Patents

Literature

41results about How to "Low weight loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three dimensionally periodic structural assemblies on nanometer and longer scales

InactiveUS6261469B1Low melting pointEasily de-infiltrateSilicaPaper/cardboard articlesChromatographic separationThermoelectric materials

This invention relates to processes for the assembly of three-dimensional structures having periodicities on the scale of optical wavelengths, and at both smaller and larger dimensions, as well as compositions and applications therefore. Invention embodiments involve the self assembly of three-dimensionally periodic arrays of spherical particles, the processing of these arrays so that both infiltration and extraction processes can occur, one or more infiltration steps for these periodic arrays, and, in some instances, extraction steps. The product articles are three-dimensionally periodic on a scale where conventional processing methods cannot be used. Articles and materials made by these processes are useful as thermoelectrics and thermionics, electrochromic display elements, low dielectric constant electronic substrate materials, electron emitters (particularly for displays), piezoelectric sensors and actuators, electrostrictive actuators, piezochromic rubbers, gas storage materials, chromatographic separation materials, catalyst support materials, photonic bandgap materials for optical circuitry, and opalescent colorants for the ultraviolet, visible, and infrared regions.

Owner:ALLIEDSIGNAL INC

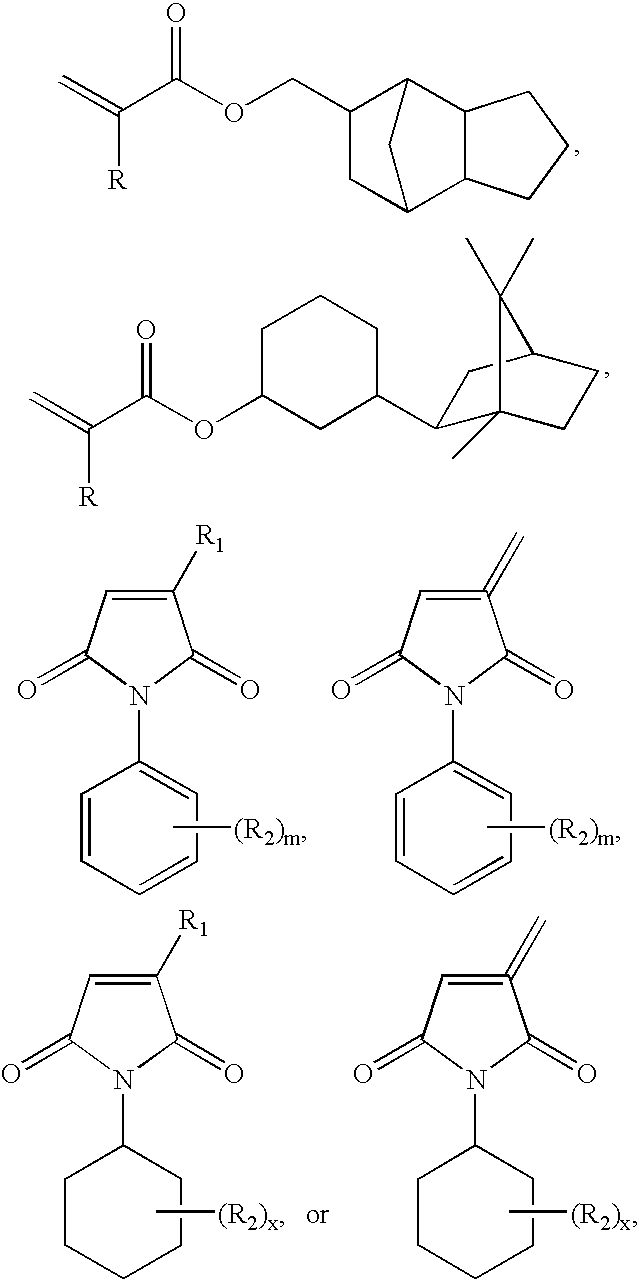

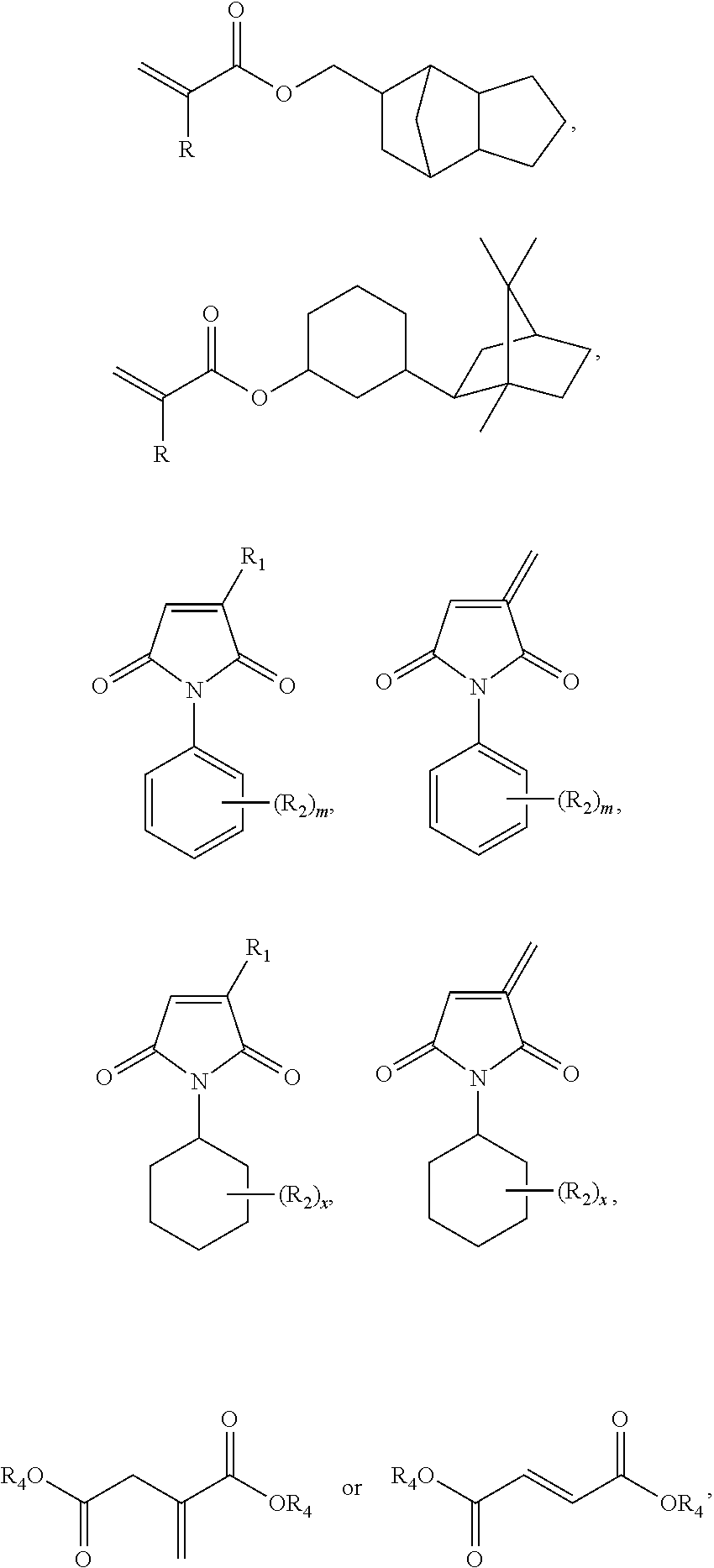

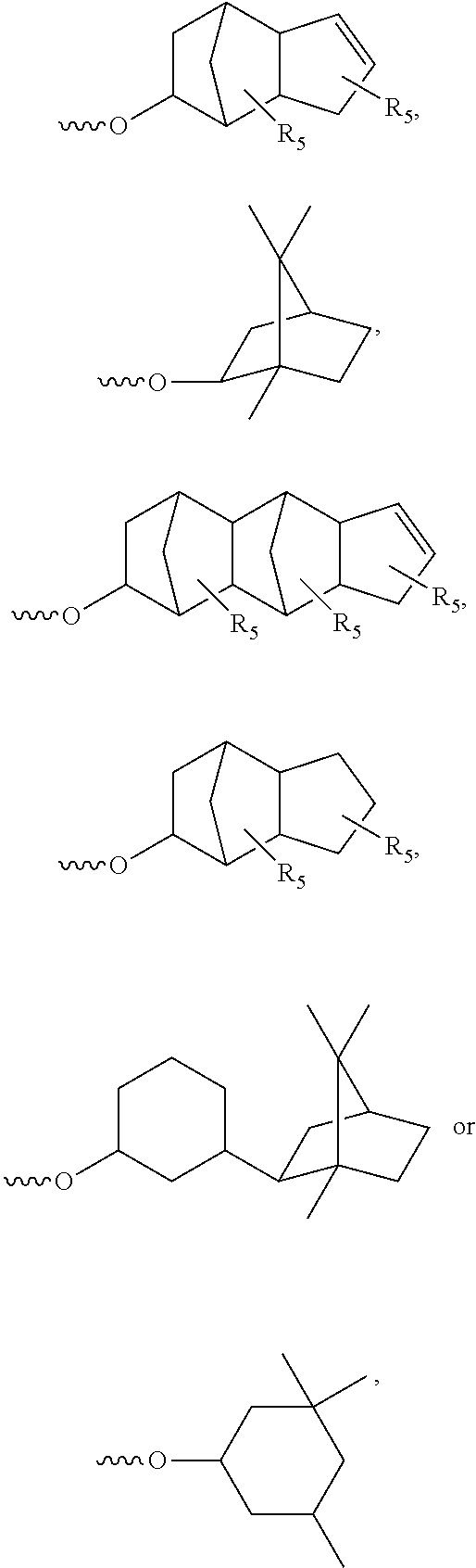

Mono-functional monomers and methods for use thereof

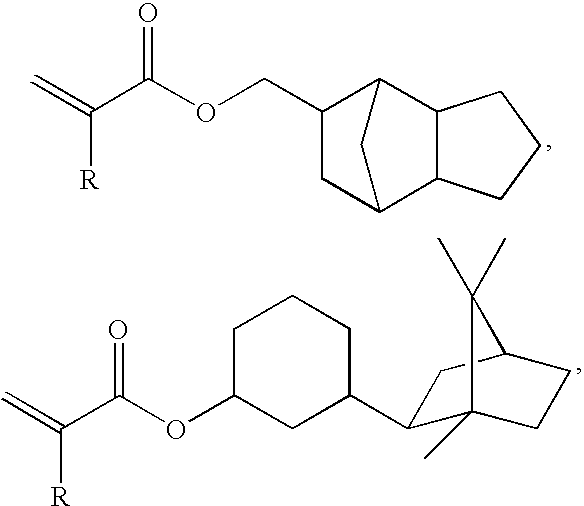

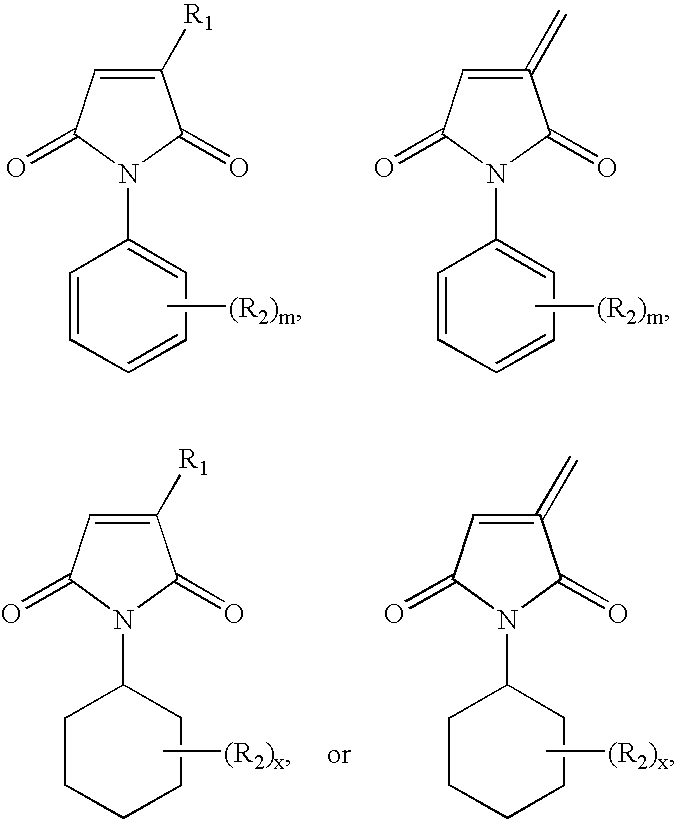

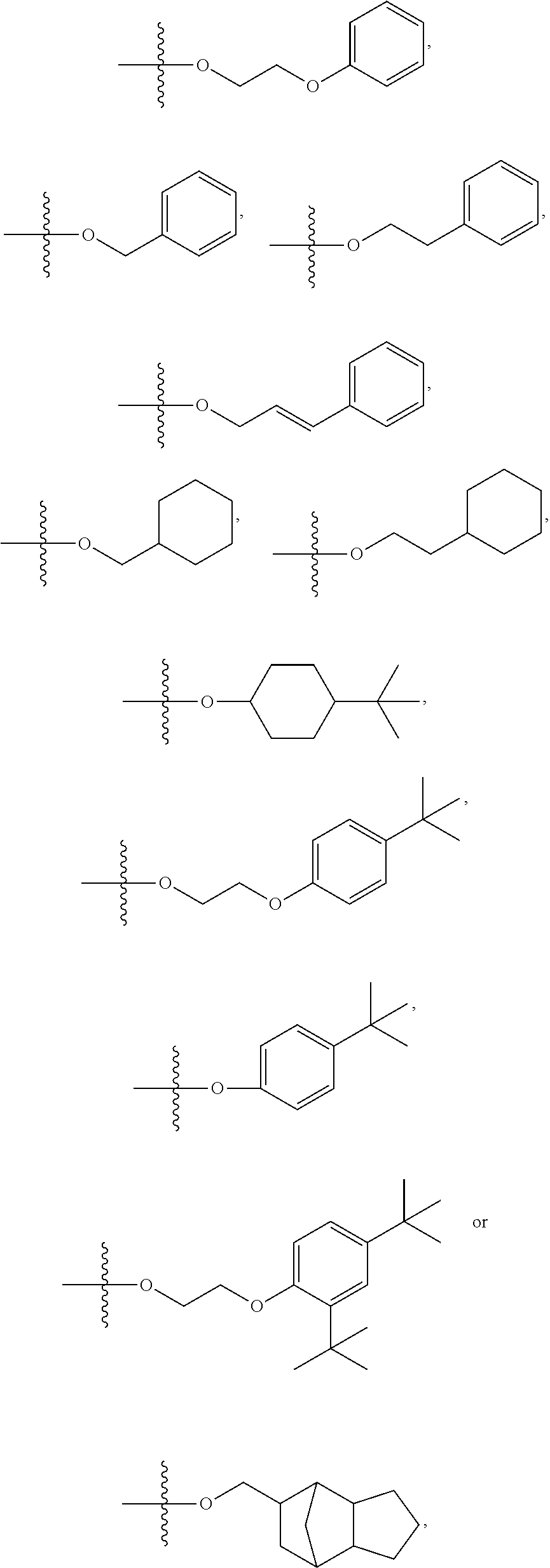

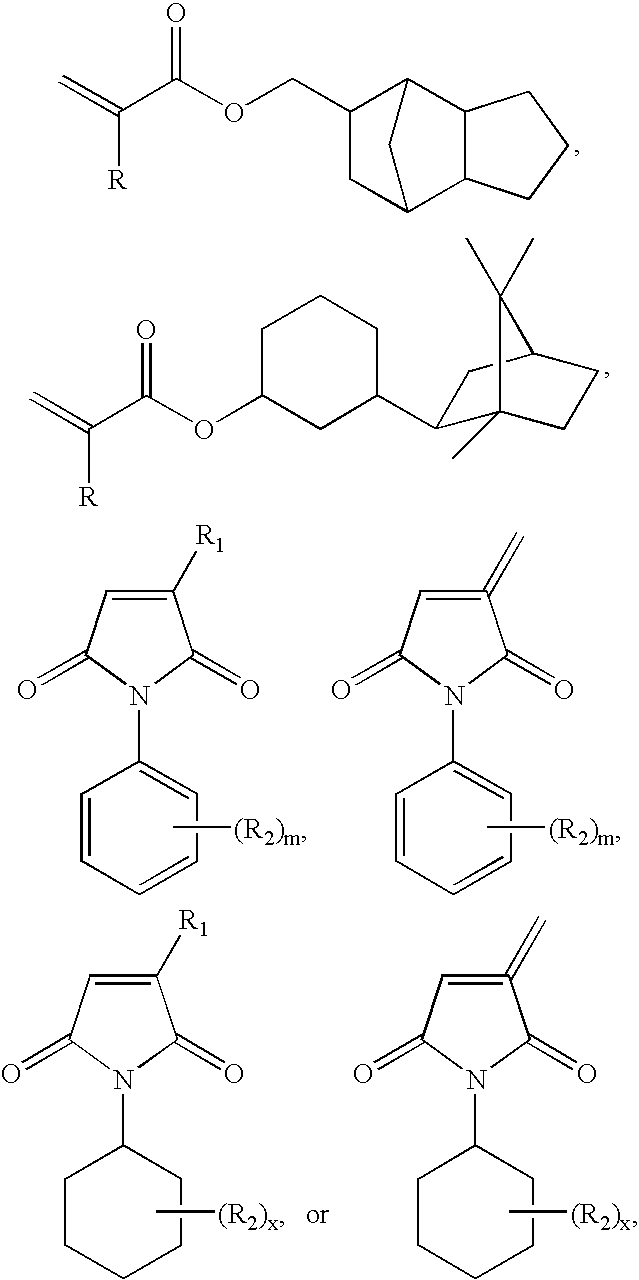

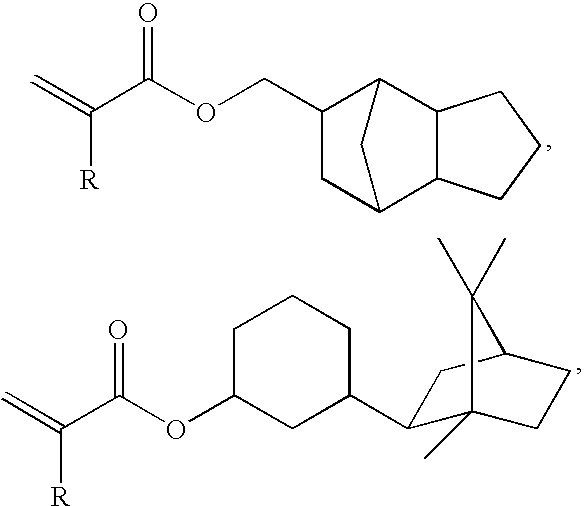

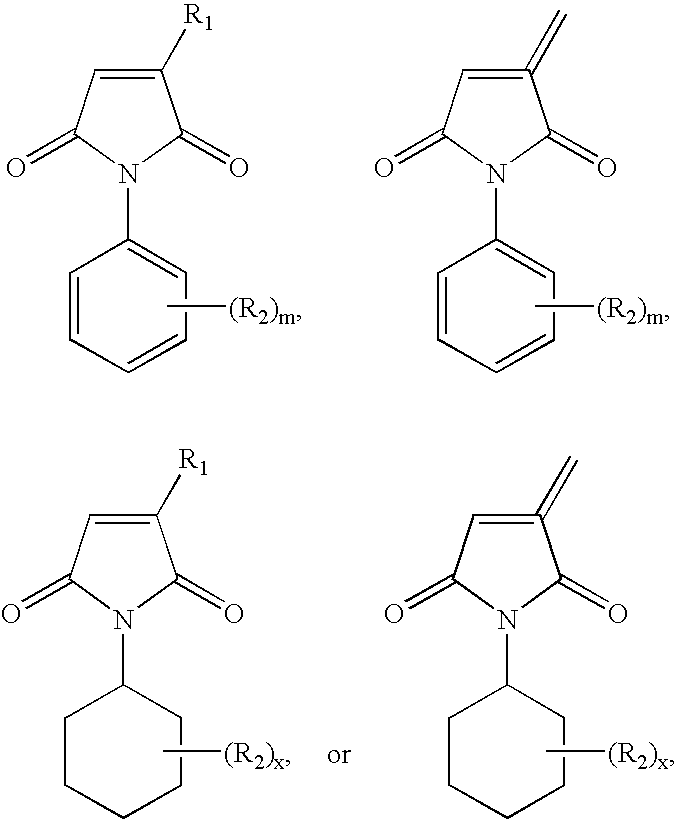

ActiveUS20070155869A1Little weight lossHigh glass transition temperatureCosmetic preparationsToilet preparationsFunctional monomerGlass transition

The invention is based on the discovery that adhesive compositions containing certain low-viscosity, mono-ethylenically unsaturated monomers have surprisingly good cure parameters, resulting in very little weight loss upon cure. Many of these monofunctional monomers used alone or in combination with other monofunctional monomers described herein have high glass transition temperatures when cured. Moreover, since these monomers are monofunctional the crosslink density of the adhesive composition does not increase (relative to multi-functional monomers), which in turns results in lower stress, lower modulus adhesive compositions. As such, these monomers are useful in a variety of thermoset adhesive compositions, such as for example, die attach adhesive compositions.

Owner:DESIGNER MOLECULES

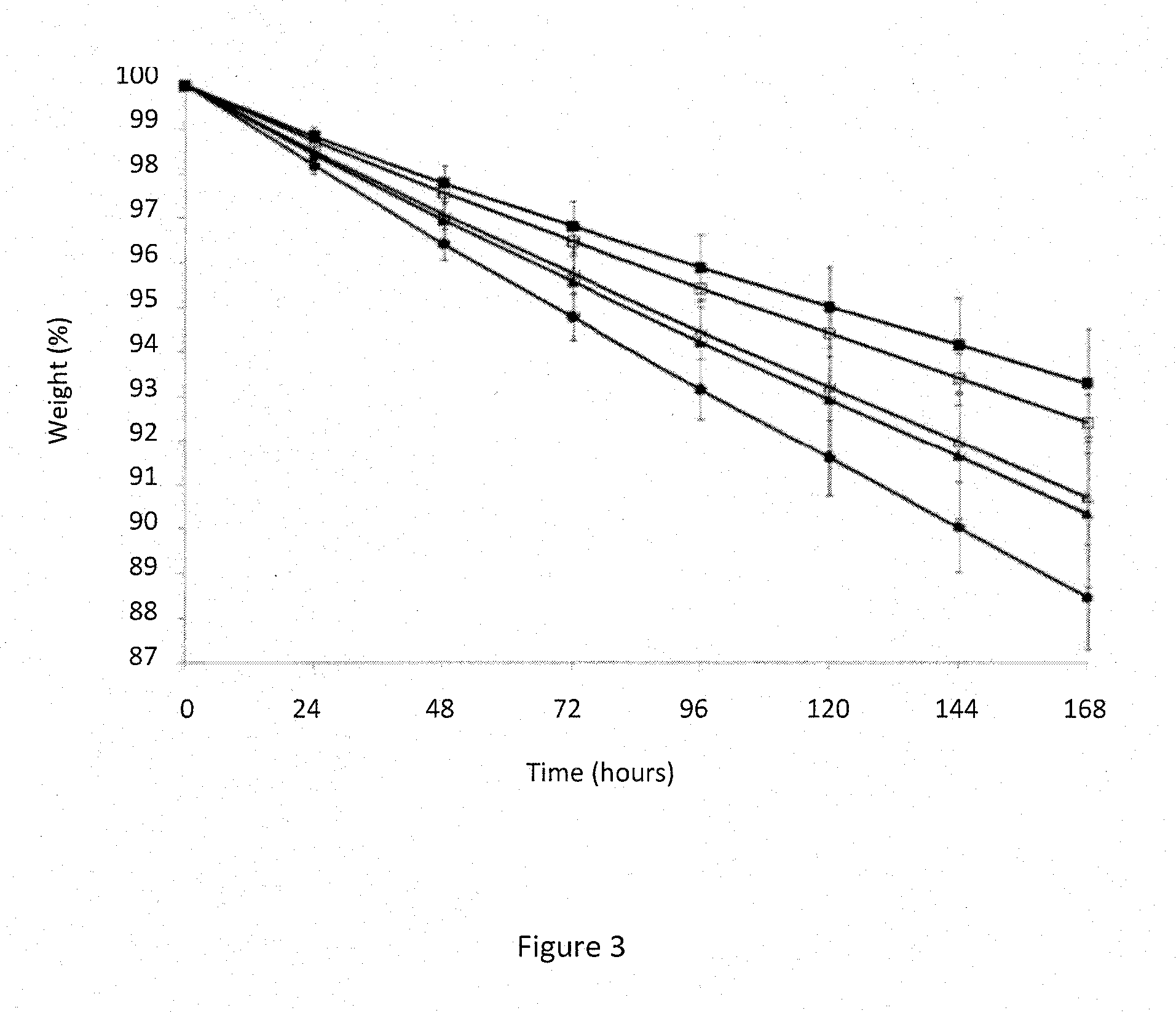

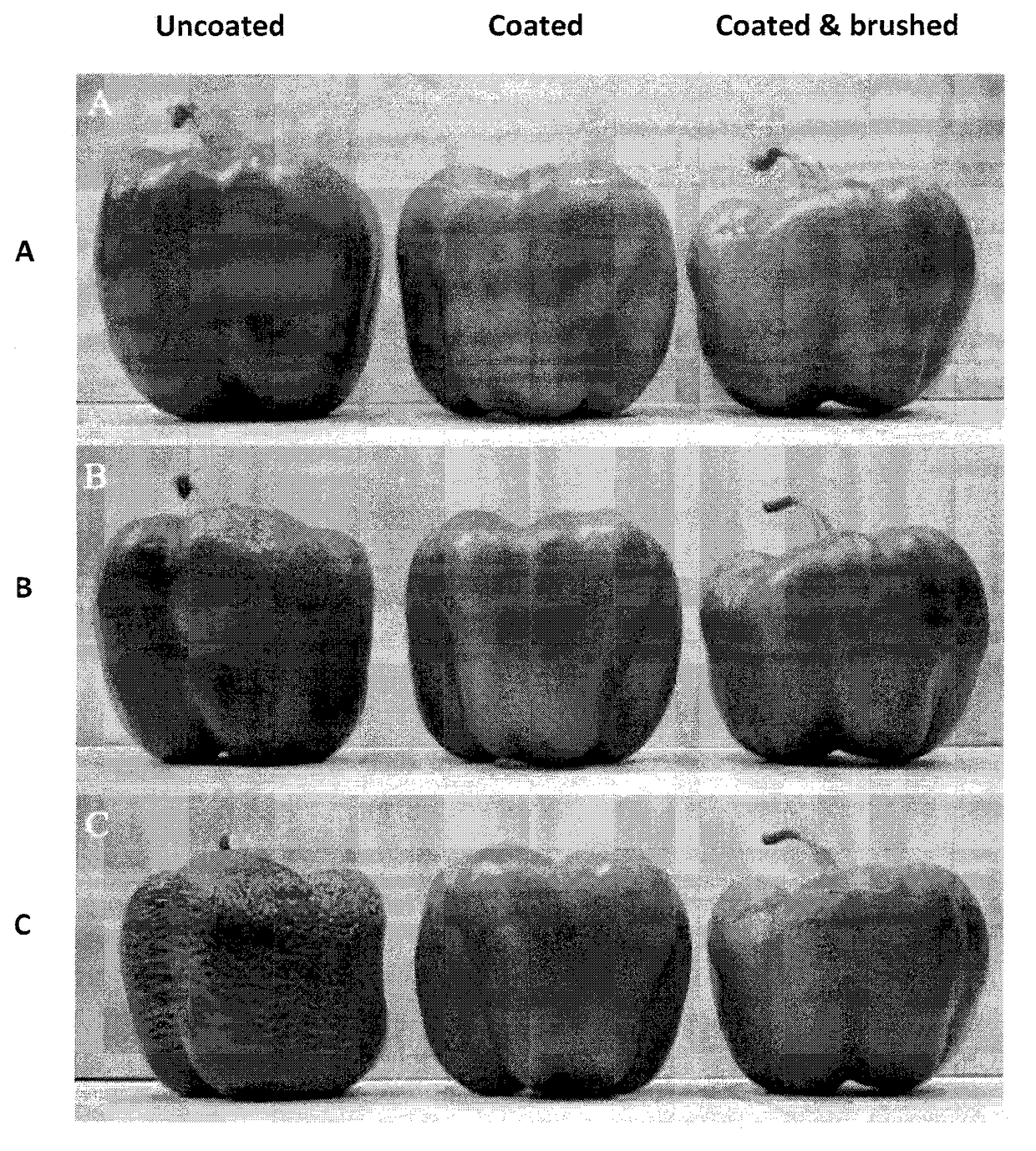

Edible coating for plant matter

ActiveUS20150079248A1High natural glossLimited water reservoir capacityDead plant preservationDough treatmentWaxColloid

The present invention discloses composition and methods for reducing the weight loss and / or preserving the natural gloss of post-harvest edible plant matter. In particular, the methods comprising applying to the surface of the plant matter a composition comprising an edible wax having a melting temperature below 70° C.; a hydrocolloid; a fatty acid; an emulsifier; and water, wherein said edible wax is present in a weight percent ranging from about 10% to about 25% of the total weight of the composition.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

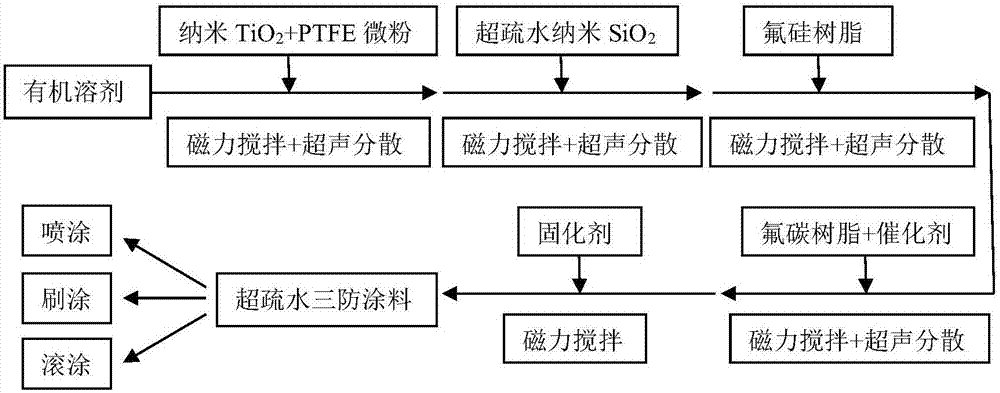

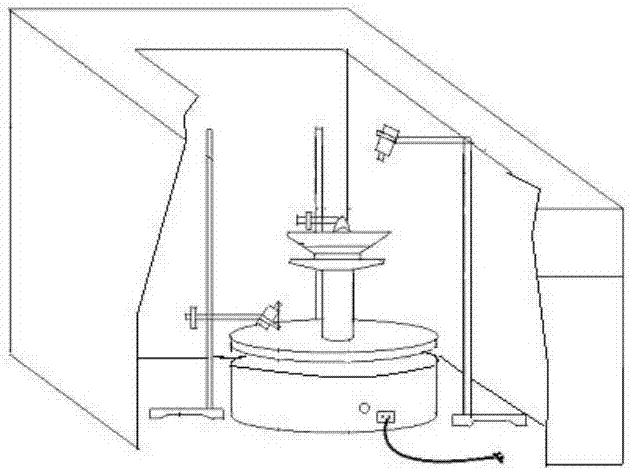

Super-hydrophobic conformal coating, and preparation method and application method thereof

InactiveCN107446424AImprove overall performanceGood weather resistanceAntifouling/underwater paintsPretreated surfacesChemistryNanometre

The invention discloses a super-hydrophobic conformal coating, and a preparation method and an application method thereof. The super-hydrophobic conformal coating is composed of, by mass, 5 to 40% of fluorocarbon resin, 10 to 30% of fluorosilicon resin, 20 to 60% of an organic solvent, 10 to 30% of silica, 1 to 10% of titanium dioxide, 1 to 10% of polytetrafluoroethylene, 0.1 to 0.5% of a catalyst, and 1 to 5% of a curing agent. According to the preparation method, the ingredients are subjected to stirring mixing and ultrasonic uniform dispersion in sequence at a certain ratio. According to the application method, the super-hydrophobic conformal coating is subjected to direct spraying or brush coating onto the surfaces of insulators and outdoor electric power facilities; the thickness of obtained coating layers is controlled to be 0.1 to 0.5mm preferably; and 20 to 60min of normal temperature curing is needed. The preparation method is simple; the cost is low; the super-hydrophobic conformal coating is convenient to use, possesses extremely high hydrophobicity and weatherability, is capable of realizing self cleaning, is a nanometer composite hybrid normal-temperature cured fluorocarbon coating, is capable of realizing stain prevention, pollution flashover prevention, and corrosion prevention of insulators and outdoor electric power facilities effectively, and is promising in application prospect.

Owner:昆明理工大电力工程技术有限公司

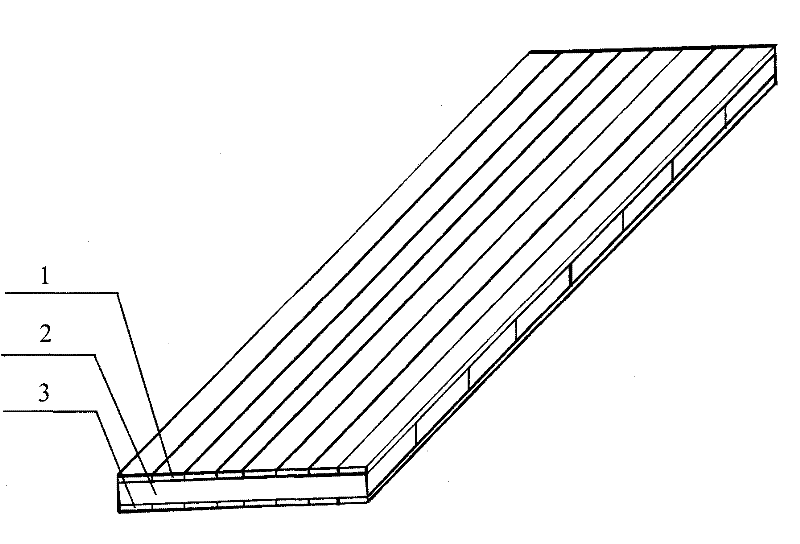

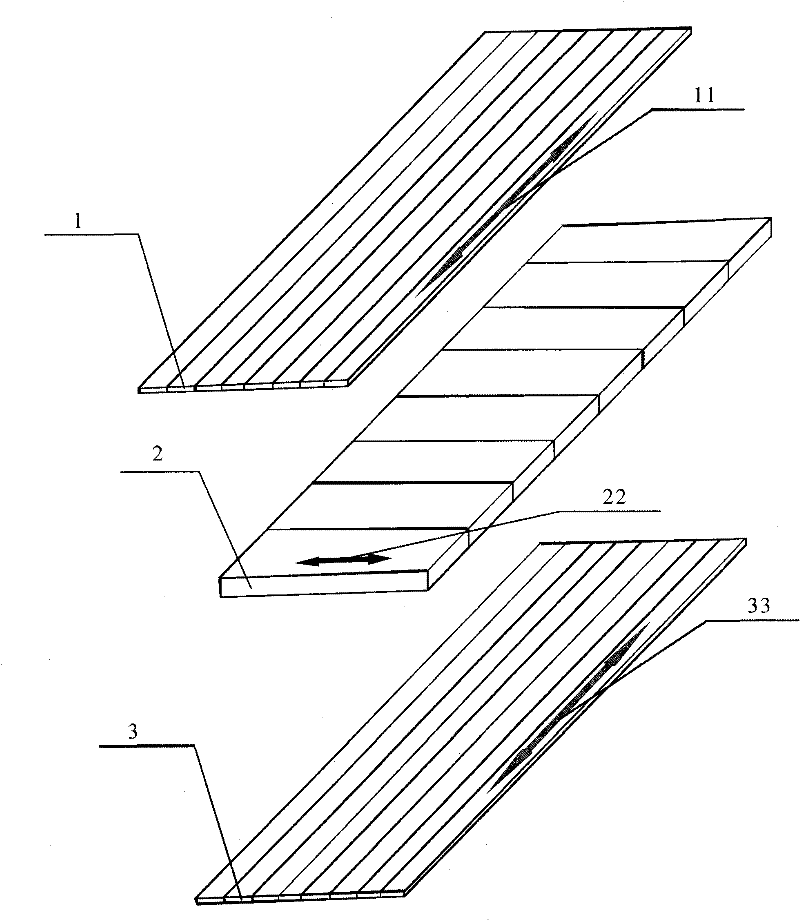

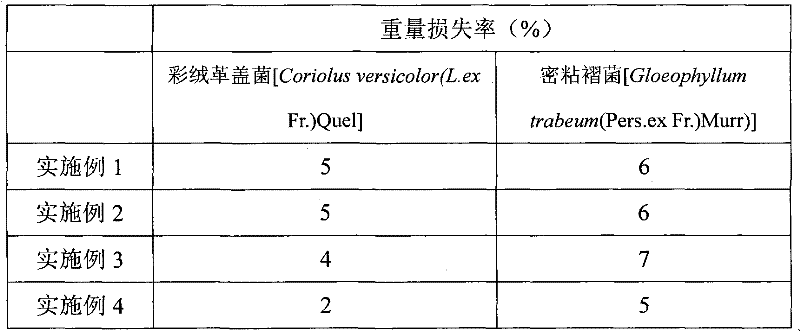

Bamboo-wood composite board and preparation method thereof

InactiveCN101745947AFully absorbedReach the designed drug loadingWood veneer joiningThermal compressionHigh surface

The invention relates to an anti-corrosion bamboo-wood composite board and a preparation method thereof. The preparation method of the anti-corrosion bamboo-wood composite board comprises the following steps: firstly preparing anti-corrosion bamboo strips and heat-treated wood; next, respectively assembling and compressing the anti-corrosion bamboo strips and the heat-treated wood into anti-corrosion bamboo wood and a heat-treated sheet material; and then carrying out assembling and hot compression on the anti-corrosion bamboo wood and the heat-treated sheet material to obtain the anti-corrosion bamboo-wood composite board. The bamboo-wood composite board prepared by the method of the invention has excellent corrosion resistance which reaches the corrosion resisting level specified in national standard GB / T13942.1-1992 Method for Laboratory Test of Natural Decay Resistance of Woods, and also has very high surface abrasion resistance and high mechanical strength which reach the national standards in GB / T 18103-2000 national composite floor.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

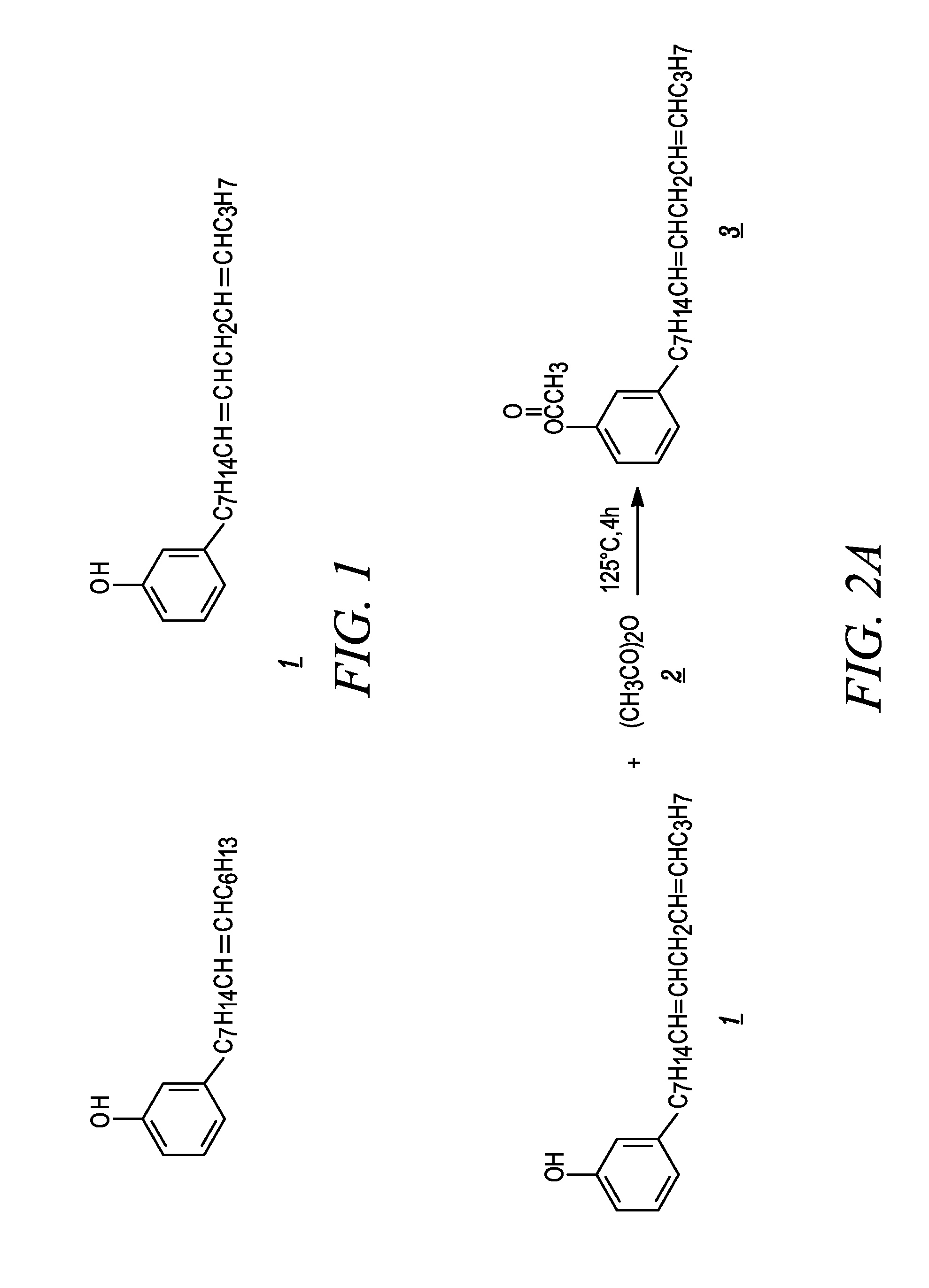

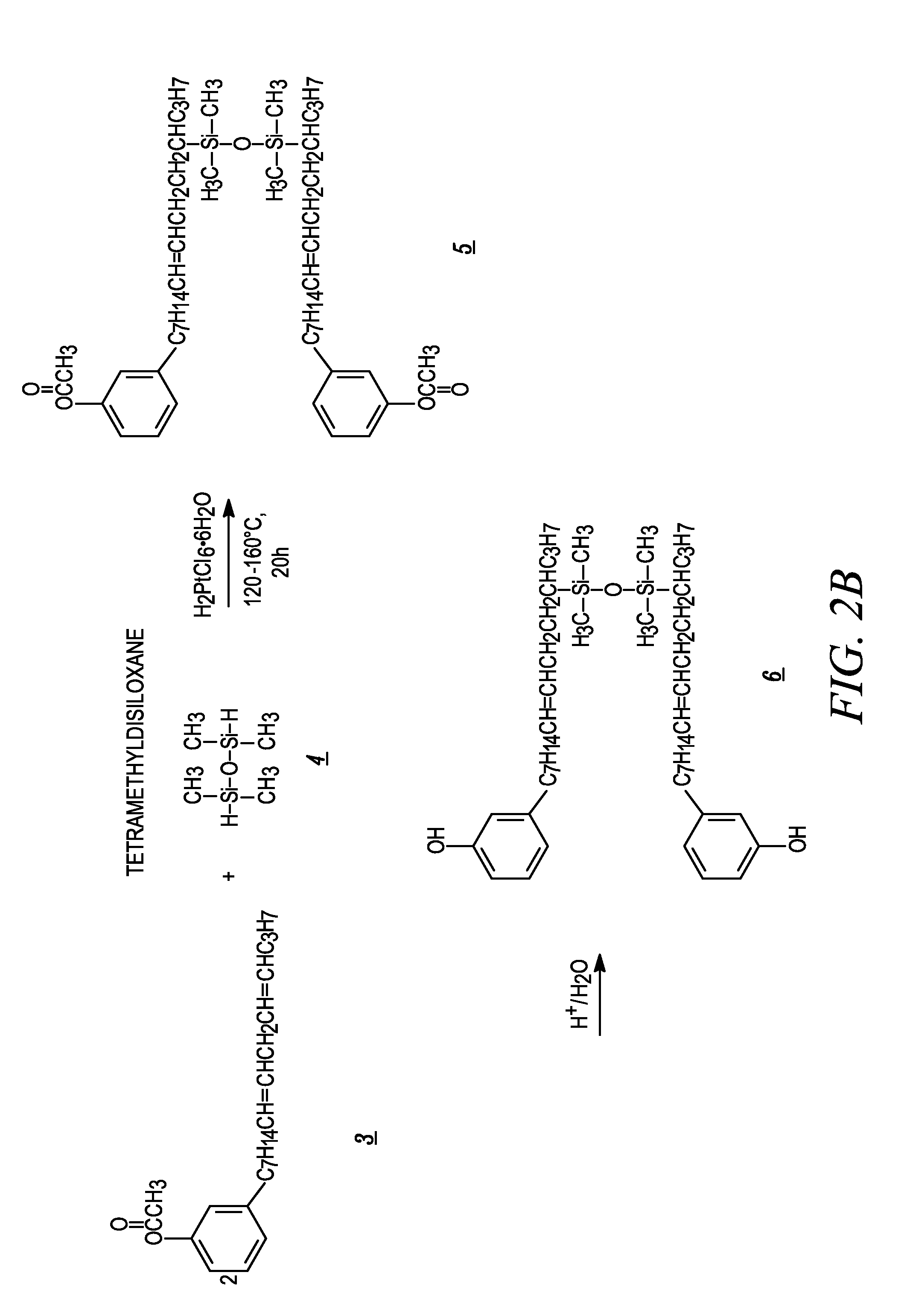

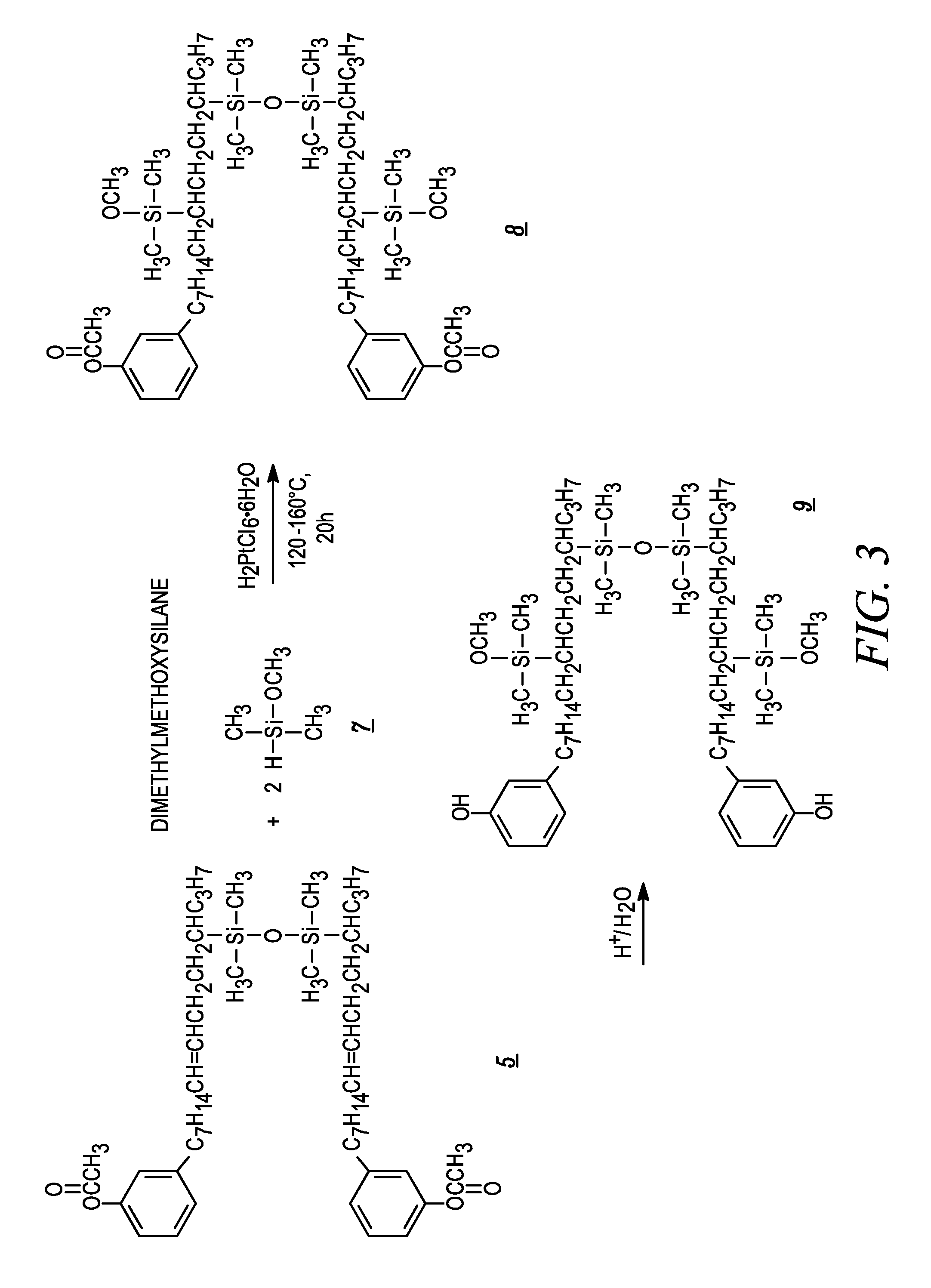

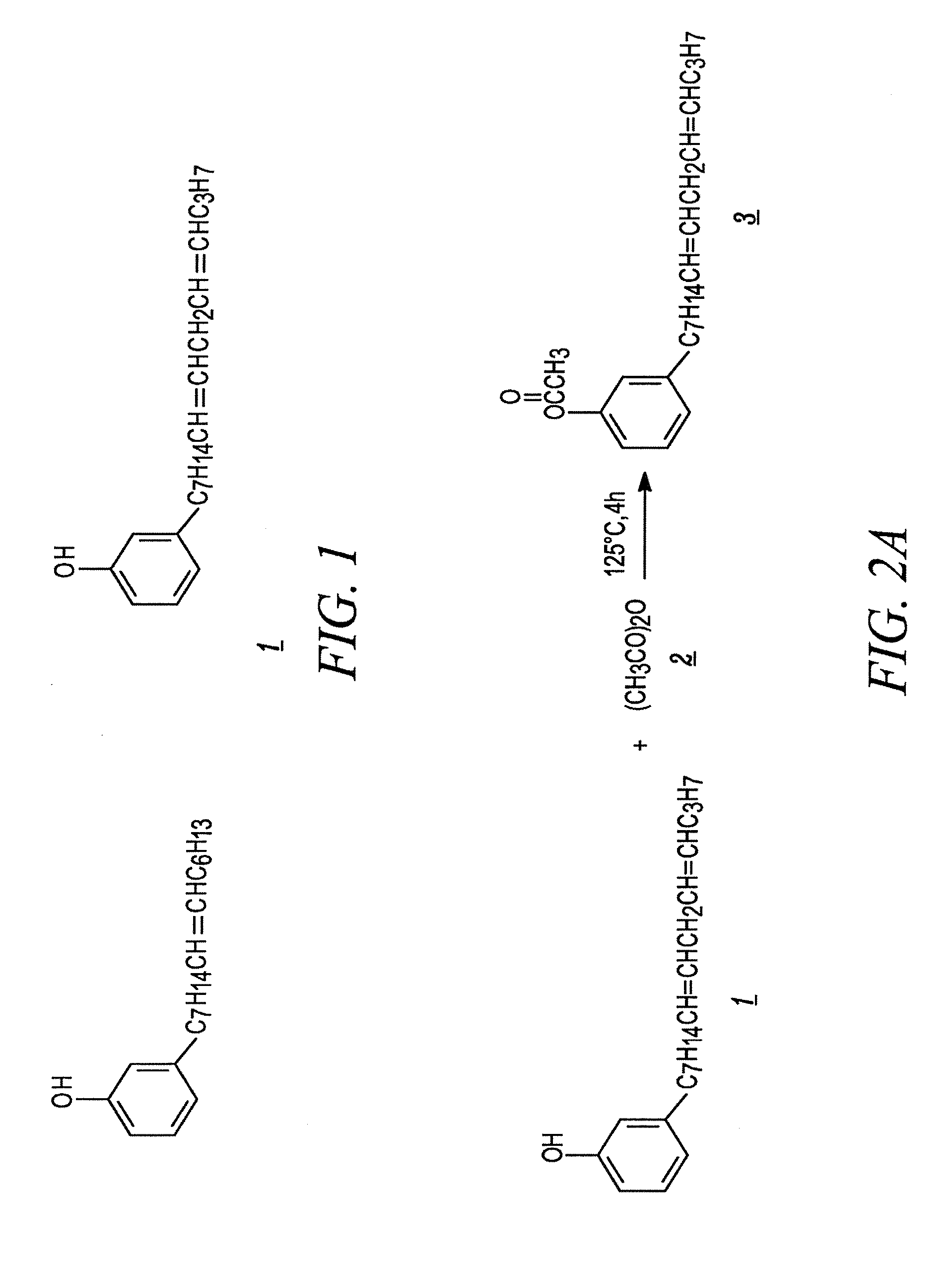

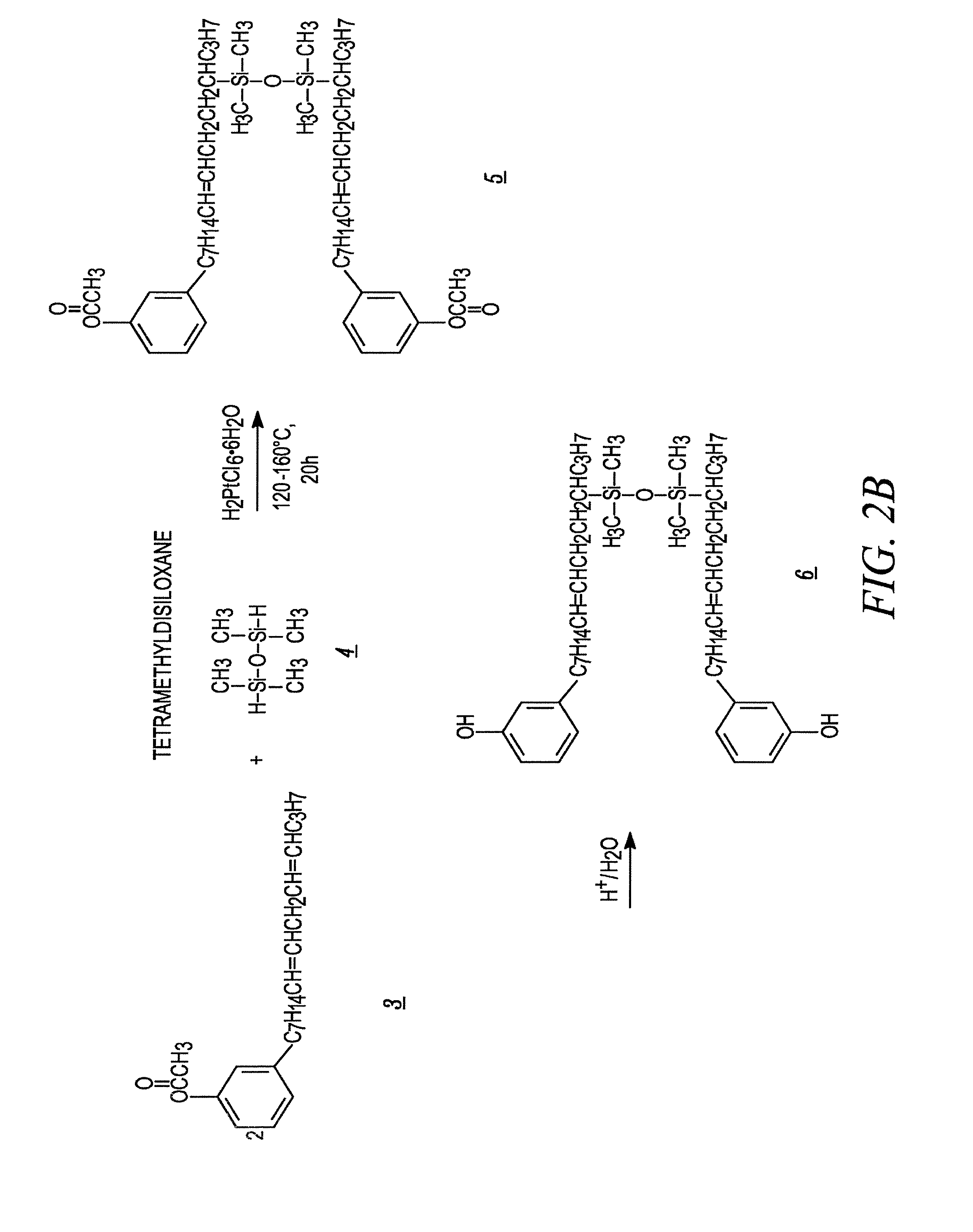

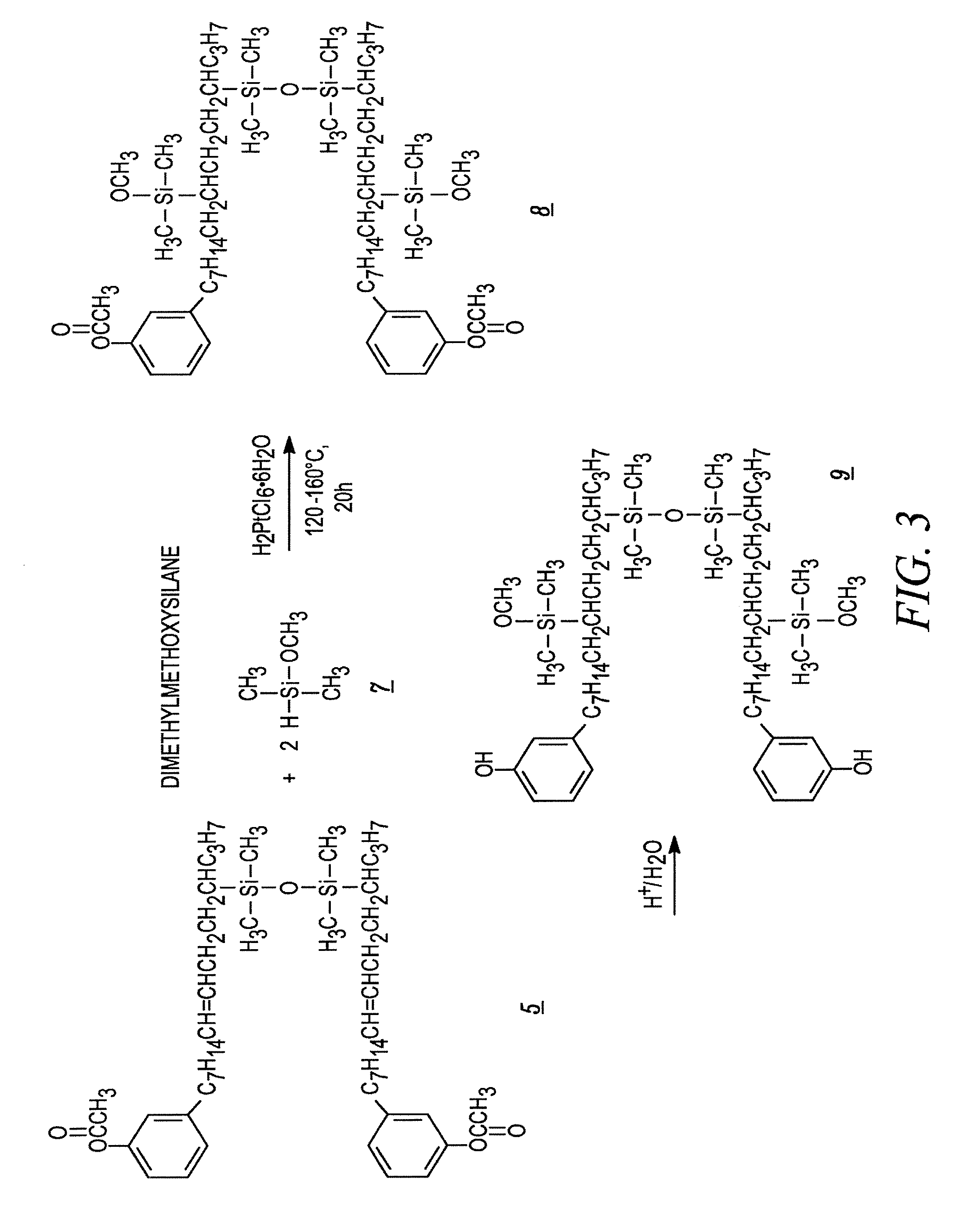

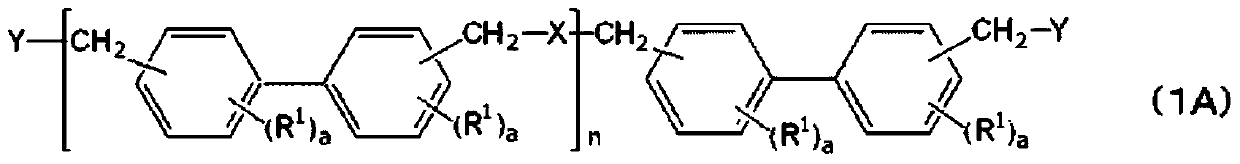

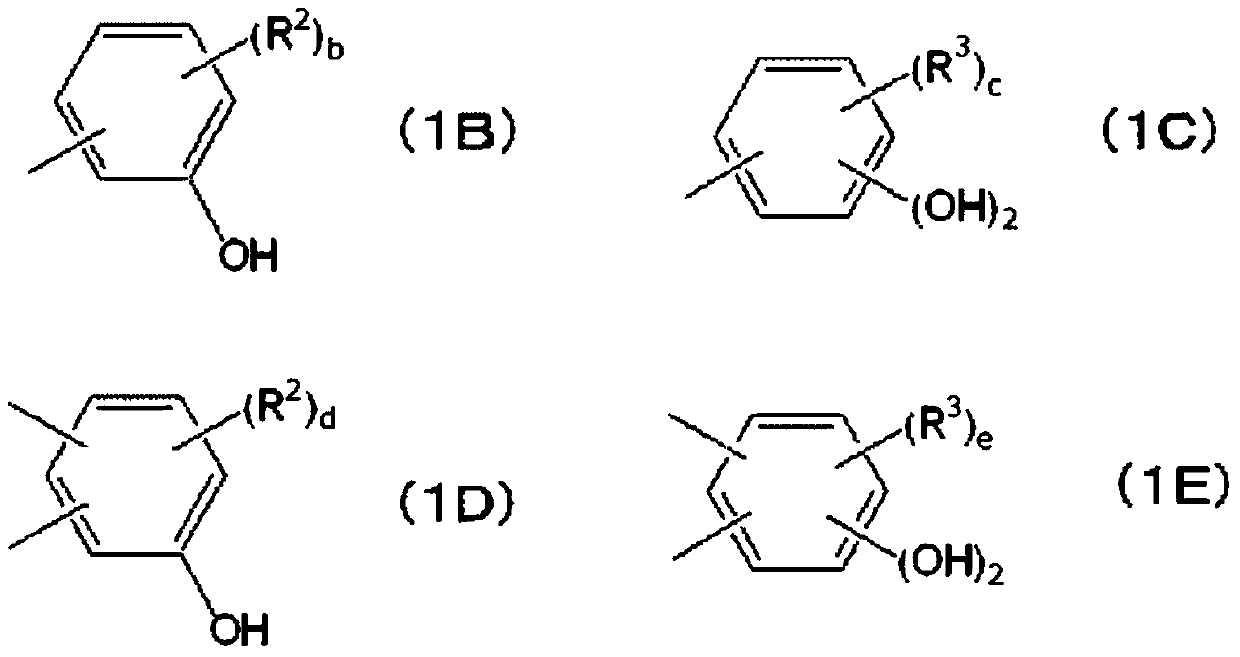

Cardanol based dimers and uses therefor

InactiveUS20080275204A1Reduce coefficient of frictionImprove adhesionSilicon organic compoundsCoatingsSilanesHydrosilylation

Cardanol based dimers are provided. The cardanol dimers are formed by hydrosylylation with silanes. Cardanol based dimers may be further reacted to form epoxy curing agents and epoxies which can be used as anti-fouling coatings on ship hulls and marine structures. The cardanol dimers may also be used to produce friction particles or phenolic resins. Methods of synthesizing the cardanol based dimers, the epoxy curing agents and the epoxies are also provided.

Owner:CARDOLITE CORP

Thermosetting adhesive compositions

InactiveUS20130187095A1Little weight lossHigh glass transition temperatureConductive materialEster polymer adhesivesFunctional monomerGlass transition

The invention is based on the discovery that adhesive compositions containing certain low-viscosity, mono-ethylenically unsaturated monomers have surprisingly good cure parameters, resulting in very little weight loss upon cure. Many of these monofunctional monomers used alone or in combination with other monofunctional monomers described herein have high glass transition temperatures when cured. Moreover, since these monomers are monofunctional the crosslink density of the adhesive composition does not increase (relative to multi-functional monomers), which in turns results in lower stress, lower modulus adhesive compositions. As such, these monomers are useful in a variety of thermoset adhesive compositions, such as for example, die attach adhesive compositions.

Owner:DESIGNER MOLECULES

Functional type wood plastic composite (WPC) with light core-shell structure

ActiveCN101992576AIncreased durabilityCorrosion resistantSynthetic resin layered productsStearic acidMaterials science

The invention claims a functional type wood plastic composite (WPC) with a light core-shell structure. HDPE (high-density polyethylene) or HDPE / PP (Propene Polymer) blend is taken as a substrate for the WPC. Wood fiber accounting for 0-45% of the substrate by weight is added into the substrate to obtain a mixed plastic wood material; then, a chemical foaming agent accounting for 10-20% of the mixed plastic wood material by weight and a blowing promoter accounting for 0-5% of the mixed plastic wood material by weight are added and taken as a sandwich layer material; wood fibre accounting for 0-20% of the HDPE by weight and stearic acid modified nanometer CaCO3 or talcum powder accounting for 0-30% of the HDPE by weight are added to form a surface shell layer material; the sandwitch layer material and the surface shell layer material obtained in the previous steps are respectively fused to form material flows through different extruders, the material flows converge and are extruded in the converging chamber of a mould to form the functional type WPC with the light nuclear shell structure. The functional type WPC with the light nuclear shell structure has corrosion prevention, antibiosis, good mechanical intensity, rigidity, hardness and wear-resisting property.

Owner:南京聚锋新材料有限公司 +1

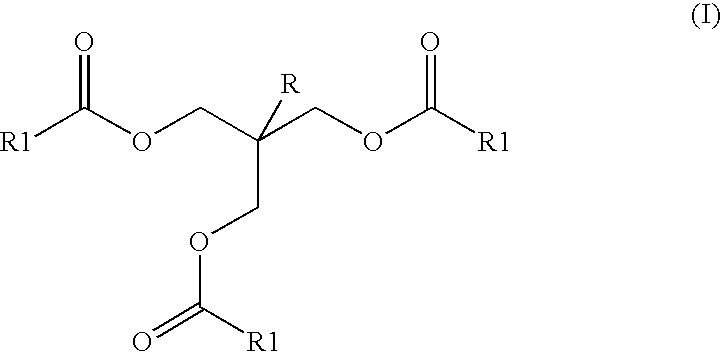

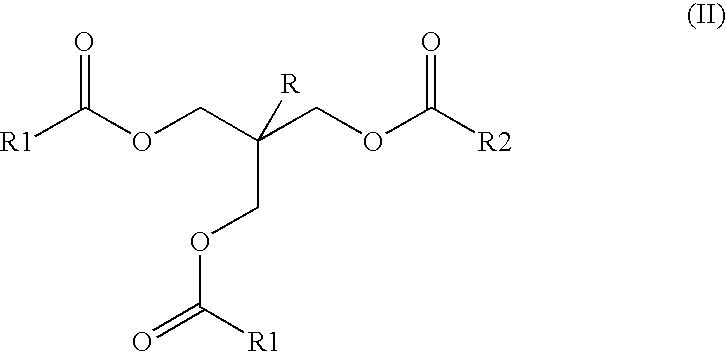

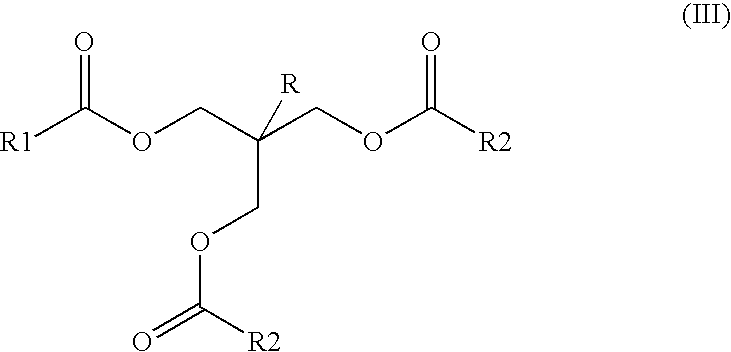

Ester mixtures

InactiveUS20060135685A1Reduce volatilityImprove compatibilityGroup 4/14 element organic compoundsEmulsion paintsPlasticizerCarboxylic acid

Owner:LANXESS DEUTDCHLAND GMBH

Room temperature cured vinyl silazane compositions

A polysilazane composition, formulated from a vinyl silazane and an organometallic accelerator, and associated methods thereof.

Owner:TEXAS RES INT

Aqueous amine-carbohydrate thermosets having reduced weight loss upon cure and improved early dry strength

ActiveUS20130323492A1Low weight lossReduce energy costsStarch adhesivesPretreated surfacesGlass fiberPolysaccharide

The present invention provides thermosetting aqueous binder compositions comprising one or more reducing sugar, one or more diprimary diamine or poly(primary amine), and from 7 to 45 wt. %, based on total solids, of one or more polysaccharide having a dextrose equivalent (DE) value of from 5 to 30. The compositions provide treated articles, such as fiberglass mat. The binders provide articles having a dramatically reduced binder weight loss upon cure and a reduction in cure energy needed to achieve early dry strength.

Owner:ROHM & HAAS CO

Edible coating for plant matter

ActiveUS9648890B2High natural glossLimited water reservoir capacityDead plant preservationFruits/vegetable preservation by coatingWaxColloid

The present invention discloses composition and methods for reducing the weight loss and / or preserving the natural gloss of post-harvest edible plant matter. In particular, the methods comprising applying to the surface of the plant matter a composition comprising an edible wax having a melting temperature below 70° C.; a hydrocolloid; a fatty acid; an emulsifier; and water, wherein said edible wax is present in a weight percent ranging from about 10% to about 25% of the total weight of the composition.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

Polysilazane coatings

ActiveUS20090050737A1Easy to sprayLow viscositySynthetic resin layered productsSpecial tyresPolysilazaneDiluent

A composition and process for manufacturing a camouflaged aircraft component. The process includes providing an aircraft component; applying an uncured coating onto the aircraft component wherein the uncured coating comprises polysilazane resin, at least one pigment, at least one matting agent, and at least one diluent; allowing the diluent to evaporate; curing the coating to provided a cured coating that comprises cured polysilazane, at least one pigment, and at least one matting agent.

Owner:TEXAS RES INT

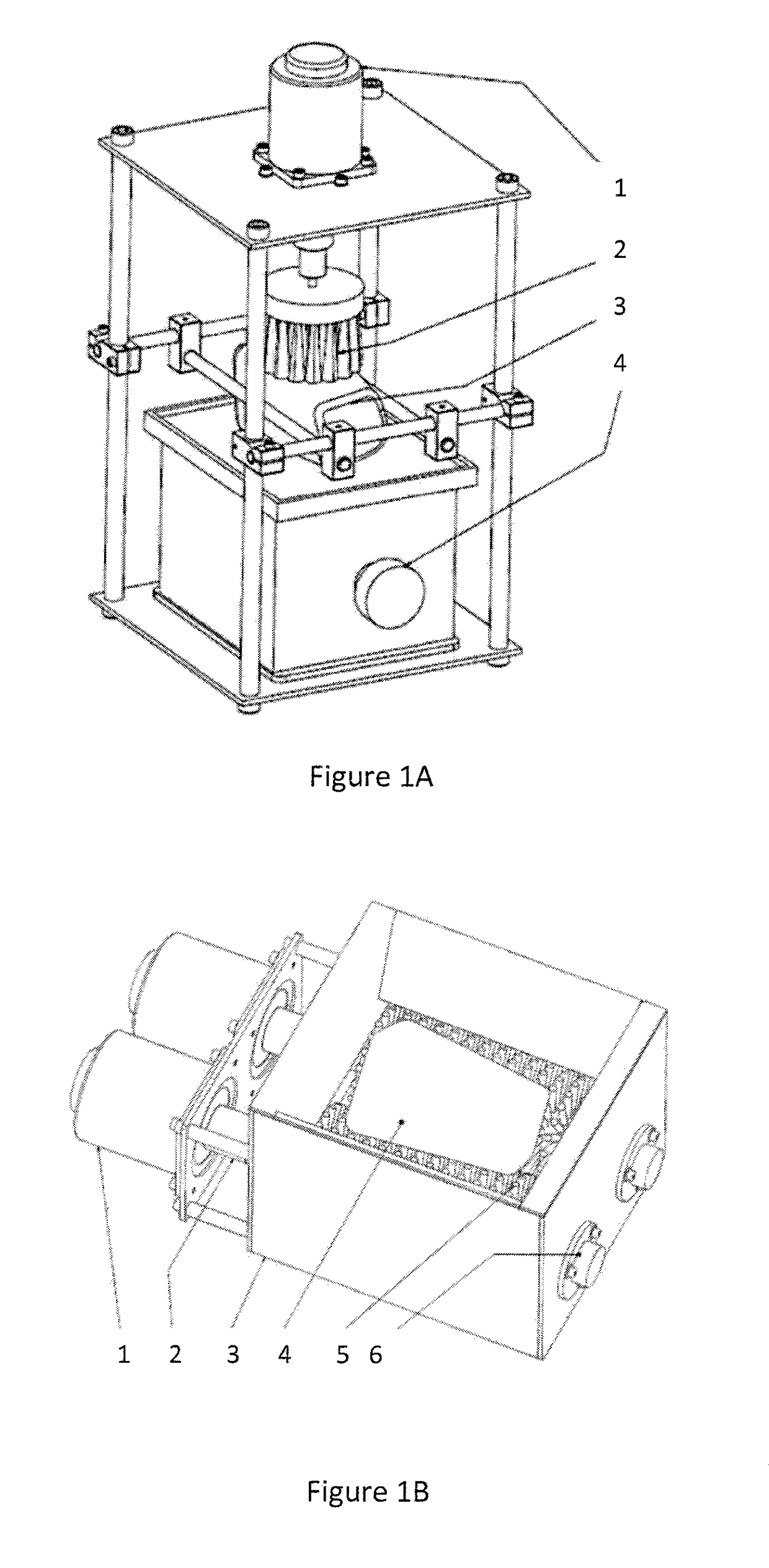

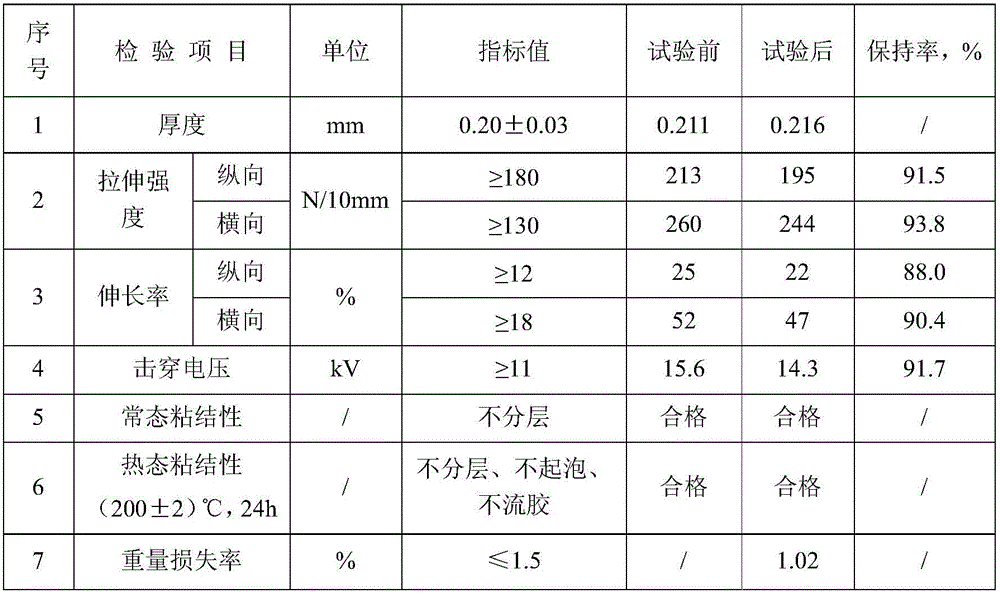

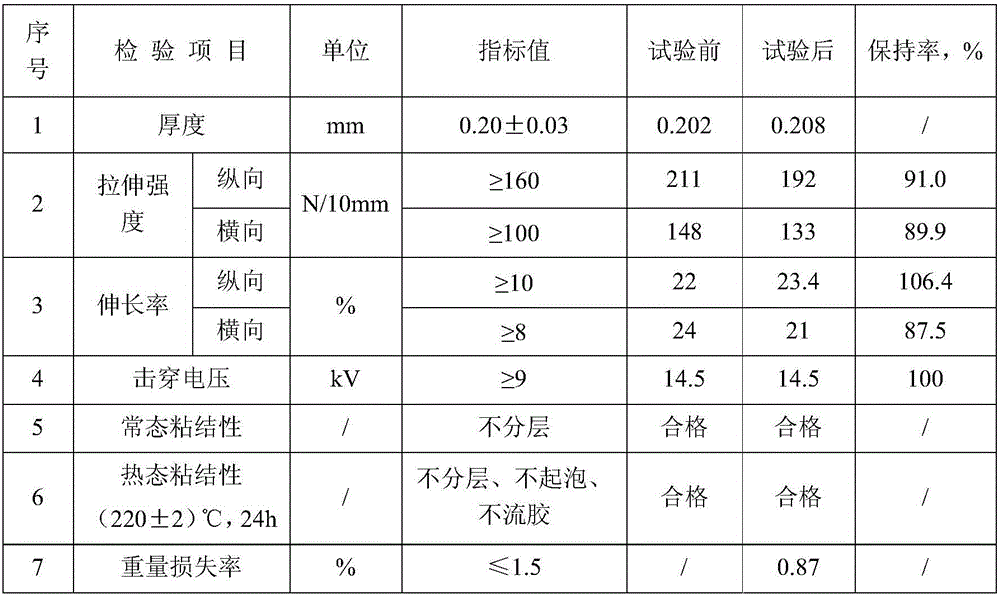

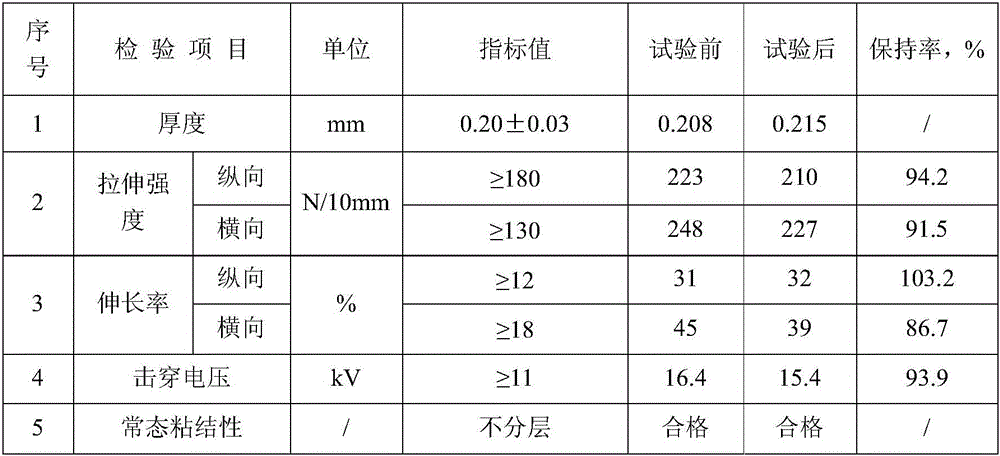

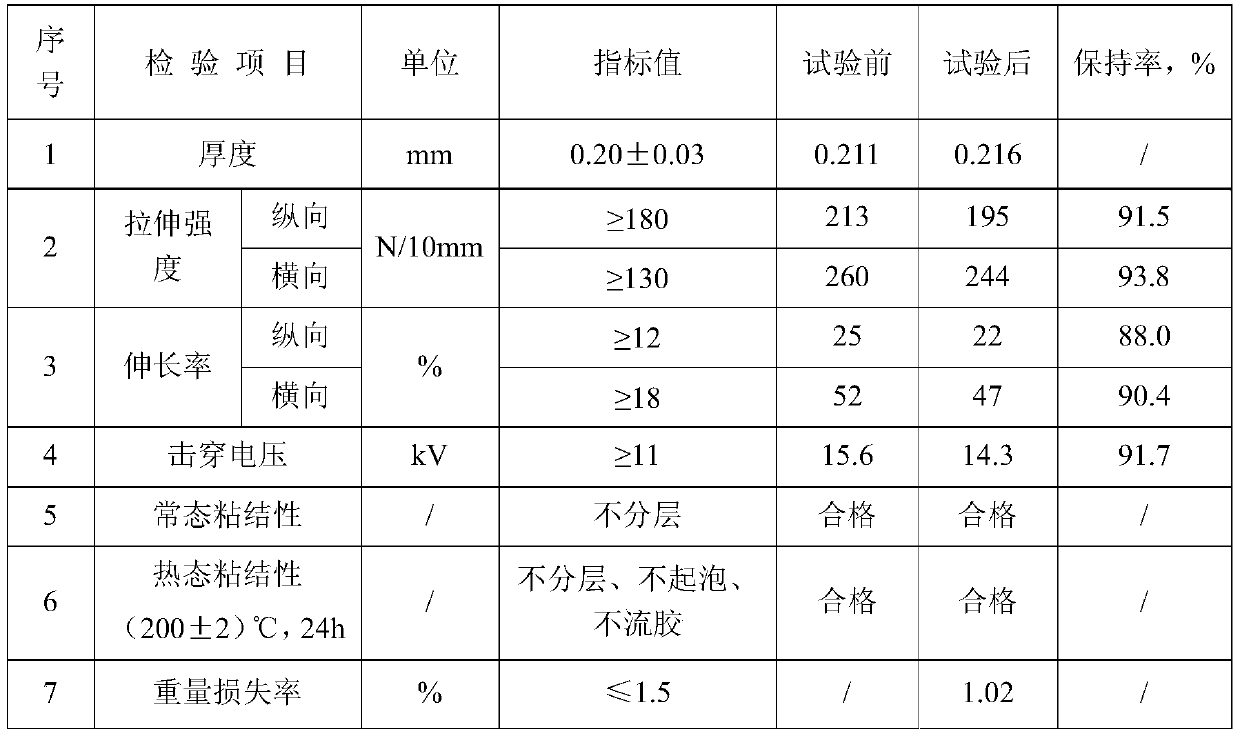

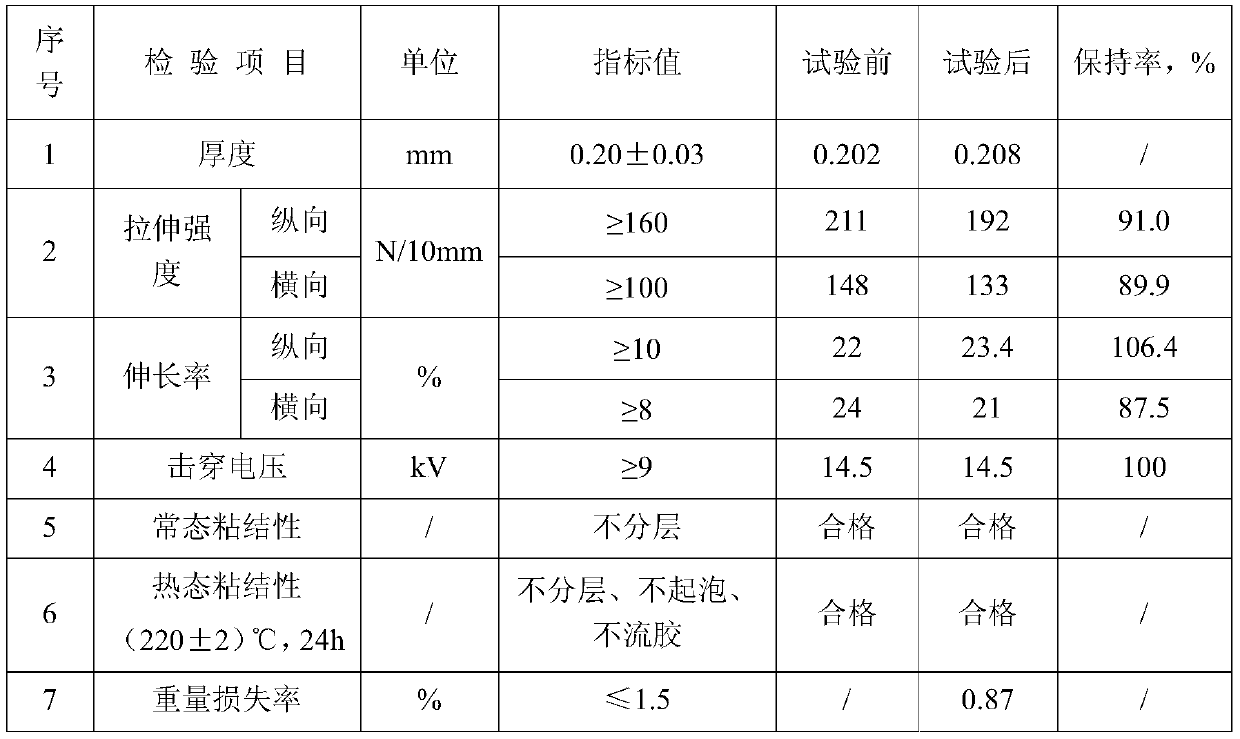

Refrigerant-resistant adhesive and preparation method thereof and refrigerant-resistant soft composite material and preparation method thereof

ActiveCN106497491AImprove heat resistanceImprove adhesionPolyureas/polyurethane adhesivesOil/fat/wax adhesivesAdhesiveSolvent

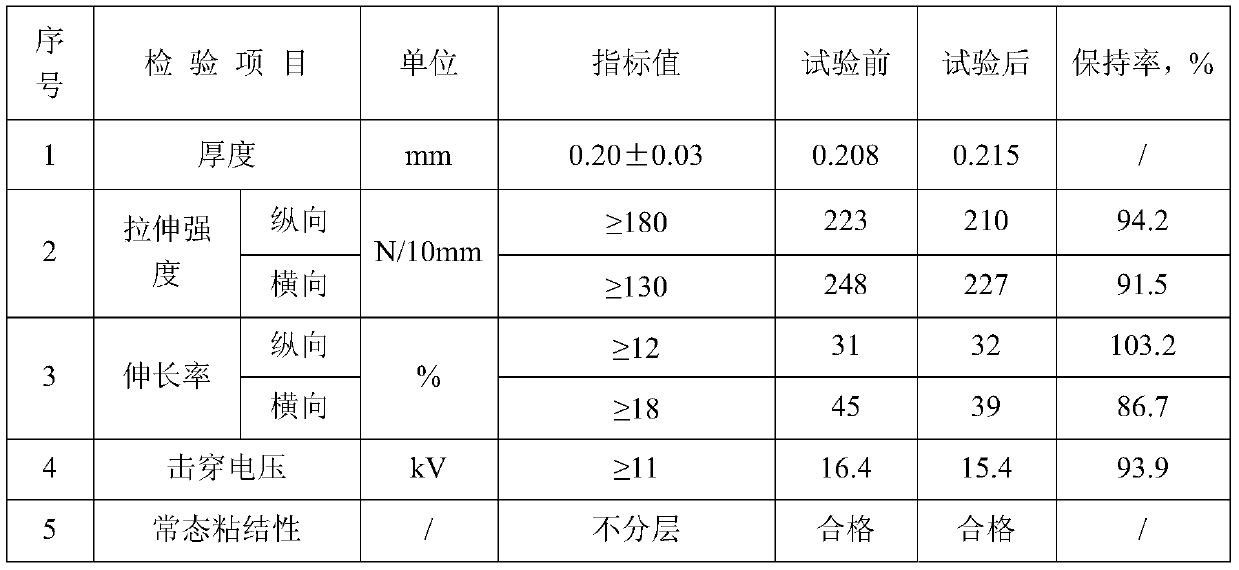

The invention discloses a refrigerant-resistant adhesive which is mainly prepared by mixing modified epoxy glue and polyurethane glue in a mass ratio of (0.01:1)-(0.6:1), wherein the modified epoxy glue is mainly prepared from the following raw materials: plant oil, acid anhydride, amide resin, epoxy resin, a solvent and an accelerant. The invention further discloses a preparation method of the refrigerant-resistant adhesive, a refrigerant-resistant soft composite material prepared from the refrigerant-resistant adhesive, and a preparation method of the refrigerant-resistant soft composite material. As the epoxy glue is adopted to modify polyurethane glue to prepare the refrigerant-resistant adhesive, the polyurethane glue of a high thermal resistant grade is adopted as a main body component, and the product thermal resistant grade of UL (Underwriter Laboratories Inc.) certification can be greater than grade 180. The refrigerant-resistant soft composite material disclosed by the invention is free of physical or chemical damage such as layering, bubbling and gumming in the testing and application process, is low in weight loss rate and free of conspicuous change of appearance, and results of refrigerant resistance tests show that properties such as tensile strength and breakdown voltage can be maintained to be greater than 85%.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

Cardanol based dimers and uses therefor

InactiveUS20080312399A1Reduce coefficient of frictionImprove adhesionSilicon organic compoundsCoatingsSilanesHydrosilylation

Cardanol based dimers are provided. The cardanol dimers are formed by hydrosilylation with silanes. Cardanol based dimers may be further reacted to form epoxy curing agents and epoxies which can be used as anti-fouling coatings on ship hulls and marine structures. The cardanol dimers may also be used to produce friction particles or phenolic resins. Methods of synthesizing the cardanol based dimers, the epoxy curing agents and the epoxies are also provided.

Owner:CARDOLITE CORP

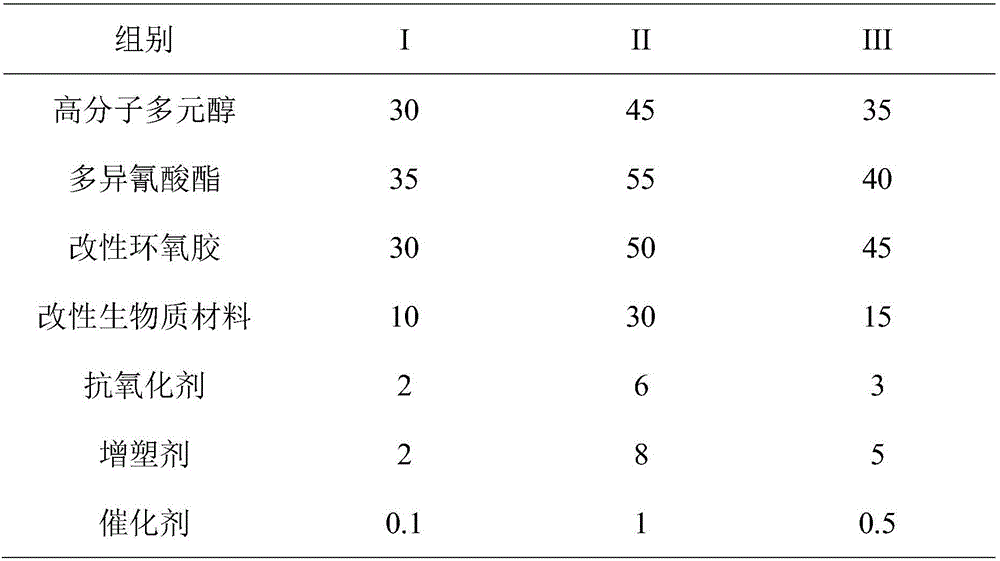

Reactive polyurethane sealant composition and preparation method thereof

InactiveCN107177343ALow weight lossEasy to operateNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesIsocyanateBiomass

The invention discloses a reactive polyurethane sealant composition and a preparation method thereof, which consist of high molecular polyol, polyisocyanate, catalyst, plasticizer, antioxidant, modified epoxy glue and modified biomass material. Compared with the prior art, the reactive polyurethane sealant composition of the present invention uses the introduced epoxy glue to modify the polyurethane glue. In addition to retaining the original characteristics, the cured product has a dense structure and high crosslinking density; The introduction of modified biological materials, through the surface treatment of agricultural and forestry biological materials with amino silane coupling agents after ashing, effectively improves the comprehensive properties of polyurethane sealants such as tensile strength, elongation at break and tear strength. ; The preparation method of the reactive polyurethane sealant composition of the present invention is simple to operate, the reaction is controllable, and the safety factor is high.

Owner:江苏海川卓越密封材料有限公司

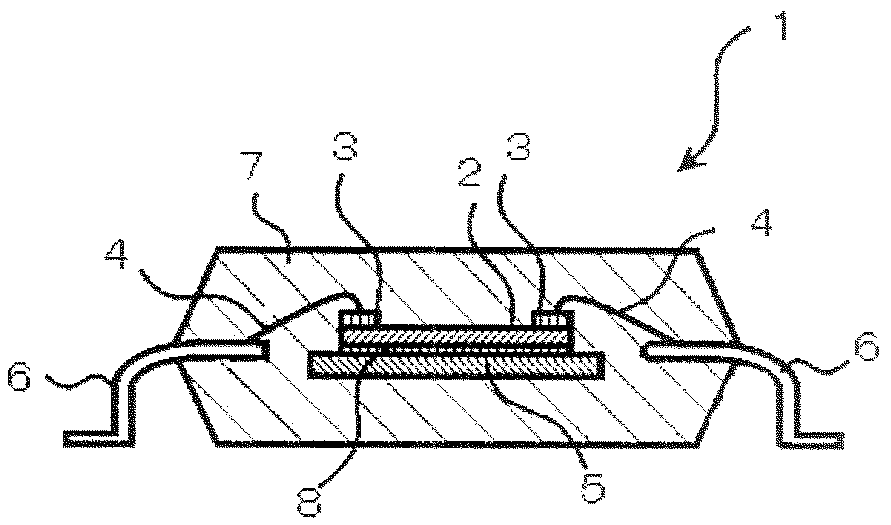

Sealing resin composition and electronic device using same

ActiveCN104136480AReliable and reliableHigh glass transition temperatureSemiconductor/solid-state device detailsSolid-state devicesEpoxyElectronic component

Provided are: a resin composition for sealing electronic components which comprises a phenol resin curing agent, an epoxy resin, and a mold releasing agent with a 5% weight loss temperature of 240°C or more; a resin composition for sealing electronic components which comprises an epoxy resin and a mold releasing agent with a 5% weight loss temperature of 240°C or more; a sealing resin composition for sealing electronic components which comprises a phenol resin curing agent, an epoxy resin, and a mold releasing agent with a 5% weight loss temperature of 240°C or more, the glass transition temperature (Tg) of a cured product of the sealing resin composition being 200°C or more, and the weight loss rate of the cured product when heated in an ambient atmosphere at 200°C for 1,000 hours is 0.3% or less; and an electronic device which comprises electronic components that are sealed with said resin composition.

Owner:SUMITOMO BAKELITE CO LTD

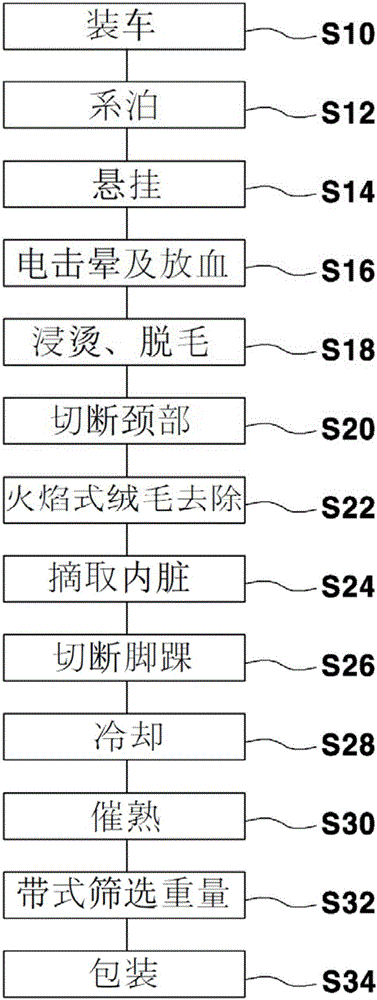

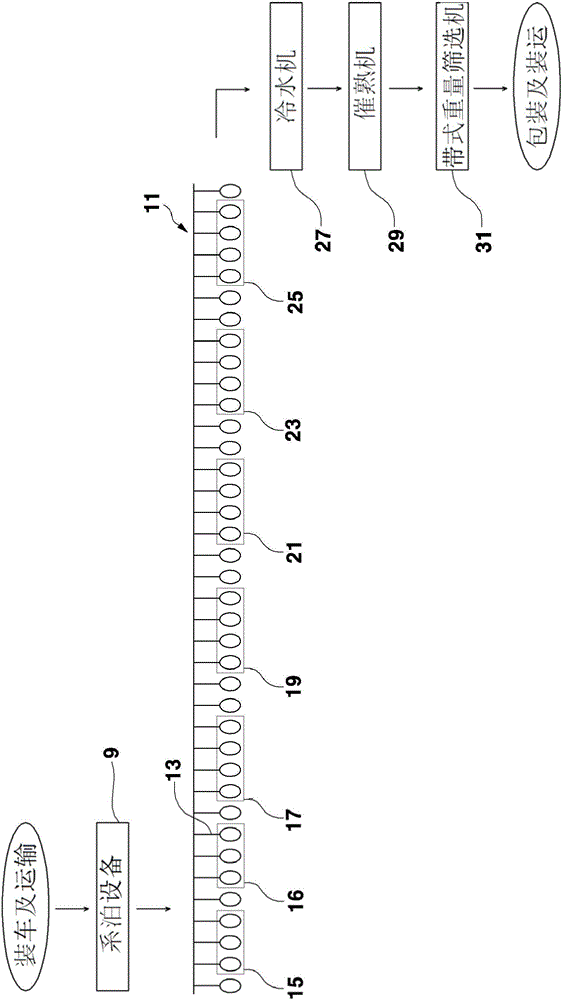

Chicken processing method and chicken processing system

InactiveCN106172680APremium Chicken Carcass ProductsCongestion does not occurPoultry/fish slaughtering/stunningPoultry transferring/conveying devicesEngineeringShackle

The invention provides a chicken slaughtering and processing method for laying hens and a chicken slaughtering and processing system. The chicken slaughtering and processing method for laying hens includes: taking out live chickens from the farm cage, putting them into a plastic box, moving the plastic box, and loading it on a live chicken transport vehicle; mooring the above plastic box to a blue light with blocked external light Atmospheric mooring equipment; hanging the chickens contained in the above-mentioned plastic boxes on the hooks of the conveyor; passing the chickens through a stun machine, thereby being stunned by electricity with a gradually increasing voltage; bleeding steps; implementing scalding and depilation; passing the chickens through mowing head machine to cut off the chicken neck; pass the chicken through a flame machine to burn the chicken fluff; pass the chicken through the eviscerator to remove the giblets; ankle cutting step; cool the chicken in cooling water; ripen the chicken in the ripening chamber ; moving the chickens on belts and screening by weight; and packing the chickens.

Owner:金俊亨

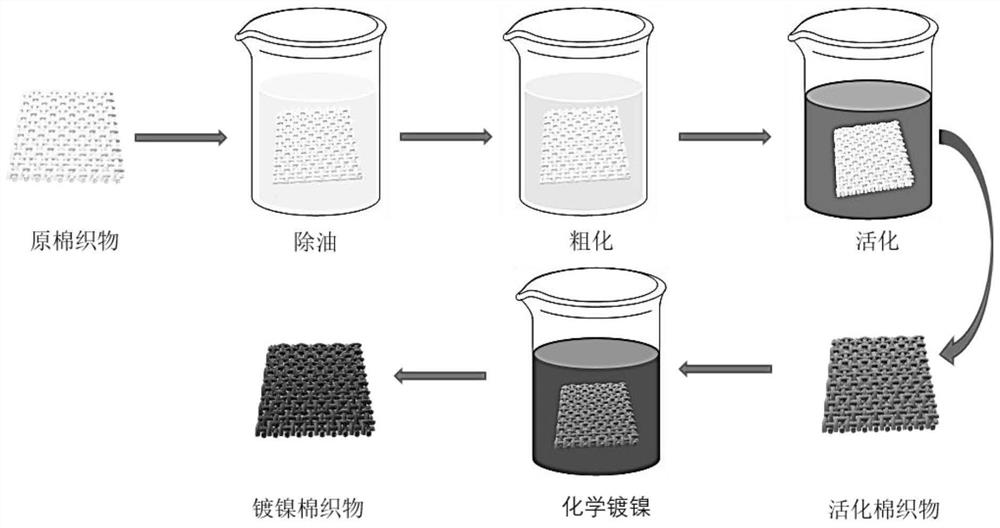

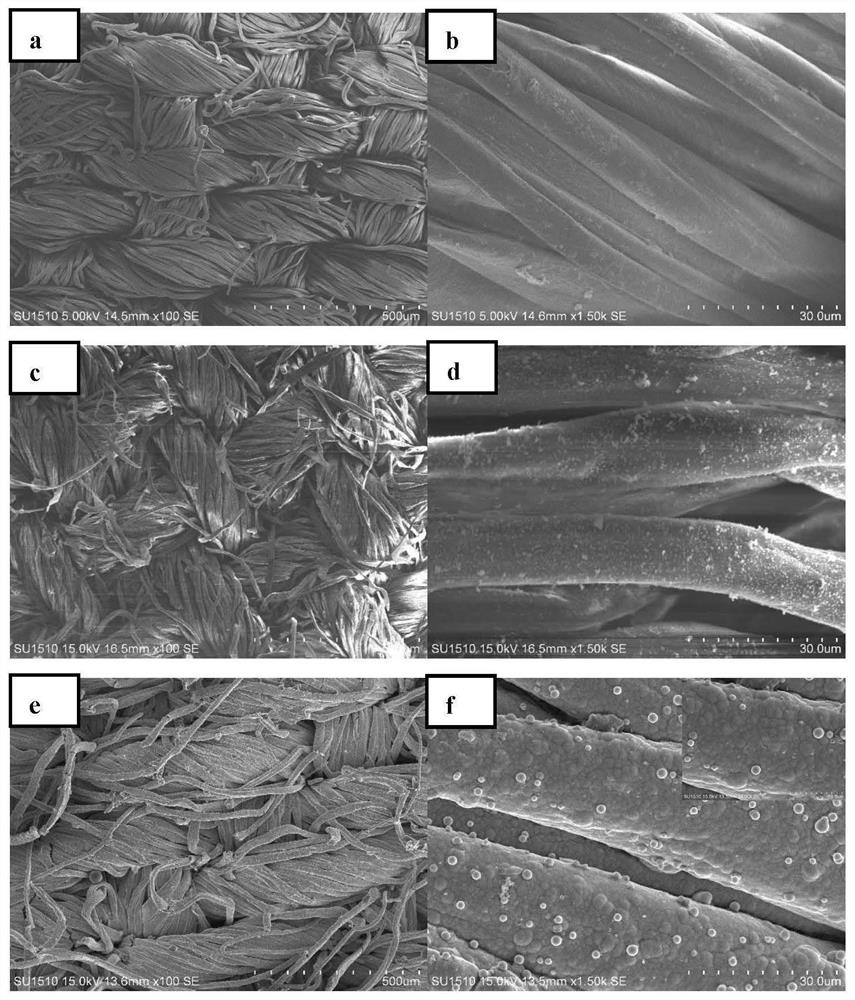

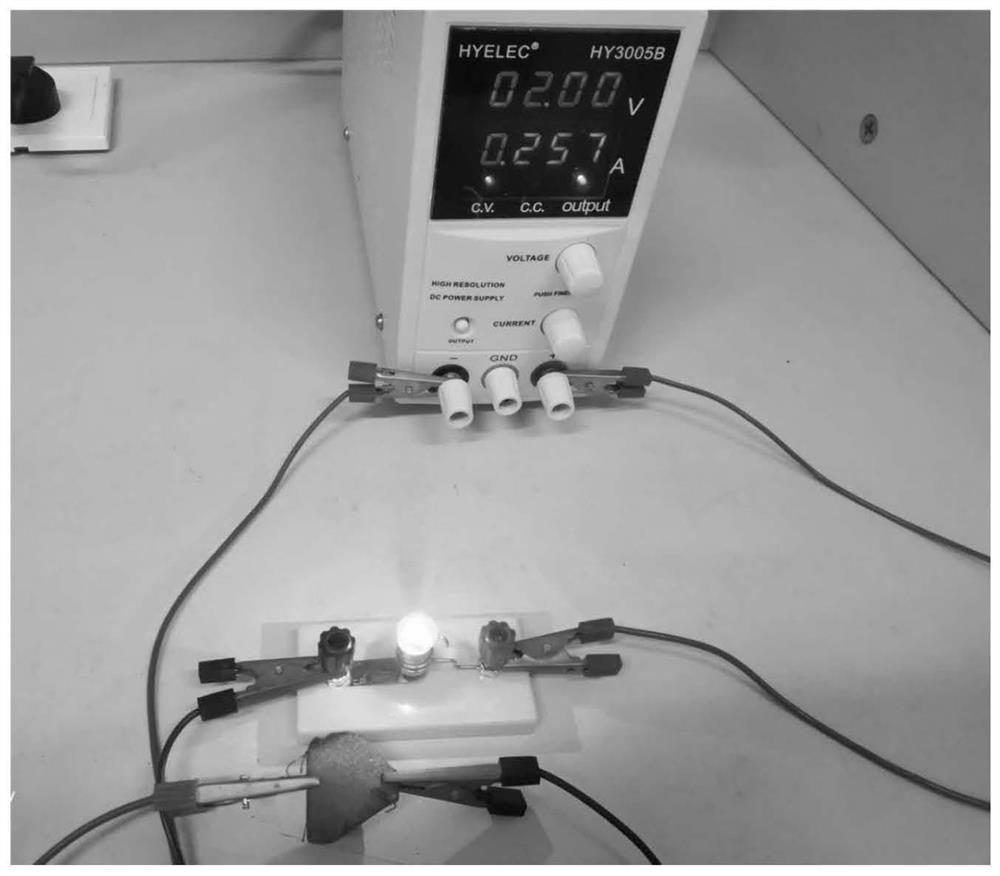

Palladium-free activated nickel-plated conductive cotton fabric and preparation method thereof

InactiveCN111621977ALow priceSimple processPhysical treatmentVegetal fibresNickel sulfate hydrateNickel sulfate hexahydrate

The invention discloses palladium-free activated nickel-plated conductive cotton fabric and a preparation method thereof, and belongs to the field of functional materials. The preparation method of the palladium-free activated nickel-plated conductive cotton fabric comprises the following steps of performing oil removal, coarsening, ultrasonic activation and chemical nickel plating on cotton fabric to obtain the conductive cotton fabric, wherein an activating solution adopted in the ultrasonic activation step comprises the following components: a reducing agent, nickel sulfate hexahydrate andwater, and the mass ratio of reducing agent to nickel sulfate hexahydrate to water is 2:1.5:30. The preparation method of the palladium-free activated nickel-plated conductive cotton fabric is simpleto operate, short in process flow and low in production cost, and the palladium-free activated nickel-plated conductive cotton fabric is endowed with good conductivity on the premise of ensuring uniform nickel plating of the cotton fabric.

Owner:JIANGNAN UNIV

Method for quickly processing surface oxidation layer of rolled-state molybdenum product

The invention discloses a method for quickly processing a surface oxidation layer of a rolled-state molybdenum product. The method comprises the following steps: at normal temperature and pressure, putting the molybdenum product in a mixed cleaning solution for soak cleaning, then rushing the molybdenum product with flowing water, and finally carrying out drying processing. At normal temperature and pressure, the method adopts a mixture of sodium hydroxide and hydrogen peroxide to clean the molybdenum product. Thus, the method has the advantages of being convenient to operate, quick, efficient and environmental-friendly, the surface of the processed molybdenum product is smooth, has no pit and is rich of metallic luster, and the weight loss ration of the product after being cleaned is smaller than 1 percent.

Owner:JINDUICHENG MOLYBDENUM CO LTD

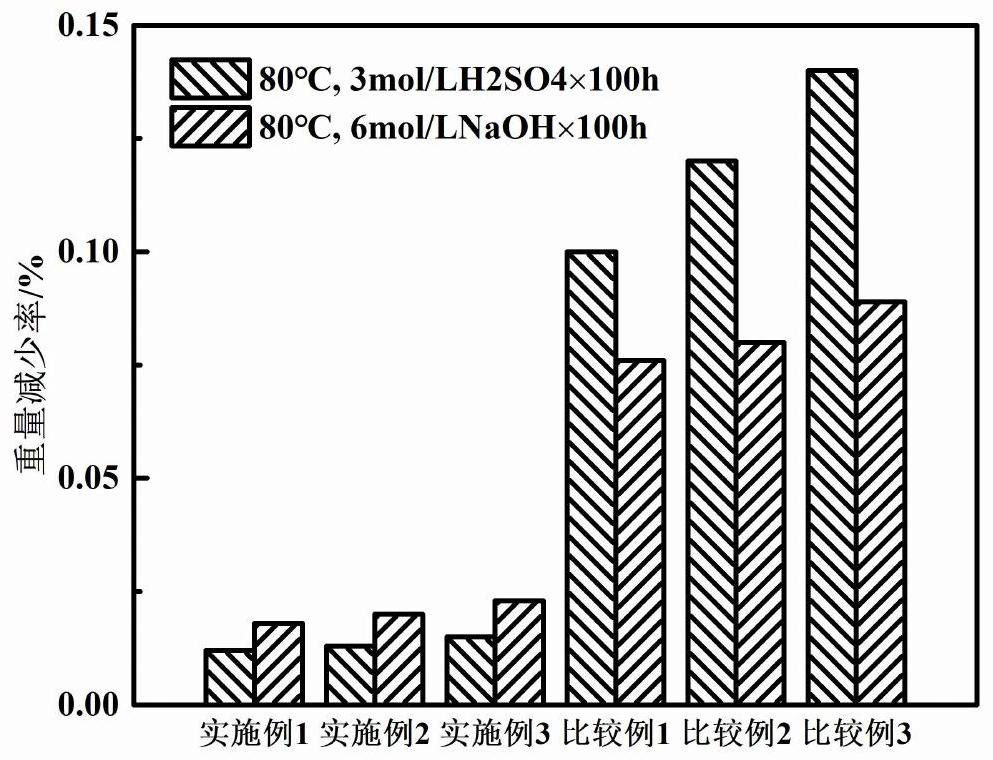

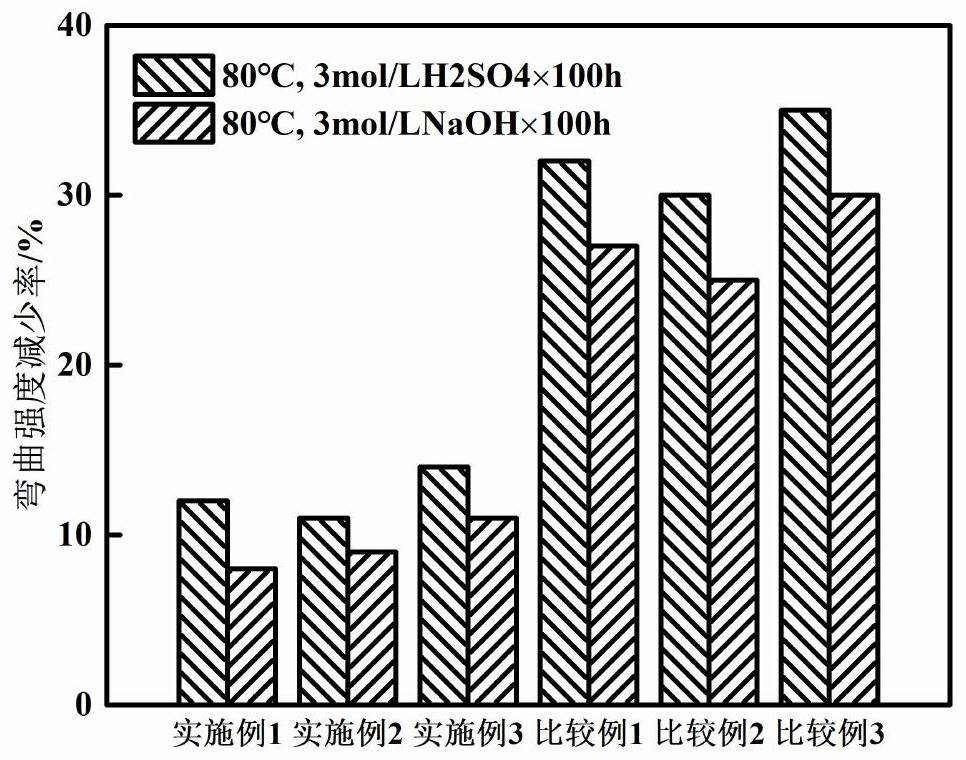

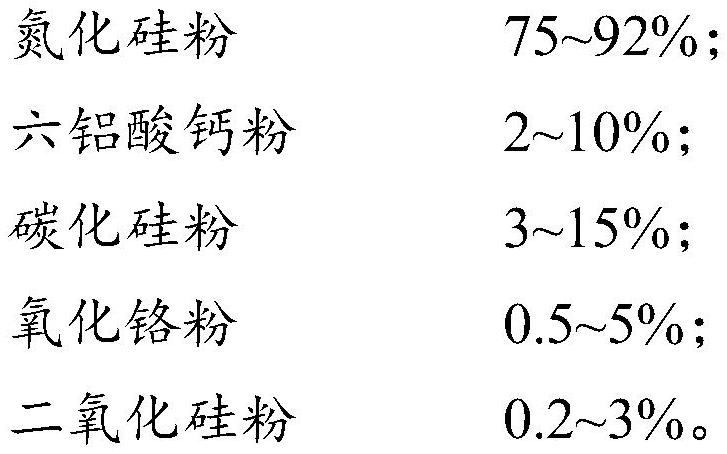

Corrosion-resistant silicon nitride ceramic and preparation method thereof

ActiveCN111995403AImprove corrosion resistancePromotes sintering densificationCarbide siliconCalcium aluminates

The invention provides corrosion-resistant silicon nitride ceramic as well as a preparation method and an application thereof, and belongs to the technical field of preparation of silicon nitride ceramic. The corrosion-resistant silicon nitride ceramic is prepared from the following raw materials in percentage by mass: 75-92% of silicon nitride powder; 2-10% of calcium hexaluminate powder; 3-15% of silicon carbide powder; 0.5-5% of chromium oxide powder; and 0.2-3% of silica powder. According to the invention, calcium hexaluminate is used as a main sintering aid; chromium oxide and silicon dioxide are used as auxiliary sintering aids, calcium hexaluminate has excellent corrosion resistance and can form a high-corrosion-resistance grain boundary phase in the sintering process, so that the corrosion resistance of the silicon nitride ceramic is improved, and the obtained silicon nitride ceramic has a low weight reduction rate and a low bending strength reduction rate in an acidic or alkaline environment.

Owner:SINOMA ADVANCED NITRIDE CERAMICS CO LTD

Thermosetting adhesive compositions

ActiveUS8378017B2Easy curingLittle curingCosmetic preparationsToilet preparationsFunctional monomerGlass transition

The invention is based on the discovery that adhesive compositions containing certain low-viscosity, mono-ethylenically unsaturated monomers have surprisingly good cure parameters, resulting in very little weight loss upon cure. Many of these monofunctional monomers used alone or in combination with other monofunctional monomers described herein have high glass transition temperatures when cured. Moreover, since these monomers are monofunctional the crosslink density of the adhesive composition does not increase (relative to multi-functional monomers), which in turns results in lower stress, lower modulus adhesive compositions. As such, these monomers are useful in a variety of thermoset adhesive compositions, such as for example, die attach adhesive compositions.

Owner:DESIGNER MOLECULES

Preparing method for lightning prevention and ablation resisting alloy

InactiveCN106893919ALow weight lossImproves ablation resistanceSpark gap detailsInsulatorsCombustionRare earth

The invention relates to a preparing method for a lightning prevention and ablation resisting alloy and belongs to the technical field of preparing of alloys. The preparing method includes the steps that firstly, nickel, tungsten and other metal are smashed and screened, and mixed powder is obtained; then, graphite is treated, and expanded graphite is obtained, wherein the graphite has good lightning prevention and arc ablation resistance properties; after the graphite is oxidized, active sites are led into the graphite through the microbial action, and then rare earth metal resistant to arc ablation is led into the graphite through in-situ deposition; and then alloy powder is pressed into a blank, the expansion graphite is wrapped at the outer portion of the alloy through the polydopamine action, a lightning prevention and arc ablation resisting film is formed after pressing to protect the alloy, and therefore the lightning prevention and ablation resisting alloy is obtained. The prepared lightning prevention and ablation resisting alloy has the relatively high arc ablation resisting capability and is not likely to be burnt out during arc combustion, the service life of the alloy is prolonged, and a wide application prospect is achieved.

Owner:宁波高新区远创科技有限公司

Flame retardant wood modifier and preparation method thereof

InactiveCN109968481AImprove flame retardant performanceImprove anti-corrosion performanceWood treatment detailsWood impregnation detailsPhosphoric acidPolyethylene glycol

The invention belongs to the field of wood modification treatment, and particularly relates to a flame retardant wood modifier, comprising the following raw materials by weight: dicyandiamide, boric acid, borax, triethanolamine, urea, ammonium persulfate, ammonium bicarbonate, polyphosphate, methyl methacrylate, phosphoric acid, polyethylene glycol, polyoxyethylene alkyl ether, sodium dodecyl sulfate, 1,2,3,4-butane tetracarboxylic acid and water; and a preparation method of the modifier. Catalytic reaction effects of the urea and the phosphoric acid are improved through adding the ammonium persulfate and the ammonium bicarbonate. Wood flame retardance and corrosion resistance in a wood modification process are improved through adding the polyethylene glycol, the ammonium bicarbonate, thedicyandiamide and the polyphosphate. Wood dimension stability in a wood modification process can be improved through adding the polyoxyethylene alkyl ether, the methyl methacrylate and other related components.

Owner:赛为木业(石首)有限公司

Polysilazane coatings

ActiveUS7919189B2Easy to sprayLow viscositySynthetic resin layered productsSpecial tyresPolysilazanePigment

A composition and process for manufacturing a camouflaged aircraft component. The process includes providing an aircraft component; applying an uncured coating onto the aircraft component wherein the uncured coating comprises polysilazane resin, at least one pigment, at least one matting agent, and at least one diluent; allowing the diluent to evaporate; curing the coating to provided a cured coating that comprises cured polysilazane, at least one pigment, and at least one matting agent.

Owner:TEXAS RES INT

Method for stimulating weight loss and/or for lowering triglycerides in patients

InactiveUS20080146668A1Good for weight lossLower triglyceridesBiocidePeptide/protein ingredientsCoronary heart diseaseCvd risk

Administration of a therapeutically effective amount of 3,5-diiodothyropropionic acid stimulates weight loss in patients, lowers triglyceride levels and reduces risk of death or progression of coronary heart disease in patients with metabolic syndrome.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA UA +1

Room temperature cured vinyl silazane compositions

ActiveUS8809445B2Efficient use ofFast dryingPretreated surfacesSpecial tyresMedicineRoom temperature

A polysilazane composition, formulated from a vinyl silazane and an organometallic accelerator, and associated methods thereof.

Owner:TEXAS RES INT

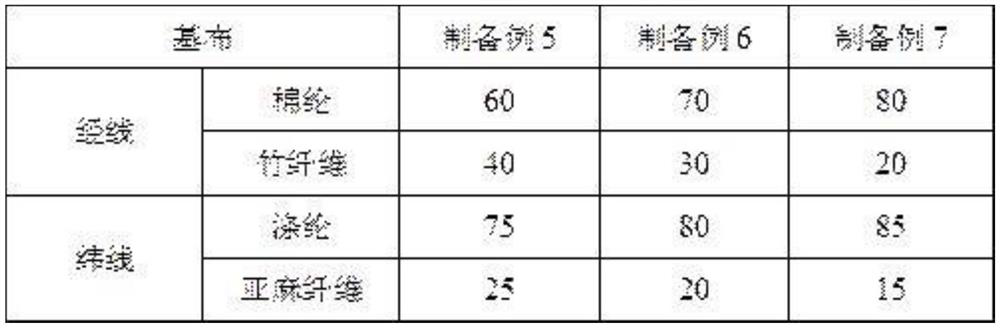

Composite fiber fabric with high air permeability and preparation method thereof

PendingCN114182536AImprove wear resistanceImprove corrosion resistanceTextiles and paperCalcium silicateFiber

The invention relates to the field of composite fiber fabrics, and particularly discloses a high-air-permeability composite fiber fabric and a preparation method thereof.The high-air-permeability composite fiber fabric comprises base cloth, and the surface of one side or the surfaces of the two sides of the base cloth is coated with a wear-resistant coating; the wear-resistant coating comprises the following components in parts by weight: 25-45 parts of polyester resin, 15-25 parts of calcium silicate powder, 5-15 parts of polyacrylamide powder, 3-10 parts of nano silicon dioxide, 2-9 parts of titanium dioxide, 1-5 parts of sodium benzoate and 30-55 parts of ethanol; the high-air-permeability composite fiber fabric provided by the invention has relatively good wear resistance.

Owner:深圳市玛依尔科技有限公司

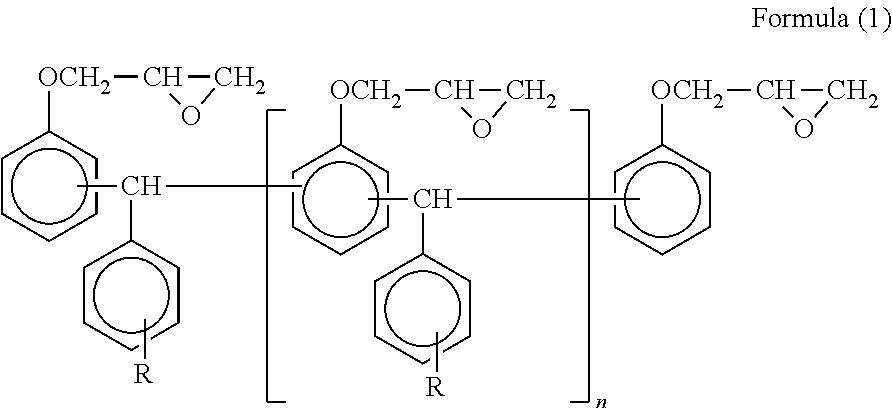

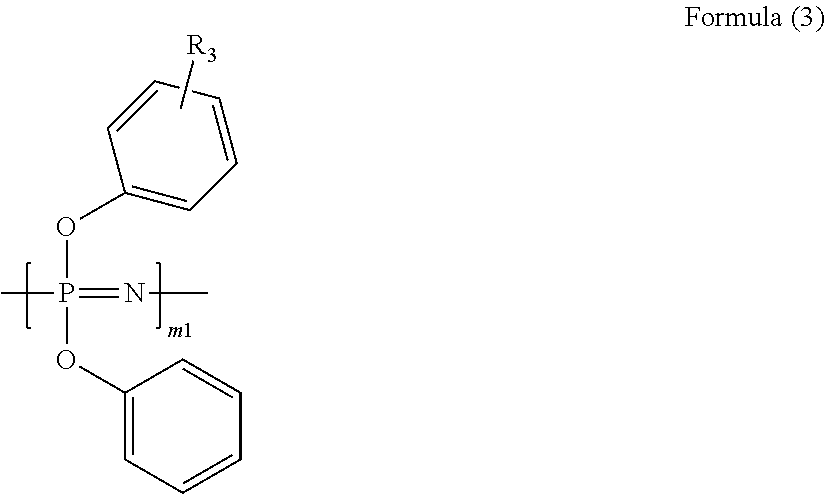

Resin composition and article made therefrom

ActiveUS20190390055A1High yield rateLow dust weight lossSynthetic resin layered productsElectrical equipmentEpoxyHeat resistance

A resin composition comprises 100 parts by weight of epoxy resin; 2 to 50 parts by weight of carboxyl-containing butadiene acrylonitrile resin; 1 to 40 parts by weight of phosphazene; and 1 to 8 parts by weight of acrylic triblock copolymer. The resin composition may be made into various articles, such as prepregs, laminates, printed circuit boards or rigid-flex boards, and meets one, more or all of the following properties: high yield rate in solder pad fall-off test at high temperature, low dust weight loss, low stickiness, high thermal resistance, high peel strength to copper foil, and high bonding strength to polyimide layer.

Owner:ELITE ELECTRONICS MATERIAL ZHONGSHAN

Refrigerant-resistant adhesive and preparation method thereof, refrigerant-resistant soft composite material and preparation method thereof

ActiveCN106497491BImprove heat resistanceImprove adhesionPolyureas/polyurethane adhesivesOil/fat/wax adhesivesAdhesiveSolvent

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com