Ammoniation granulator and composite fertilizer production novel technique

A technology of granulator and compound fertilizer, which is applied to fertilizer forms, fertilization devices, fertilizer mixtures, etc., can solve the problem of increased biuret content in compound fertilizers, shortened service life of tubular reactors, and aggravated corrosion of tubular reactors. and other problems, to achieve the effect of improving physical and chemical properties, wide use range of raw materials, and flexible use range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

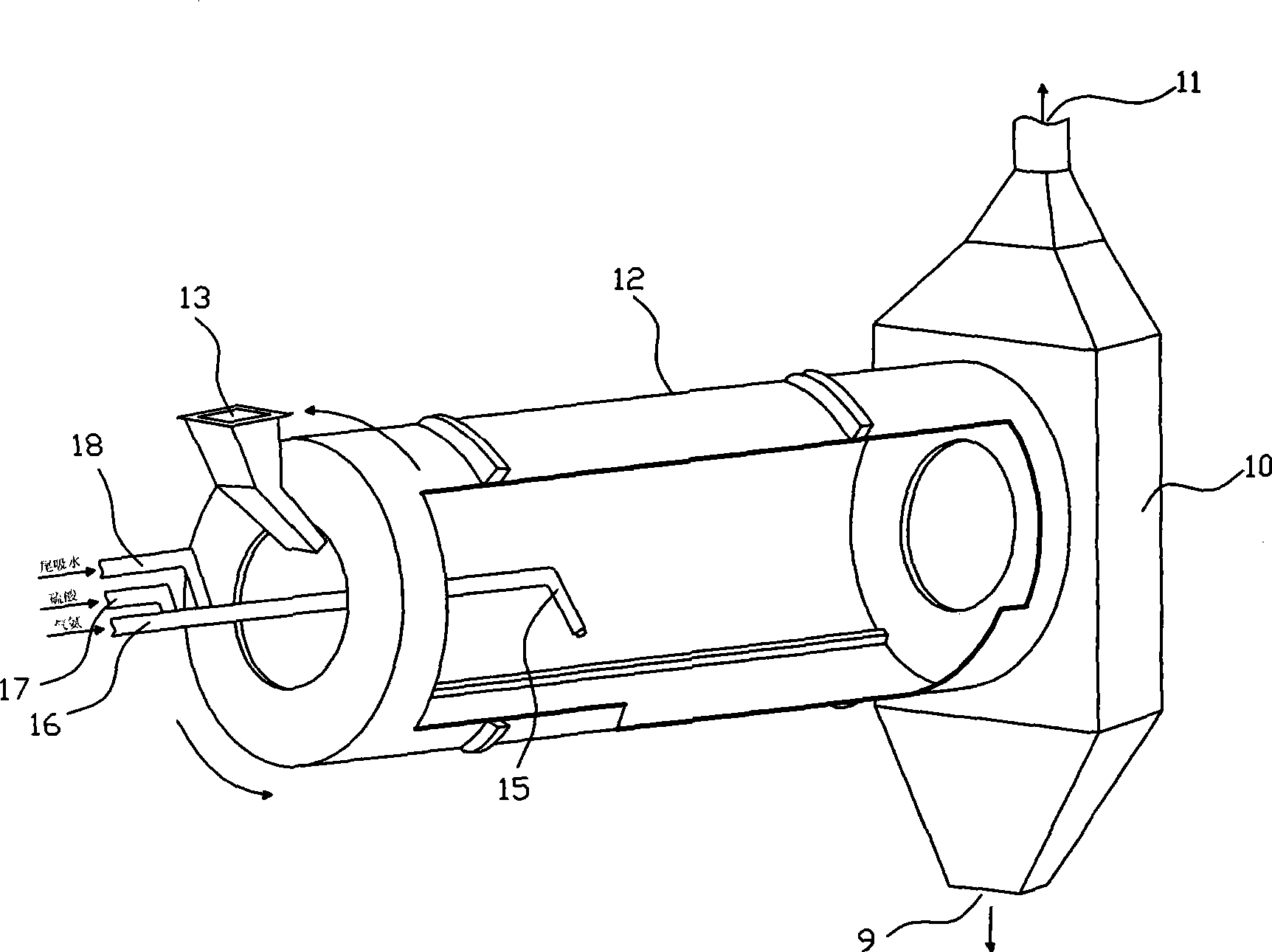

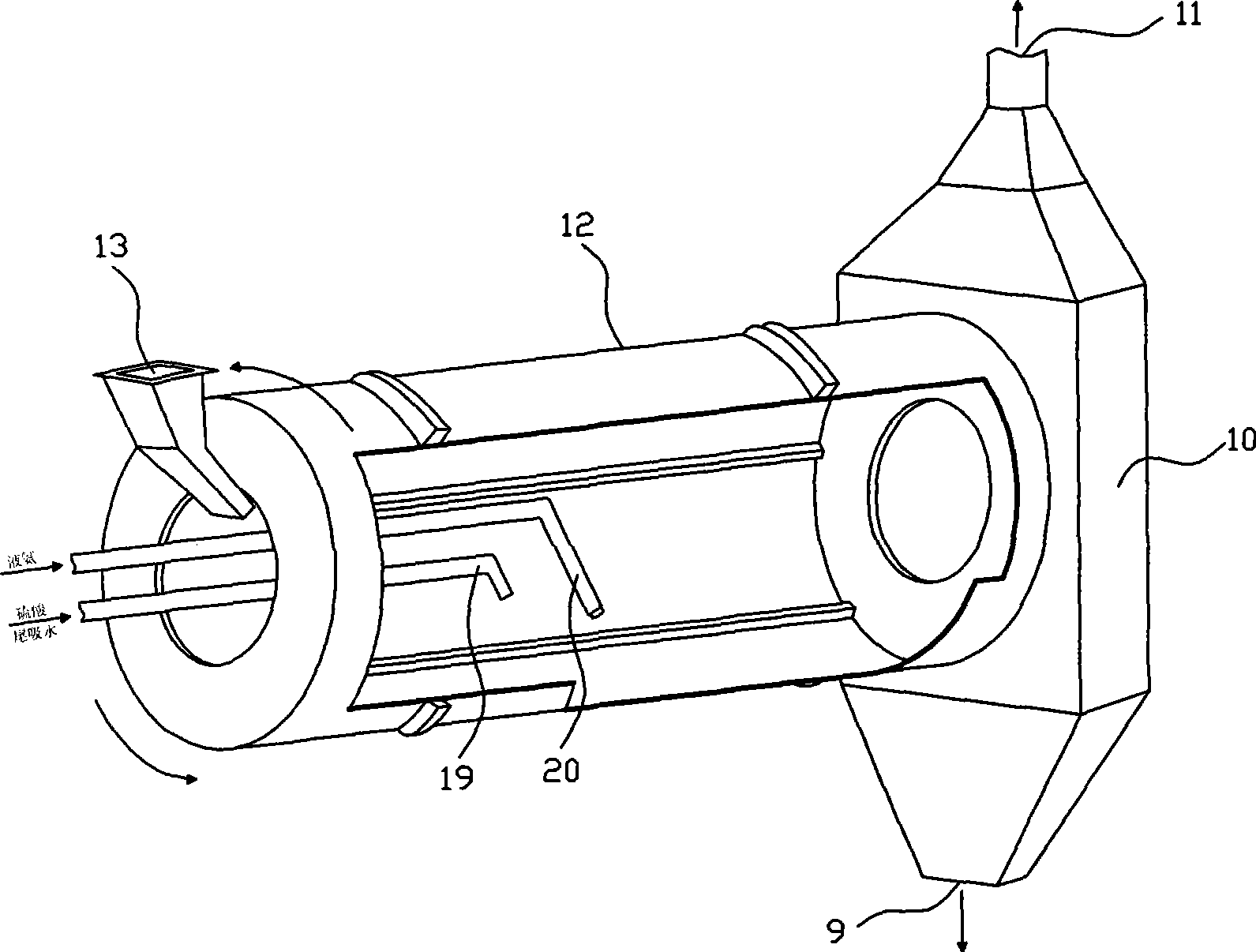

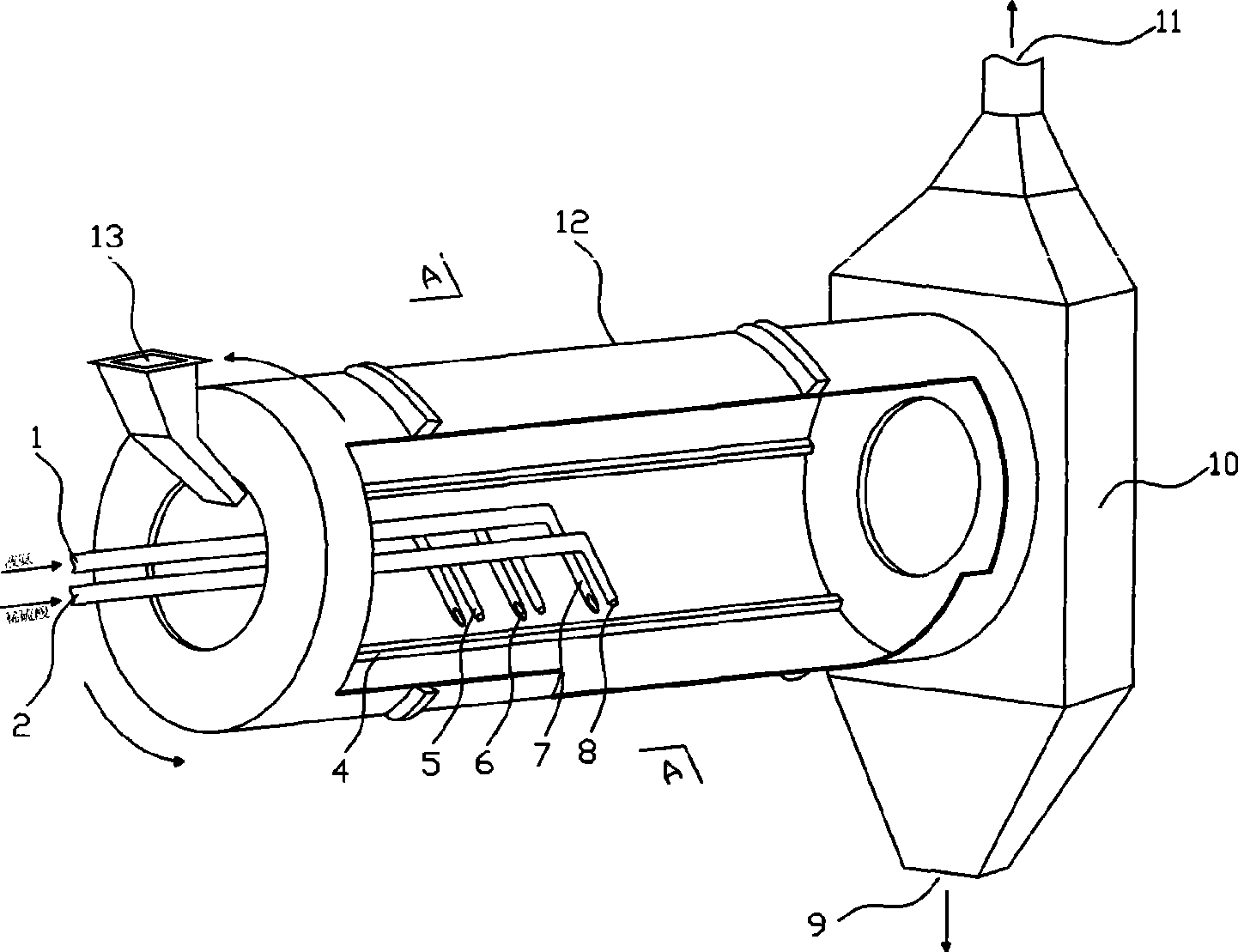

[0034] Embodiment 1, a kind of ammoniation granulator, see image 3 , Figure 4, including the drum body 12 (Φ2200×8000mm) placed in the drum body 12 ammonia distributor and acid distributor, the drum drive mechanism, one end of the drum body 12 is provided with a feed port 13, and the other end communicates with the gas-solid separation chamber 10, the The upper part of the gas-solid separation chamber 10 is provided with an air outlet 11, and the lower part is provided with a material outlet 9. The ammonia distributor is composed of an ammonia delivery pipe 1 and three ammonia injection branch pipes 7 with inclined nozzles 6. The ammonia injection branch pipes 7 are installed on the drum The cross-section of body 12 forms an angle of 45° with the vertical line, and its inclined plane nozzle 6 is consistent with the rotation direction of drum body 12. The radial distance from the inclined plane nozzle 6 to the inner wall of drum body 12 is 500mm; 2 and three groups of acid s...

Embodiment 2

[0037] Embodiment 2 A kind of ammoniation granulator, see image 3 , Figure 4 , including an ammonia distributor and an acid distributor placed in the drum body 12, and a drum driving mechanism. One end of the drum body 12 is provided with a feed port 13, and the other end communicates with a gas-solid separation chamber 10. The gas-solid separation chamber 10 The upper part is provided with an air outlet 11, and the lower part is provided with a material outlet 9. The ammonia distributor is composed of an ammonia delivery pipe 1 and two sets of ammonia injection branch pipes 7 with inclined nozzles 6. The ammonia injection branch pipes 7 are arranged on the cross section of the drum body 12. It forms an angle of 40° with the plumb line, and its inclined plane nozzle 6 is consistent with the rotation direction of the drum body 12, and the radial distance from the inclined plane nozzle 6 to the inner wall of the drum body 12 is 1 / 2 of the radius of the drum body; The acid pip...

Embodiment 3

[0040] Example 3 An ammoniated granulator, which is basically the same as Example 1, except that a neoprene plate is used as the inner lining of the drum, and the inner wall of the drum is evenly divided into 6 large areas, and 6 pieces of neoprene are used to The rubber plates are evenly spliced together as the lining film, and the width of each lining film is 1.25 times the arc length of the 1 / 6 section of the cylinder, and several breathing holes are drilled on the cylinder; when the cylinder rotates, the material runs with the cylinder At the lowest point, the weight of the material discharges the air in the contact room between the rubber film and the cylinder wall from the cylinder with breathing holes, so that the contact area between the materials can be as large as possible. When the height is high, the pressure of the material on the rubber lining film drops, and the air enters the contact chamber from the breathing hole under the action of the external atmospheric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com