Spray drying type fruit and vegetable powder and preparing method thereof

A manufacturing method and technology of fruit and vegetable powder, applied in the field of food processing, can solve problems such as difficult powder extraction, low powder extraction rate, manufacturing difficulty and cost increase, and achieve low addition amount, high effective nutrient content, and good applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

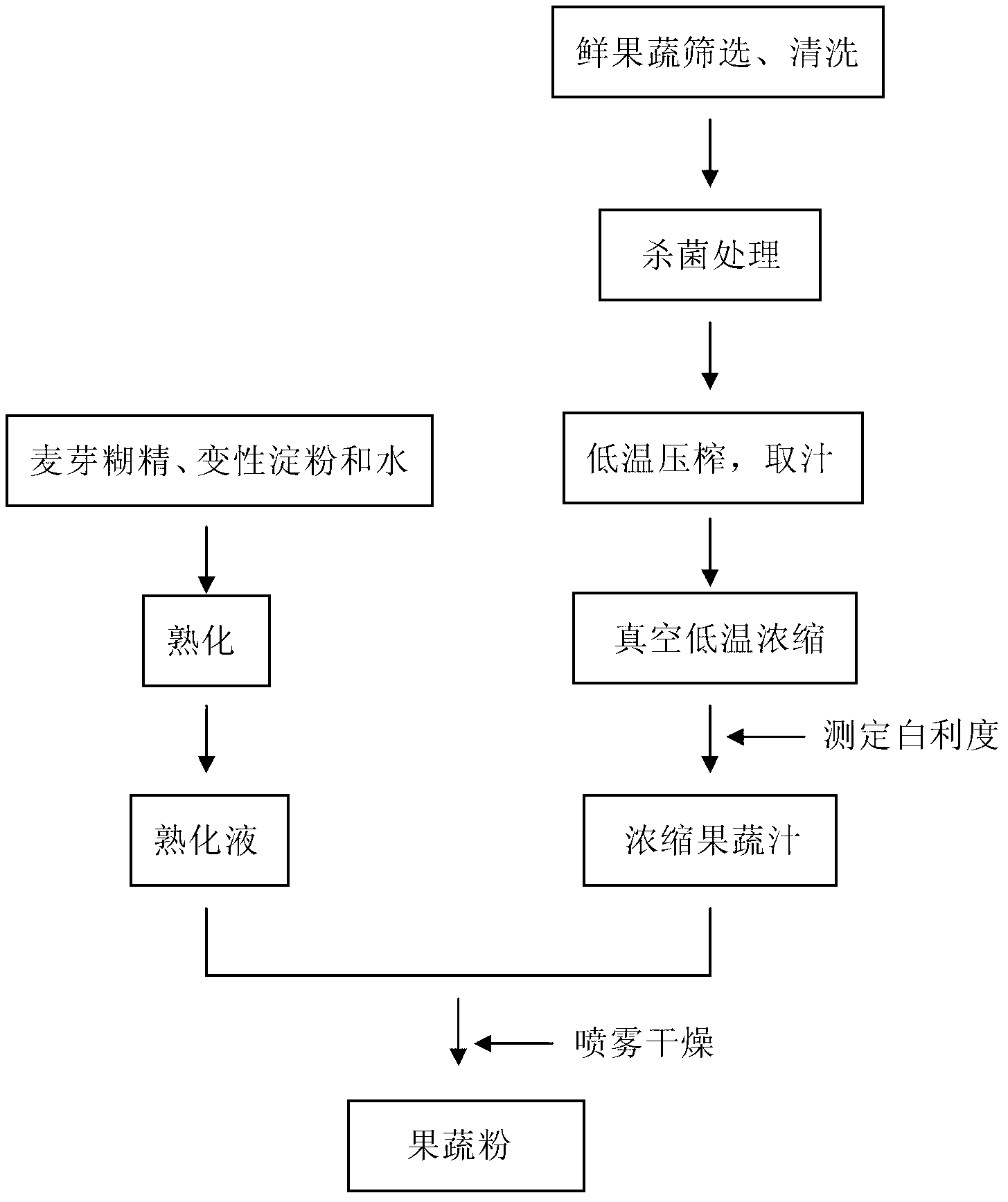

Image

Examples

Embodiment 1

[0035] The formula of fruit and vegetable powder is:

[0036]

[0037] Manufacturing method:

[0038] (1) Screen, clean and sterilize fresh fruits and vegetables;

[0039] (2) Under clean space conditions, squeeze the juice at a low temperature of 5°C;

[0040] (3) Put the fruit and vegetable juice into the reaction kettle to concentrate at a low temperature in vacuum to a Brix ≥ 30% to obtain concentrated fruit and vegetable juice; the conditions for the vacuum low temperature concentration are: the degree of vacuum is 0.002 MPa, and the temperature is 20°C ;

[0041] (4) In another reaction kettle, mix the maltodextrin, modified starch and water according to the above weight percentage, heat, stir, dissolve, and fully mature. The curing temperature is 93°C and kept for 3 minutes to obtain a curing solution;

[0042] (5) Mix the concentrated fruit and vegetable juice prepared in step (3) with the ripening liquid prepared in step (4) according to the dosage in the above ...

Embodiment 2

[0045] The formula of fruit and vegetable powder is:

[0046]

[0047] Manufacturing method:

[0048] (1) Screen, clean and sterilize fresh fruits and vegetables;

[0049] (2) Under clean space conditions, squeeze the juice at a low temperature of 15°C;

[0050] (3) Put the fruit and vegetable juice into the reaction kettle to concentrate at a low temperature in vacuum to a Brix ≥ 30% to obtain concentrated fruit and vegetable juice; the conditions for the vacuum low temperature concentration are: the degree of vacuum is 0.004 MPa, and the temperature is 30°C

[0051] (4) In another reaction kettle, mix the maltodextrin, modified starch and water according to the above weight percentage, heat, stir, dissolve, and fully mature. The curing temperature is 100°C and kept for 10 minutes to obtain a curing solution;

[0052] (5) Mix the concentrated fruit and vegetable juice prepared in step (3) with the ripening liquid prepared in step (4) according to the dosage in the above ...

Embodiment 3

[0055] The formula of fruit and vegetable powder is:

[0056]

[0057] Manufacturing method:

[0058] (1) Screen, clean and sterilize fresh fruits and vegetables;

[0059] (2) Under clean space conditions, squeeze the juice at a low temperature of 10°C;

[0060] (3) Put the fruit and vegetable juice into the reaction kettle to concentrate at a low temperature in vacuum until the Brix (Brix) ≥ 30% to obtain concentrated fruit and vegetable juice; the conditions for the vacuum low temperature concentration are: the vacuum degree of the evaporation chamber is 0.003 MPa, and the temperature at 25°C;

[0061] (4) In another reaction kettle, mix the maltodextrin, modified starch and water according to the above weight percentage, heat, stir, dissolve, and fully mature. The curing temperature is 96°C and kept for 6 minutes to obtain a curing solution;

[0062] (5) Mix the concentrated fruit and vegetable juice prepared in step (3) with the ripening liquid prepared in step (4) acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com