Corrosion-resistant silicon nitride ceramic and preparation method thereof

A technology of silicon nitride ceramics and corrosion resistance, applied in the field of silicon nitride ceramics, can solve the problems of poor corrosion resistance and low service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

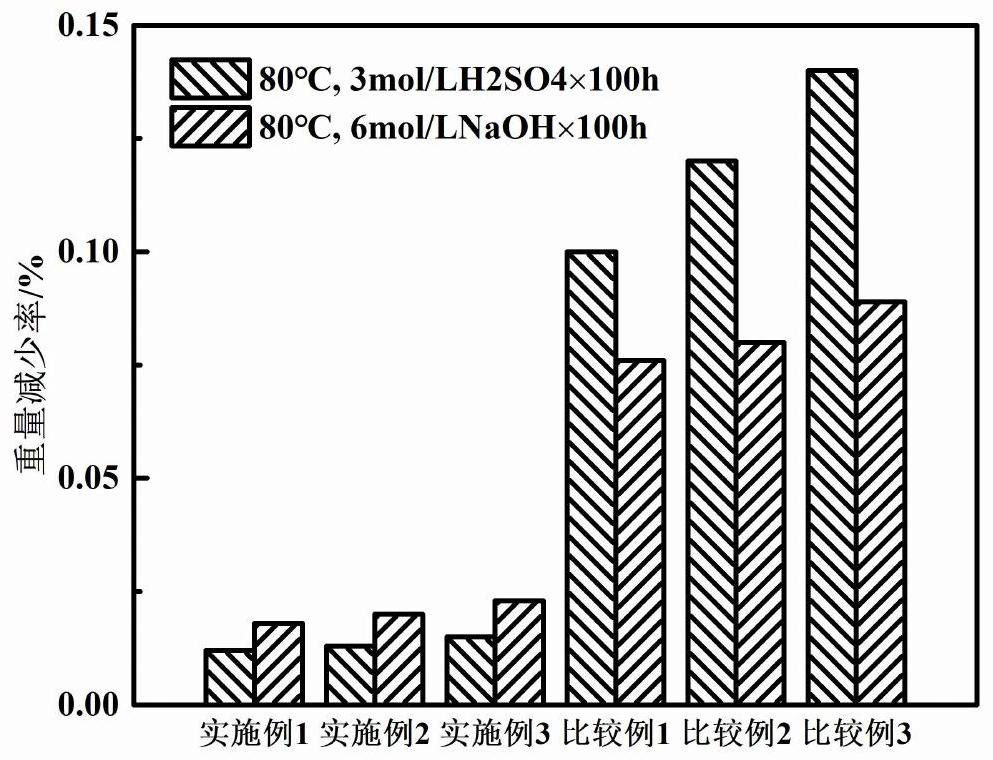

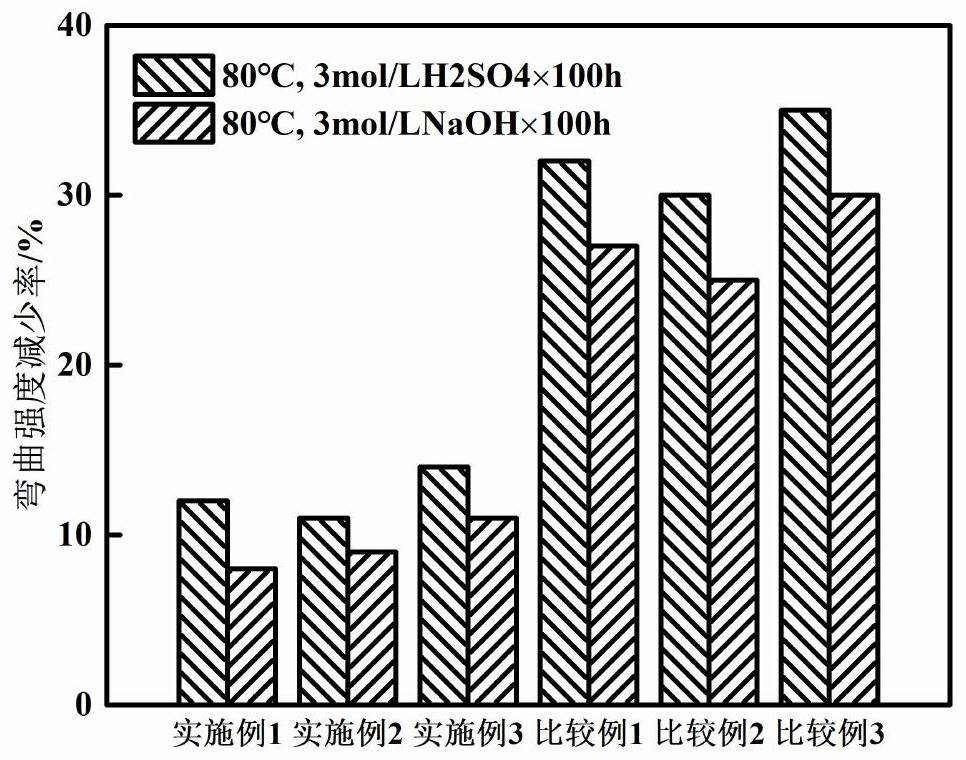

Examples

preparation example Construction

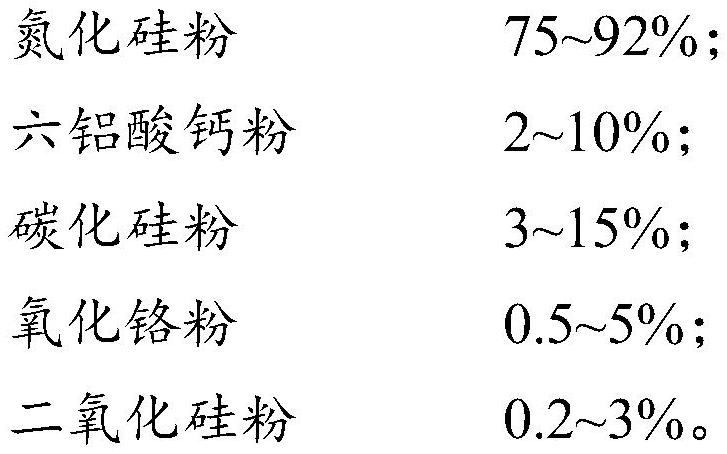

[0040] The invention provides a method for preparing the above-mentioned corrosion-resistant silicon nitride ceramics, comprising the following steps:

[0041] (1) Mix silicon nitride powder, calcium hexaaluminate powder, silicon carbide powder, chromium oxide powder, silicon dioxide powder with a solvent, and grind to obtain a mixed powder slurry;

[0042] (2) adding a binder to the mixed powder slurry, followed by stirring and mixing and spray drying to obtain granulated powder;

[0043] (3) performing dry pressing and cold isostatic pressing to the granulated powder successively to obtain ceramic samples;

[0044] (4) Debinding and gas pressure sintering are performed sequentially on the ceramic sample blocks to obtain silicon nitride ceramics with high corrosion resistance.

[0045]The invention mixes silicon nitride powder, calcium hexaaluminate powder, silicon carbide powder, chromium oxide powder and silicon dioxide powder with a solvent, grinds them, and obtains a mix...

Embodiment 1

[0054] (1) Silicon nitride powder (α-Si 3 N 4 content is 91%, oxygen content is 2%, particle size D50 is 5 μm), 5% calcium hexaaluminate powder (purity is 99.5%, particle size D50 is 20 μm), 5.5% silicon carbide powder (purity is 98.5% , particle size D50 is 5 μm), 2% chromium oxide powder (purity is 99.5%, particle size D50 is 1 μm), 0.5% silica powder (purity is 99.9%, particle size D50 is 0.5 μm) put into sand Grinding in the mill for 2 hours at a speed of 1000r / min, the grinding solvent is absolute ethanol, the grinding medium is silicon nitride balls, the ball-to-material ratio is 3:1, and a mixed powder slurry with a solid content of 45% is obtained after grinding , the particle size D50 of the mixed powder is 0.8 μm;

[0055] (2) Add 1% polyvinyl butyral (PVB) and 1.5% polyacrylic acid emulsion with a solid content of 50% to the slurry, stir for 4 hours, and spray dry under nitrogen protection pressure to obtain granules Granulated powder with a diameter D50 of 100 μ...

Embodiment 2

[0062] (1) Silicon nitride powder (α-Si 3 N 4 content is 91%, oxygen content is 2%, particle size D50 is 5μm), 6% silicon carbide powder (purity is 98.5%, particle size D50 is 5μm), 5% calcium hexaaluminate powder (purity is 99.5% , particle size D50 is 20 μm), 1% chromium oxide powder (purity is 99.5%, particle size D50 is 1 μm), 1% silica powder (purity is 99.9%, particle size D50 is 0.5 μm) put into sand Grinding in the mill for 2 hours at a speed of 1000r / min, the grinding solvent is absolute ethanol, the grinding medium is silicon nitride balls, the ball-to-material ratio is 3:1, and a mixed powder slurry with a solid content of 45% is obtained after grinding , the particle size D50 of the mixed powder is 0.8 μm;

[0063] (2) Add 1% PVB of mixed powder mass and 1.5% polyacrylic acid emulsion with a solid content of 50% to the slurry, stir for 4 hours, and obtain a granulated powder with a particle diameter D50 of 100 μm by spraying and drying under nitrogen protection p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com