Reactive polyurethane sealant composition and preparation method thereof

A technology of polyurethane sealant and composition, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., to achieve the effects of high safety factor, improved tensile strength, and high crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

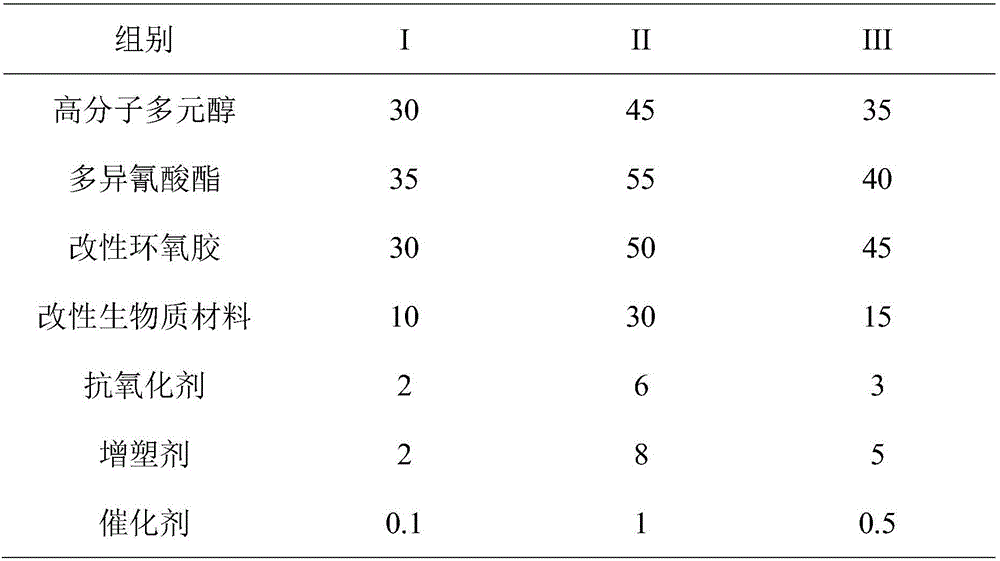

[0025] Embodiment 1: the preparation ratio of each raw material in the reactive polyurethane sealant composition

[0026] The raw materials in the reactive polyurethane sealant composition were mixed in parts by mass as described in Table 1 to obtain three groups of reactive polyurethane sealant compositions I to III with different mixing ratios.

[0027] Table 1 The reactive polyurethane sealant composition of different mixing ratios (parts by mass)

[0028]

Embodiment 2

[0029] Embodiment 2: the preparation method of reactive polyurethane sealant composition

[0030] Step 1. Preparation of modified epoxy glue: Put 18 parts of linseed oil and 15 parts of phthalic anhydride into the reaction kettle, raise the temperature to 80°C, control the stirring speed to 300r / min, and after the reaction is uniform, lower the system temperature to 70°C, add 40 parts of glycidyl ether type epoxy resin and stir evenly, lower the system temperature to 30°C, then dissolve 35 parts of trimethylolpropane tris(2-piperazinylethyl)aminocrotonate in 20 Parts of ethyl acetate, then added dropwise to the reactor, stirred while adding dropwise, and kept warm for 15min after the dropwise addition, to obtain the modified epoxy glue;

[0031] Preparation of modified biomass material: first dry the biomass material until the moisture content is below 16%, crush it into a powder of 100-400 mesh, then place the powder in 1mol / L hydrochloric acid at 80°C and stir evenly, soak f...

Embodiment 3

[0034] Embodiment 3: the preparation method of reactive polyurethane sealant composition

[0035]Step 1. Preparation of modified epoxy glue: Put 30 parts of linseed oil and 25 parts of phthalic anhydride into the reaction kettle, raise the temperature to 110°C, control the stirring speed at 600r / min, and after the reaction is uniform, lower the system temperature to 90°C, add 55 parts of novolak type epoxy resin and stir evenly, lower the system temperature to 40°C, then dissolve 50 parts of trimethylolpropane tris(2-piperazinylethyl)amino crotonate in 40 parts in ethyl acetate, and then added dropwise to the reaction kettle, stirring while adding dropwise, and keeping warm for 30 minutes after the dropwise addition, to obtain the modified epoxy glue;

[0036] Preparation of modified biomass material: first dry the biomass material until the moisture content is below 16%, crush it into a powder of 100-400 mesh, then place the powder in 1mol / L hydrochloric acid at 80°C and stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com