Composite fiber fabric with high air permeability and preparation method thereof

A composite fiber, highly breathable technology, used in textiles and papermaking, etc., can solve the problems of poor wear resistance and short service life of fabrics, and achieve the effects of excellent wear resistance, reduced end breakage, and improved wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-4

[0041] The wear-resistant coating of preparation example 1-4, its each raw material and each raw material consumption are as shown in table 1, and its preparation steps are as follows:

[0042] Weigh each raw material according to the amount in Table 1, and heat and mix each raw material evenly to obtain a wear-resistant coating.

[0043] The wear-resistant coating each raw material of table 1 preparation example 1-4 and each raw material consumption (kg)

[0044] Preparation Example 1 Preparation example 2 Preparation example 3 Preparation Example 4 polyester resin 25 32 40 45 Calcium silicate powder 25 22 18 15 polyacrylamide powder 5 8 12 15 Nano silica 10 8 5 3 Titanium dioxide 2 4 7 9 sodium benzoate 5 4 2 1 ethanol 55 45 35 30

preparation example 5-7

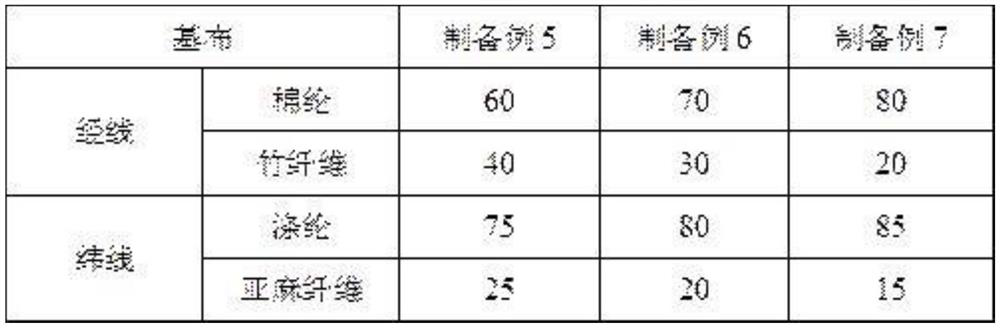

[0046] The base cloth of preparation example 5-7, its each raw material and each raw material consumption are as shown in table 2, and its preparation steps are as follows:

[0047] 1) Weigh each raw material according to the amount in Table 2, and then blend each raw material into warp and weft;

[0048] 2) Interweave the warp and weft to obtain the base fabric.

[0049] Each raw material of the base cloth of table 2 preparation example 5-7 and each raw material consumption (kg)

[0050]

Embodiment 1

[0053] A kind of high air permeability composite fiber fabric of embodiment 1, its preparation steps are as follows:

[0054] 1) unfold the base cloth, spray distilled water onto the base cloth, and then dry to obtain a dried base cloth;

[0055] 2) blending polyester resin, calcium silicate powder, polyacrylamide powder, nano silicon dioxide, titanium dioxide, sodium benzoate and ethanol to obtain a wear-resistant coating;

[0056] 3) coating the wear-resistant coating on the surface of the drying base cloth to obtain a preliminary fabric;

[0057] 4) Drying the preliminary fabric to obtain a composite fiber fabric with high air permeability.

[0058] Among them, the wear-resistant coating is from Preparation 1, the molecular weight of the polyester resin is 4000, the grade of calcium silicate powder is 400 mesh, the thickness of the wear-resistant coating is 0.1 mm, and the base fabric is from Preparation 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com