Ammoniation granulator and composite fertilizer production novel technique

A granulator and compound fertilizer technology, applied in the form of fertilizers, fertilization devices, fertilizer mixtures, etc., can solve the problems of shortened service life of tubular reactors, high price of tubular reactors, and increased material loss, and achieve raw material Flexible use range, wide range of raw material use, reducing the effect of system circulating materials

Inactive Publication Date: 2010-12-01

JIANGSU ABOLUO COMPOUND FERTILIZER

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

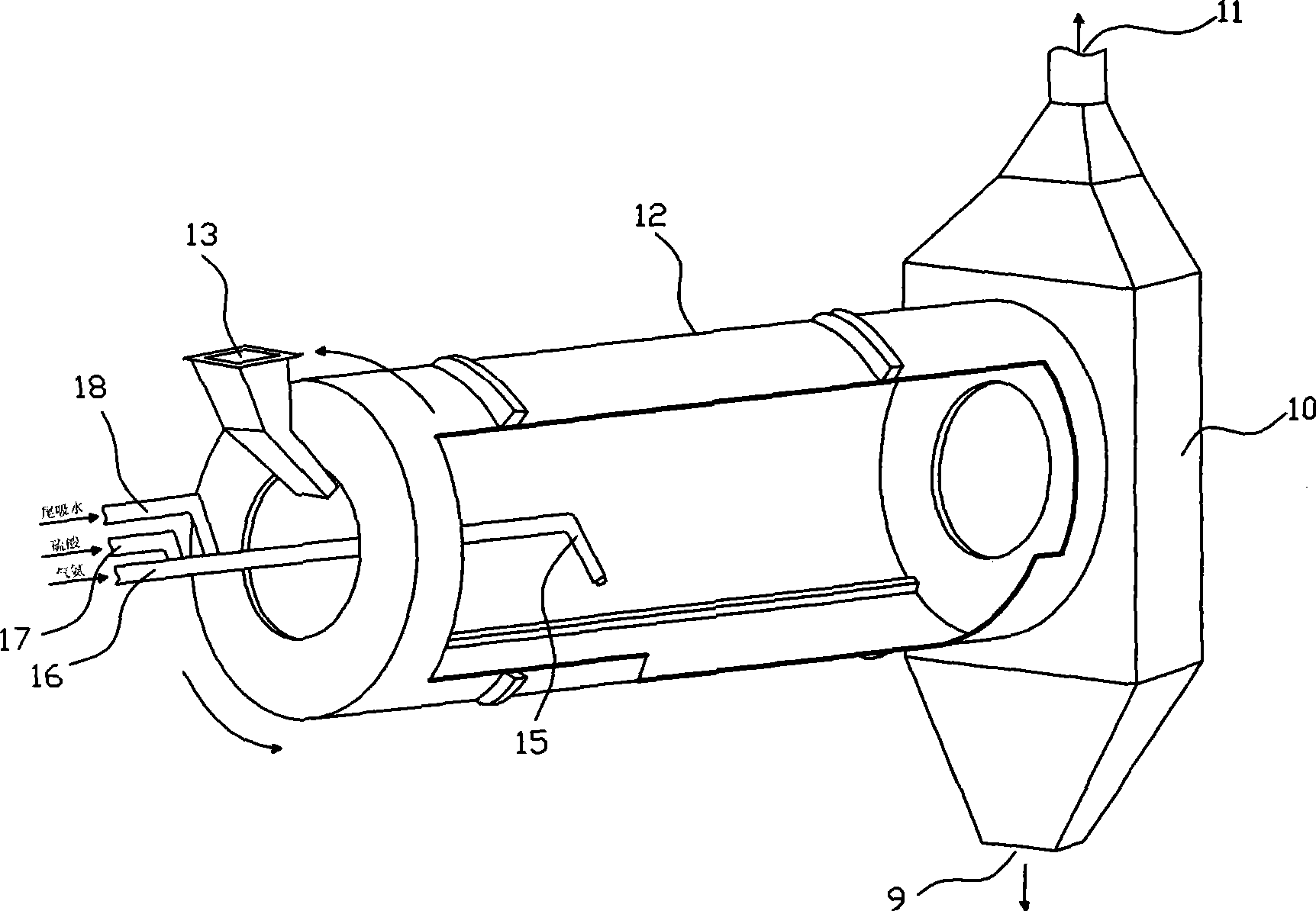

1. Sulfuric acid-ammonia tubular reactor type granulator, see Figure 1. In the figure, 12 is the drum body, 13 is the feed inlet, 15 is the acid tubular reactor, 16 is the gas ammonia pipeline, and 17 is the sulfuric acid pipeline , 18 is the tail suction pipe, 10 is the gas-solid separation chamber of the granulator, 9 is the discharge port, and 11 is the tail gas outlet. When this type of granulator is ammoniated and granulated, the acid neutralization reaction is in the tubular reactor Due to the large amount of heat generated during the reaction, the temperature of the ammonium sulfate solution is as high as 300-350°C. In the case of such high temperature and the presence of acid at the same time, the corrosion of the tubular reactor 15 will be aggravated, causing the tubular reaction The service life of the device is shortened; secondly, when producing high-nitrogen fertilizers, due to the addition of urea in the ingredients, the local high temperature generated is easy to decompose the urea to produce biuret, which increases the content of biuret in the compound fertilizer and causes damage to crops; In addition, the tubular reactor is expensive and the maintenance cost is high, and some also need to install a complicated washing pipeline system

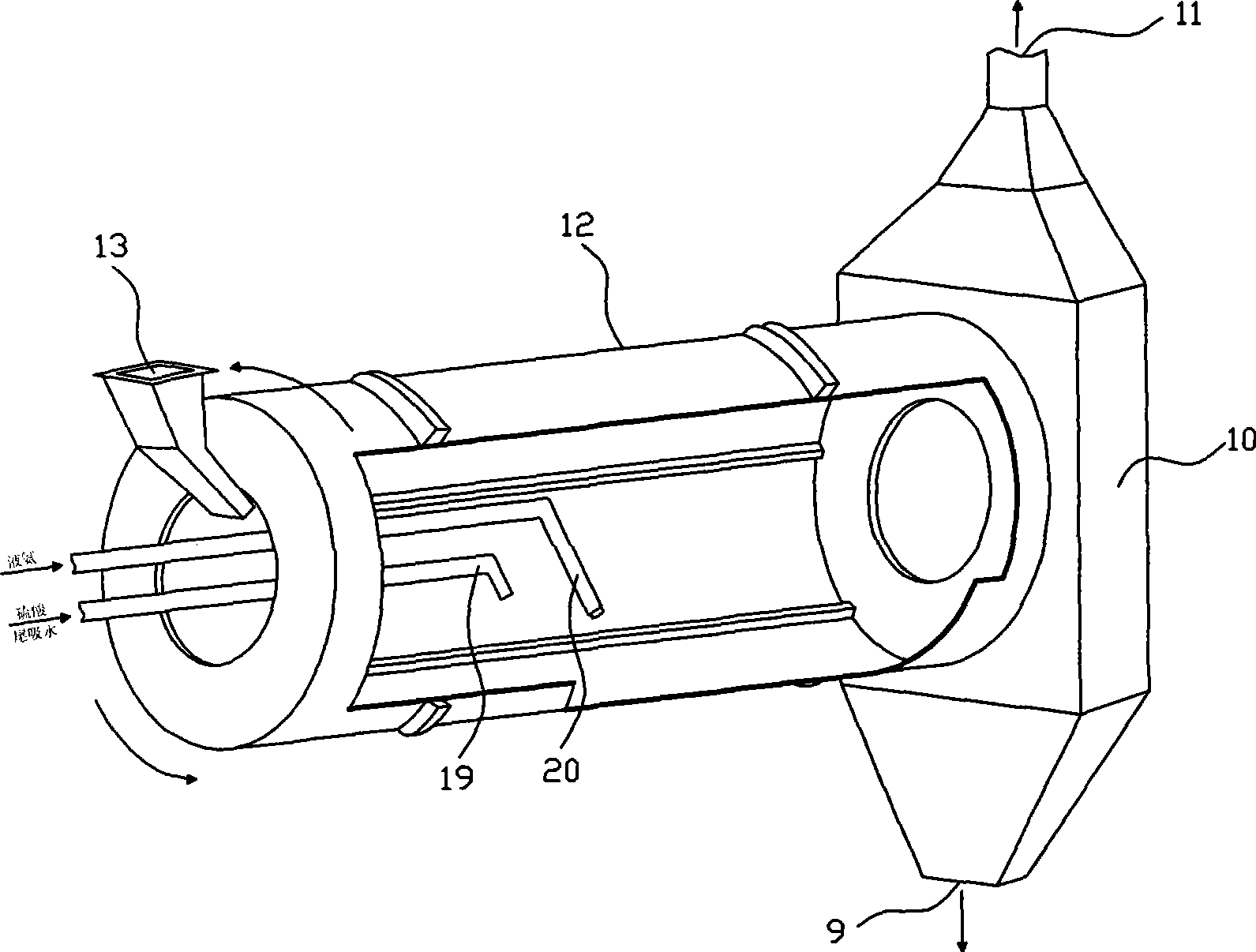

2. Traditional sulfuric acid-ammonia nozzle type granulator, see Figure 2, in which 12 is the drum body, 13 is the feed inlet, 20 is the liquid ammonia distributor, 19 is the sulfuric acid distributor, and 10 is the gas flow of the granulator. In the solid separation chamber, 9 is the discharge port, and 11 is the tail gas outlet. When this type of granulator is ammoniated and granulated, sulfuric acid is sprayed on the material layer, and liquid ammonia is directly sprayed in the material, so it is easy to make the acid distribution uneven. Sulfuric acid reacts with other materials

Among them, the reaction of ① and ② will increase the loss of materials, and the reaction of ③ will lead to the phenomenon of "mixing mud" in the granulator, making the granulation impossible.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Login to View More

Abstract

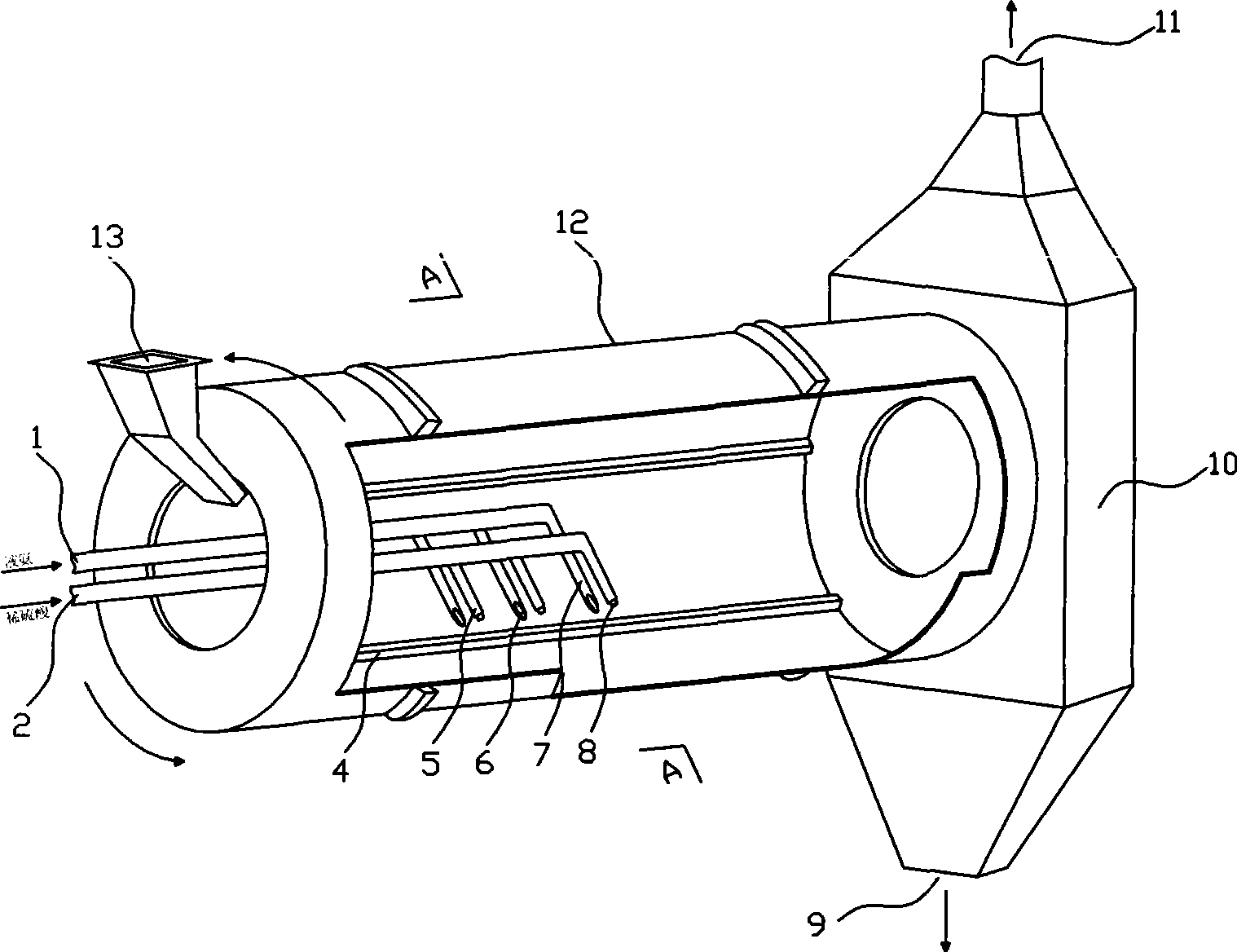

The invention relates to an ammoniation granulator and a compound fertilizer production technology by an amino acid method, aiming at solving the technical problems in the compound fertilizer production process that: biuret is easy to generate, the granulating effect is not good, the production efficiency is low and the energy consumption is high. An amino acid distributor of the ammoniation granulator is respectively and independently arranged, an amino spraying branch pipe provided with an inclined plane spout has an angle of 30 to 60 degrees with a vertical line on the cross section of a cylinder, the rotating directions of the inclined plane spout and the cylinder are consistent; the spout of an acid spraying branch pipe is correspondingly arranged in the opening direction of the inclined spout of the amino spraying branch pipe; and when ammoniation granulating, the granulator sprays liquid ammonia in a material layer with the pressure of 0.5 to 1.0MPa through the amino distributor, an acid distributor sprays sulphuric acid of 50 to 70 percent in the material layer with the pressure of 0.2 to 0.5Mpa, and each ton of solid material is injected with 15 to 25kg of liquid ammoniaand 16.8 to 39.2kg of dilute sulphuric acid. The invention is applied in various raw materials and suitable for the scale production of various compound fertilizers; and the finished products have perfectly round and solid particles, are water resistant and movement resistant and not easy to be crushed and agglomerated.

Description

Ammonia granulator and compound fertilizer production process technical field The invention relates to a granulation device and a compound fertilizer production process, in particular to a compound fertilizer ammoniation granulator and a compound fertilizer ammonia production process. technical background my country's compound fertilizer production began in the 1970s and developed rapidly after entering the 1980s. Especially since 1990, compound fertilizers have been increasing at a rate of 1 million tons (physical volume) almost every year, and have gradually shifted to the production of high-concentration nitrogen, phosphorus and potassium compound fertilizers. Nevertheless, the current application of compound fertilizers in my country only accounts for about 25% of the total application of chemical fertilizers, and the domestic production of compound fertilizers only accounts for 20% of the total output of chemical fertilizers, and they are mainly low-concentration comp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C05G5/00

Inventor 赖涛

Owner JIANGSU ABOLUO COMPOUND FERTILIZER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com