Preparation method of super absorbent resin under high salt concentration

A technology of superabsorbent resin and high salt concentration, applied in absorbent pads, medical science, bandages, etc., can solve the problems of no patent report on the absorption characteristics of superabsorbent resin, strong carcinogenicity of acrylamide, and large safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

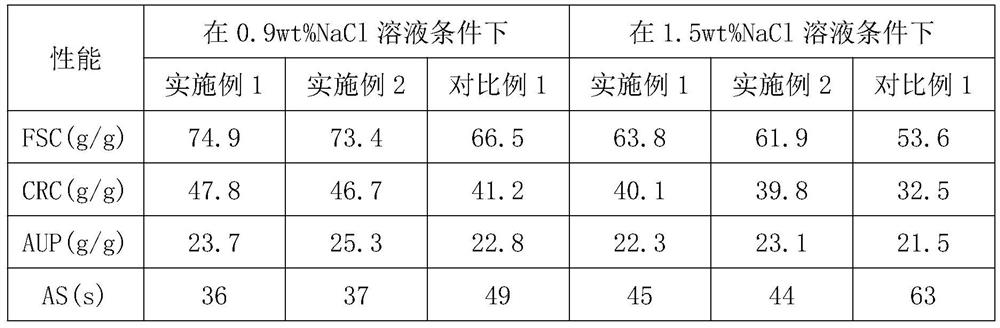

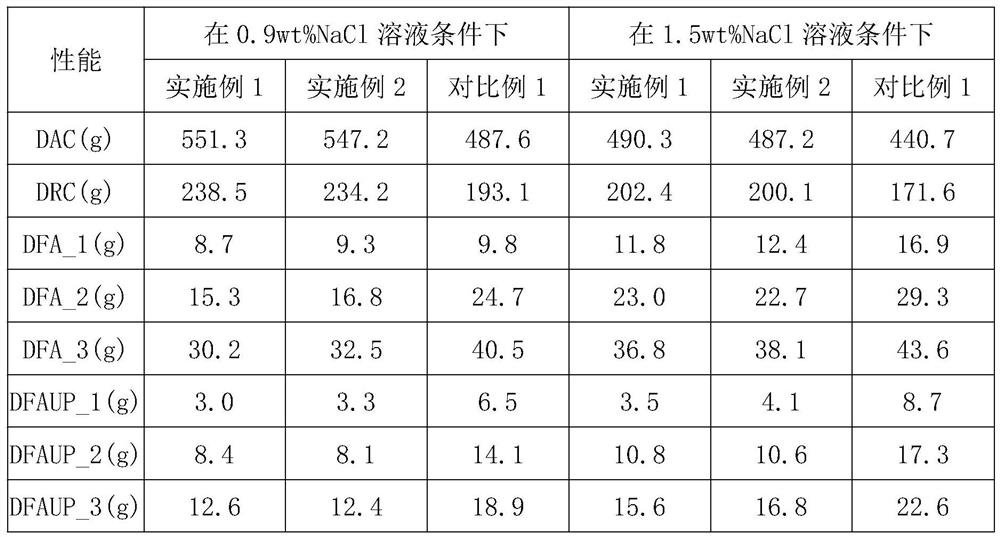

Examples

Embodiment 1

[0059] A preparation method of superabsorbent resin under high salt concentration, comprising the following preparation steps:

[0060] a) Add 42.78 parts of deionized water to 100.00 parts of high-purity acrylic acid, slowly add 135.31 parts of 32wt% NaOH aqueous solution, and control the neutralization temperature at 30-40°C to obtain a monomer concentration of 44.5% and a neutralization degree of 78%. monomer solution.

[0061] b) Then add 3.000 parts of 35% acidic silicon dioxide solution, 0.515 parts of polyethylene glycol (400) diacrylate, 0.835 parts of polyethylene glycol (1000) diacrylate, and polyoxyethylene sorbate to the monomer solution. Anhydrous sugar-alcohol monostearate 150ppm, fully stir and mix evenly.

[0062] c) Heating the reaction solution to 80° C., then adding 2.880 parts of 5% sodium persulfate solution, and simultaneously feeding 1 L / min of high-purity nitrogen into the reaction solution until the reaction solution thickens.

[0063] d) The gel obt...

Embodiment 2

[0065] A preparation method of superabsorbent resin under high salt concentration, comprising the following preparation steps:

[0066] a) Add 37.58 parts of deionized water to 100.00 parts of high-purity acrylic acid, slowly add 138.77 parts of 32wt% NaOH aqueous solution, and control the neutralization temperature at 30-40°C to obtain a monomer concentration of 45% and a neutralization degree of 80%. monomer solution.

[0067] b) Then add 3.000 parts of 35% acidic silicon dioxide solution, 0.554 parts of polyethylene glycol (400) diacrylate, 0.646 parts of polyethylene glycol (600) diacrylate, polyoxyethylene sorbate to the monomer solution Anhydrous sugar-alcohol monostearate 150ppm, fully stir and mix evenly.

[0068] c) Heating the reaction solution to 78°C, then adding 3.244 parts of 5% sodium persulfate solution, 16% Na 2 CO 3 1.800 parts of solution;

[0069] d) The gel obtained after the reaction is granulated, dried, ground, sieved, and surface treated sequential...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com