Fruit pulp preservation method and application thereof

A fresh-keeping method and fruit technology, applied in the field of food processing, can solve the problems of color browning, taste distortion, flavor reduction, etc., and achieve the effects of retaining flavor and taste, reducing osmotic pressure difference, and avoiding slow sales.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

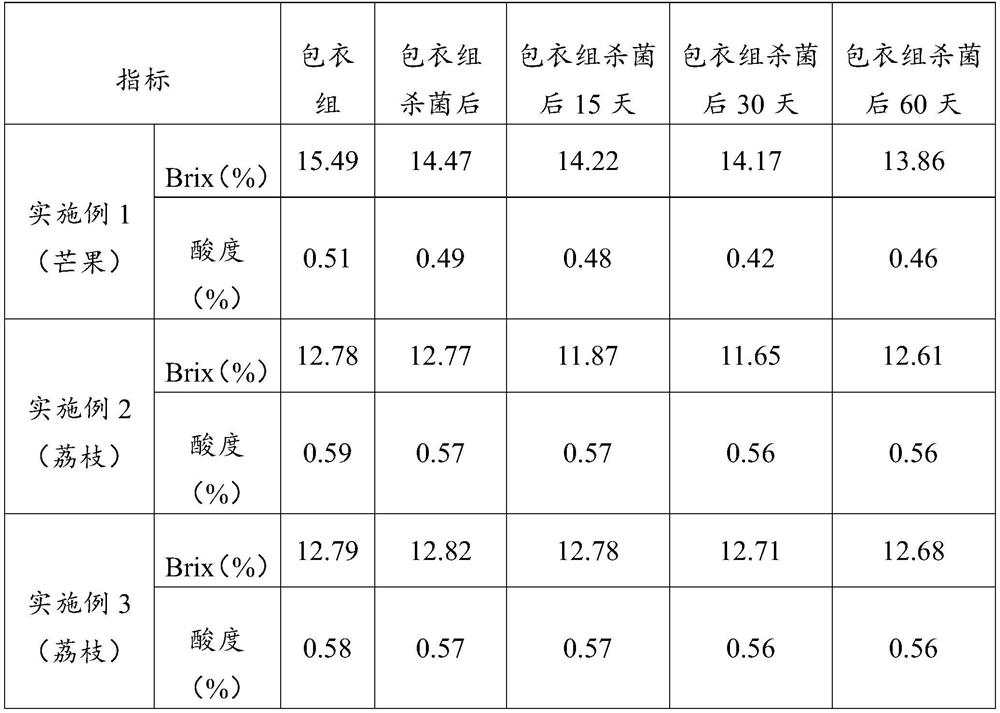

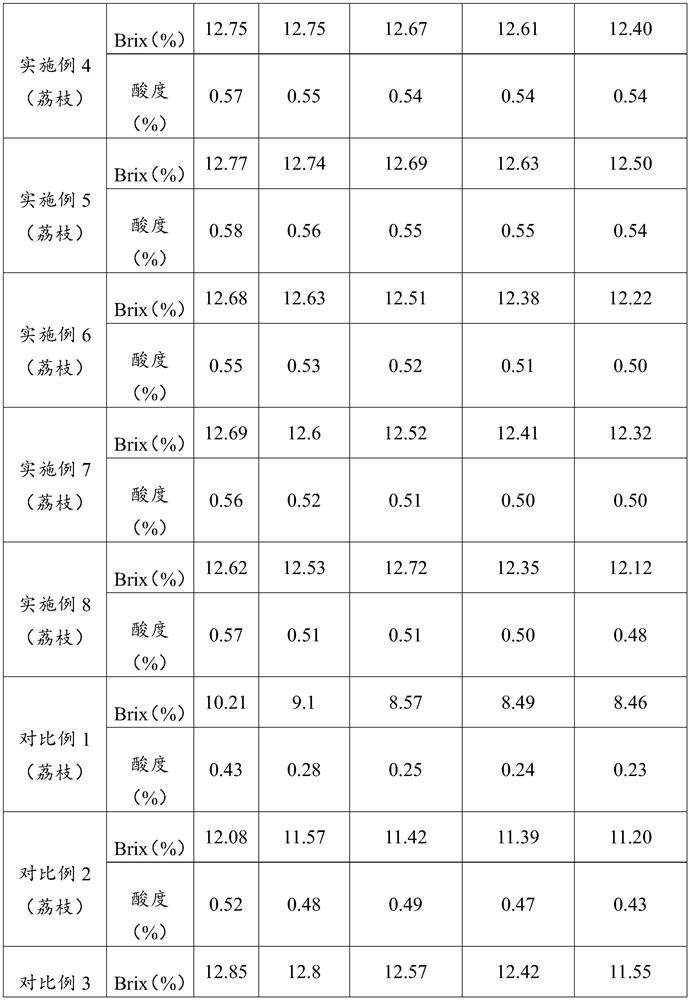

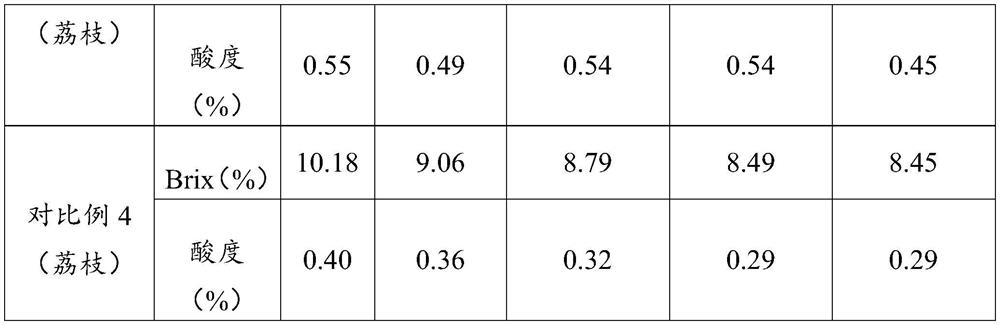

Examples

Embodiment 1

[0025] A method for preserving fruit pulp, comprising the following steps:

[0026] (1) Mango is peeled and cored and cut into pieces to obtain fruit pulp, which is immersed in a calcium salt solution (food grade calcium lactate, the mass concentration of the calcium salt solution is 1%, and the temperature of the calcium salt solution is 25° C.) after vacuum treatment, the Continue soaking the fruit pulp after vacuum treatment, soaking time 60min, the vacuum degree of vacuum treatment is 0.06-0.08Mpa, and the time of vacuum treatment is 30s;

[0027] (2) Immerse the fruit pulp treated in step (1) into a compound thickener solution; the compound thickener includes the following components by weight: 85 parts of sodium alginate, 10 parts of curdlan, carrageenan 5 parts, the mass concentration of the compound thickener solution is 0.5%, the viscosity of sodium alginate is 500mpa.s, and the pulp soaking time is 5min;

[0028] (3) Immersing the fruit pulp treated in step (2) into...

Embodiment 2

[0030] A method for preserving fruit pulp, comprising the following steps:

[0031] (1) Litchi is peeled and cored and divided into two to obtain fruit pulp, which is then vacuum-treated after being immersed in a calcium salt solution (calcium chloride solution, the mass concentration of the calcium salt solution is 2.8%, and the temperature of the calcium salt solution is 15° C.) , continue soaking the fruit pulp after vacuum treatment, the soaking time is 60min, the vacuum degree of vacuum treatment is 0.06-0.08Mpa, and the time of vacuum treatment is 60s;

[0032] (2) Immerse the fruit pulp treated in step (1) into a compound thickener solution; the compound thickener includes the following components by weight: 85 parts of sodium alginate, 10 parts of curdlan, carrageenan 5 parts, the mass concentration of the compound thickener solution is 1.5%, the viscosity of sodium alginate is 200mpa.s, and the pulp soaking time is 3min;

[0033] (3) Immerse the fruit pulp treated in...

Embodiment 3

[0035] A method for preserving fruit pulp, comprising the following steps:

[0036] (1) The litchi is peeled and pitted and divided into two to obtain the fruit pulp, which is immersed in a calcium salt solution (food grade calcium lactate, the mass concentration of the calcium salt solution is 1.5%, and the temperature of the calcium salt solution is 25° C.) after vacuum treatment , continue soaking the fruit pulp after the vacuum treatment, the soaking time is 45min, the vacuum degree of the vacuum treatment is 0.06-0.08Mpa, and the time of the vacuum treatment is 45s;

[0037] (2) Immerse the fruit pulp treated in step (1) into a compound thickener solution; the compound thickener includes the following components by weight: 85 parts of sodium alginate, 10 parts of curdlan, carrageenan 5 parts, the mass concentration of the compound thickener solution is 1.5%, the viscosity of sodium alginate is 370mpa.s, and the pulp soaking time is 4min;

[0038] (3) Immerse the fruit pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com