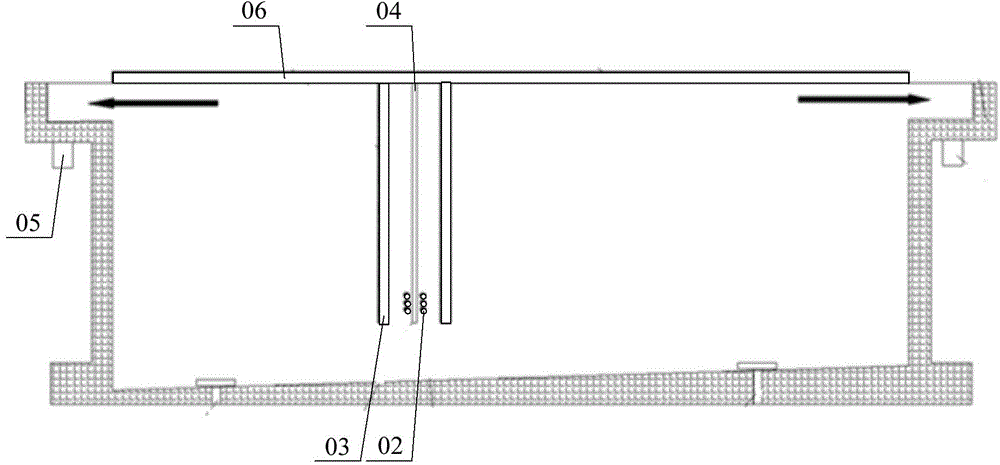

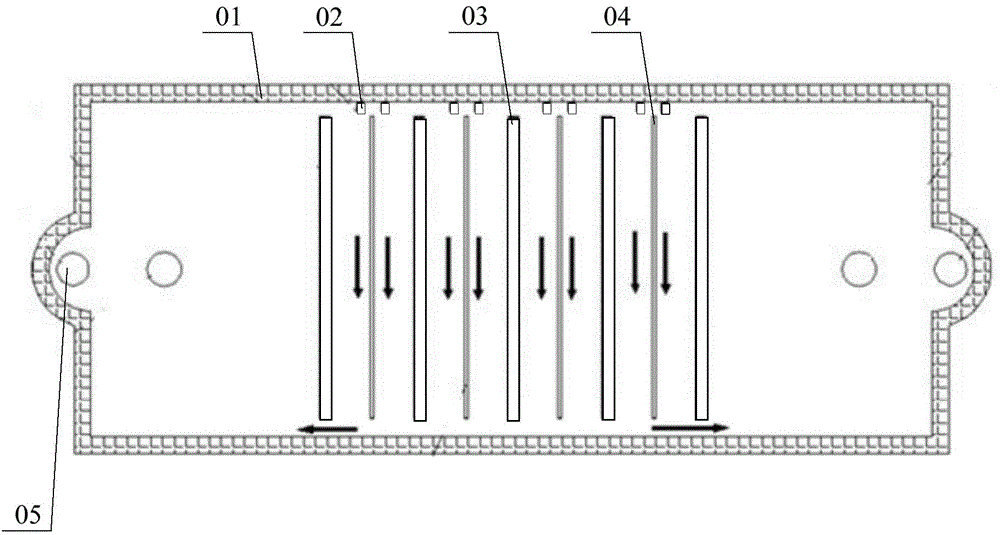

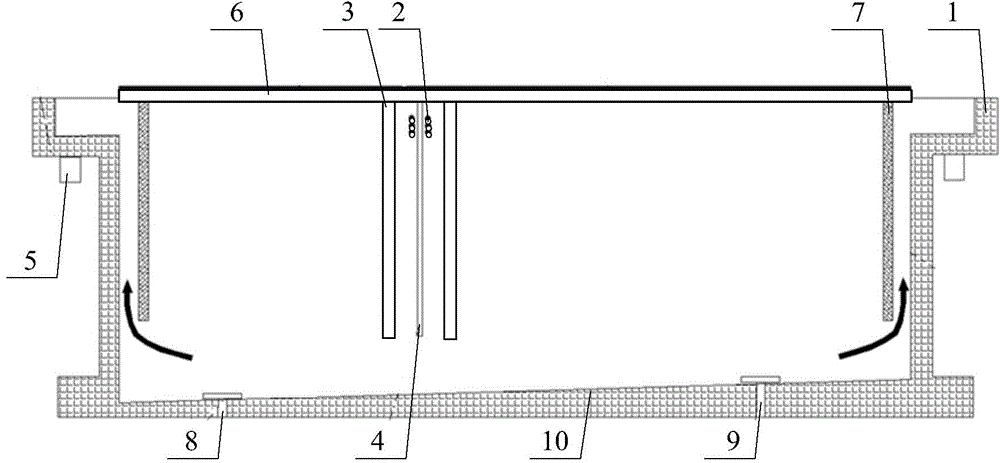

[0038] Please refer to Figure 3 to Figure 6 , in a specific embodiment, the metal electrolytic cell provided by the present invention includes a cell body 1, a conductive row 6, an anode plate 3, a cathode plate 4, and arc-shaped liquid-guiding protrusions 11 installed at opposite ends of the cell body 1, specifically Yes, preferably, the arc of the arc-shaped liquid guiding protrusion 11 is 60° to 180°, specifically, the arc of the arc-shaped liquid guiding protrusion 11 is 75°. Both ends of the cathode plate 4 abut against t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com