Treatment system and method for separating uranyl ions in concentrated nitric acid system by adopting membrane technology

A technology of uranyl ion and treatment system, which is applied to the field of treatment system of uranyl ion under membrane technology separation and concentrated nitric acid system, can solve the problems of increasing operating pressure, inability to operate, and difficulty in reaching concentrated materials, and achieves improved removal efficiency and reduced The effect of operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

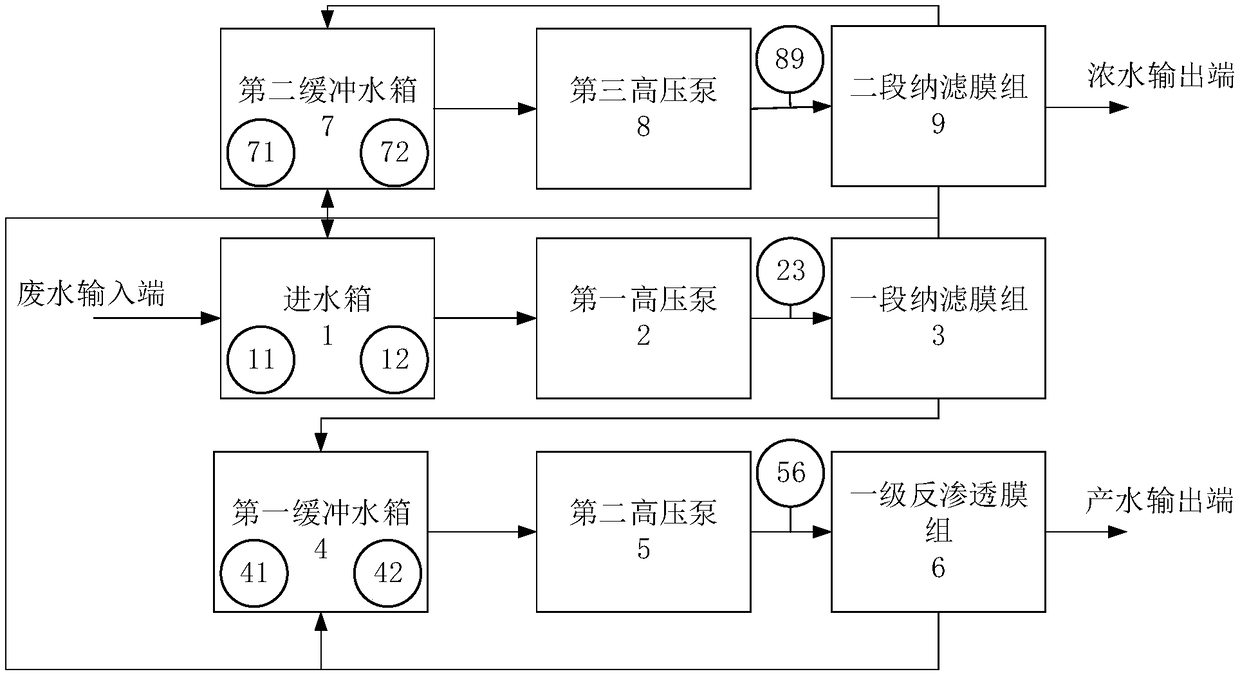

[0058] This case uses this system to treat acidic uranium-containing waste liquid with a uranyl ion concentration of 20g / L and a volume of 1m3.

[0059] The volume of the inlet tank, the first buffer tank and the second buffer tank is set to 1.5m 3 、1.5m 3 、0.5m 3 ; The processing flow rate of the first feedwater pump and the first high-pressure pump is 4m 3 / h, the heads are 30m and 300m respectively; the processing flow rate of the second feed water pump and the second high pressure pump are both 3m 3 / h, the heads are 30m and 400m respectively; the processing flow rate of the third feed water pump and the third high pressure pump are both 1m 3 / h, the heads are 30m and 600m respectively. When the liquid level gauge is at a high level, the water volumes of the inlet tank, the first buffer tank and the second buffer tank are 1.3m respectively 3 、1.0m 3 and 0.3m 3 , when the liquid level gauge is at a low level, the water volumes of the inlet tank, the first buffer tank...

Embodiment example 2

[0063] This case uses this system to treat acidic uranium-containing waste liquid with a uranyl ion concentration of 50g / L and a volume of 1m3.

[0064] The volume of the inlet tank, the first buffer tank and the second buffer tank is set to 2.0m 3 、1.5m 3 、0.7m 3 ; The processing flow rate of the first feedwater pump and the first high-pressure pump is 4m 3 / h, the heads are 30m and 600m respectively; the processing flow rate of the second feed water pump and the second high pressure pump are both 3m 3 / h, the heads are 30m and 400m respectively; the processing flow rate of the third feed water pump and the third high pressure pump are both 1m 3 / h, the heads are 30m and 800m respectively. When the liquid level gauge is at a high level, the water volumes of the inlet tank, the first buffer tank and the second buffer tank are 1.6m respectively 3 、1.2m 3 and 0.4m 3 , when the liquid level gauge is at a low level, the water volumes of the inlet tank, the first buffer tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com