Palladium-free activated nickel-plated conductive cotton fabric and preparation method thereof

A palladium-free activated, conductive cotton technology, applied in physical treatment, plant fibers, textiles and papermaking, etc., can solve the problems of inability to apply well, incapable of large-scale production, and high cost of metal palladium, achieving low cost and activation consumption. Less energy and better wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

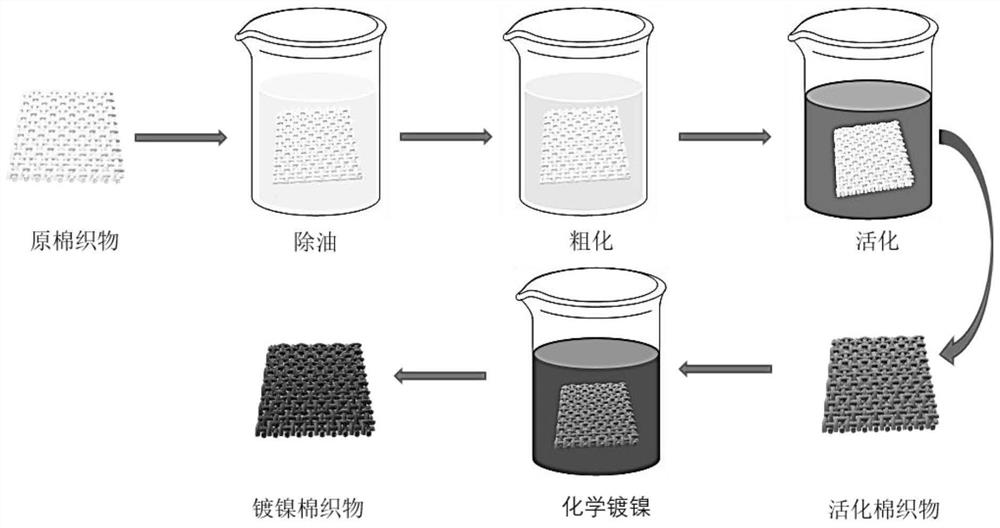

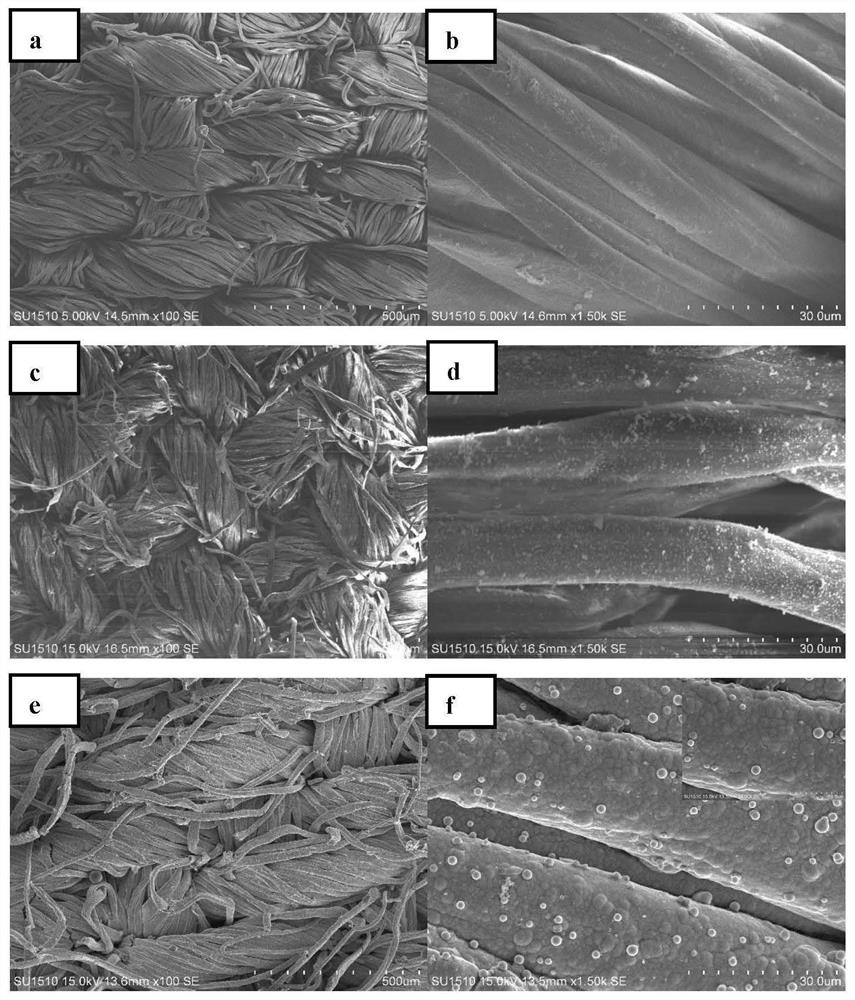

[0049] A kind of preparation method of palladium-free activated nickel-plated conductive cotton fabric, such as figure 1 shown, including the following steps:

[0050] Step 1: Put a 2×2cm cotton fabric into the degreasing solution for 8 hours, let it stand for 16 hours, then take it out and dry it to obtain the degreasing cotton fabric; the volume of acetone, absolute ethanol, and water in the degreasing solution The ratio is 1:2:2;

[0051] Step 2: Put the oil-removing cotton fabric in 40g / L sodium hydroxide solution, use temperature 70°C, frequency 80Hz, ultrasonic for 1h, take it out and dry it, and obtain roughened cotton fabric;

[0052] Step 3: Put the roughened cotton fabric into the activation solution, use temperature 60°C, frequency 80Hz, and ultrasonic for 30 minutes to obtain activated cotton fabric; wherein, the mass ratio of sodium hypophosphite, nickel sulfate hexahydrate, and water in the activation solution is 2:1.5:30;

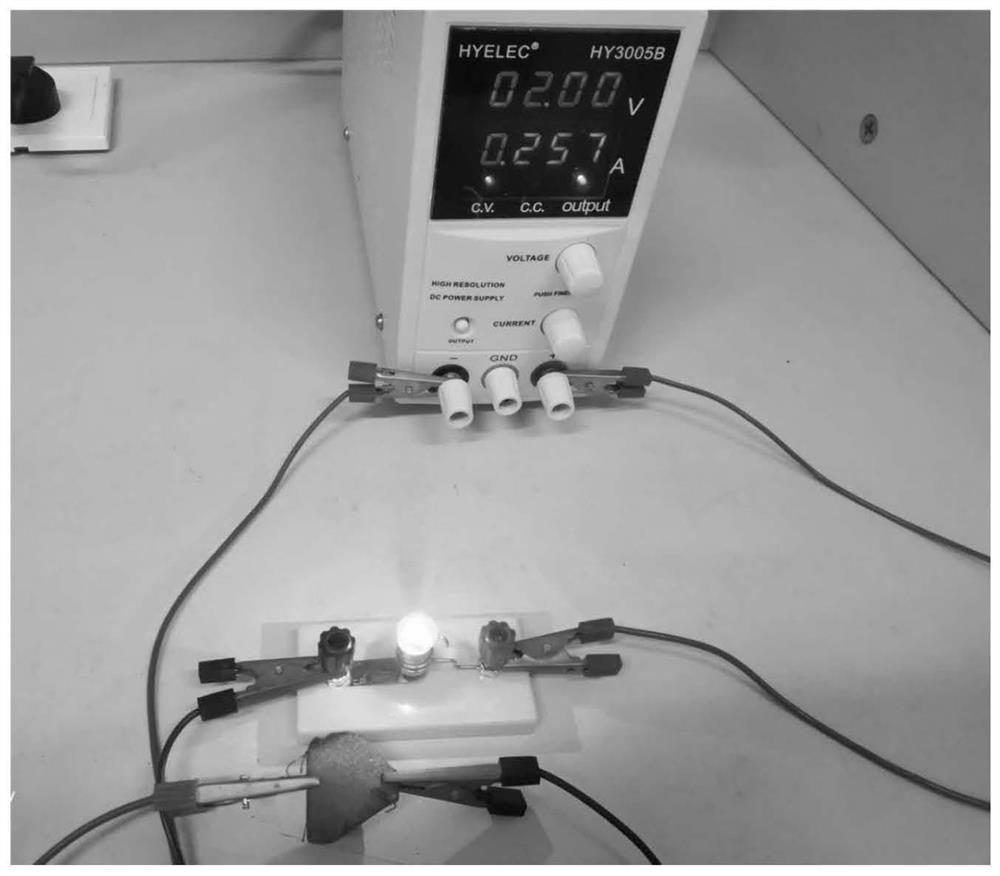

[0053] Step 4: Put 25g / L of nickel ...

Embodiment 2

[0057] Adjust the electroless nickel plating solution in step 4 in embodiment 1 to be: nickel sulfate hexahydrate 20g / L, sodium hypophosphite 25g / L, anhydrous sodium acetate 7g / L, sodium citrate 7g / L, pH is adjusted to 5; other parameters are consistent with embodiment 1, obtain palladium-free activated nickel-plated conductive cotton fabric.

Embodiment 3

[0059] Adjust the electroless nickel plating solution in the step 4 in the embodiment 1 to be: nickel sulfate hexahydrate 30g / L, sodium hypophosphite 20g / L, anhydrous sodium acetate 10g / L, sodium citrate 10g / L, pH is adjusted to 6; other parameters are kept the same as in Example 1 to obtain palladium-free activated nickel-plated conductive cotton fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com