Patents

Literature

82results about How to "Preserve the taste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

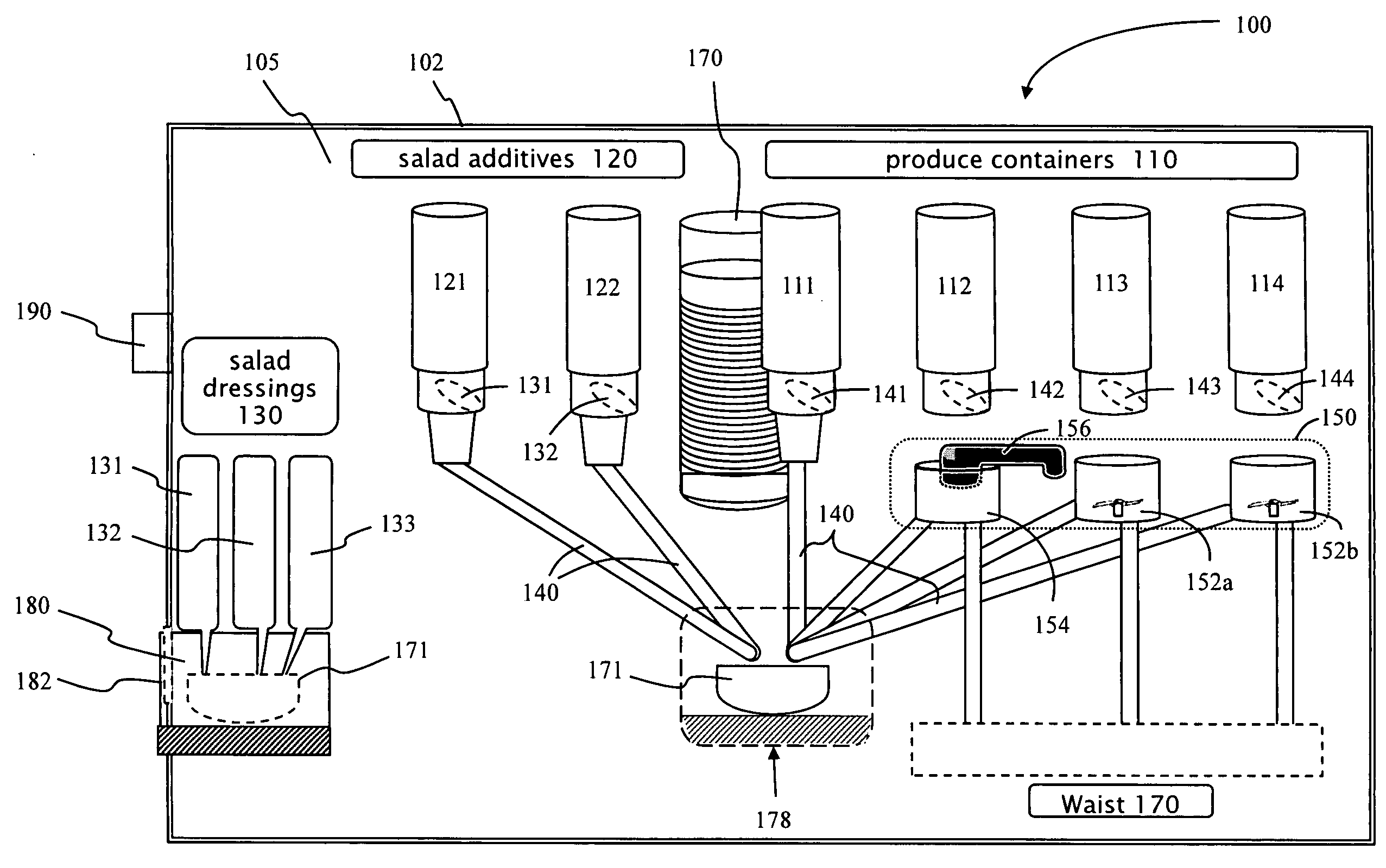

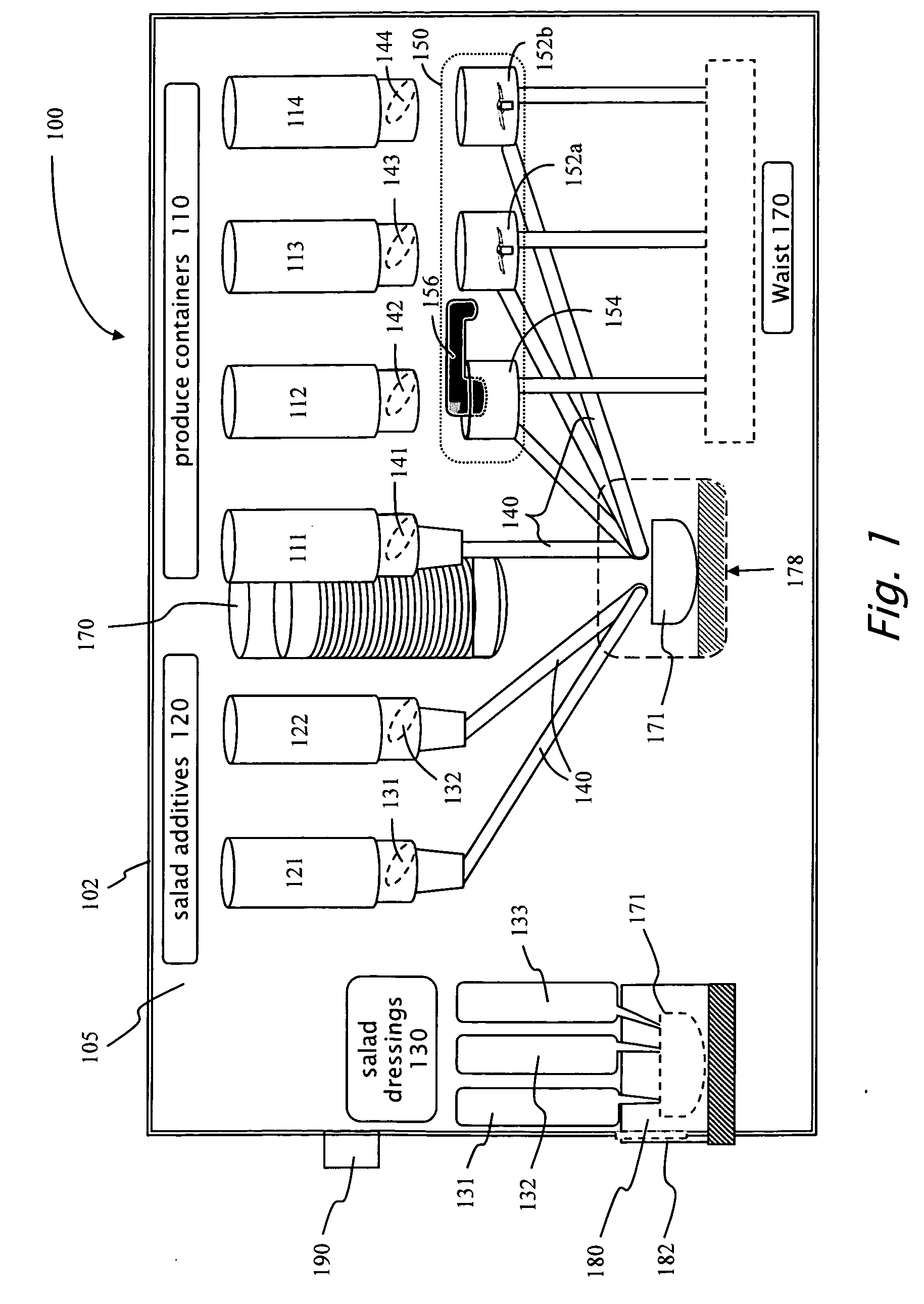

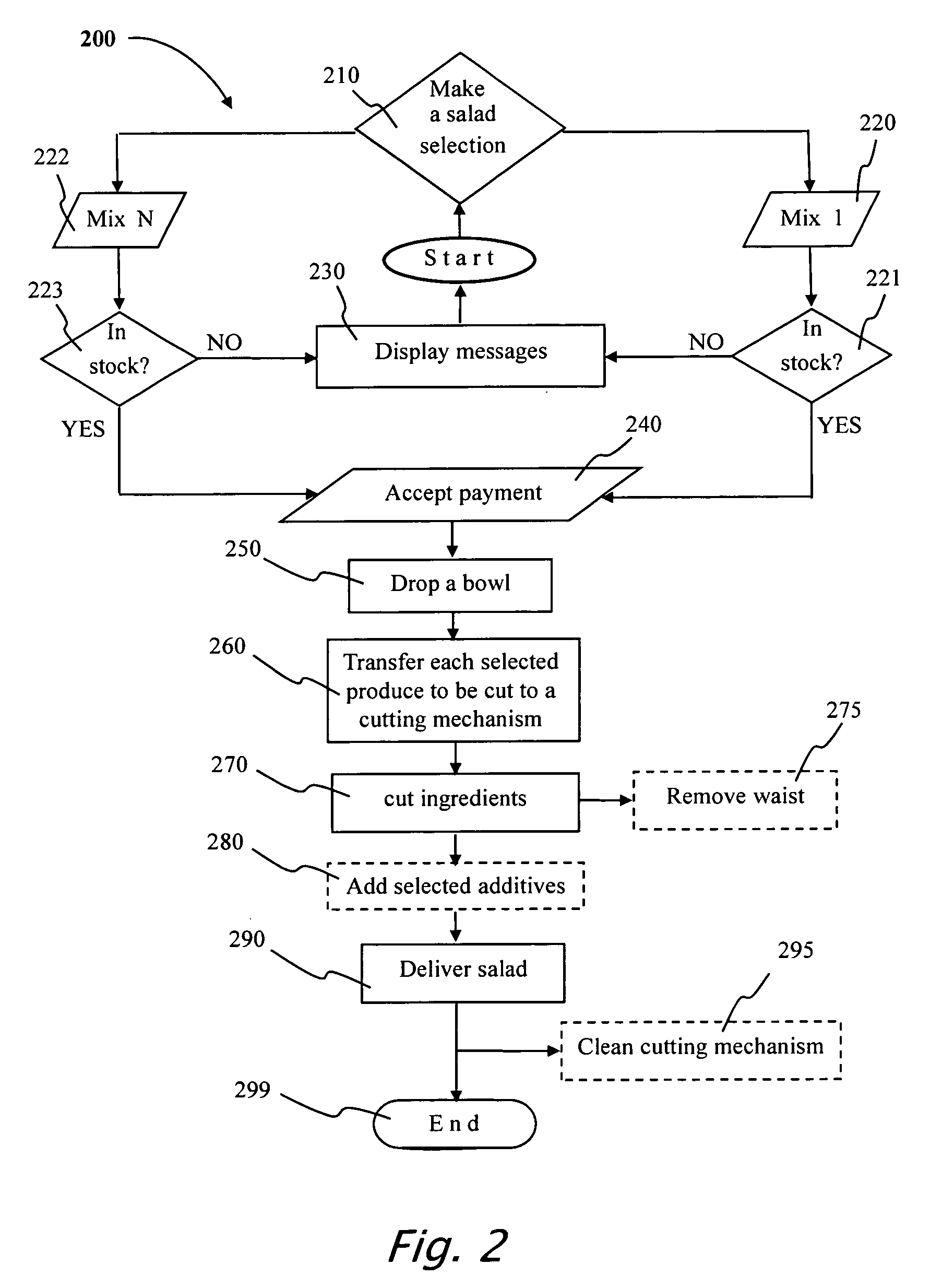

Vending apparatus for dispensing made-to-order salads

InactiveUS20080314918A1Preserve nutritional valuePreserve the tasteRacksCoin-freed apparatus detailsEngineeringSalad dressing

Vending machines for freshly cut and prepared-to-order salads, including containers containing produce products, salad additives and salad dressings. A vending machine can provide a user with a salad of vegetables and / or fruits, that are freshly cut and prepared, and that is made-to-order. Freshly cut and prepared salads preserve their nutritional value, taste and the user selects only items to his liking.

Owner:NURIELY ERAN

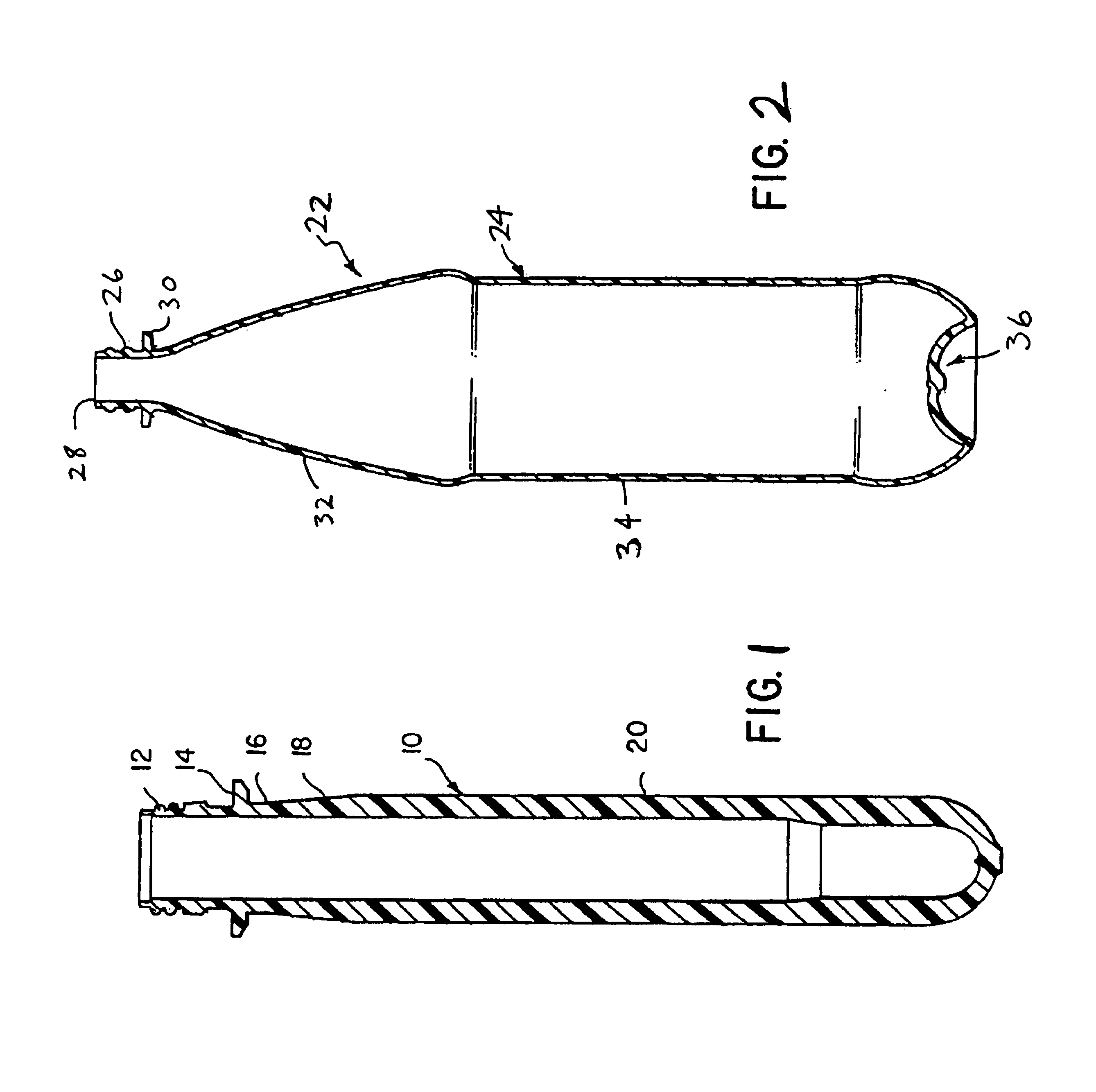

Polyester composition and articles with reduced acetaldehyde content and method using hydrogenation catalyst

A polyester composition with reduced acetaldehyde concentration comprising polyester, at least one hydrogenation catalyst, and at least one source of reactive hydrogen. A method for making the polyester composition is also disclosed along with polyester articles made with the polyester composition. Suitable articles include containers such as bottles. A packaged beverage comprising a container made with the polyester composition is disclosed.

Owner:THE COCA-COLA CO

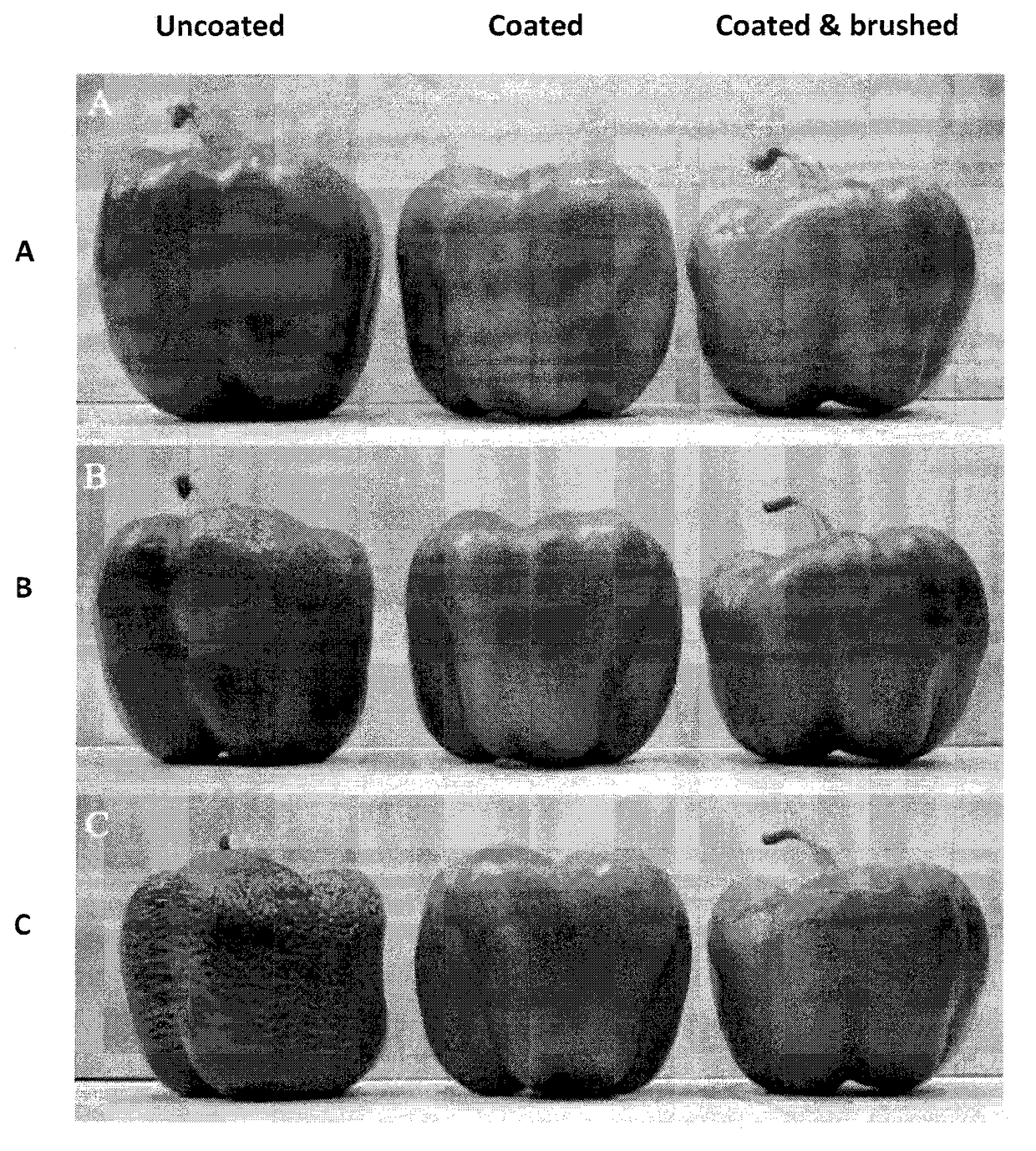

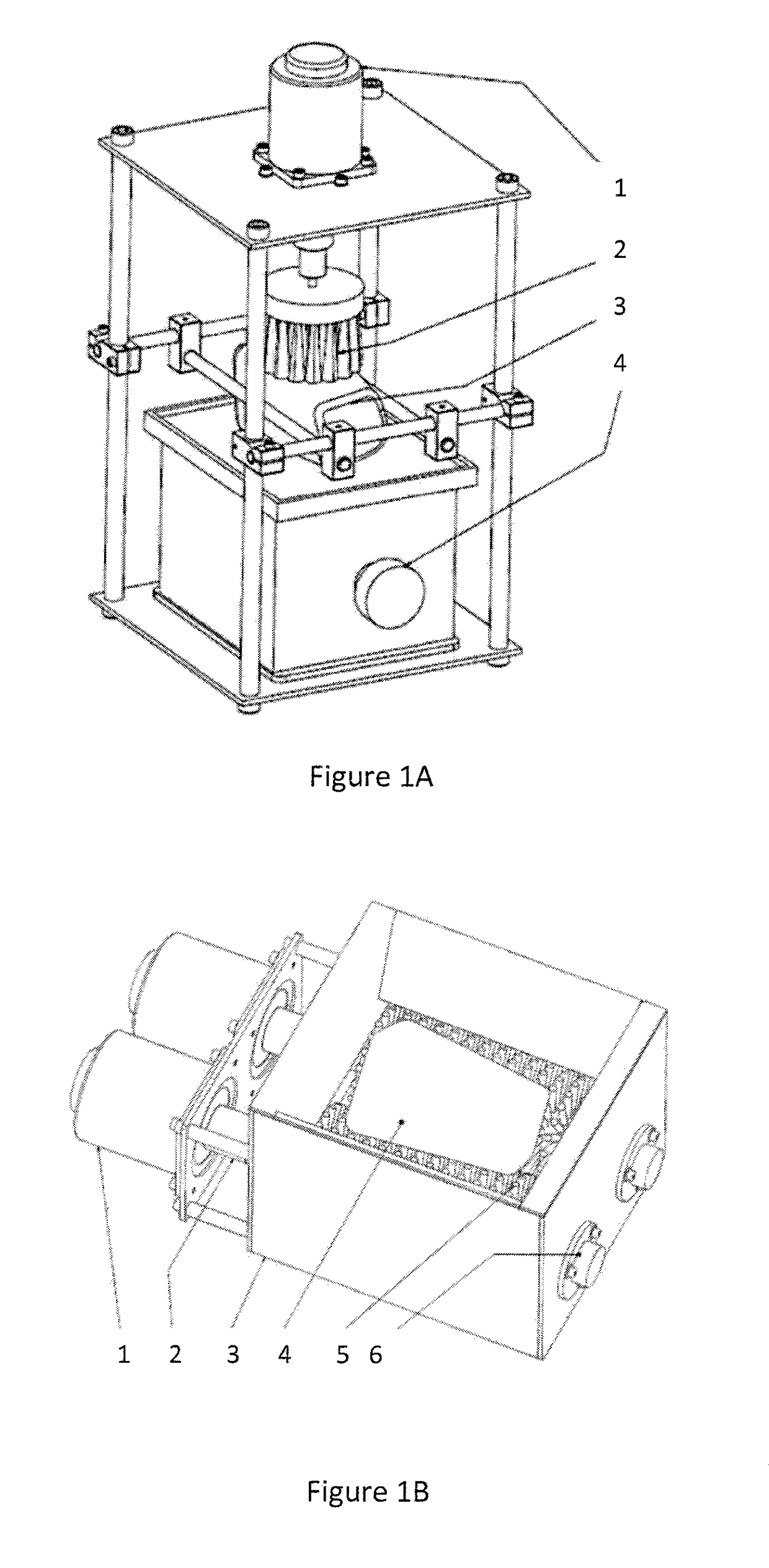

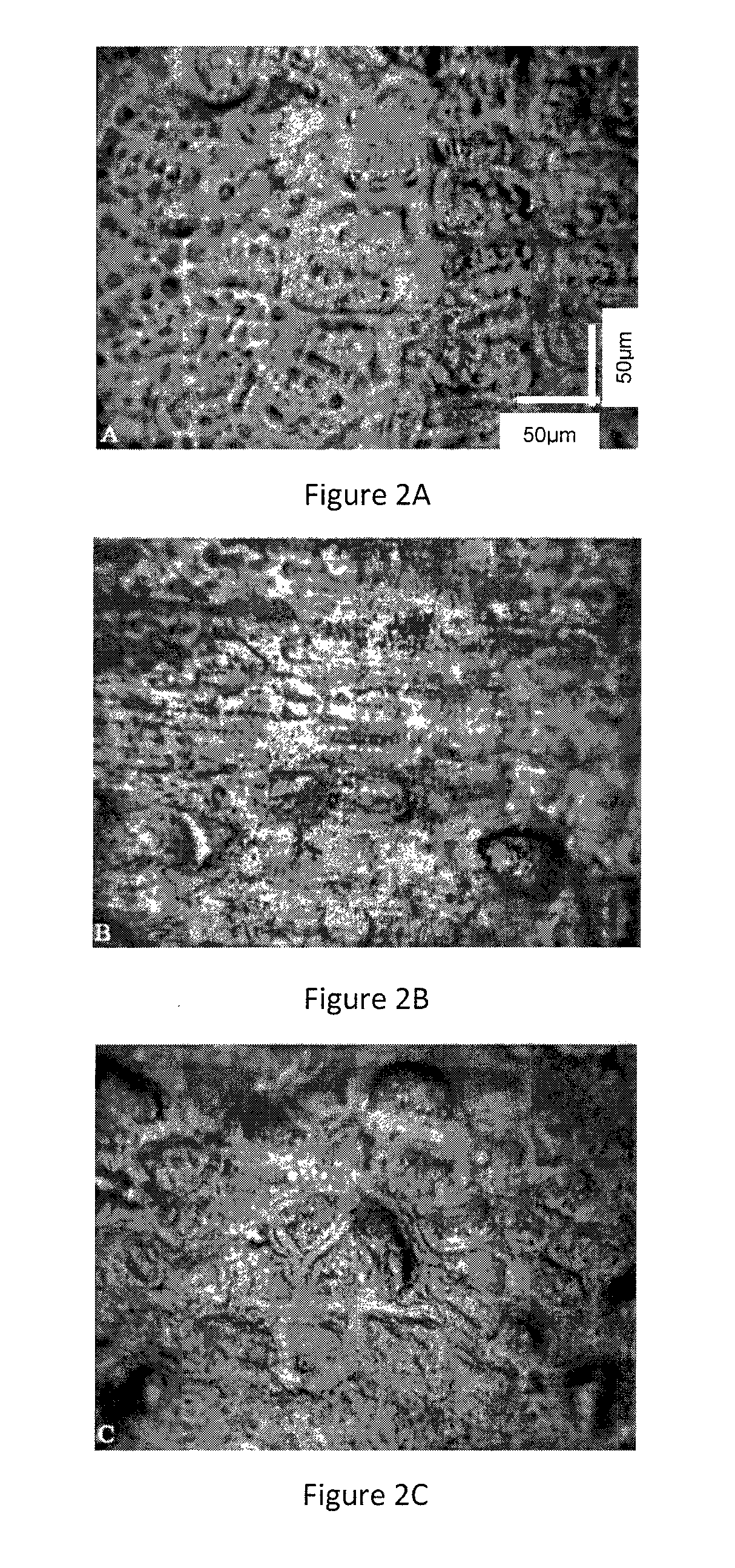

Edible coating for plant matter

ActiveUS20150079248A1High natural glossLimited water reservoir capacityDead plant preservationDough treatmentWaxColloid

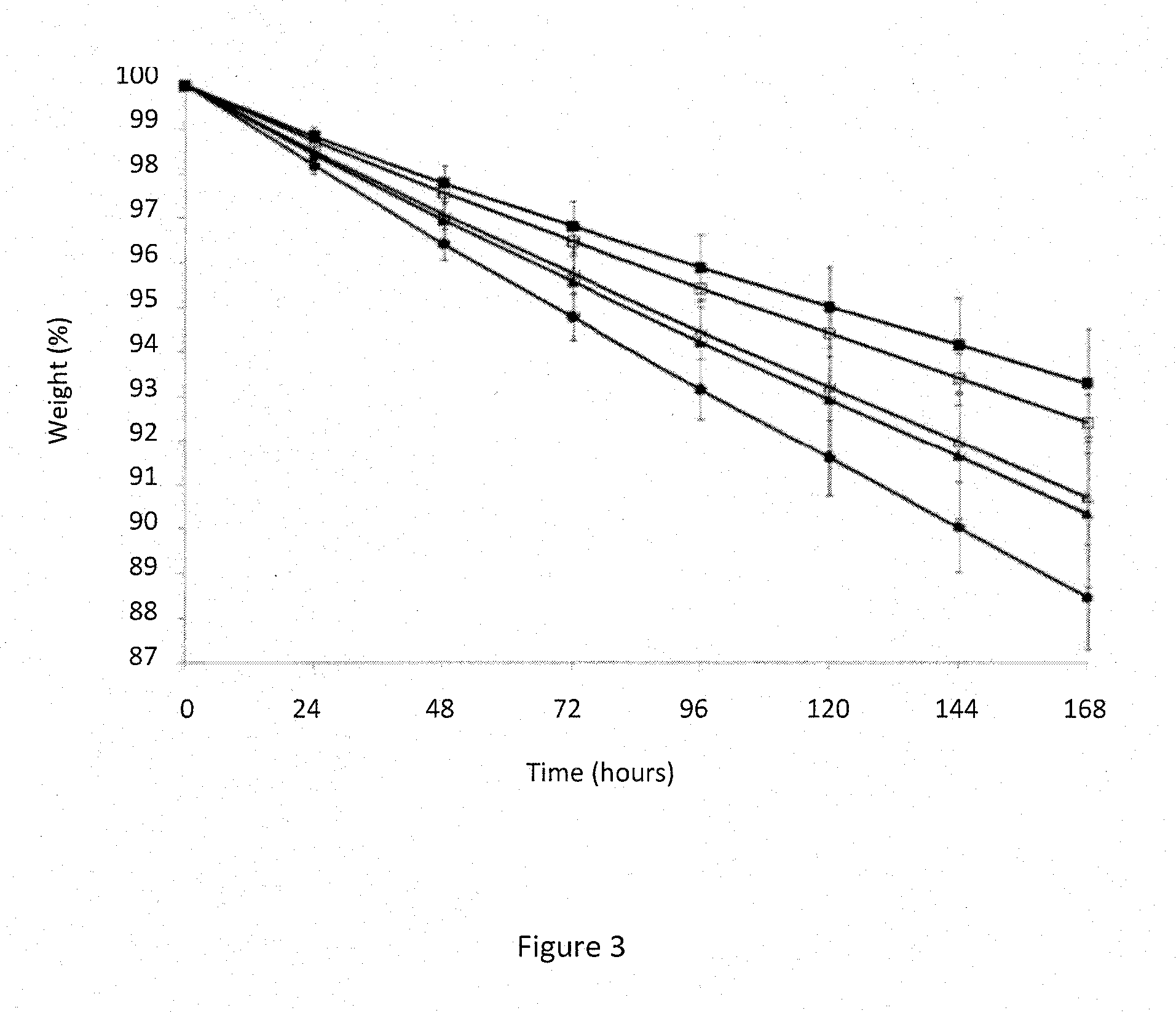

The present invention discloses composition and methods for reducing the weight loss and / or preserving the natural gloss of post-harvest edible plant matter. In particular, the methods comprising applying to the surface of the plant matter a composition comprising an edible wax having a melting temperature below 70° C.; a hydrocolloid; a fatty acid; an emulsifier; and water, wherein said edible wax is present in a weight percent ranging from about 10% to about 25% of the total weight of the composition.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

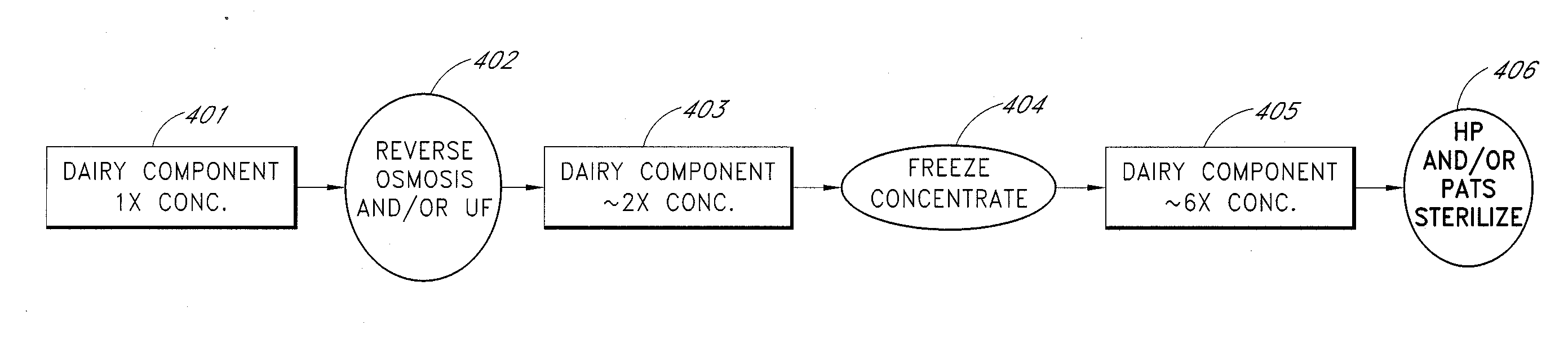

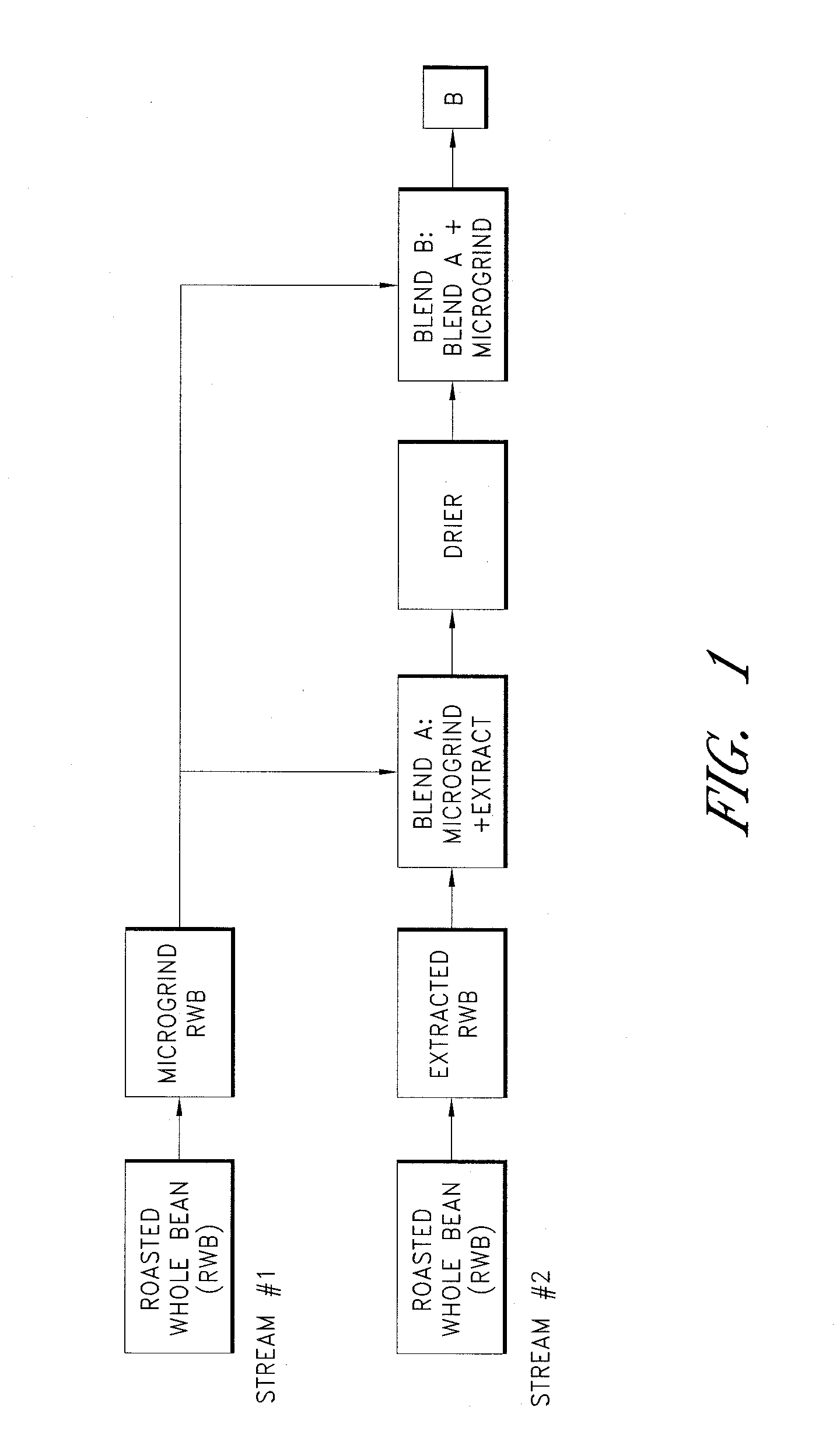

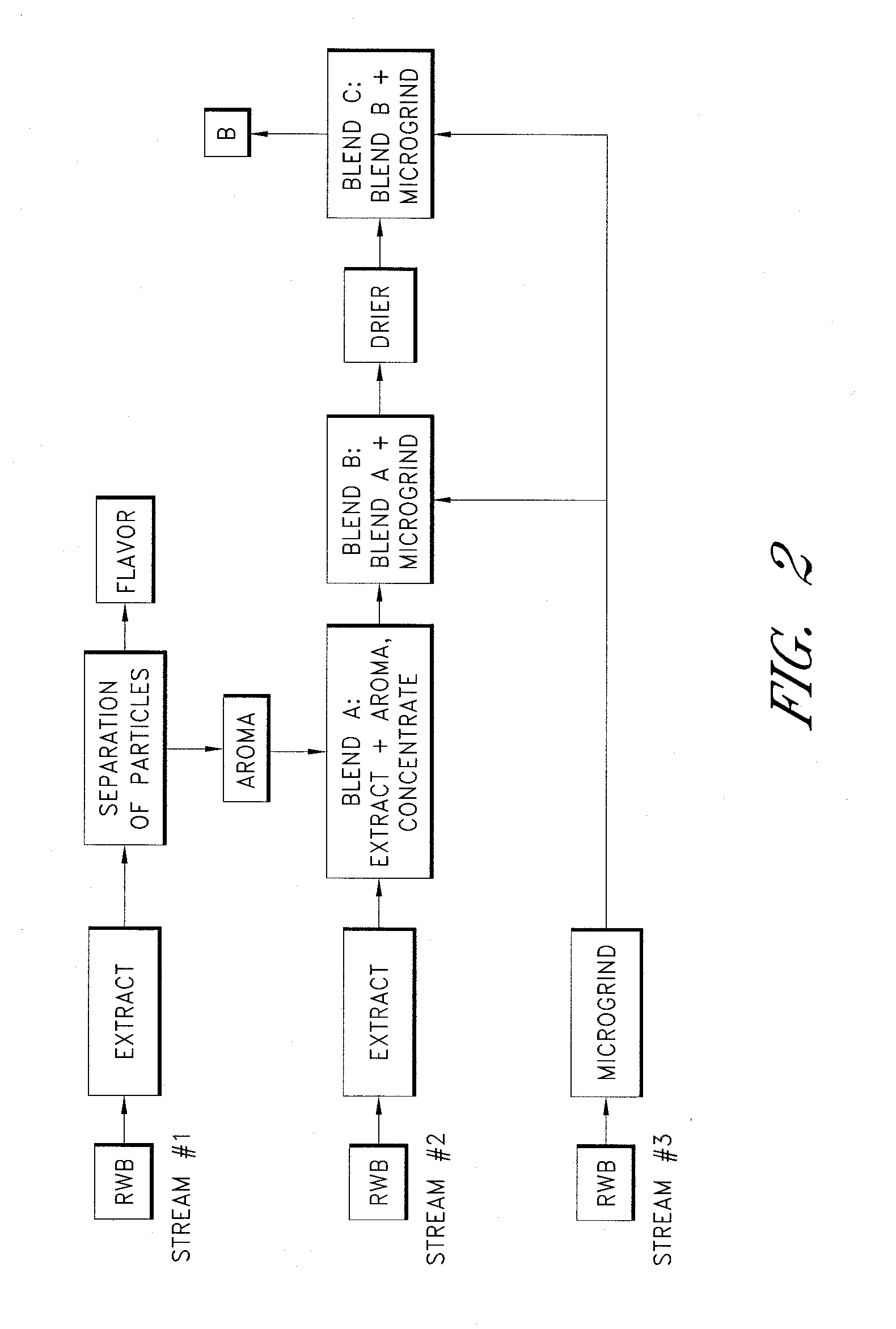

Dairy containing beverages with enhanced flavors and method of making same

InactiveUS20110135803A1Preserve the tastePreserve mouthfeelMilk preparationRoasted coffee treatmentFood flavorMilk products

Owner:STARBUCKS

Method for preparing blowfish can

InactiveCN101301092AAccelerateHigh temperature control accuracyFish washing/descalingMeat/fish preservation by heatingNutrientPre treatment

The invention relates to a method for making globe fish can, including the following steps: material preprocessing, cutting, soup stock production, mixing, canning, pre-boiling, sealing, sterilization, cooling, casing. The key technology of the method is adopting the wave-type hot water injection of an automatic spraying sterilizer and the temperature rise regulating sterilization in multi-stage. The making method has a strict and general sterilization to the globe fish materials, makes use of the advanced processing devices, temperature rise regulating sterilization in multi-stage and reasonable making technology. The can products are not only safe, nutrient, but also maintain the natural taste of the globe fish.

Owner:刘烈

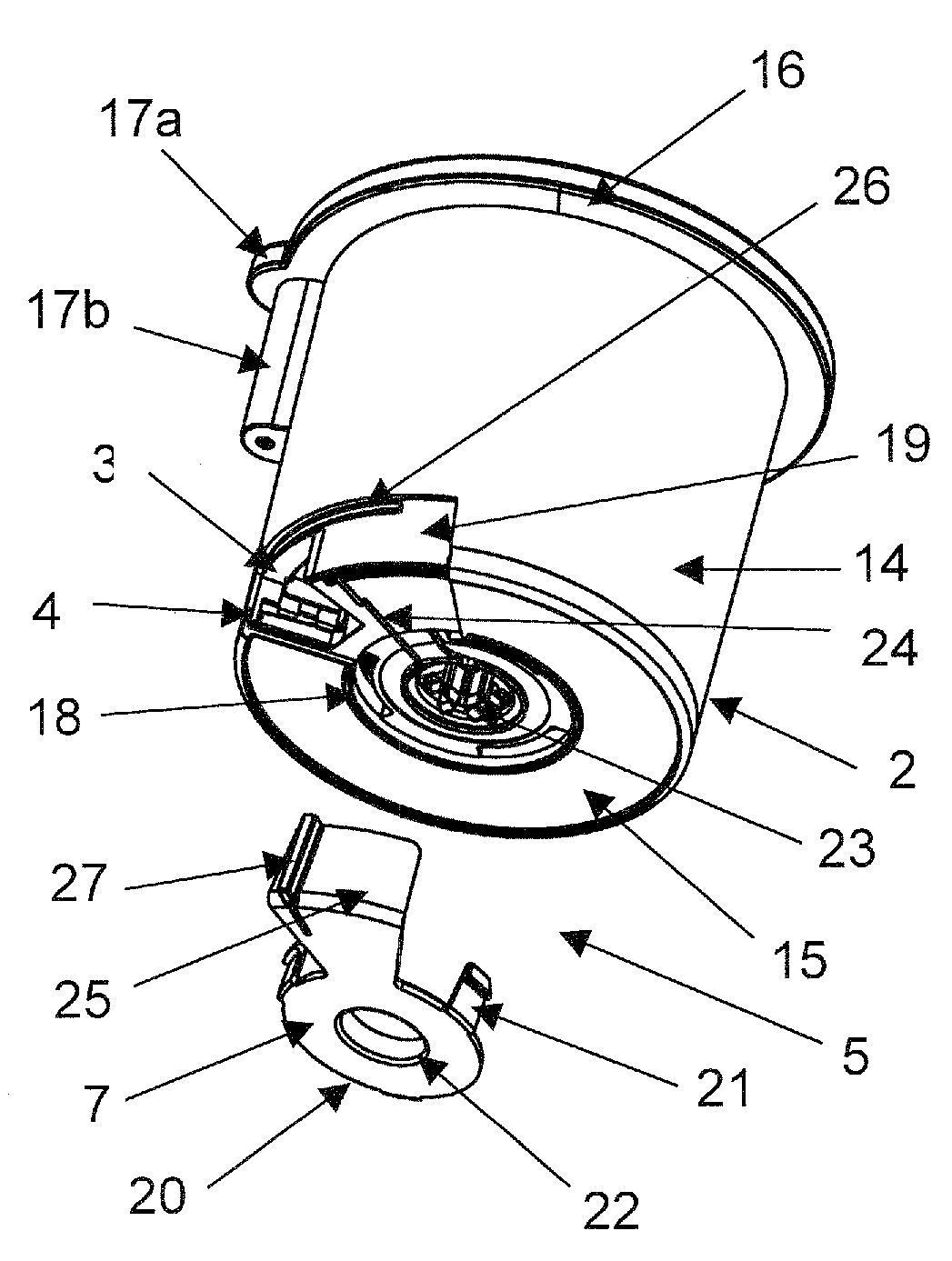

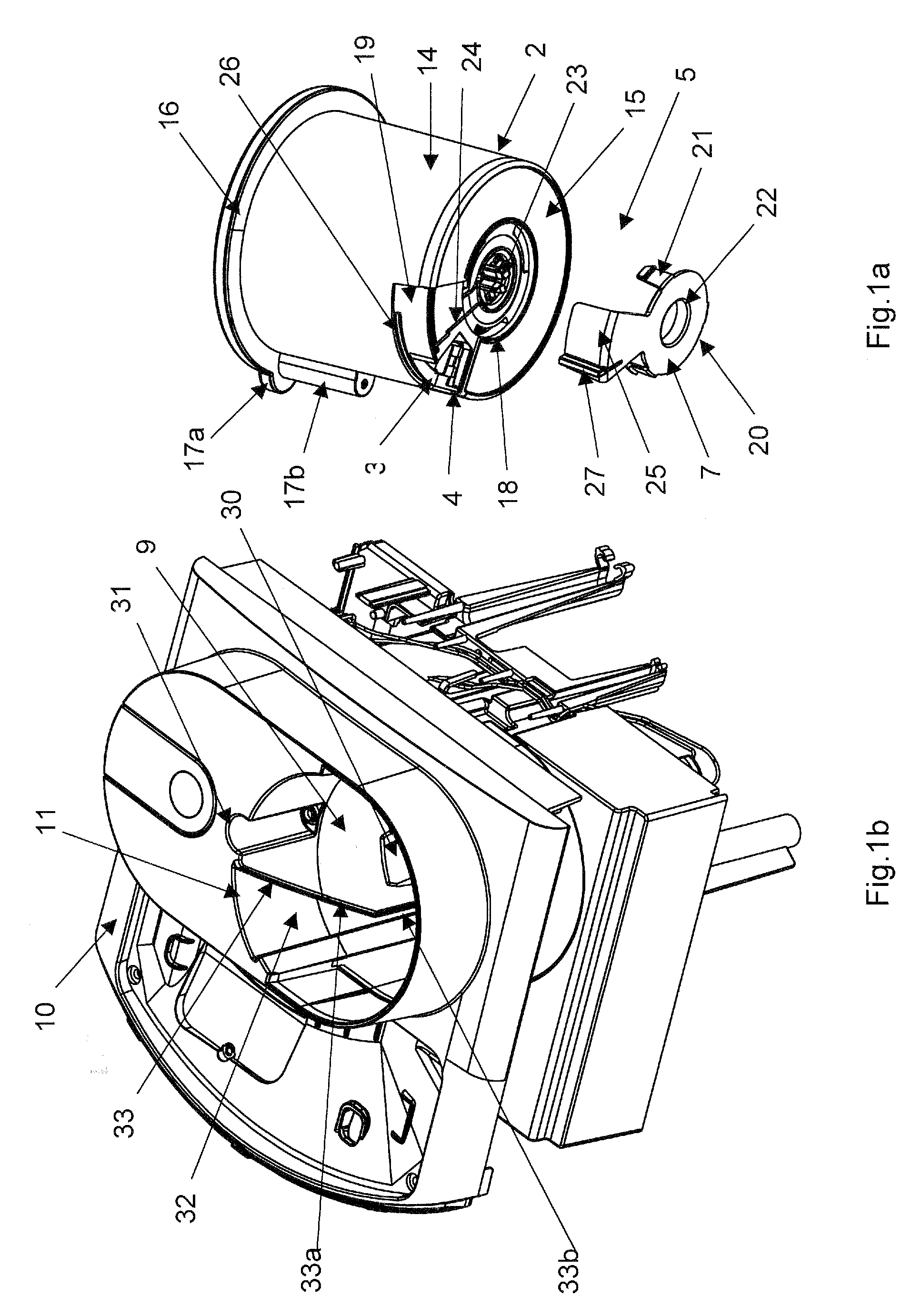

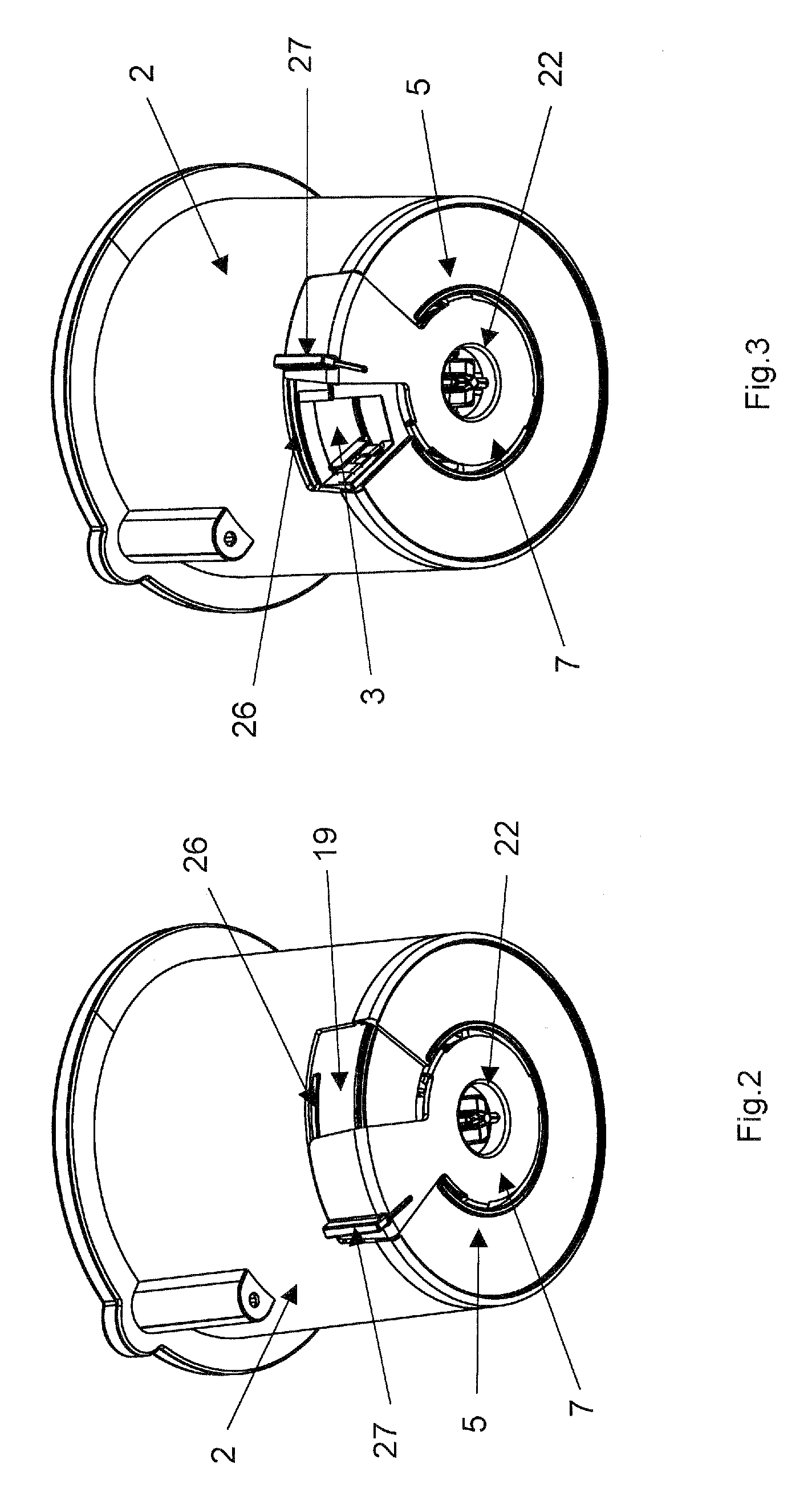

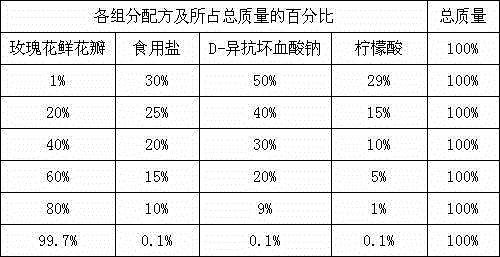

Dispenser of powdered product having a removable reservoir

InactiveUS20070290003A1Reduce riskPreserve the tasteClosuresMovable measuring chambersLinear motionEngineering

A dispenser of a product in powder from, composed of: a case delimiting a housing; a reservoir removably installed in the housing, the reservoir being adapted to contain the product in powder form and having a dispensing orifice; and a device for obturating the dispensing orifice. The device has a blocking member in the form of a shutter mounted to the reservoir for movement between a position for closing the dispensing orifice and a position for opening the dispensing orifice. The housing, the reservoir and the device are constructed to enable the reservoir to be installed in the housing by a vertical linear movement and to cause automatic movement of the shutter from the position for closing to the position for opening in response to the vertical linear movement of the reservoir into the housing.

Owner:SEB SA

Packaging method for prolonging expiration date of cooked marinated products

ActiveCN103693295AExtended shelf lifeShelf life storagePackaging under vacuum/special atmosphereSealingOxygenRaw material

The invention discloses a packaging method for prolonging the expiration data of cooked marinated products, and relates to the technical field of food fresh keeping. The packaging method comprises the following steps of taking out raw materials and processing the raw materials into crude products; placing the crude products in brine to be marinated so as to obtain semi-finished cooked marinated products; placing the semi-finished cooked marinated products in an air-regulating packaging box after the semi-finished cooked marinated products are cooled down; and performing air-regulating packaging on the semi-finished cooked marinated products by using an air-regulating packaging machineso that the content of nitrogen in the air-regulating packaging box is 99%-100%. By using the packaging method, the expiration data of the cooked marinated products can be effectively prolonged, the nitrogen is inert gas, microorganisms in the packaging box is difficult to breed under the condition that the content of oxygen is lower than 1%, and growth of the microorganisms is effectively restrained; and after air-regulating packaging is performed on the cooked marinated products, the loss speed of flavor substances can be effectively reduced, and the cooked marinated products are clean and sanitary.

Owner:湖北周黑鸭食品工业园有限公司

Dairy containing beverages with enhanced flavors and method of making same

InactiveUS20120164299A1Preserve the tastePreserve mouthfeelMilk preparationMilk preservationChemistryMilk products

Owner:STARBUCKS

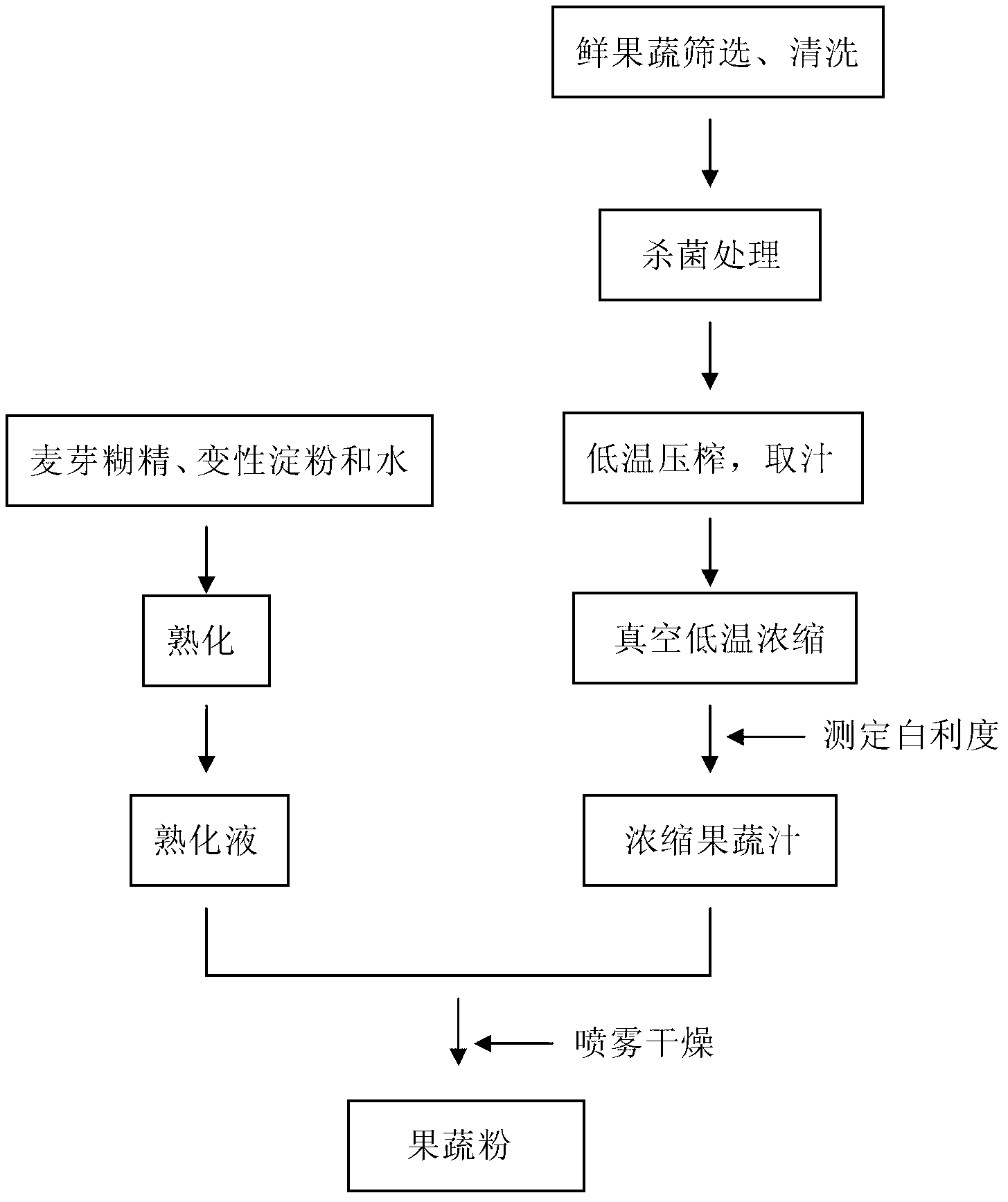

Spray drying type fruit and vegetable powder and preparing method thereof

The invention discloses spray drying type fruit and vegetable powder and a preparing method thereof. The spray drying type fruit and vegetable powder is prepared by concentrated fruit and vegetable juice, maltodextrin, modified starch and water through a spray drying method; and has the characteristics of developmental nutrition and good taste. The invention also discloses the preparing method of the spray drying type fruit and vegetable powder. The method can overcome the defects existing in the prior art, the extraction rate of the fruit and vegetable powder can be effectively improved, the shape of a product is improved, and the nutrition of the fruit and vegetable cannot be damaged.

Owner:天津市真如果食品工业有限公司

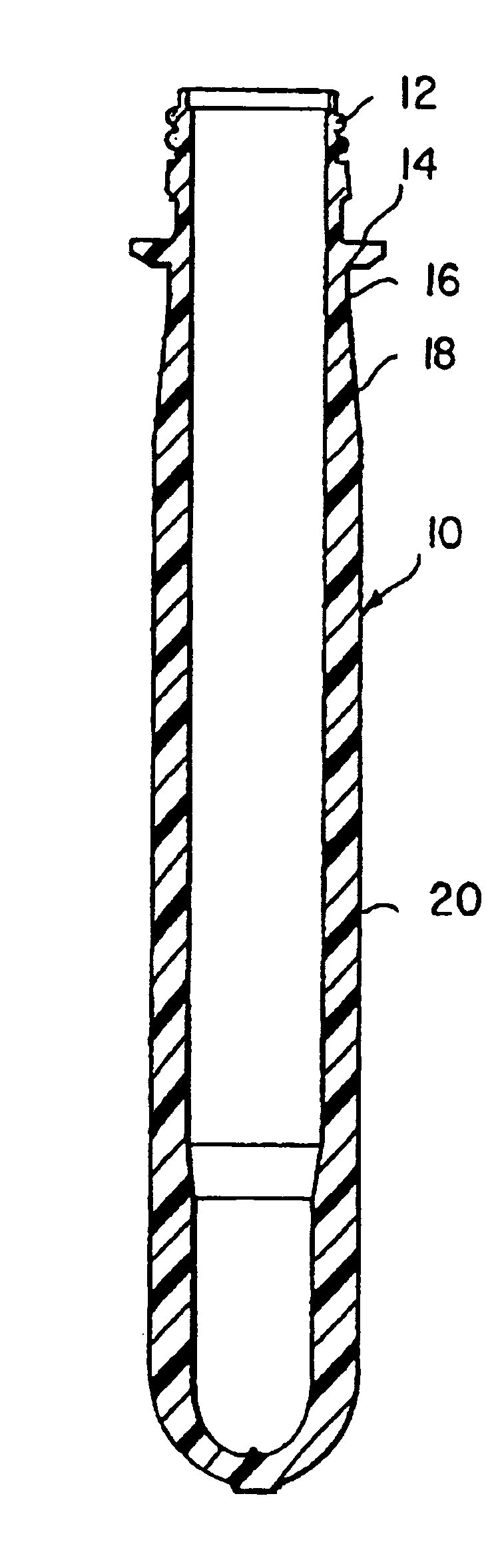

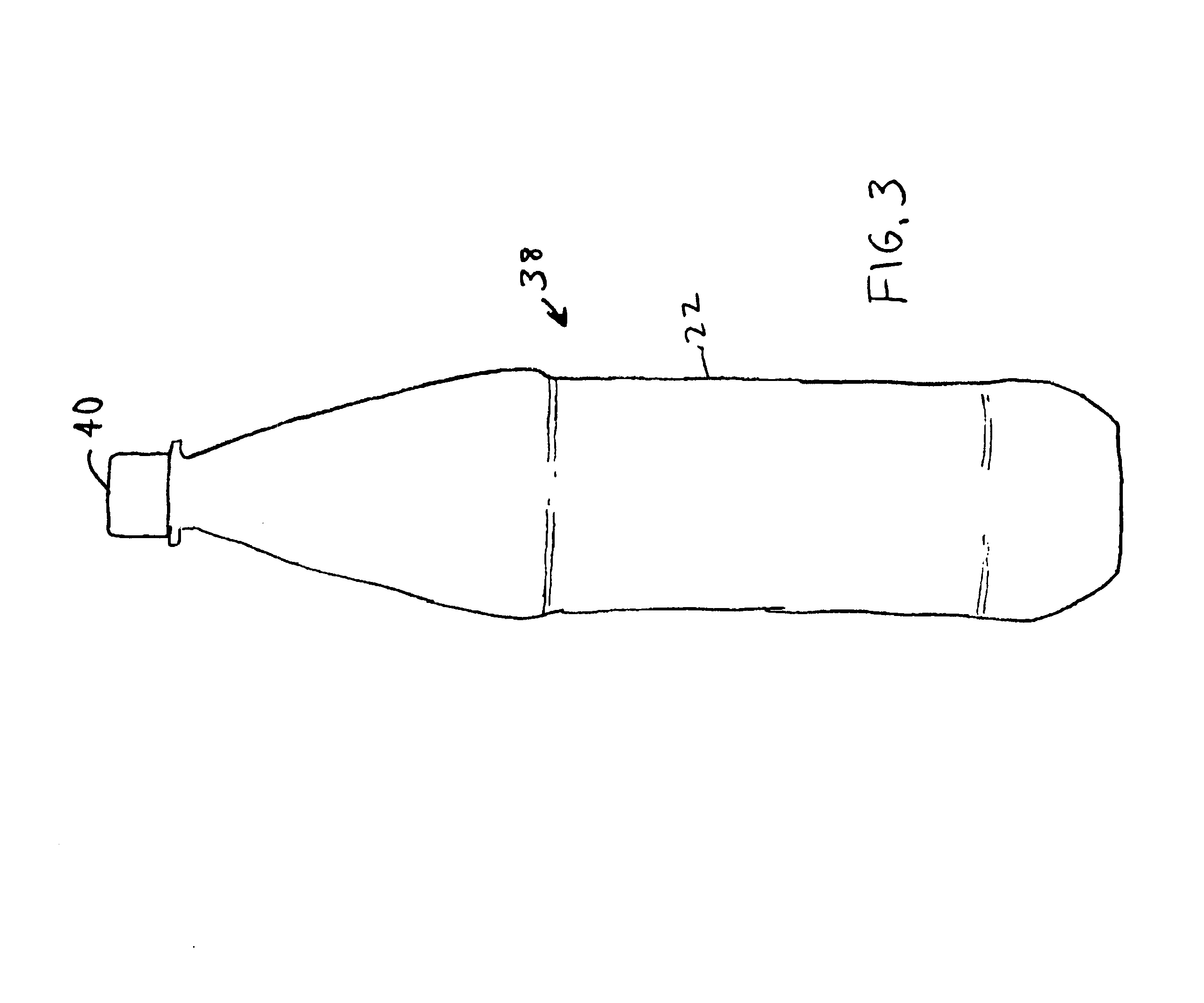

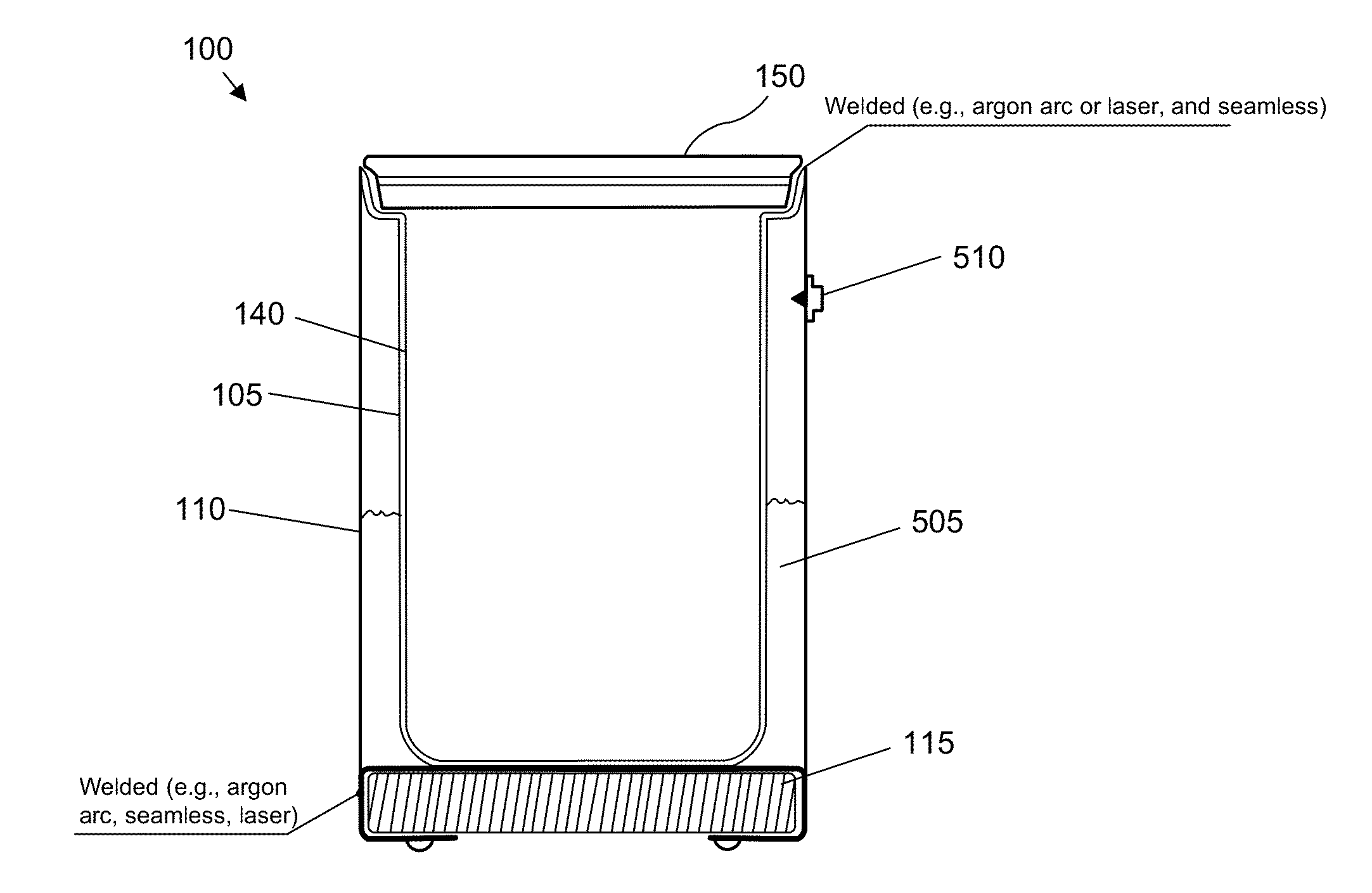

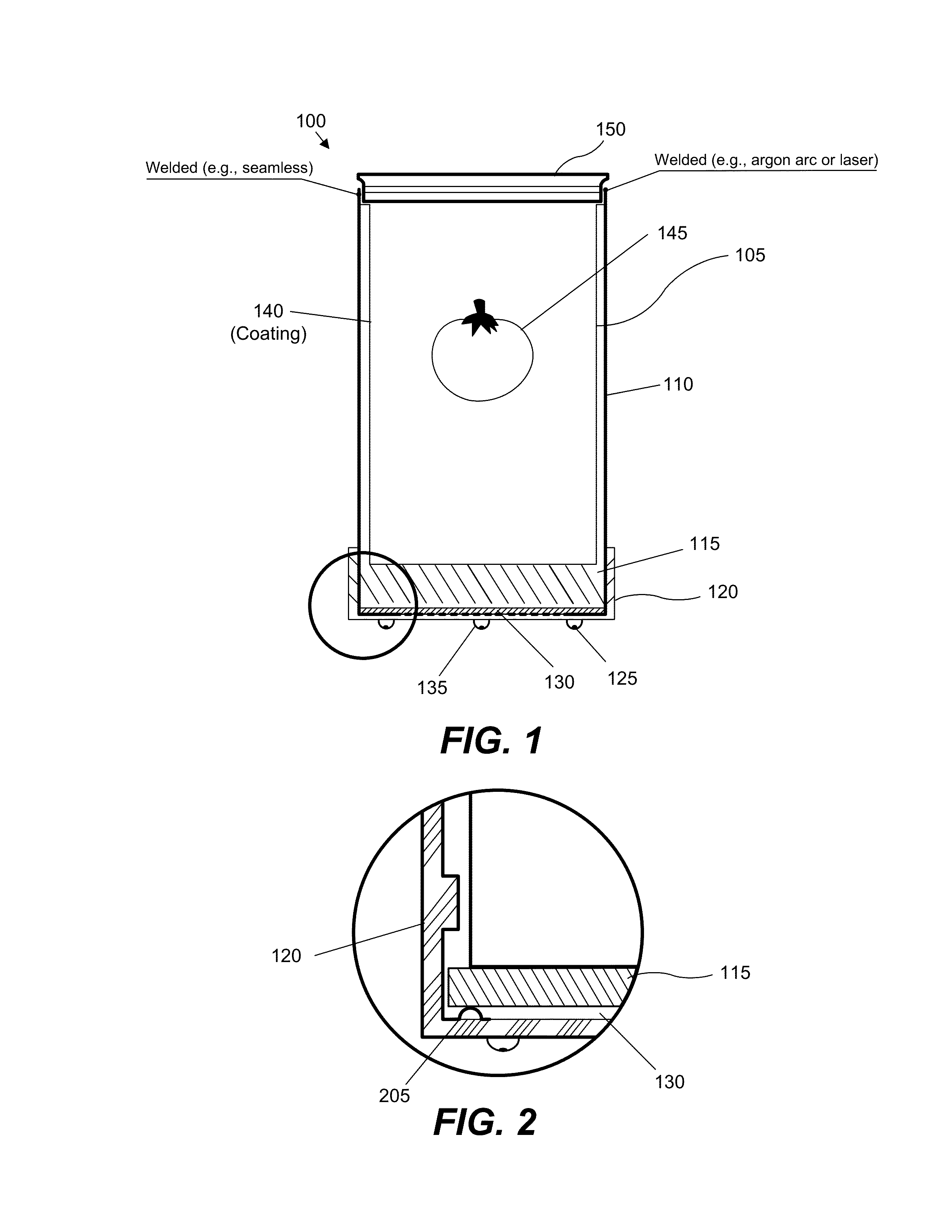

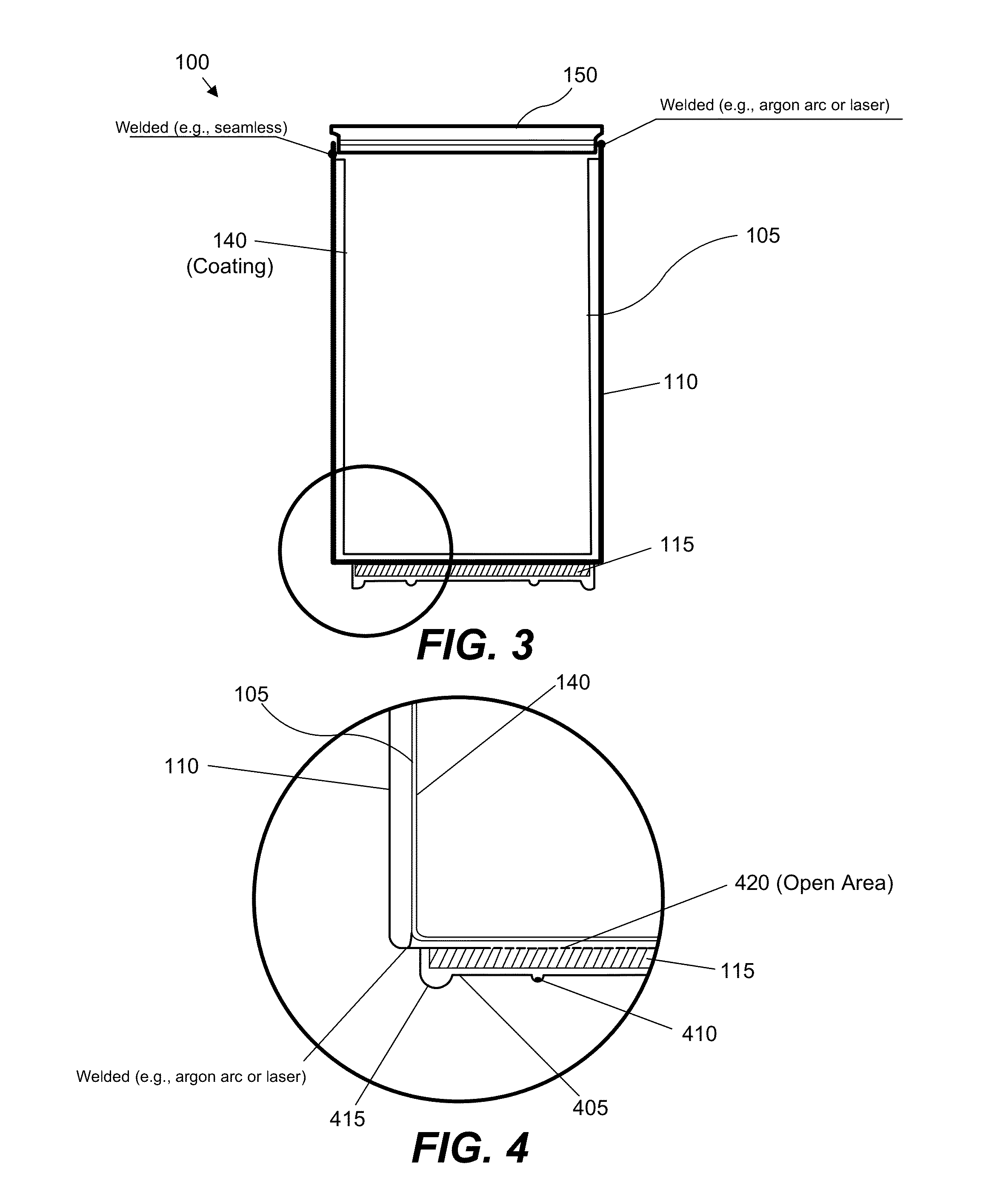

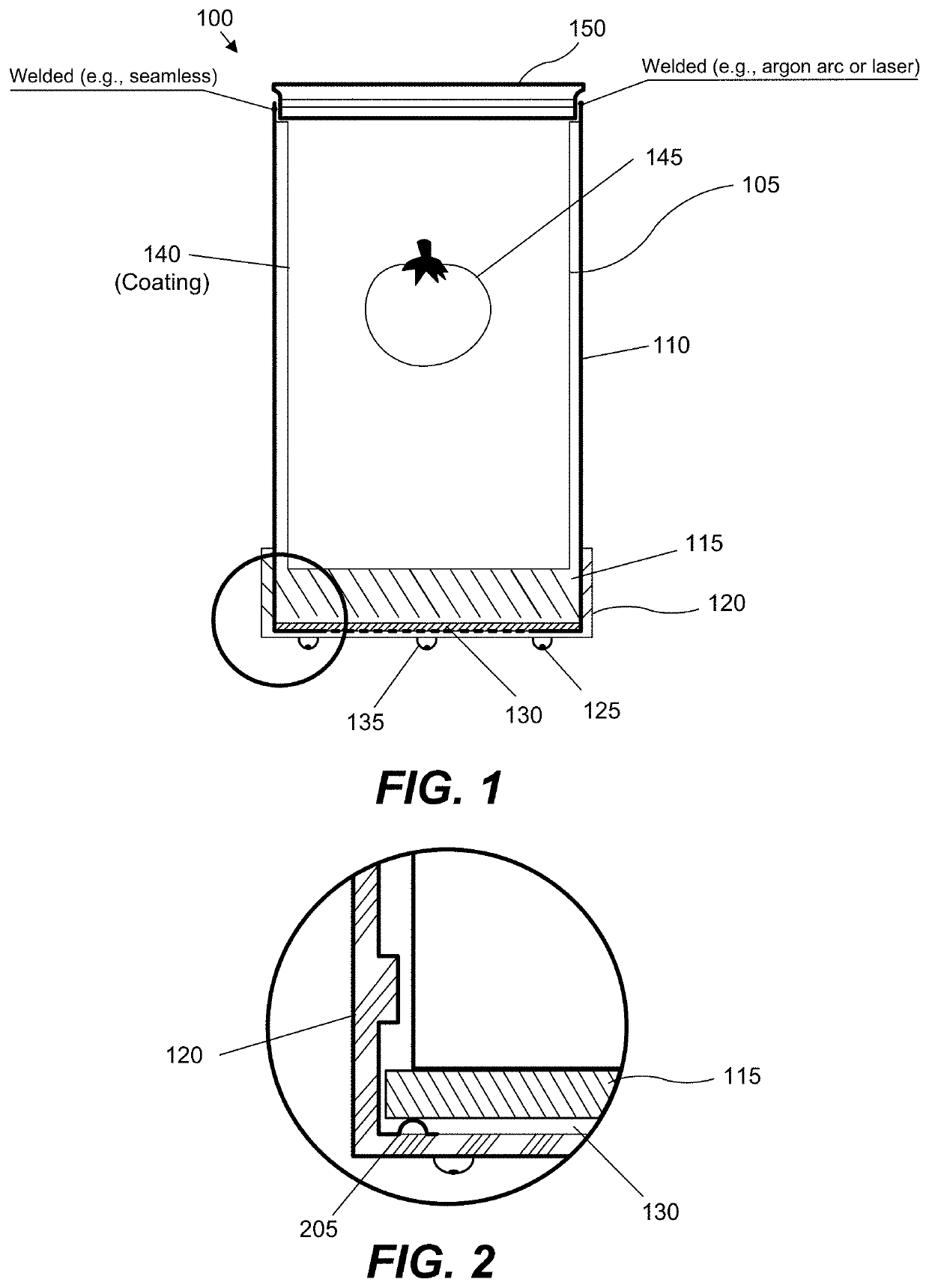

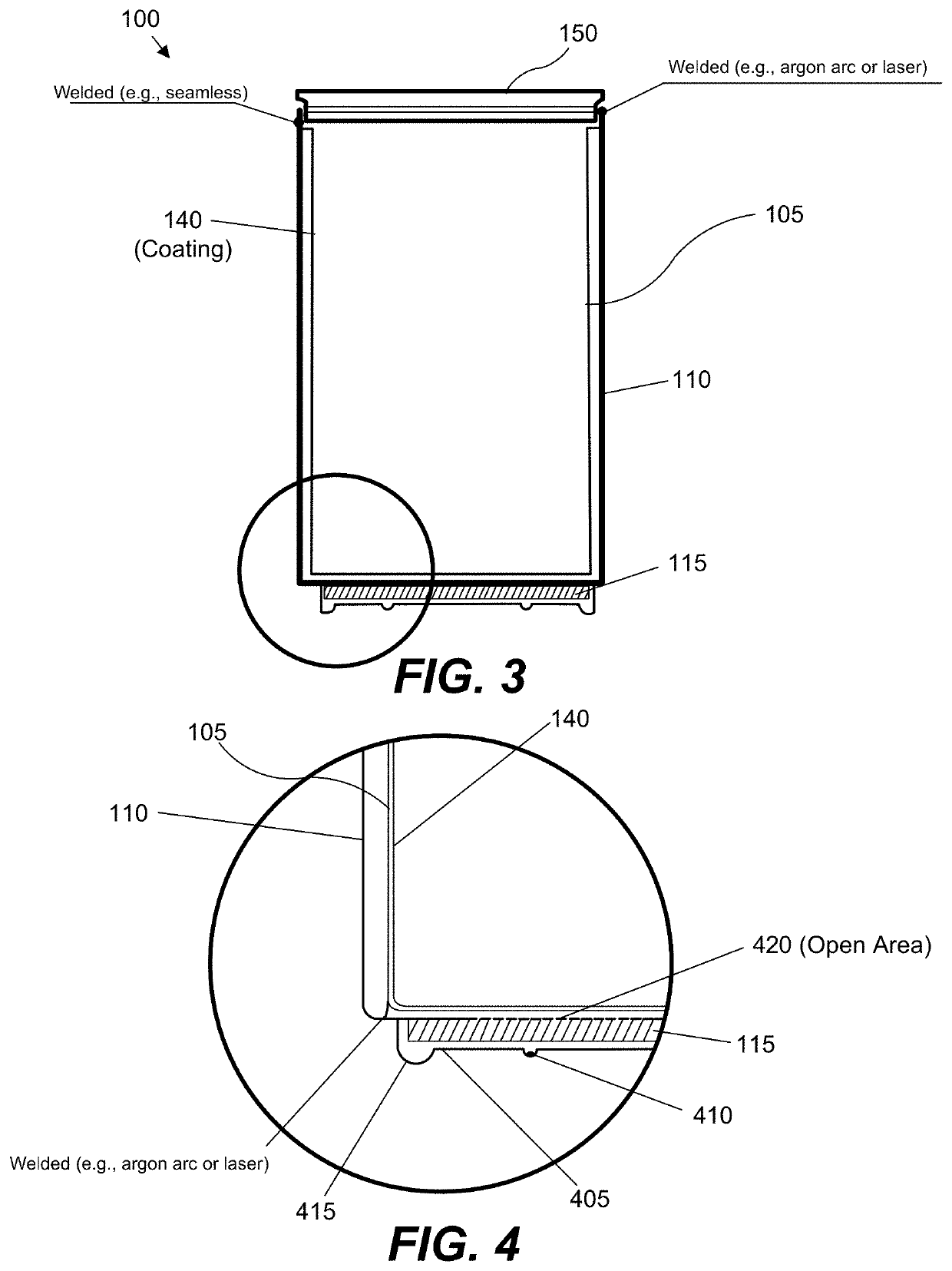

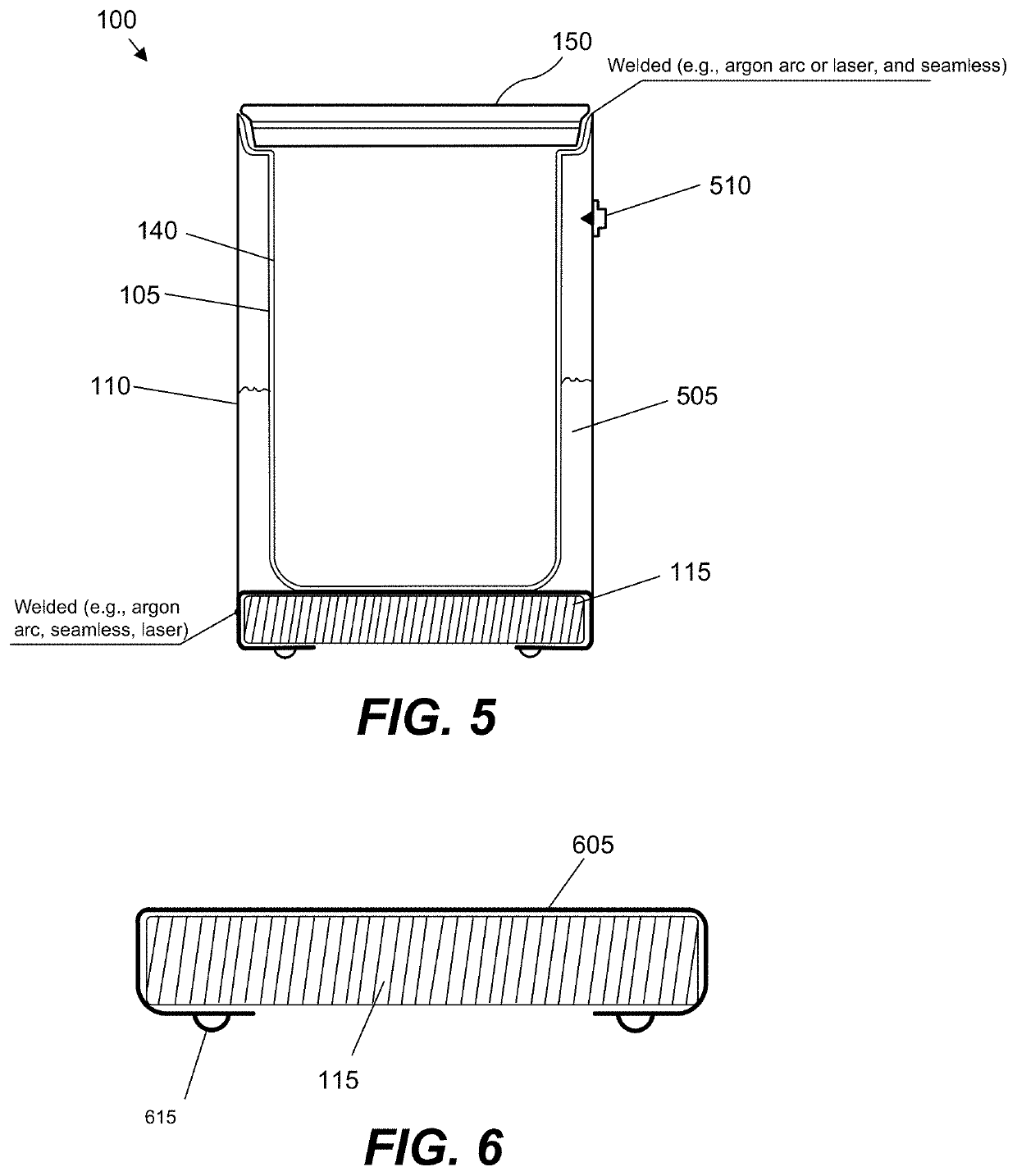

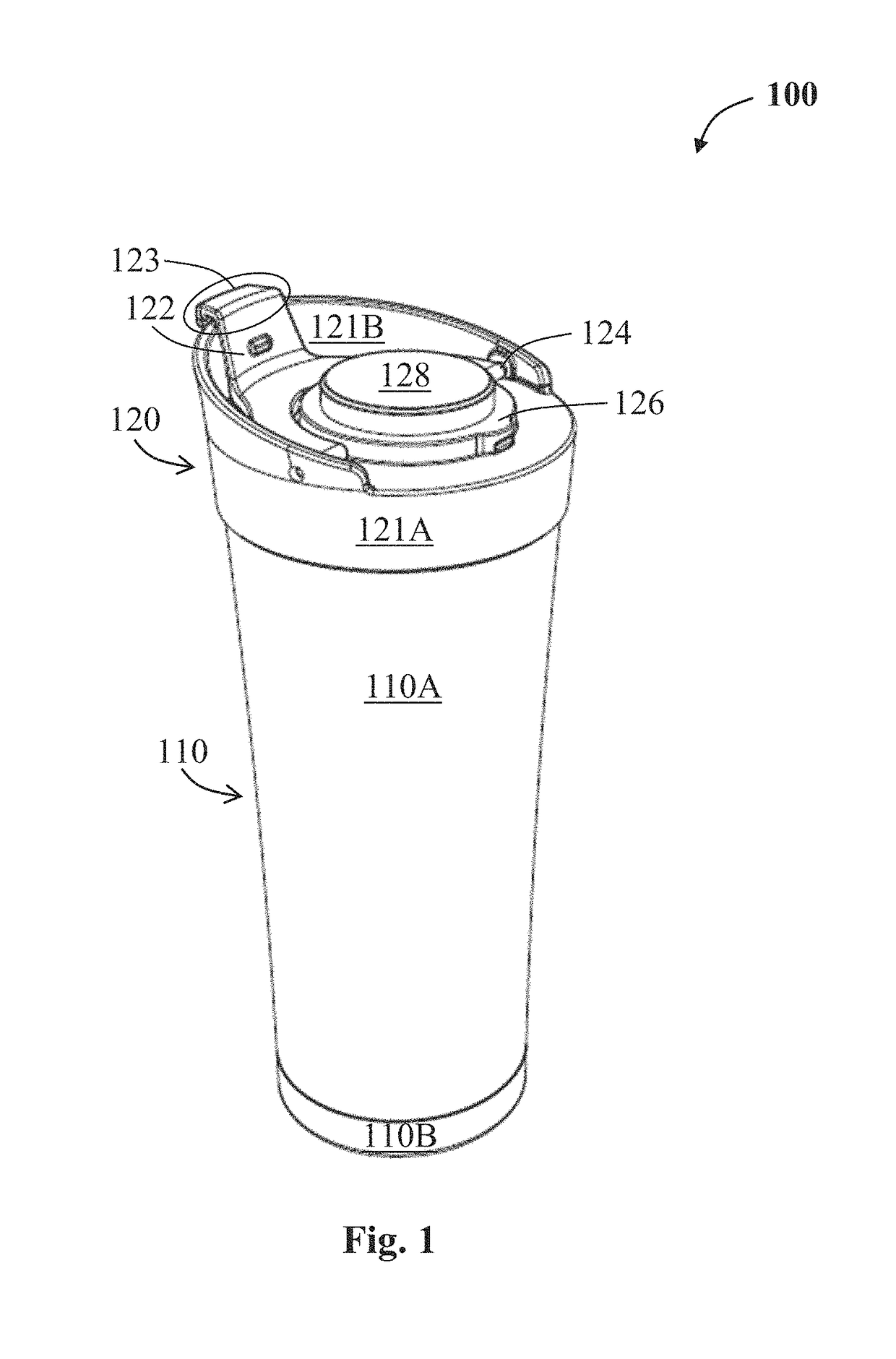

Microwaveable vessel

ActiveUS20150282258A1Quickly and evenly heatQuickly and evenly and cookCooking-vessel materialsMicrowave heatingMicrowaveEngineering

Some embodiments provide a microwaveable vessel that can quickly and evenly heat or cook different types of food. In some embodiments, the vessel includes a metallic body adapted to hold food or drinks. The outer portion of the body is coated with a layer of heat-generating glaze. In some embodiments, the vessel also includes a heat-resistant outer cover that covers the heat-generation layer. The vessel of some embodiments has a multi-layered structure with inner and outer shells that are joined together to form a cavity between the shells.

Owner:PARK JONG PETER

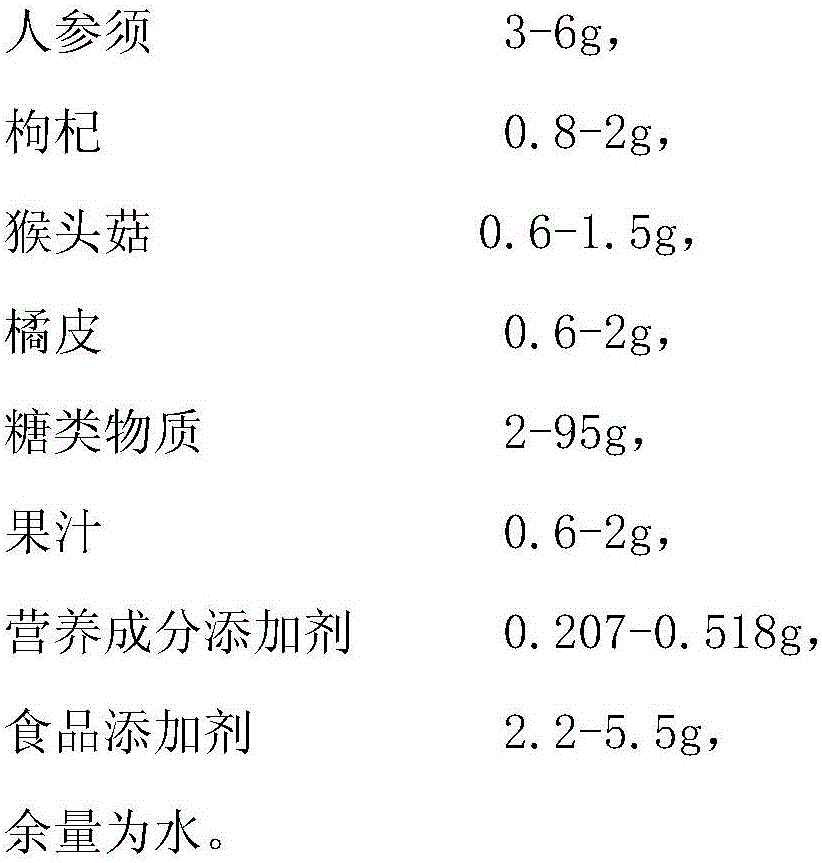

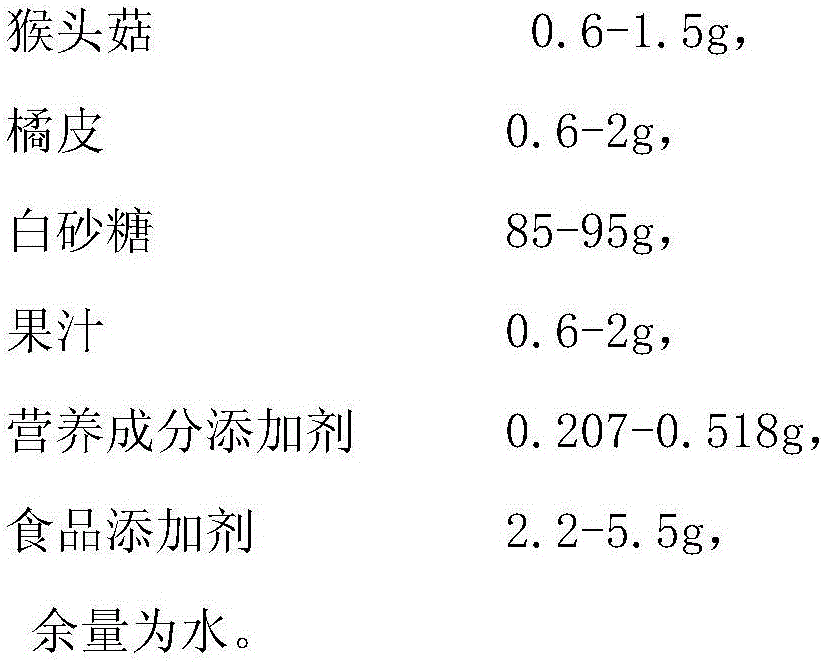

Ginseng vitamin drink and processing method thereof

InactiveCN106306893AHigh nutritional valuePromote circulationNatural extract food ingredientsFood ingredient functionsFood additiveMedicinal herbs

The invention discloses a ginseng vitamin drink. Every 1kg of ginseng vitamin drink is prepared from the following substances: 3-6g of ginseng fibrous root, 0.8-2g of barbary wolfberry fruits, 0.6-1.5g of hericium erinaceus, 0.6-2g of orange peels, 2-95g of carbohydrate, 0.6-2g of juice, 0.207-0.518g of a nutritional ingredient additive, 2.2-5.5g of a food additive and the balance of water. The ginseng vitamin drink is prepared from the extract of four major medicinal materials together with the nutritional ingredient additive, and the nutritional value and the healthcare function of the drink are greatly improved; by adopting proper technology, water quantity, temperature and time in the extraction process of medicinal materials, the nutrient elements of the medicinal materials are sufficiently maintained, the extraction of harmful components caused by excessive extraction is avoided, and the original nutritional value and flavor and mouthfeel of the medicinal materials are maintained; and by adding grape juice containing vitamins, anthocyanin, amino acids, antioxidants and multiple trace elements, the nutritional value and the mouthfeel of the drink can be improved.

Owner:广州加维舒医药有限公司

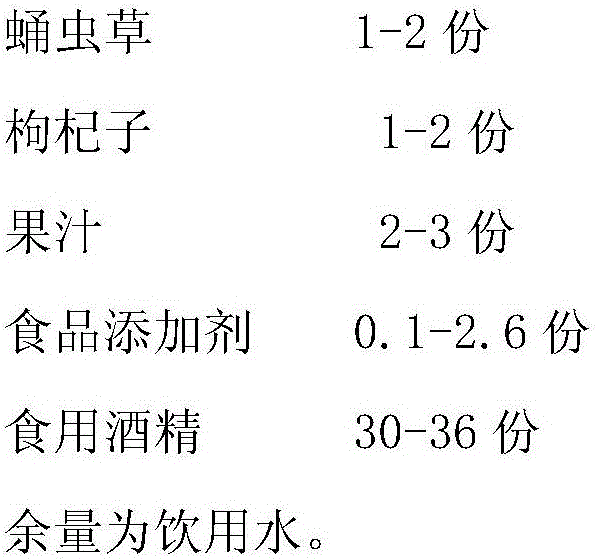

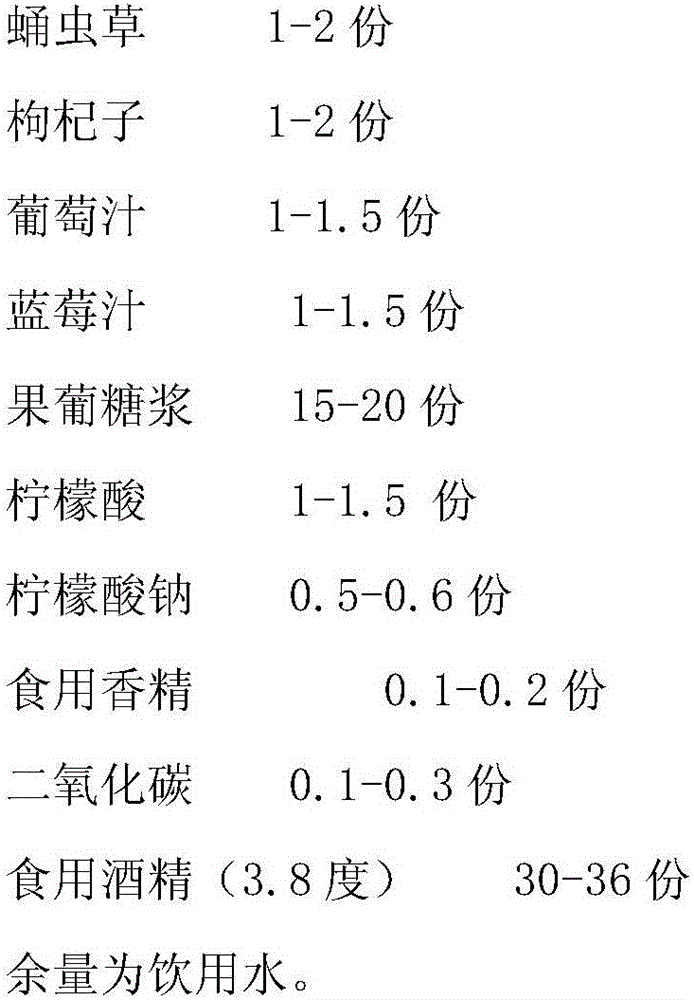

Cordyceps militaris prepared wine and preparation method thereof

InactiveCN106281919AImprove tasteImprove immunityDigestive systemAntinoxious agentsCordycepsCarbon dioxide

The invention discloses a cordyceps militaris prepared wine and a preparation method thereof. Cordyceps militaris and wolfberry at specific ratio are taken as main raw materials, so that the prepared wine has nutritive value and healthcare function; the fruit juice, including grape juice, blueberry juice, and the like, is added, so that the vitamins and trace elements required by a human body can be supplied and the nutritional ingredients of the prepared wine can be promoted; the food additives, including high fructose corn syrup, carbon dioxide, citric acid, sodium citrate, essence, and the like, are added, so that the taste is improved. The cordyceps militaris prepared wine has the effects of enhancing immunity, delaying senescence, supporting healthy energy, protecting heart and liver, resisting bacteria and virus, preventing and treating cerebral thrombosis, and the like, and is especially suitable for body regulation.

Owner:广州加维舒医药有限公司

Chili sauce and preparing method thereof

InactiveCN106722818APreserve the tasteReduce salt contentFood scienceMonosodium glutamateCapsicum annuum

The invention relates to a chili sauce. The chili sauce is prepared from chilies, edible oil, minced garlic, dry yellow soybean sauce, edible salt, edible sugar, vinegar and monosodium glutamate; the preparing method comprises the following steps of mincing the chilies into blocks to obtain blocky chilies for ready use; heating the edible oil, adding the minced garlic, the blocky chilies, the dry yellow soybean sauce, the edible salt and the edible sugar into the hot edible oil, stirring evenly, and then conducting decoction to obtain an intermediate product; adding mature vinegar into the intermediate product, continuing the decoction, and adding the monosodium glutamate after the decoction to obtain the chili sauce. The chili sauce has the advantages that no additive of a preservative, an essence and the like are added in the chili sauce, the original mouthfeel and nutrition of the chilies are maintained, the salt content of the chili sauce is low, that is, the original mouthfeel and nutrition of the chilies are maintained, no side effect can be exerted on a body after long-term taking, excessive internal heat cannot be resulted in, and the safety is relatively high.

Owner:温明明

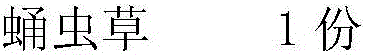

Technology for removing fishy smell from squids

InactiveCN106901139AKeep the flavorAvoid spoilageMeat/fish preservation using chemicalsEucalyptus oilFiltration

The invention provides a technology for removing fishy smell from squids. The technology comprises the following steps of (1) pretreatment: removing skin, internal organs, heads and feet from fresh squids, performing thorough cleaning, and performing draining; (2) preparation of fishy smell removing liquid, wherein the fishy smell removing liquid comprises the following components of tea tree oil, eucalyptus oil, dihydrate sodium citrate, a surfactant AES, glycyrrhizic acid, calcium oxide, BS-12, propylene glycol and water; taking water in parts by weight, adding the taken water into a reaction kettle, performing stirring, adding the surfactant AES and the calcium oxide, raising the temperature to 70 DEG C, performing stirring, sequentially adding the tea tree oil, the eucalyptus oil, the dihydrate sodium citrate and the glycyrrhizic acid, performing emulsification for 35min, adding the BS-12, performing stirring, adding the propylene glycol, performing cooling to 27 DEG C, performing defoaming, and performing filtration, so as to obtain the fishy smell removing liquid; (3) fishy smell removal: placing the drained squids into the fishy smell removing liquid, soaking the squids for 7min, draining the soaked squids, placing the drained squids into a fresh keeping agent, soaking the squids for 14 min, draining the soaked squids, and performing cold air drying; and (4) low-temperature storage: performing vacuum packaging on the dried squids, and performing low-temperature storage.

Owner:舟山金星水产有限公司

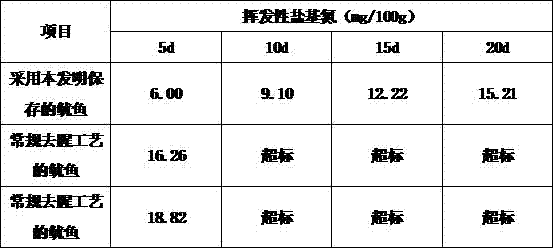

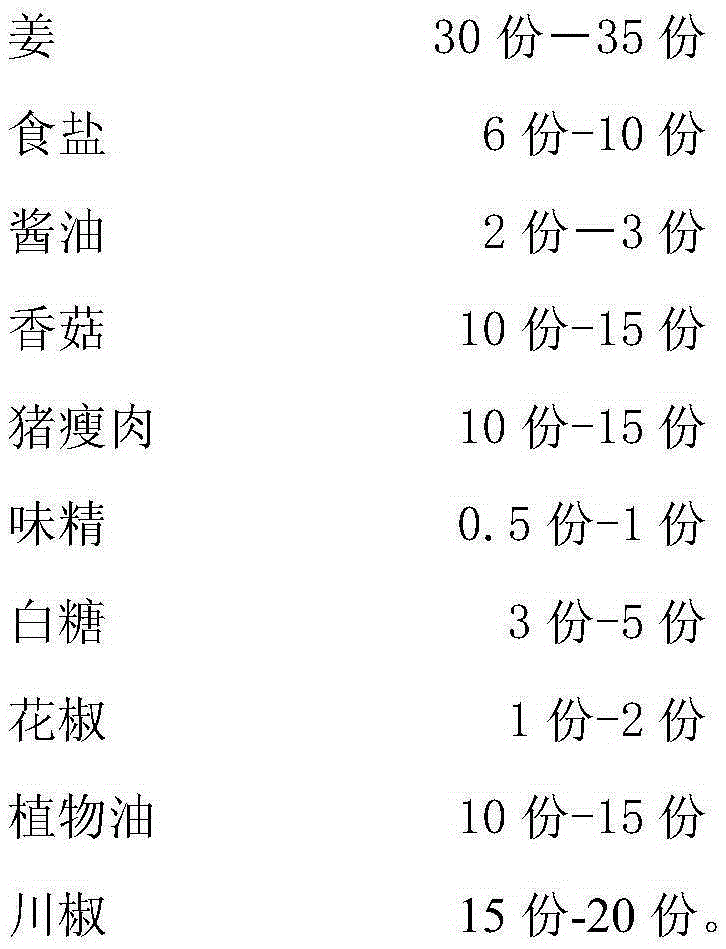

Ready-to-eat ginger appetizer and preparation method thereof

InactiveCN105310033AMarinated evenlyImprove palatabilityClimate change adaptationFood ingredient functionsMonosodium glutamateReady to eat

The invention discloses a ready-to-eat ginger appetizer and a preparation method thereof. The preparation method comprises the following steps: pickling ginger, dicing the pickled ginger, putting the diced ginger into an ultrasonic cleaner for ultrasonic treatment, and then removing water; drying the diced ginger without water in a drying box, and then cooling the dried diced ginger; carrying out primary roasting, and then cooling the roasted diced ginger; carrying out secondary roasting for 2-4 hours, and then taking out the finally obtained diced ginger for standby application; dicing shiitake, and frying the diced shiitake in hot vegetable oil till the fried diced shiitake becomes golden yellow; cleaning pork tenderloin, and dicing the cleaned pork tenderloin; cleaning Szechwan peppers, and dicing the cleaned Szechwan peppers; putting vegetable oil in a wok for heating, putting zanthoxylum in the hot vegetable oil for frying till the zanthoxylum aroma appears, taking out the fried zanthoxylum, and leaving the hot vegetable oil for standby application; mixing the following ingredients in parts by weight: 30-35 parts of the finally obtained diced ginger, 10-15 parts of the fried diced shiitake, 10-15 parts of the diced pork tenderloin, 1-2 parts of zanthoxylum, 15-20 parts of the diced Szechwan peppers, 2-3 parts of soy, 0.5-1 part of monosodium glutamate, 3-5 parts of white sugar and 6-10 parts of table salt; pouring 10-15 parts of the standby hot vegetable oil for uniform mixing and bottling, and then carrying out sterilization and cooling, so as to obtain the ready-to-eat ginger appetizer. No any artificially synthesized preservative and essence are added in the preparation process, so that the ready-to-eat ginger appetizer has a good taste, and the problem of a difficulty in ginger storage is solved.

Owner:BOHAI UNIV

Flower steamed cake and preparation method thereof

InactiveCN105851814AThe power of good nutritionAvoid churnSugar food ingredientsLipidic food ingredientsFlavorVegetable oil

The invention provides flower steamed cake and a preparation method thereof. The flower steamed cake is made of low-gluten flour, milk, sugar, salt, egg, vegetable oil, lemonade, rose, lily and honey. The flower steamed cake is soft and special in taste and nutritious, has functions of nourishing beauty and enhancing immunity, and is flavored with rose and lily. With honey, flowery flavor is sweeter and easily acceptable. The preparation method is simple and can keep nutrition of flower better.

Owner:XUCHANG UNIV

Preparation method of frozen mango pulp

InactiveCN105614559APreserve the tasteRetain colorFood preservationFood preparationFlavorChlorine dioxide

The invention discloses a preparation method of frozen mango pulp. In the process that mangoes are made into the mango pulp, the mangoes are easy to deteriorate due to imperfect sterilization measures, and a conventional preparation method for the mango pulp has the defects that high temperature instantaneous sterilization at 130-135 DEG C is adopted, bacteria are sterilized, at the same time, the color of the pulp is changed, the original mouth feel is changed or disappears, and the loss of nutrient components is generated due to high temperature. The preparation method disclosed by the invention comprises the following steps of selecting mangoes, cutting off mango stems, sending the mangoes without the stems into a brush machine, and spraying water for cleaning the surfaces of the mangoes; disinfecting the cleaned mangoes with an 80-100PPm chlorine dioxide solution; unpeeling the disinfected mangoes and removing kernels of the unpeeled mangoes so as to obtain mango flesh; preparing the mango flesh into the pulp with a pulping machine, and filtering the pulp with a 60-80 mesh filter net; putting the filtered pulp in the same batch in a storage tank for uniform stirring; and precooling the pulp to 0 DEG C by a telescoping water freezing precooling machine, and then lowering the temperature of the precooled pulp to minus 18 DEG C within 6-8 hours. According to the prepared mango pulp, the total bacterial count is controlled to be 10000cuf / mg or below, and high-temperature sterilization is not needed, so that the original flavor, the original mouth feel, the original color, and the original nutrient components of the mangoes are reserved.

Owner:丽江华坪金芒果生态开发有限公司

Microwaveable vessel

InactiveUS20200077836A1Quickly and evenly heatQuickly and evenly and cookCooking-vessel materialsDwelling equipmentThermodynamicsEngineering

Some embodiments provide a microwaveable vessel that can quickly and evenly heat or cook different types of food. In some embodiments, the vessel includes a metallic body adapted to hold food or drinks. The outer portion of the body is coated with a layer of heat-generating glaze. In some embodiments, the vessel also includes a heat-resistant outer cover that covers the heat-generation layer. The vessel of some embodiments has a multi-layered structure with inner and outer shells that are joined together to form a cavity between the shells.

Owner:PARK JONG PETER

Processing method of dendrobium nobile lindl flowers

InactiveCN108853360ANot easy to oxidize and change colorImprove immunityMetabolism disorderDigestive systemNutrientFlavor

The invention discloses a processing method of dendrobium nobile lindl flowers. The method includes the steps of picking the dendrobium nobile lindl flowers, soaking the cleaned dendrobium nobile lindl flowers in soaking liquid for color protection treatment, and fishing up and draining the flowers, wherein the soaking liquid is prepared from nisin, vitamin C, cellulase, grape oxidase and phytic acid; filling the peel of a XinHui dried-tangerine-peel tangerine with the color-protected dendrobium nobile lindl flowers, covering the peel with a fruit cover, and putting the dried-tangerine-peel tangerine on a tray; putting the tray into the lyophilizer, starting a vacuum pump to vacuumize for 1h to 1.5h, heating the tray to 35-40 DEG C for 2h, adjusting the temperature to 45-50 DEG C, performing drying for 8h, performing cooling and packaging, and storing an obtained product in a cool dry place to obtain the dried dendrobium nobile lindl flowers. The processing method has the advantages that the dried dendrobium nobile lindl flowers obtained by the method can retain effective nutrient components, appearance and color of the dendrobium nobile lindl flowers to the greatest extent, are not liable to oxidation stain after long-time storage, have fruit aroma and nutrient components of the Xinhui dried-tangerine-peel tangerine, and have mellow and fragrant tea flavor, thereby being popular among customers.

Owner:赤水芝绿金钗石斛生态园开发有限公司

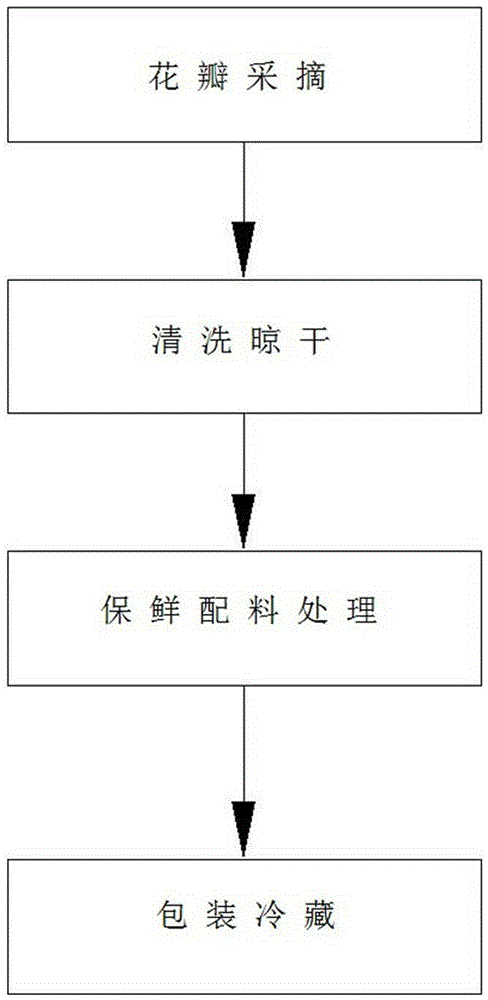

Rose petal fresh-keeping formula and fresh-keeping method

InactiveCN105211056AExtended shelf lifeSave the smellDead plant preservationAdditive ingredientPetal

The invention discloses a rose petal fresh-keeping formula. The rose petal fresh-keeping formula comprises, by mass, 1%-99.7% of fresh rose petals, 0.1%-30% of edible salt, 0.1%-50% of D-sodium erythorbate and 0.1%-20% of citric acid. The rose petal fresh-keeping method comprises the steps of petal picking, cleaning and airing, fresh-keeping ingredient treatment and packaging and refrigeration, wherein after petal picking is conducted, cleaning and airing are conducted, fresh-keeping ingredient treatment is conducted, and packaging and refrigeration are conducted. The formula and the corresponding fresh-keeping method can prolong the refreshing time of rose petals to one year, the fresh-keeping cost is low, the occupied area is small, discoloration, off odor and deformation do not occur for the petals, and original odor, mouthfeel and biological tissue structure of the rose petals are preserved.

Owner:孟继武

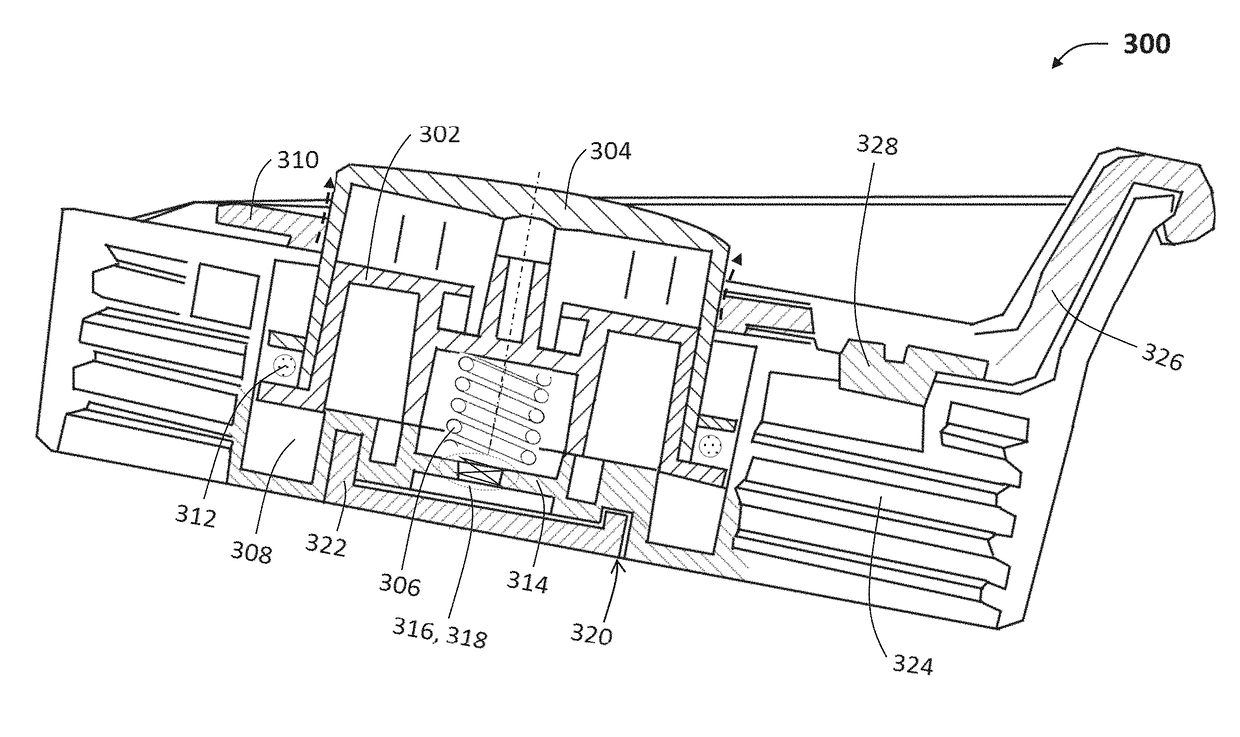

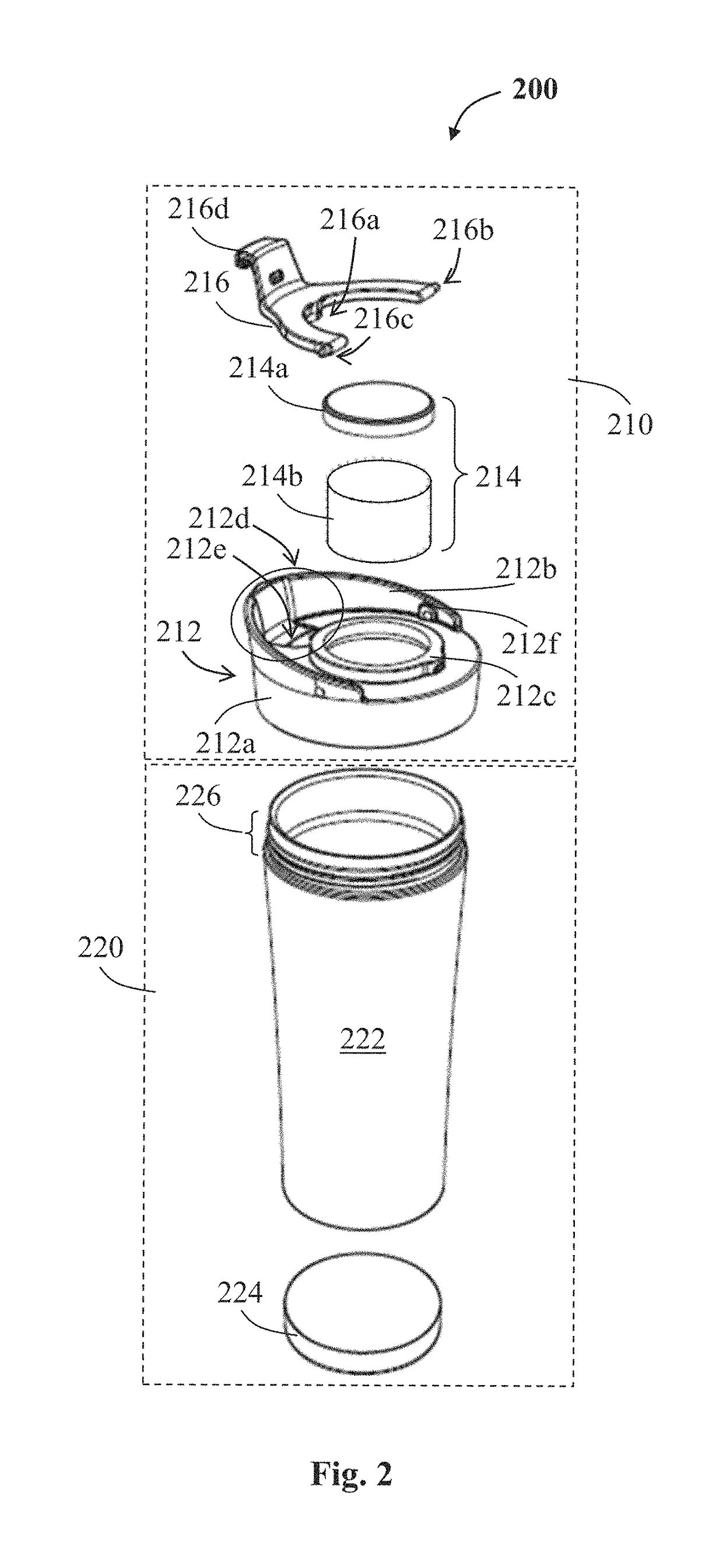

Sealable drinking container with air-extracting mechanism for oxygenation suppression

ActiveUS10000319B2Improve preserving freshness and taste and nutrient and natural appearanceLow costDomestic cooling apparatusClosuresEngineeringMechanical engineering

A sealable drinking container for preserving the freshness, taste, nutrients and natural appearance of a smoothie / fruit and vegetable juice / green drinks, where a container body and an upper cap assembly have a sealable coupling mechanism forming the sealable drinking container and an air extracting device for extracting air from the sealable space, and where the air-extracting mechanism may be incorporated within an air-extracting chamber associated with the upper cap assembly and used with various types of containers.

Owner:PISAREVSKY ARIE

Edible coating for plant matter

ActiveUS9648890B2High natural glossLimited water reservoir capacityDead plant preservationFruits/vegetable preservation by coatingWaxColloid

The present invention discloses composition and methods for reducing the weight loss and / or preserving the natural gloss of post-harvest edible plant matter. In particular, the methods comprising applying to the surface of the plant matter a composition comprising an edible wax having a melting temperature below 70° C.; a hydrocolloid; a fatty acid; an emulsifier; and water, wherein said edible wax is present in a weight percent ranging from about 10% to about 25% of the total weight of the composition.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

Processing method of headless shrimps

InactiveCN104856129APreserve the tasteEasy to storeMeat/fish preservation by freezing/coolingFood preparationShrimpEngineering

The invention provides a processing method of headless shrimps and belongs to the technical field of marine product processing. The processing method of the headless shrimps comprises the steps of (1) selection of raw materials, (2) sorting of the raw materials, (3) head removal, (4) washing of the headless shrimps, (5) water drainage, (6) weighing and placement on a tray, (7) removal from the tray and ice glazing, (8) packaging and metal detection, and (9) warehousing and freezing. According to the processing method of the headless shrimps, provided by the invention, the taste of the shrimps can be well preserved, the shrimps do not contain any toxic and harmful substances, and the preservation time is long.

Owner:FANGCHENGGANG HAISHITONG SEAFOOD

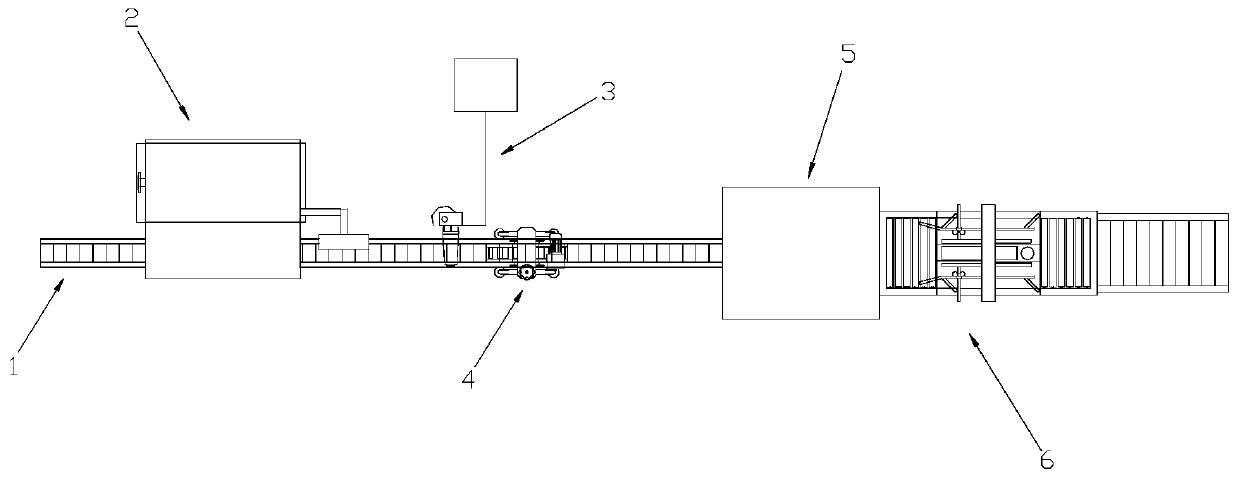

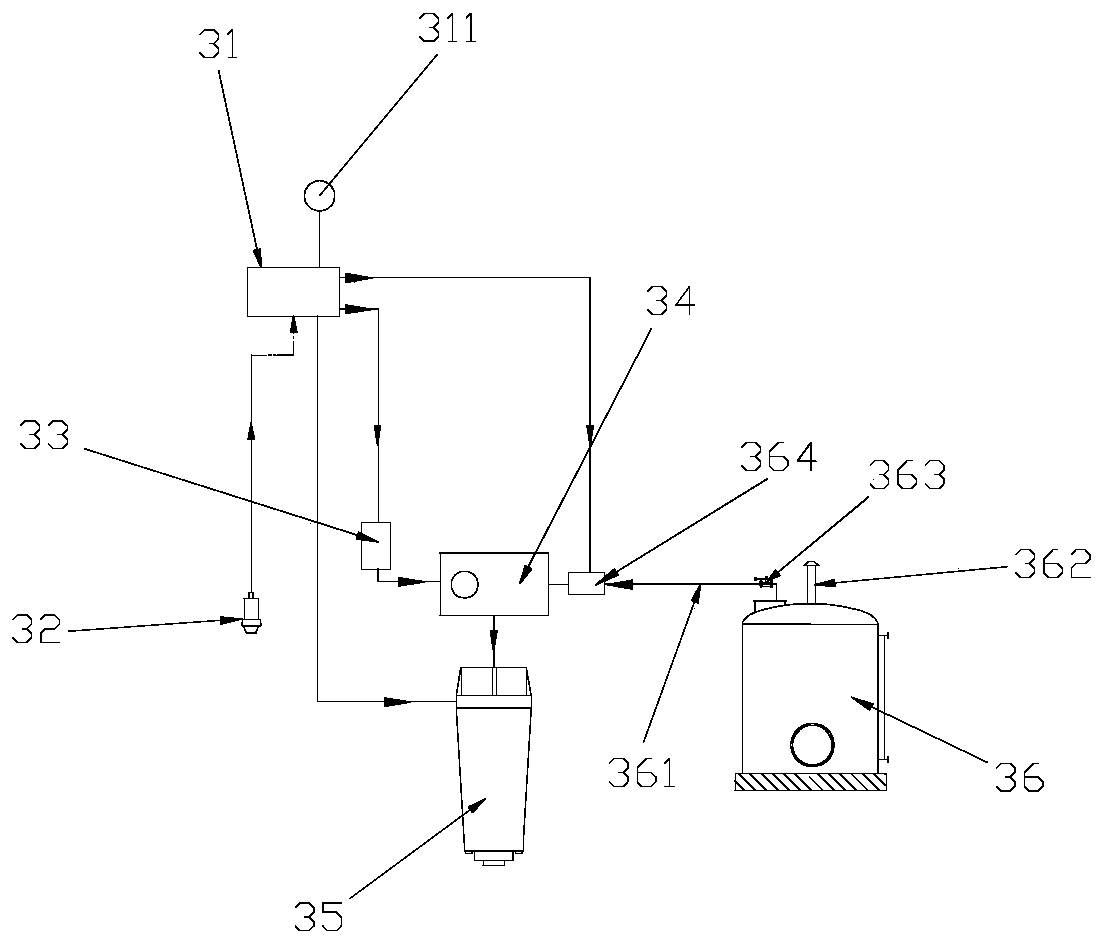

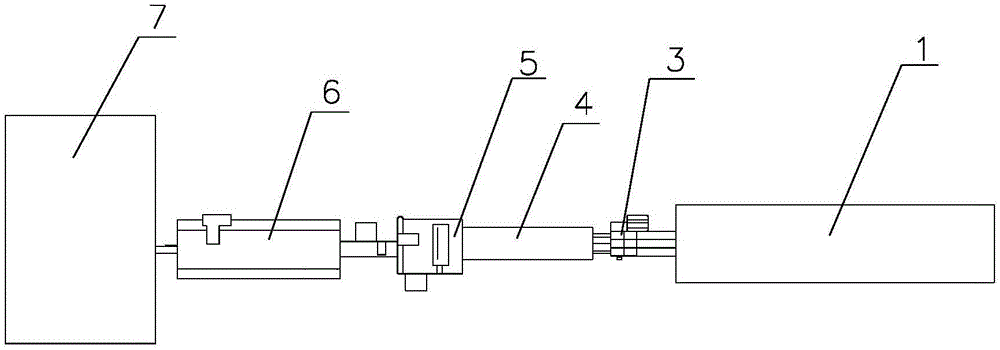

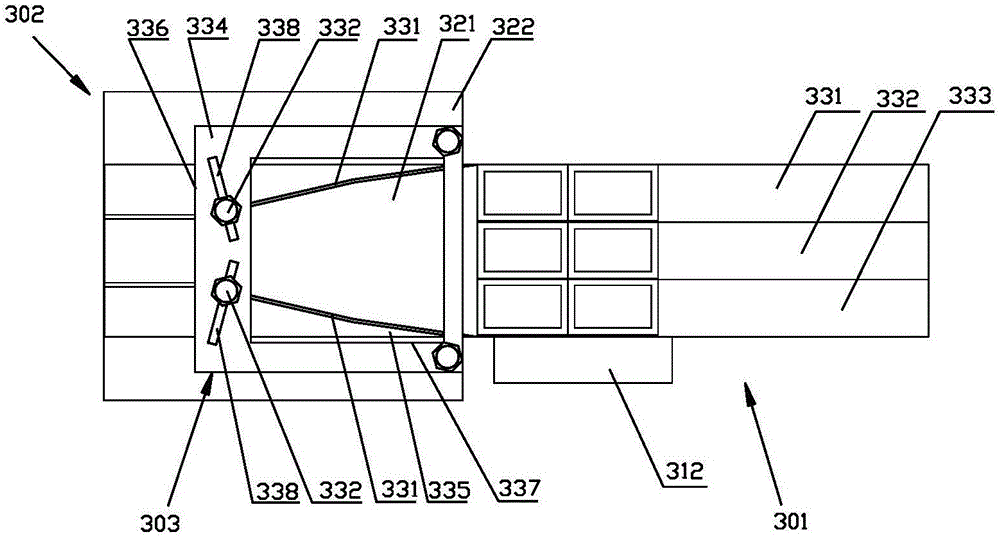

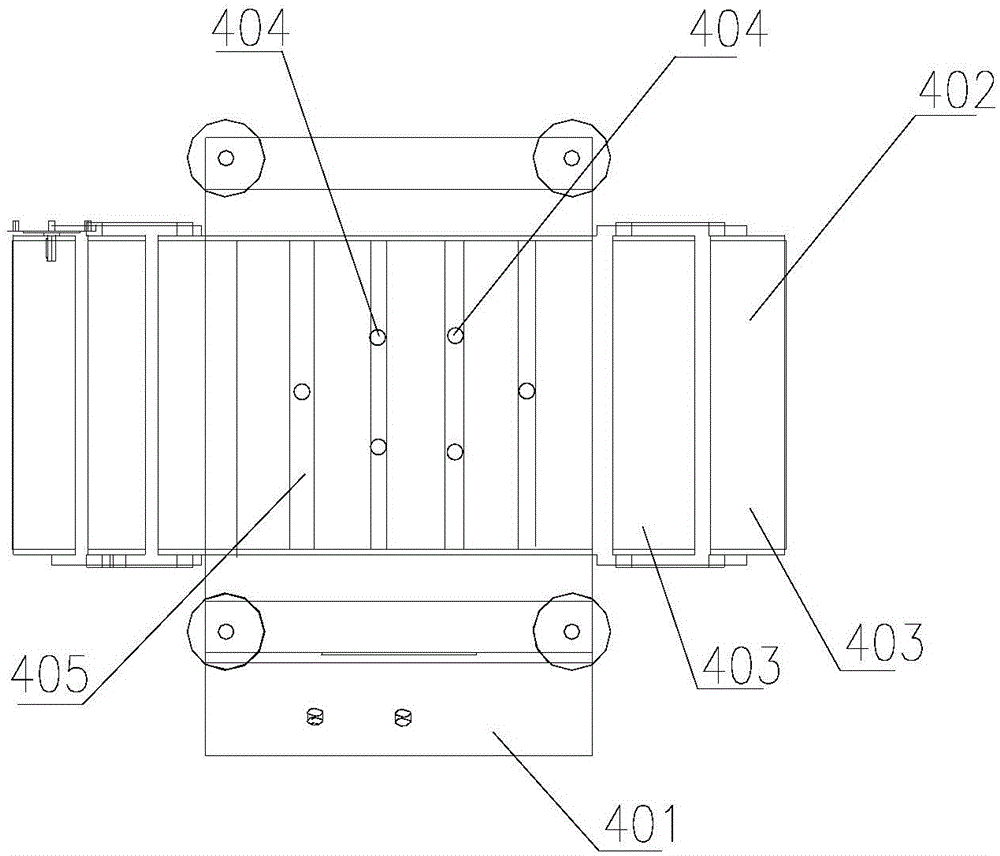

Liquid nitrogen fresh-keeping filling production line for camellia oleifera seed oil

InactiveCN110683499AAvoid situations where extraction is not possibleAvoid negative pressureLiquid bottlingBiotechnologyCamellia oleifera

The invention discloses a liquid nitrogen fresh-keeping filling production line for camellia oleifera seed oil. The liquid nitrogen fresh-keeping filling production line comprises a conveying frame, acamellia oleifera seed oil filling machine, a filling device, a capping machine, a working platform and a box sealing machine; and the filling device comprises an automatic controller, an infrared optical sensor, a time-delay relay, an electronic flowmeter, an electronic filling gun and a liquid nitrogen tank. By quantificationally filling food-grade liquid nitrogen into oil bottles through the filling device, the oxidation effect of air on the oleifera seed oil can be isolated by the food-grade liquid nitrogen, under the condition that no preservative and no synthetic antioxidant is added, the inherent mouthfeel, taste and nutritive value of the oleifera seed oil are effectively preserved, in addition, the conveying speed of the oil bottles and the filling amount of the liquid nitrogen can be automatically adjusted by the filling device on the filling production line, or when the filling device breaks down, the filling production line is stopped in time for adjusting so as to guarantee the filling efficiency of the food-grade liquid nitrogen, thus the purpose of quick packaging for fresh keeping of the oleifera seed oil in the oil bottles is achieved, production is automaticallycontrolled under the safety guarantee, and the production efficiency is improved advantageously.

Owner:广东康帝绿色生物科技有限公司

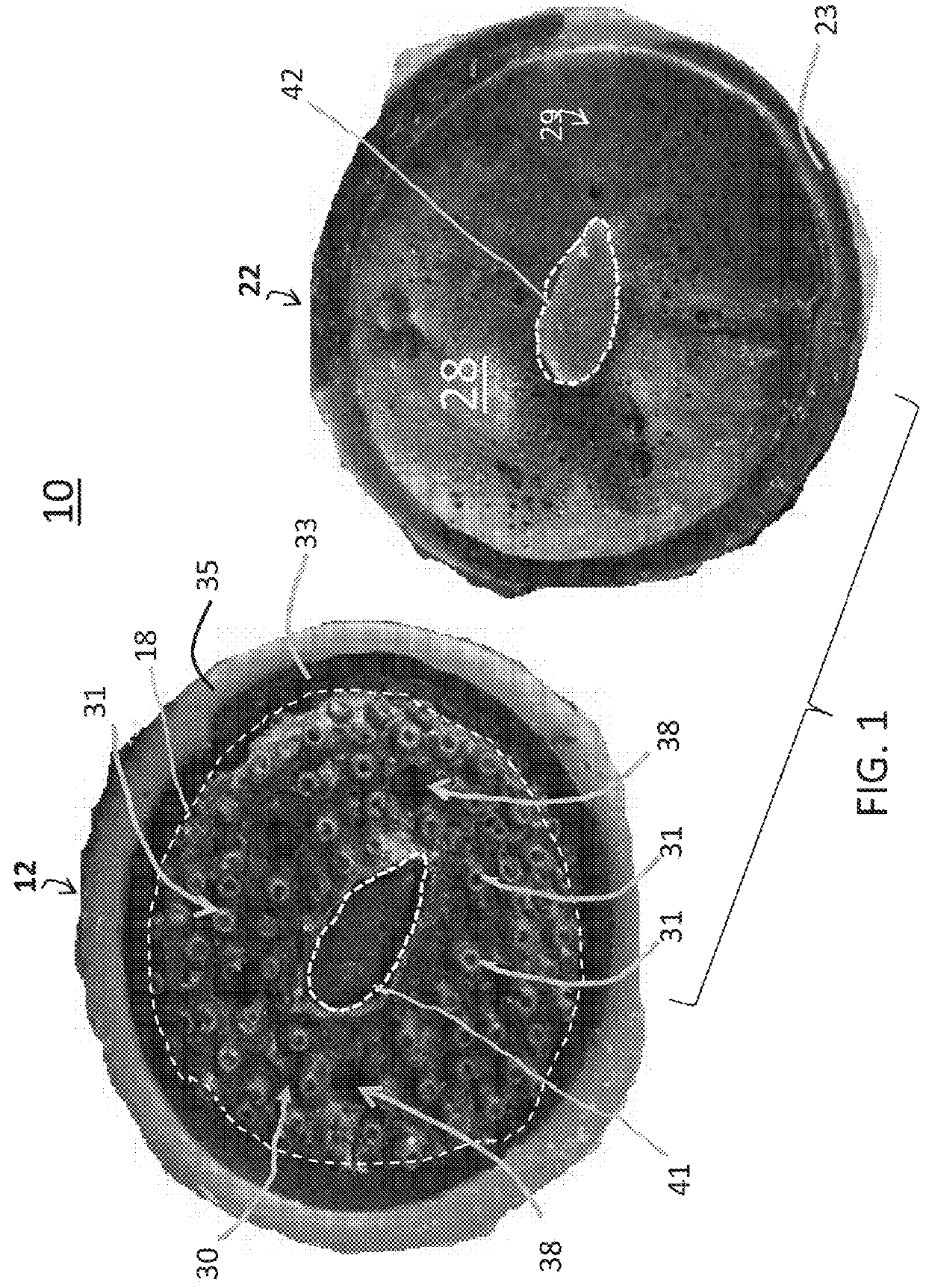

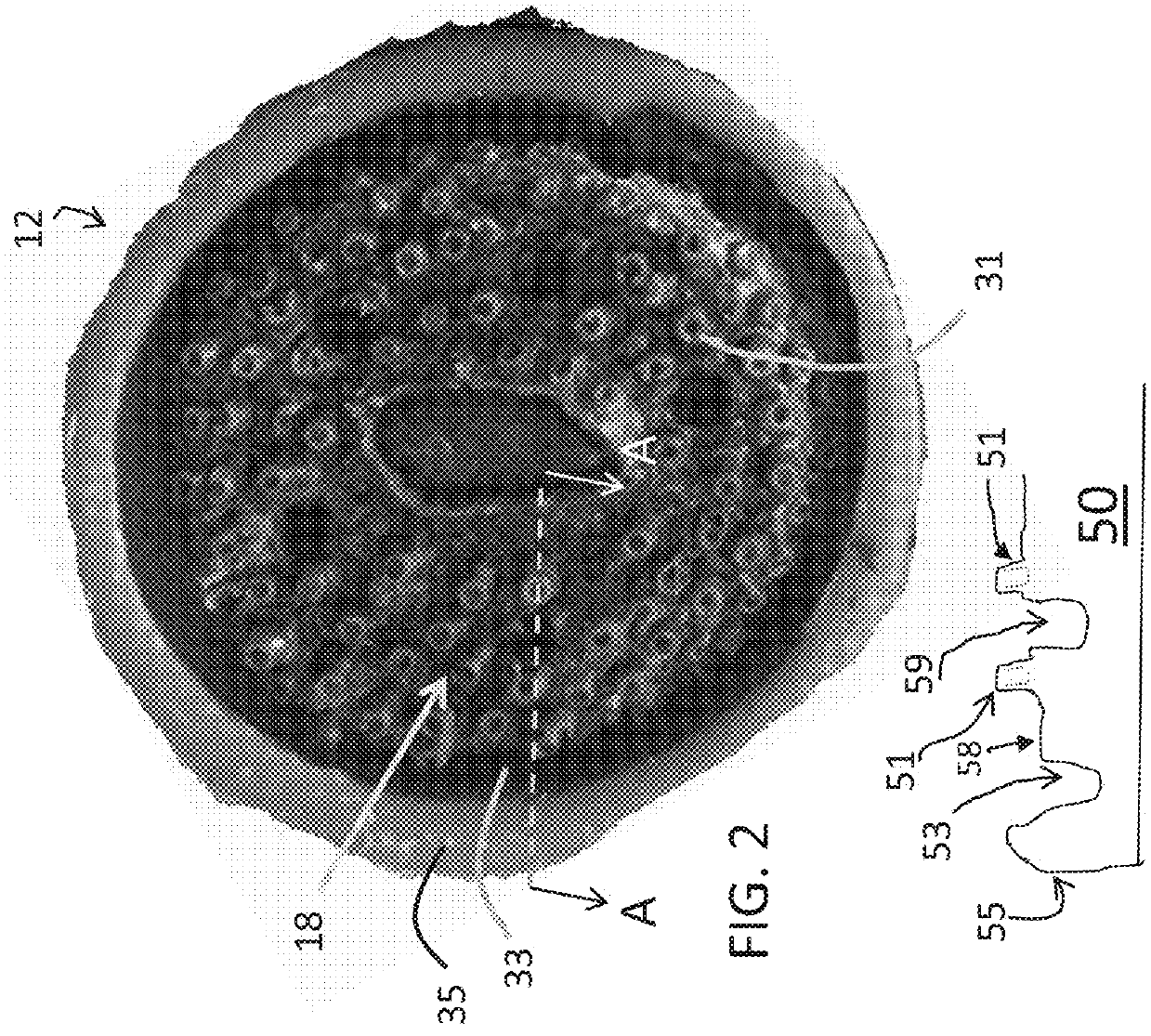

Scooped out bagel product, apparatus and method of making scooped out bagel

A scooped out bagel dough product, bagel mold halves, and an apparatus using the bagel mold halves for making a scooped out bagel product. The scooped out bagel product is a baked bagel product half having: a crunchy blistered outer shell with a substantially reduced amount of doughy inner chamber that provides its unique flavor. This scooped out bagel product utilizes a predesigned custom mold that creates stalactites, i.e., flavor spikes, and holes or flavor “pit” formations that each encapsulate the soft doughy inner contents within a boiled and baked blister shell and increases a surface area of dough on an inner surface thereof. The product is a “scooped out” half bagel crunchy on its outer surface but filled with the flavor spikes, and flavor pits in which substantially reduced amounts of dough are encased relative to a comparable sized whole bagel.

Owner:STERNBERG DENNIS G

Packaging line with seal detection function

InactiveCN106167115ALong storage timeAdd flavorPackaging automatic controlEngineeringPackaging machine

The invention discloses a packaging line with a seal detection function, and relates to the field of stewed product packaging. The packaging line comprises an air adjusting packaging machine, a doubling machine, a seal detecting machine, a metal detecting machine, a labeling machine and a manual boxing table which are connected in sequence. The seal detecting machine comprises a conveying device and multiple cameras, the conveying device is composed of multiple parallel conveying belt sets at intervals, a gap is formed between every two adjacent conveying belt sets, the cameras are distributed in different gaps, and camera lenses of the cameras are arranged upwards. The all detection items of air adjusting packaging boxes is automatically completed, and detection accuracy is high.

Owner:湖北周黑鸭食品工业园有限公司

Room-temperature ready-to-eat trepang and preparation method thereof

InactiveCN107594393APreserve the tastePreserve nutritionMeat/fish preservation by heatingReady to eatGlycine

The invention relates to the field of foods. A preparation method of room-temperature ready-to-eat trepang comprises the following steps of removing teeth and internal organs from trepang, performingcleaning, putting the cleaned trepang into a high-pressure chamber, performing instantaneous cooking treatment, then performing cooling, performing blanching, and performing bottling; mixing longans with Chinese jujubes and Chinese wolfberry fruits in proportion, and performing bottling; and adding purified water to bottles, performing exhausting, performing sterilization, performing cooling, performing wiping up and clearing, and performing packaging for sales, wherein xylitol and glycine are added to the purified water in proportion. The room-temperature ready-to-eat trepang disclosed by theinvention can be preserved at room temperature and can be transported at room temperature, and the mouth feel and the nutrition of the trepang can be well reserved; and natural food materials of thelongans, the Chinese jujubes, the Chinese wolfberry fruits and the like are matched, so that the mouth feel, the color and the diet scientificity of the room-temperature ready-to-eat trepang are improved.

Owner:吴强

Freshness retaining packaging technique for fresh powders

The invention provides a fresh-keeping package process for fresh noodles, which relates to an improved fresh-keeping package technique for the amylum viscous ripened food. The process is characterized in that a. the fresh noodle is ripened and aged, then cut into the shapes required by eating; b. the formed fresh noodles are put separately by a no-toxicity high-temperature braised film; c. the put fresh noodles are arranged into a package which is then pumped into vacuum, sealed and braised for disinfection. The process of the invention has the beneficial effects of keeping the original taste of the fresh noodles, being simple and convenient for eating, greatly increasing the shelf life and facilitating the transport and sale.

Owner:徐峰

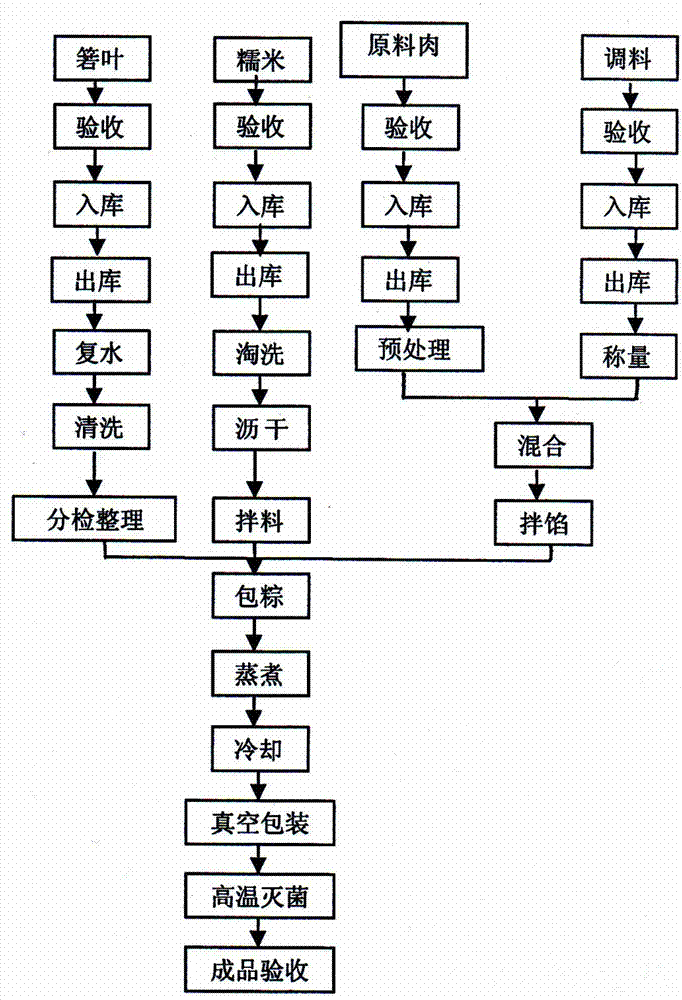

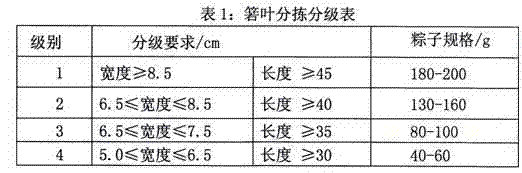

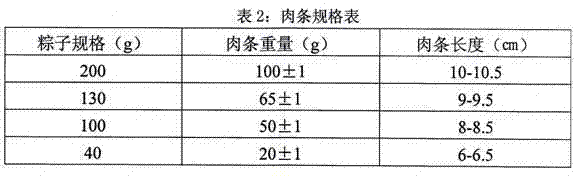

Processing method for medium square skin-on meat dumpling

The invention relates to a processing method for a medium square skin-on meat dumpling. At current, no processing method for the medium square skin-on meat dumpling which is simple in production process, processed by taking medium square skin-on meat as the stuffing raw material, alternative in fat meat and lean meat, unique in flavor and capable of achieving the effect of full stuffing when being taken exists. The processing method comprises an indocalamus leaf processing process, a glutinous rice processing process, a raw meat processing process, a binding process and a waterproof stewing process; a finished product indocalamus leaf is obtained in the indocalamus leaf processing process; finished product glutinous rice is obtained in the glutinous rice processing process; the raw meat processing process comprises the following steps of: chopping medium square skin-on meat into cutlets, rolling and twisting the cutlets by using meat stuffing seasonings, and pickling for 35-45minutes to obtain finished product cutlets, wherein the meat stuffing seasonings include soy sauce, wine, table salt, white granulated sugar and chicken powder; an un-steamed dumpling is obtained in the binding process, and the medium square skin-on meat dumpling is obtained through the waterproof stewing process. The processing method is simple in process, and the processed meat dumpling is alternative in fat meat and lean meat, unique in flavor and capable of achieving the effect of full stuffing when being taken.

Owner:ZHEJIANG QINGLIAN FOOD

Processing technology of vacuum freeze-dried dendrobium officinale

The invention relates to the field of processing of traditional Chinese medicine, and in particular relates to a processing technology of dendrobium officinale, particularly to a processing technology of vacuum freeze-dried dendrobium officinale. In the technology, the collected fresh dendrobium officinale is used as a raw material, and the raw material is processed into the vacuum freeze-dried dendrobium officinale through steps of tidying, washing, cutting, heating up in hot water, cooling, quick freezing and vacuum freeze drying; the vacuum freeze drying technology is a food process technology with practical value, can keep color, fragrance and taste of the dendrobium officinale best, and can maintain abundant nutritional ingredients and physiologically active material of the dendrobium officinale; moreover, freeze drying belongs to the physical processing methods, so that original shape of the dendrobium officinale can be kept, and the dried dendrobium officinale is prevented from the phenomena of shrinkage and hardening, has small change in color and can be easily rehydrated; as compared with the traditional production technology of dendrobium officinale, the technology provided by the invention depends mainly on equipment to finish drying, and has the advantages of high working efficiency, low labor cost, normative operation and high product quality.

Owner:云南久丽康源石斛开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com