Sealing resin composition and electronic device using same

A technology of resin composition and phenolic resin, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of reducing weight reduction rate and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

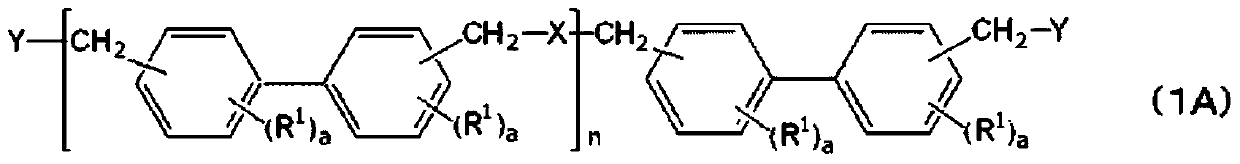

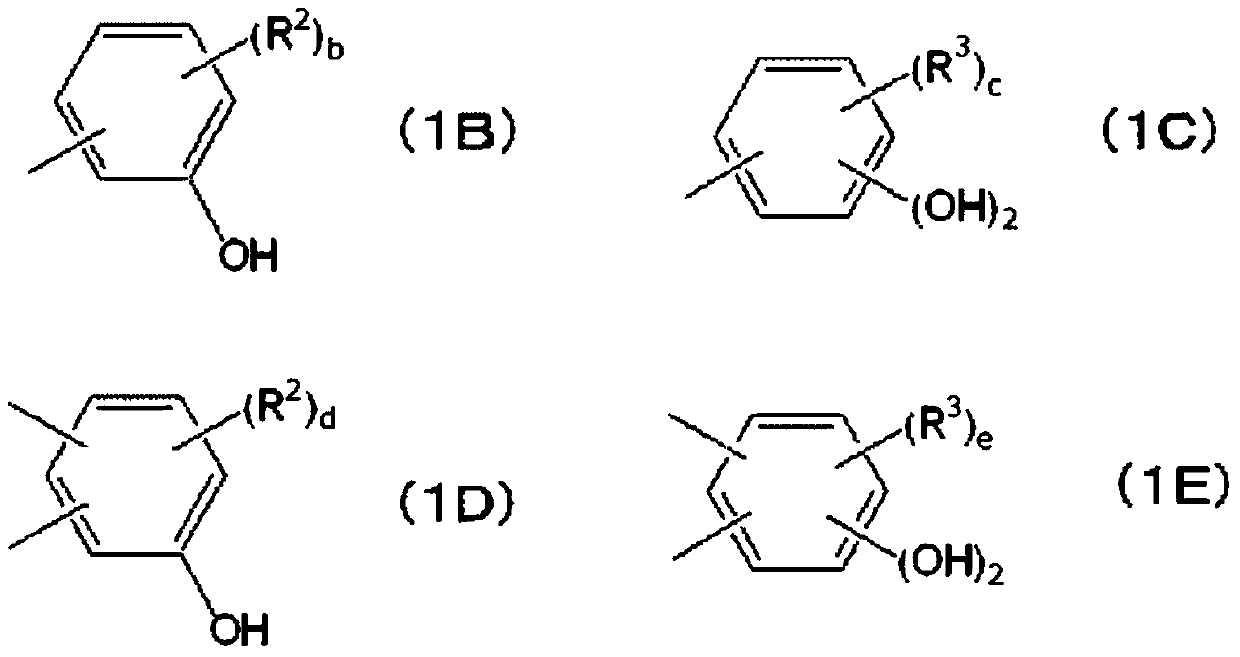

Method used

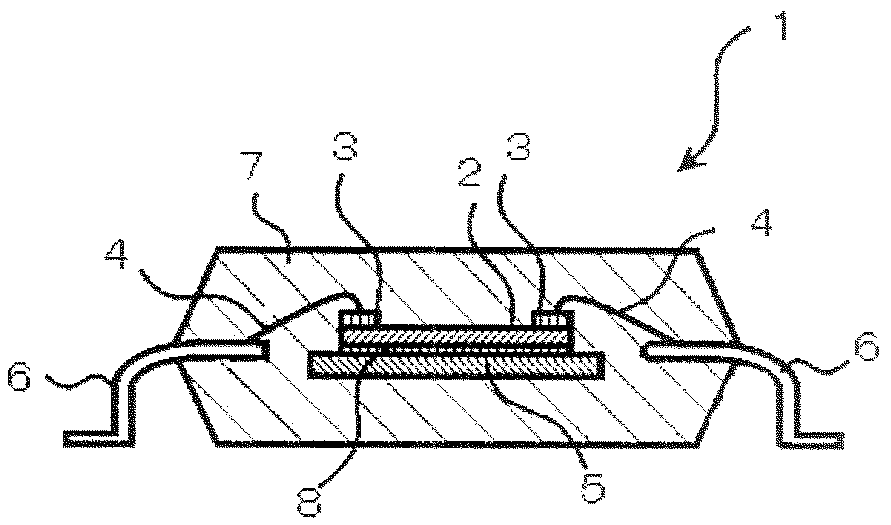

Image

Examples

Embodiment 1

[0303] Weigh respectively epoxy resin 1 (8.75 mass parts), phenolic resin curing agent 1 (5.14 mass parts), inorganic filler material 1 (75.00 mass parts), inorganic filler material 2 (10.00 mass parts), curing accelerator 3 (0.32 parts by mass), silane coupling agent 1 (0.20 parts by mass), release agent 1 (0.20 parts by mass), coloring agent 1 (0.40 parts by mass), after mixing the above materials with a mixer, use the surface temperature of 95 ° C and 25 The kneading was carried out by two rollers at ℃ to obtain a kneaded product. Next, the kneaded product was cooled and pulverized to obtain the resin composition of Example 1.

Embodiment 2~13、 comparative example 1~4

[0305] Resin compositions of Examples 2-13 and Comparative Examples 1-4 were obtained in the same manner as in Example 1 above except that the types and compounding amounts of the raw materials were changed as shown in Table 1.

[0306] 3. Evaluation

[0307] The mold release agent used and the obtained resin compositions of each Example and each Comparative Example were evaluated by the following methods.

[0308] 3-1. Evaluation of 5% weight loss temperature (Td5)

[0309] Put 10 mg of the sample (release agent) in a Pt sample pan, and measure the thermogravimetry from 30°C to 400°C at 10°C / min under nitrogen flow using a TG·DTA measuring device (manufactured by Seiko Instruments, Inc., EXSTAR7000 type) Decrease, the temperature at which the sample loses 5% of its initial weight (Td5) is determined.

[0310] 3-2. Swirl length (SF) evaluation

[0311] Using a low-pressure transfer molding machine (manufactured by Kohtaki Precision Machine Co., Ltd, "KTS-15"), in a mold for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com