Refrigerant-resistant adhesive and preparation method thereof and refrigerant-resistant soft composite material and preparation method thereof

A composite material, refrigerant-resistant technology, used in adhesives, adhesive types, oil/grease/wax adhesives, etc. Problems such as low performance retention rate, to achieve the effect of outstanding performance of refrigerant medium, low weight loss rate and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

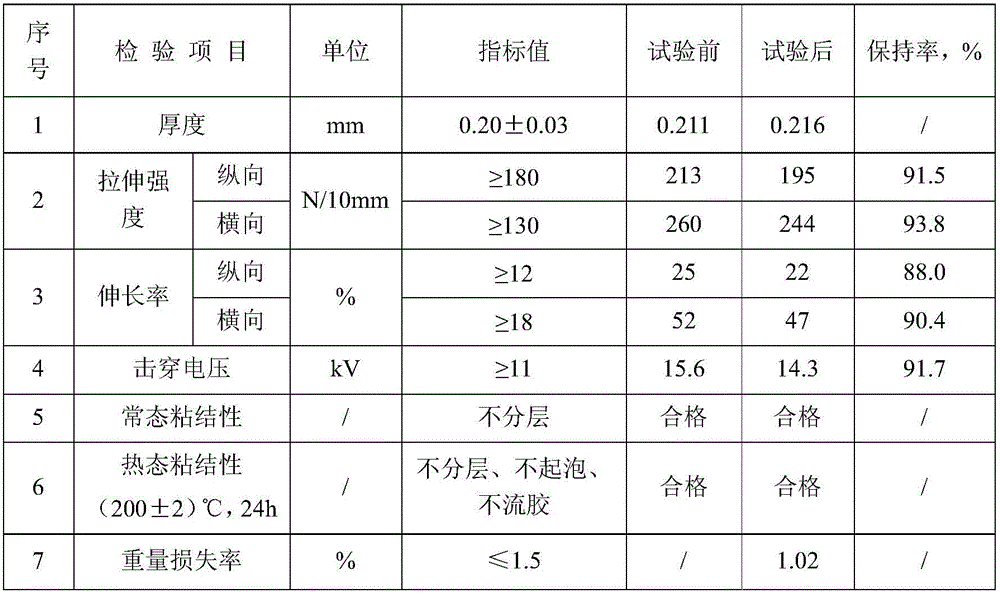

Embodiment 1

[0044] A refrigerant-resistant adhesive of the present invention is mainly prepared by mixing modified epoxy glue and polyurethane glue with a mass ratio of 0.4:1, wherein the modified epoxy glue is mainly composed of 28kg tung oil, 11kg maleic anhydride, Prepared from 7.5kg bismaleimide, 10kg E-44 epoxy resin, 13kg F-51 epoxy resin, 30kg acetone and 0.5kg DMP-30.

[0045] The preparation method of the refrigerant-resistant adhesive of the present embodiment may further comprise the steps:

[0046] (1) Heat 28kg of tung oil to 100°C and vacuumize for 1h, then add 11kg of maleic anhydride, react at 150°C for 1.5h, add 7.5kg of bismaleimide, and cool down to 100°C after the reaction is uniform , add 10kgE-44 epoxy resin and 13kgF-51 epoxy resin; when the temperature drops to 60°C, add 30kg of acetone, and when the temperature drops to 35°C, add 0.5kgDMP-30, and stir well to make a modified epoxy glue ;

[0047] (2) Prepare polyurethane glue with LOCTITE LIOFOL LA 2716 and LOCT...

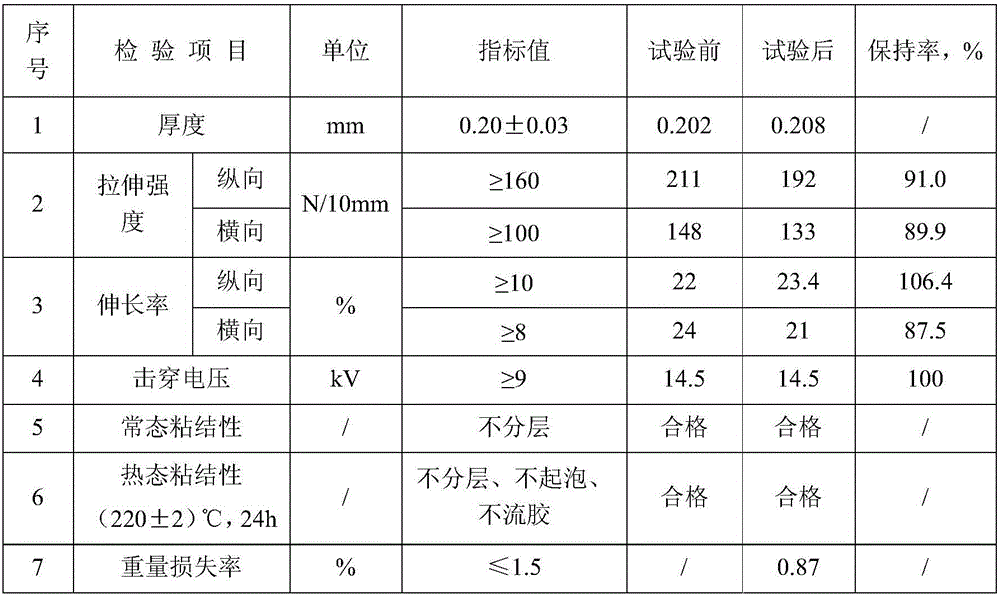

Embodiment 2

[0056] A refrigerant-resistant adhesive of the present invention is mainly prepared by mixing modified epoxy glue and polyurethane glue with a mass ratio of 0.35:1, wherein the modified epoxy glue is mainly composed of 22kg dehydrated castor oil, 8kg maleic acid Anhydride, 11kg bismaleimide, 15kg E-20 epoxy resin, 11kg F-44 epoxy resin, 32.4kg ethyl acetate and 0.6kg 2-methylimidazole.

[0057] The preparation method of the refrigerant-resistant adhesive of the present embodiment may further comprise the steps:

[0058] (1) Heat 22kg of dehydrated castor oil to 110°C and vacuumize for 1h, then add 8kg of maleic anhydride at a temperature of 60°C, react for 1h when heated to 140°C, and add 11kg of bismaleimide After the reaction is uniform, cool down to 100°C, add 15kg E-20 epoxy resin and 11kg F-44 epoxy resin; when the temperature drops to 75°C, add 32.4kg ethyl acetate; when the temperature drops to 35°C, add 0.6 kg2-methylimidazole, fully stirred evenly to prepare modified...

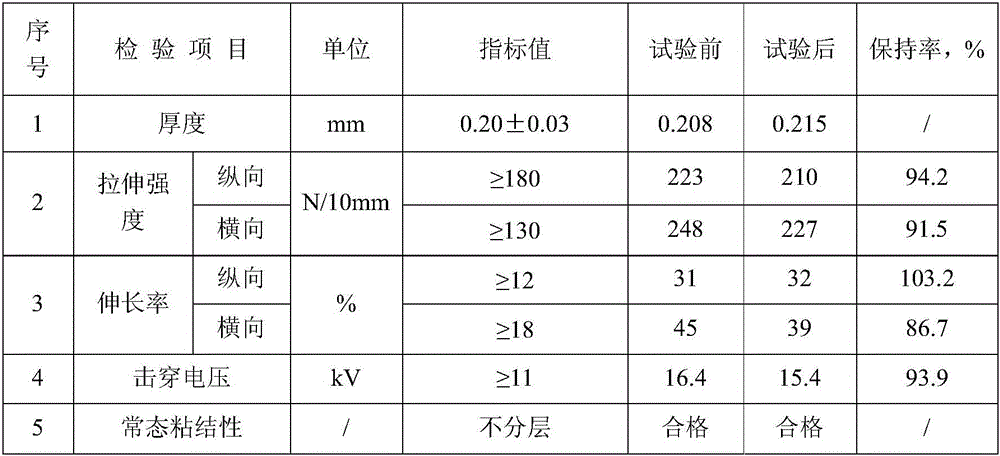

Embodiment 3

[0068] A kind of refrigerant-resistant adhesive of the present invention is mainly prepared by mixing modified epoxy glue and polyurethane glue with a mass ratio of 0.5:1, wherein the modified epoxy glue is mainly composed of 22kg dehydrated castor oil, 6.2kg maleic butene It is prepared from dianhydride, 2.5kg phthalic anhydride, 5.5kg trimellitic anhydride, 8.2kg caprolactam, 20kg AG-80 epoxy resin, 35.3kg acetone and 0.3kg triethanolamine.

[0069] The preparation method of the refrigerant-resistant adhesive of the present embodiment may further comprise the steps:

[0070] (1) Heat 22kg of dehydrated castor oil to 110°C and vacuumize for 1h, add 6.2kg of maleic anhydride, 2.5kg of phthalic anhydride, and 5.5kg of trimellitic anhydride at 160°C, and react at 180°C for 2h , add 8.2kg caprolactam, cool down to 80°C after the reaction is uniform, add 20kgAG-80 epoxy resin; add 35.3kg acetone when the temperature drops to 60°C; add 0.3kg triethanolamine when the temperature dro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com