Technology for removing fishy smell from squids

A squid and process technology, applied in the field of deodorization process, can solve problems such as insufficiency, and achieve the effects of reducing the loss of nutrients, prolonging the fresh-keeping period, inhibiting metabolism and corruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

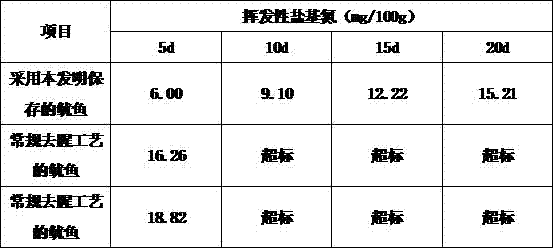

Image

Examples

Embodiment 1

[0021] Squid deodorization process, the process steps are as follows:

[0022] 1) Pretreatment: Peel the skin, viscera, head and feet of the fresh squid, wash and drain;

[0023] 2) Preparation of deodorizing liquid: deodorizing liquid consists of the following components and parts by weight: 0.5-5 parts of tea tree oil, 0.5-5 parts of eucalyptus oil, 0.001-0.02 parts of sodium citrate dihydrate, 3-15 parts of surfactant AES , Glycyrrhizic acid 0.01~0.03 parts, calcium oxide 1~10 parts, BS-12 3~12 parts, propylene glycol 2~12 parts, water 41~90 parts. Take water in parts by weight and add it to the reactor, stir and add surfactant AES, calcium oxide to raise the temperature, stir and add tea tree oil, eucalyptus oil, sodium citrate dihydrate, glycyrrhizic acid in turn, emulsify, add BS-12, stir and add propylene glycol, Cool, defoam and filter to remove the fishy liquid.

[0024] 3) To remove fishy smell: soak the drained squid in the fishy smelly liquid, drain, soak in pres...

Embodiment 2

[0033] Squid deodorization process, the preferred process steps are as follows:

[0034] 1) Pretreatment: Peel the skin, viscera, head and feet of the fresh squid, wash and drain;

[0035] 2) Preparation of deodorizing liquid: deodorizing liquid consists of the following components and preferred parts by weight: 2 parts of tea tree oil, 3 parts of eucalyptus oil, 0.0018 parts of sodium citrate dihydrate, 4 parts of surfactant AES, 0.02 parts of glycyrrhizic acid, oxidation Calcium 6 parts, BS-12 5 parts, propylene glycol 4 parts, water 88 parts. Take water in parts by weight and add it to the reaction kettle, stir and add surfactant AES, calcium oxide to raise the temperature, stir and add tea tree oil, eucalyptus oil, sodium citrate dihydrate, glycyrrhizic acid in turn, emulsify, add BS-12, stir and add propylene glycol, Cool, defoam and filter to remove the fishy liquid.

[0036] 3) To remove fishy smell: soak the drained squid in the fishy smelly liquid, drain, soak in pr...

Embodiment 3

[0045] Squid deodorization process, the process steps are as follows:

[0046] 1) Pretreatment: Peel the skin, viscera, head and feet of fresh squid, wash them, and drain at 3°C;

[0047] 2) Preparation of deodorization liquid: The deodorization liquid consists of the following components and parts by weight: 2 parts of tea tree oil, 3 parts of eucalyptus oil, 0.0018 parts of sodium citrate dihydrate, 4 parts of surfactant AES, 0.02 parts of glycyrrhizic acid, calcium oxide 6 parts, BS-12 5 parts, propylene glycol 4 parts, water 88 parts. Take water in parts by weight and add it to the reaction kettle, stir and add surfactant AES, calcium oxide and heat up to 70°C, stir and add tea tree oil, eucalyptus oil, sodium citrate dihydrate, glycyrrhizic acid in turn, emulsify for 35 minutes, add BS-12, Stir and add propylene glycol, cool to 27°C, defoam and filter to obtain fishy-removing liquid.

[0048] 3) To remove the fishy smell: soak the drained squid in the fishy smelly solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com