Patents

Literature

129results about How to "Protect shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Probiotics enriched crisp apple products and preparation method thereof

The present invention discloses probiotics enriched crisp apple products and a preparation method thereof, and belongs to the technical field of agricultural product processing. Apples are used as raw materials, the apples are washed, the washed apples are blanched, a vacuum soaking method is used to enrich probiotics into apple tissues, and then a vacuum freeze-drying and vacuum microwave combined drying method is used to prepare the probiotics enriched crisp apple products. The method comprises the following steps: (1) raw material washing and blanching; (2) probiotic soaking liquid preparing; (3) vacuum soaking; and (4) vacuum freeze-drying and vacuum microwave combined drying. The prepared probiotics enriched fruit and vegetable crisp products are mellow in fruit fragrance, and crisp and tasty. The viable probiotic number can be maintained at 10<7> CFU / g at 25 DEG C for 90 days or more. The preparation method avoids the two major defects of high cholesterol risk of the probiotic fermented milk products and the non-consumption of lactose intolerant population, and the products combine health care and leisure, and have broad market prospects.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

A method for making Fe lithium phosphate compound anode material

InactiveCN101262053AImprove uniformityEnsure consistencyElectrode manufacturing processesLithium compoundsLithium iron phosphateLITHIUM PHOSPHATE

The invention relates to a new technique for preparing a composite positive material of lithium iron phosphate. The preparation technique is that: first, precursors containing lithium, iron, phosphorus and doped elements are evenly mixed by a high-speed mixer, and then a doped lithium iron phosphate matrix is obtained by low temperature sintering in an inert atmosphere protection kiln; next, the doped lithium iron phosphate matrix and a conductive agent material are evenly mixed by the high-speed mixer, and then the composite positive material of lithium iron phosphate, which is wrapped by carbon, is obtained by high-temperature sintering in the insert atmosphere protection kiln; finally, the lithium iron phosphate material is obtained by grinding and grading process. Particle size D50 of the material is 3-10Mum, tap density and specific surface area thereof are 1.0-2.0g / cm<3> and 10-20m<2> / g. The new technique for preparing the composite positive material of lithium iron phosphate is simple and easy to be controlled and the prepared lithium iron phosphate material has good processing performance, high capacity and good amplification performance and is easy to realize industrial production.

Owner:张守文

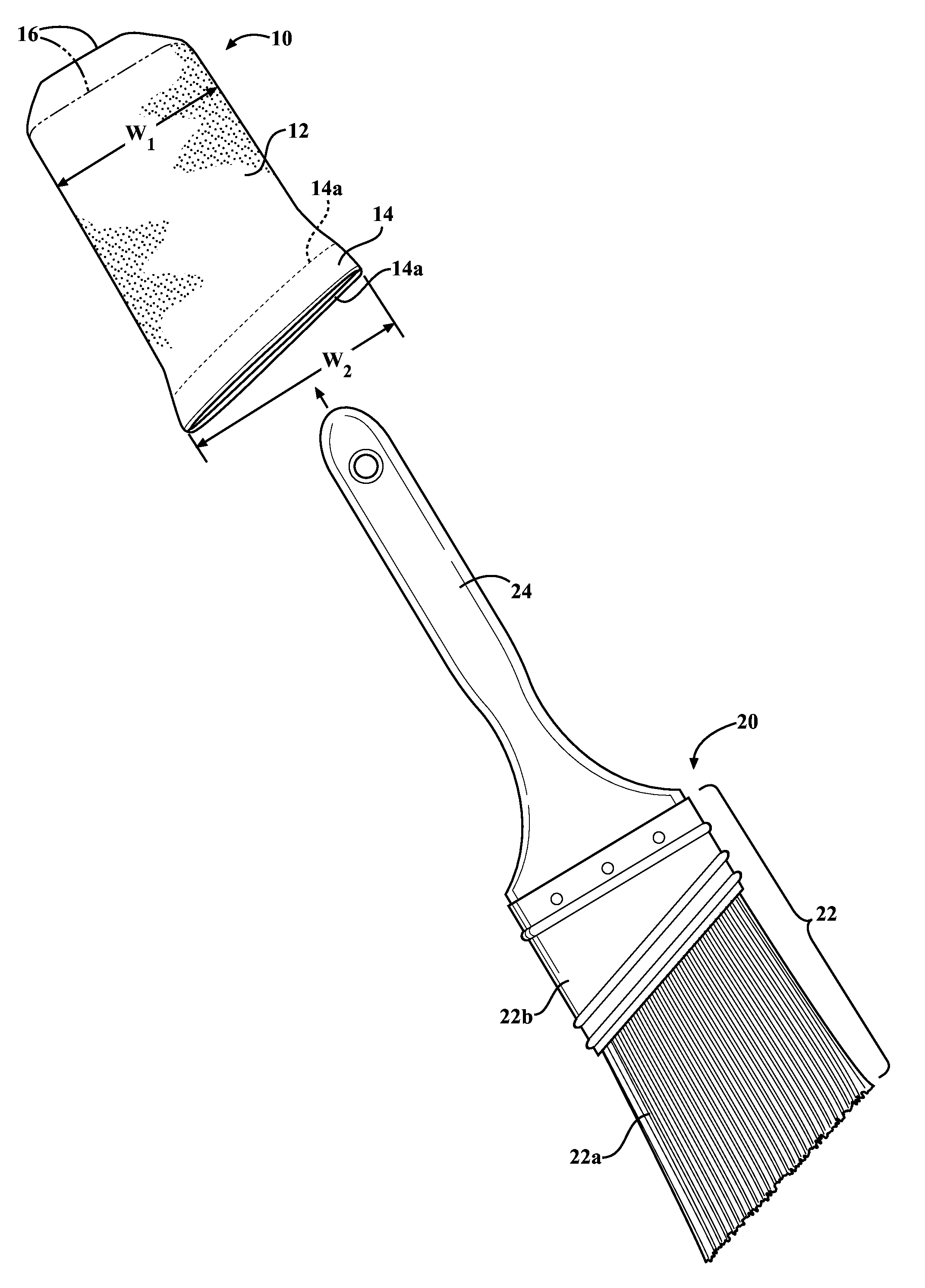

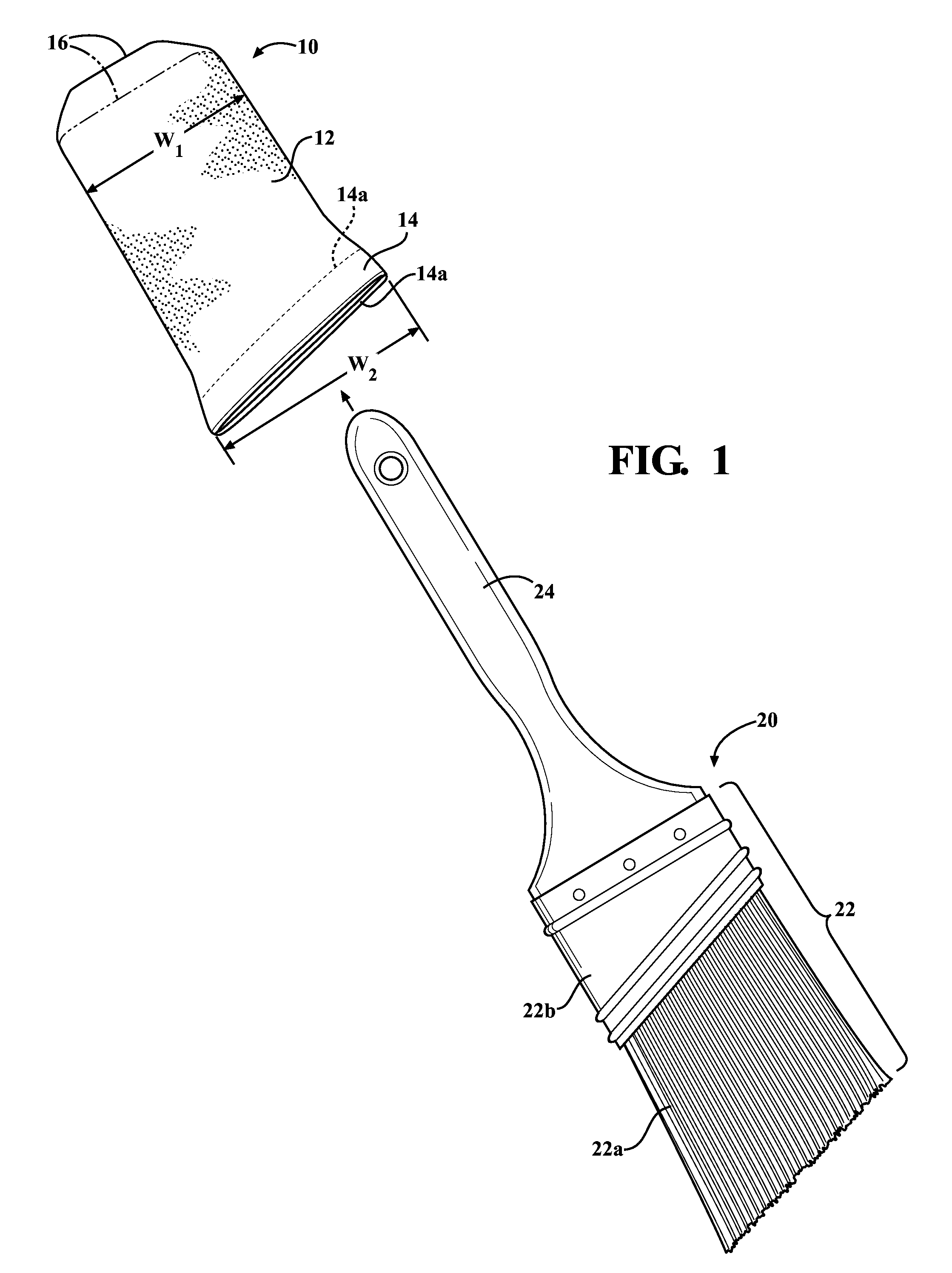

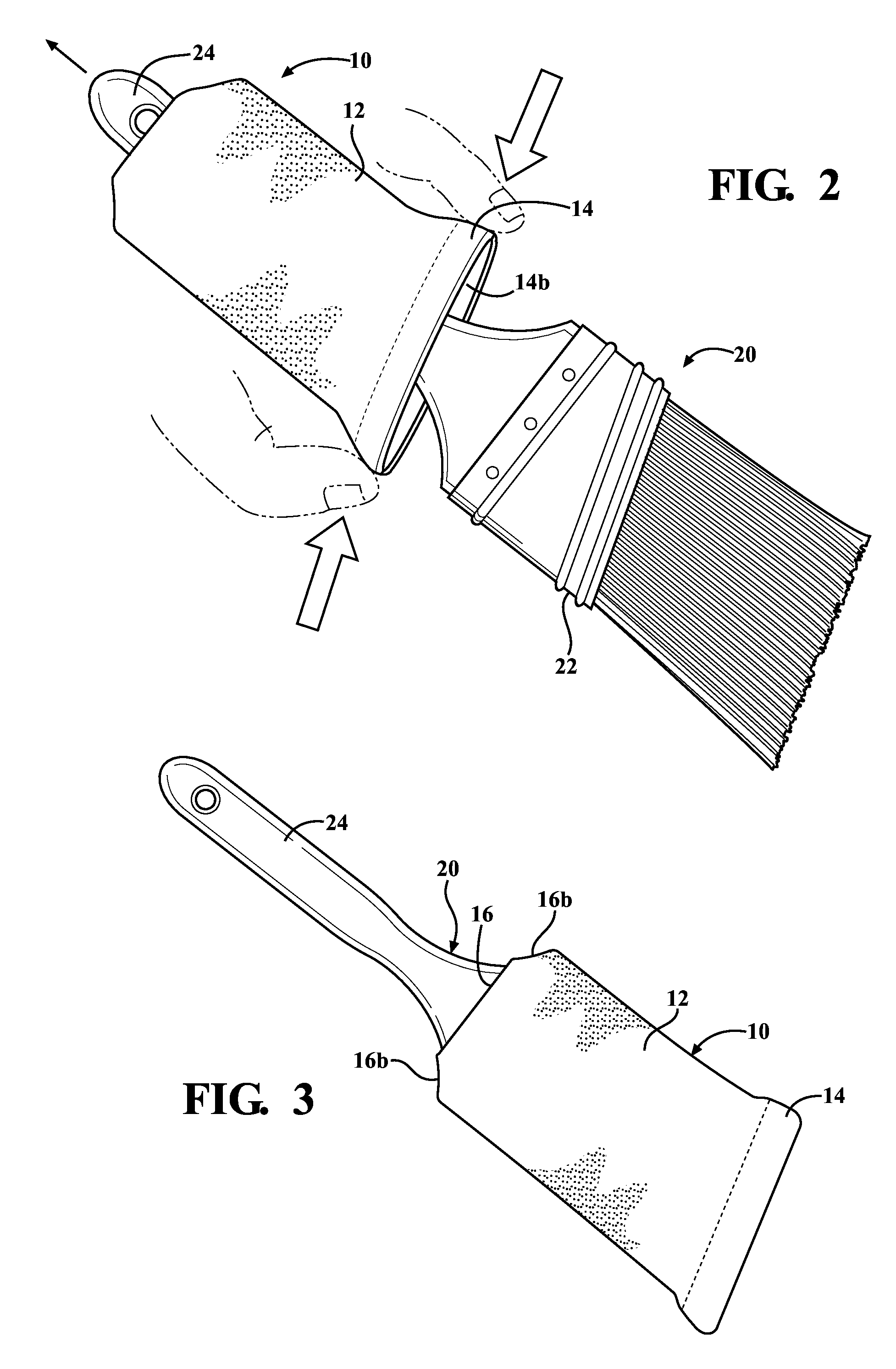

Paint brush cover

A paint brush cover has a bottom opening; a stretchable, breathable, moisture-wicking fabric body with an internal volume less than a volume of an inserted paint brush head; and a top opening narrower than the fabric body and the paint brush head and sized to freely admit the brush handle. A paint brush is inserted handle-first through the bottom opening until the wider brush head registers in a fully covered position with the brush head stretching the fabric body into moisture-wicking contact against the bristles, and with the bristle ends spaced above the bottom opening. The bottom opening may be stiffened with a flexible stiffener that flexes open when a brush head is inserted, or with a closure flap.

Owner:OLIVER ANDREW D

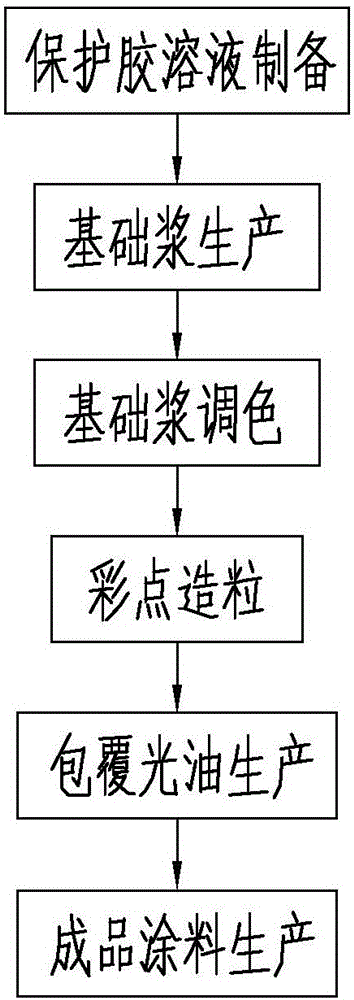

Production method of water-in-water colorful paint containing color sand

ActiveCN105925096ACost-effectiveFast manufacturingAntifouling/underwater paintsPaints with biocidesWeather resistanceSlurry

The invention discloses a production method of water-in-water colorful paint containing color sand. The production method comprises the following steps: (a), preparing a protection glue solution; (b), producing basic slurry; (c), matching the color of the basic slurry; (d), performing color point granulation; (e), producing coating gloss oil; (f), producing finished paint. Granite-shaped particle containing particles are formed on the surface of the paint produced by the method, imitated-marble granite paint can be prepared from the paint, formed patterns are simple, artistic and elegant, and the paint prepared by the method is level in surface and not easy to form ash deposition, can keep the overall appearance longer, and has stain resistance; the special coating gloss oil can keep the color on the surface of the paint to be permanent and fresh, and has weather resistance; the paint is high in water resistance and rot resistance, is neither absorbed by a wall surface nor damaged in rainy days, and can protect the overall shapes of buildings.

Owner:ZHEJIANG KEDA NEW BUILDING MATERIALS

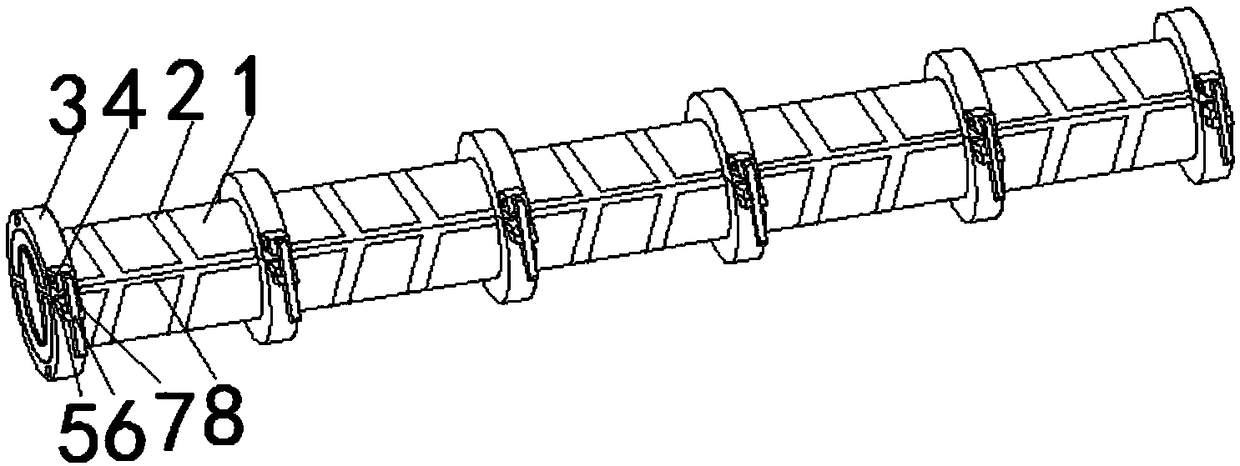

Spiral fin condenser

InactiveCN106196757AGuarantee the role of structural fixationPlay a role in structural fixationSafety devices for heat exchange apparatusEvaporators/condensersEngineering

The invention relates to a spiral fin condenser. The spiral fin condenser comprises a condensation pipe and a fin; the fin is spirally wound on the surface of the condensation pipe; and the condensation pipe is twisted and bent by multiple times to form a cuboid structure. The spiral fin condenser further comprises a fixed bracket fixedly clamped on the condensation pipe. The spiral fin condenser has such characteristics as small size, compact structure and good condensation effect.

Owner:CHANGZHOU CHANGZHENG HEAT EXCHANGER TECH

Cement casting die for manufacturing of electric wire pole

InactiveCN108908687AImprove stabilitySave the step of fixing and tightening the boltsMouldsRebarMaterials science

The invention discloses a cement casting die for manufacturing of an electric wire pole. The cement casting die comprises a die body, longitudinal reinforcing ribs and a plurality of reinforcing seats, wherein the multiple reinforcing seats are arranged on the die body; an upper die is arranged in each reinforcing seat; a lower die is arranged in each reinforcing seat and is symmetric to the corresponding upper die; buffer layers are respectively arranged in each upper die and each lower die; each reinforcing seat consists of an upper part and a lower part; an upper turnover fixed block is arranged at the left side of the upper half part of each reinforcing seat, and is rotationally connected with a lower turnover fixed block through a second rotary shaft. The cement casting die has the advantages that in the use process, each upper die is opened, a reinforcement cage of the electric wire pole is put into each lower die, a proper amount of concrete is cast, then each upper die is closed, a convex block at the lower side of the right end of each upper die is inserted into a groove, and the die can be stabilized; a locking press handle is pressed down, and a clamp block is clamped with a locking block, so that the die can be directly and effectively tightened, the step of fixing and tightening the bolt in the traditional bolt is not required, and the production time is shortened.

Owner:无为县红宇通信器材有限责任公司

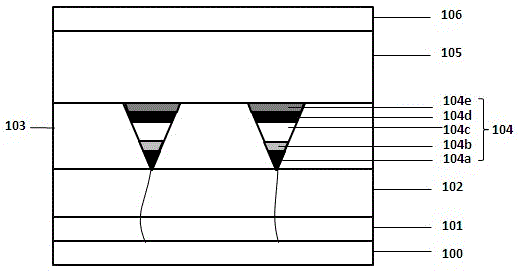

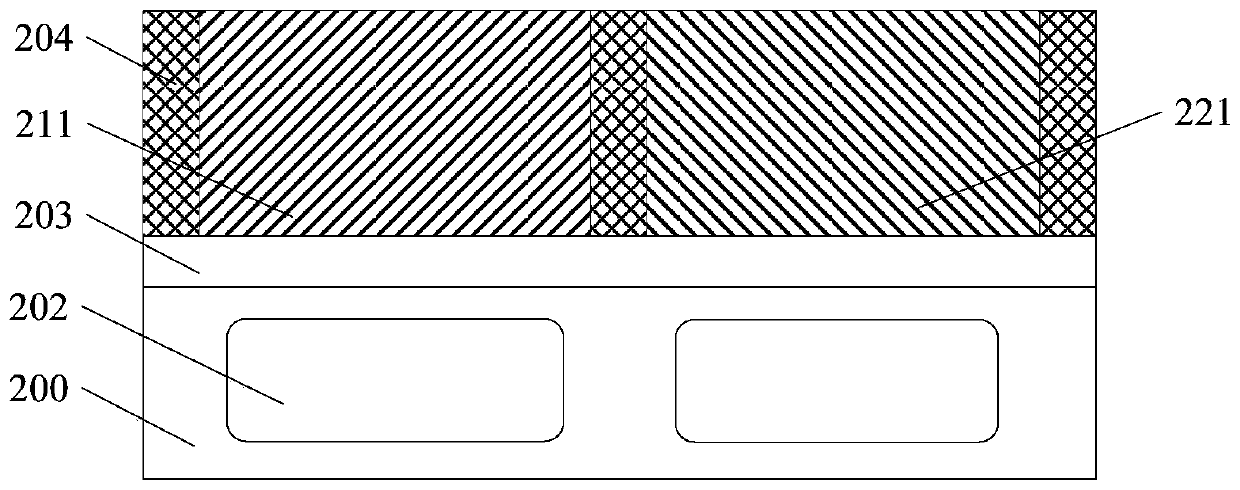

Nitride light-emitting diode

ActiveCN105870273APrevent precipitationPrevent proliferationSemiconductor devicesQuantum wellQuantum dot

The invention discloses a nitride light-emitting diode. The nitride light-emitting diode sequentially comprises a substrate, N type nitride, a multi-quantum well, V-shaped pits, first AlN / AlxGa1-xN superlattices, local area quantum states formed by In quantum dots / InN quantum dots, a composite structure formed by second AlN / AlxGa1-xN superlattices, P type nitride and a P type contact layer, the first AlN / AlxGa1-xN superlattices, the local area quantum states formed by the In quantum dots / InN quantum dots and the composite structure formed by the second AlN / AlxGa1-xN superlattices are deposited in the V-shaped pits of the multi-quantum well, an upper AlN / AlxGa1-xN superlattice structure and a lower AlN / AlxGa1-xN superlattice structure in each V-shaped pit block dislocation in the corresponding V-shaped pit and stop the dislocation from continuing extending upwards, dislocation is effectively reduced, nonradiative recombination is lowered, electric leakage is reduced, ESD is improved, and light-emitting efficiency and intensity are improved; by means of the mixed local area quantum state formed by the In quantum dots / InN quantum dots between the two superlattice structures, the quantum effect of the quantum well is improved, and light-emitting efficiency and intensity are further improved.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

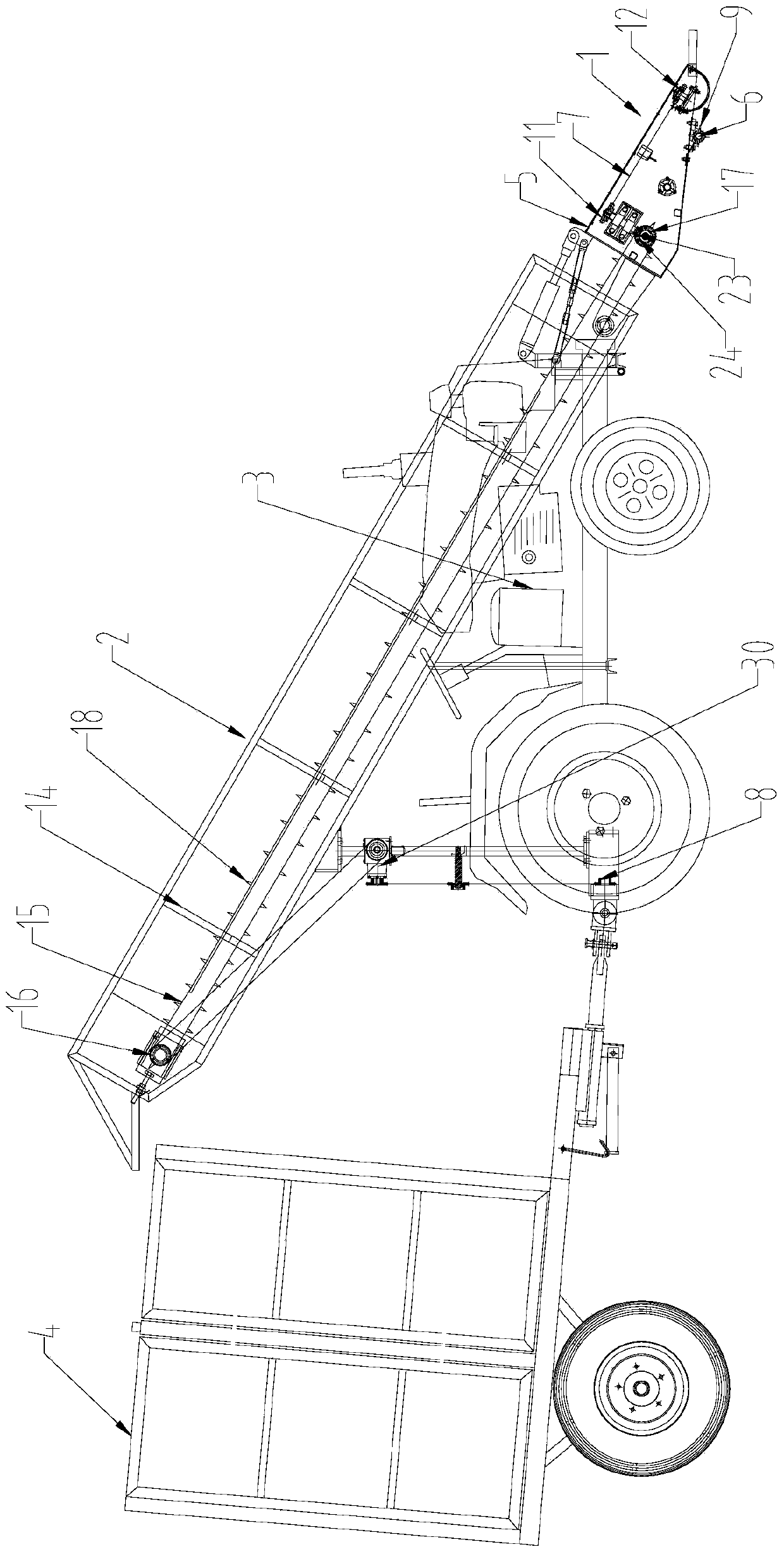

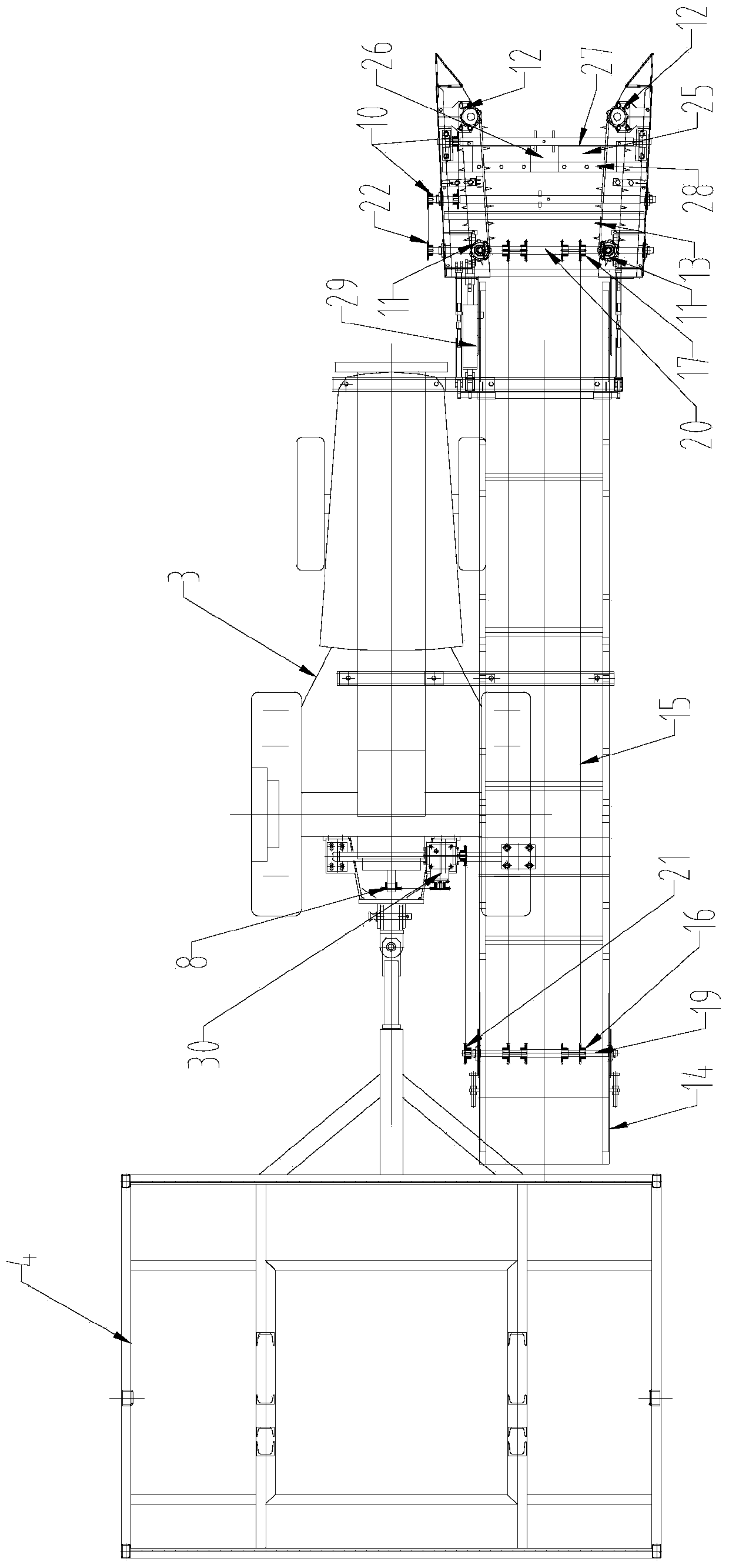

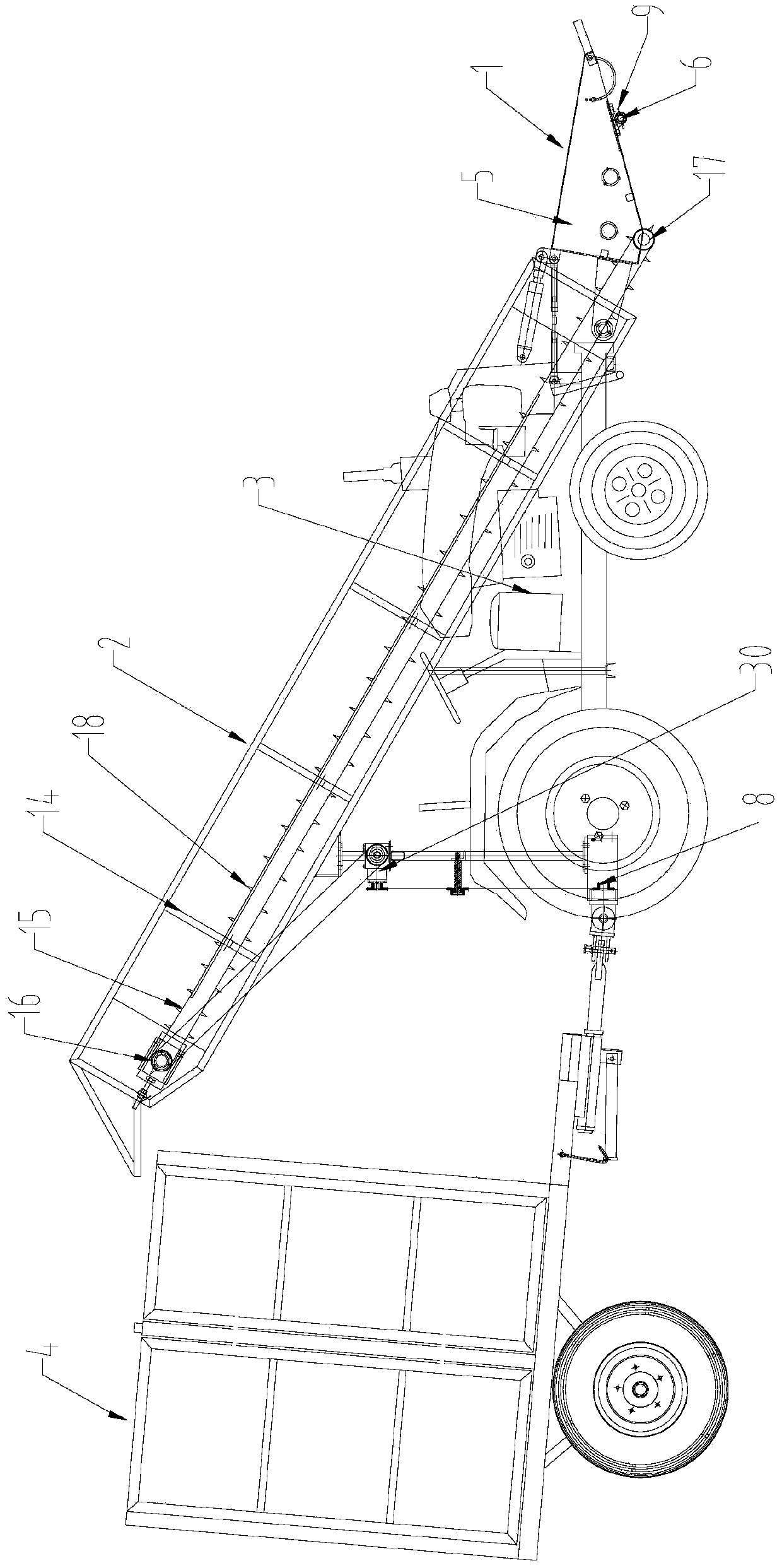

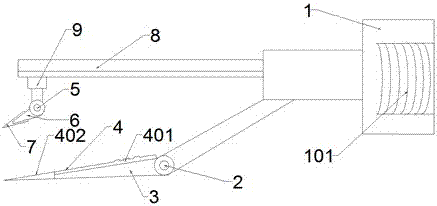

Straw bale picking device

The invention relates to a straw bale picking device. The straw bale picking device comprises a picking structure, a conveying structure and a base plate, wherein the picking structure is used for picking up straw bales from the ground, the conveying structure is located at one end of the picking structure and used for conveying the straw bales to the designated position, and the base plate provides power. The picking structure at least comprises a groove-type picking frame, a picking rotating shaft and picking chains, wherein the picking frame is fixedly connected with the base plate, the picking rotating shaft is located at the bottom of the picking frame, and the picking chains are located on the two sides of the picking frame. The picking rotating shaft rotates, the picking chains rotate, and the picking rotating shaft and the picking chains jointly act to obliquely stir the straw bales upwards. In the straw bale picking process, the picking rotating shaft rotates, the picking chains rotate, and the picking rotating shaft and the picking chains jointly act to obliquely stir the straw bales upwards, so that the straw bales cannot be extruded, force applied to the straw bales is uniform, and the shapes of the straw bales are effectively protected.

Owner:SHANDONG TRALIN PAPER

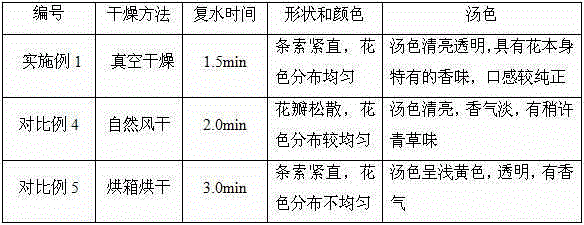

Manufacturing technology of hibiscus petal tea

The invention discloses a manufacturing technology of hibiscus petal tea. The technology comprises the following steps of 1, petal preprocessing, picking, selecting, ultrasonic cleaning and air drying; 2, punch forming, wherein preprocessed petals are punched, clipped and formed to obtain the formed petals; 3, color protection, wherein the formed petals are arranged in a color protection solution to be soaked; 4, microwave de-enzyming, wherein rinsing is performed with clean water, and microwave de-enzyming is performed after natural draining; 5, rolling, wherein the petals are spread after microwave de-enzyming is performed, standing and softening are performed, and then rolling is performed till trabs are tight and straight and stopped when the lubrication feeling is achieved; 6, vacuum drying and vacuum packaging. According to the technology, the microwave de-enzyming technology and the vacuum drying technology are adopted in a combined mode, the petal tea rehydration performance is good, and the adopted color protection solution can more effectively protect the color and the shape of the petal tea; the hibiscus petal tea is bright in color and rich in flowery flavor, the tea soup is bright in color, fragrant in smell, fresh and elegant in taste and free of herbal flavor, and the novel health care hibiscus petal tea has the certain ornamental value after being brewed.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Surface protective film

ActiveCN102149779AGood expandabilityPrevent paste residuePressure sensitive film/foil adhesivesHydrocarbon polymer adhesivesPolymer scienceConjugated diene

An adhesive composition characterized by containing a polymer (i), which is a copolymer having a structure represented by the following general formula: [A-B]n (wherein n = 1-3) or a hydrogenated product thereof, and a polymer (ii), which is a copolymer having a structure represented by the following general formula: A-B-A or the following general formula: (A-B)x-Y (wherein x >= 1 and Y represents a residue of a coupling agent) or a hydrogenated product thereof. The adhesive composition is also characterized in that the total aromatic alkenyl compound unit content in the polymers (i) and (ii)is 30-50 wt%, and the weight ratio between the total amount of A and the total amount of B contained in the polymers (i) and (ii) is within the range of from 5:95 to 25:75. In this connection, A represents a polymer block mainly composed of aromatic alkenyl compound units, and B represents a polymer block which is an aromatic alkenyl-conjugated diene random copolymer block having an aromatic alkenyl compound unit content of 10-35 wt%.

Owner:SEKISUI CHEM CO LTD +1

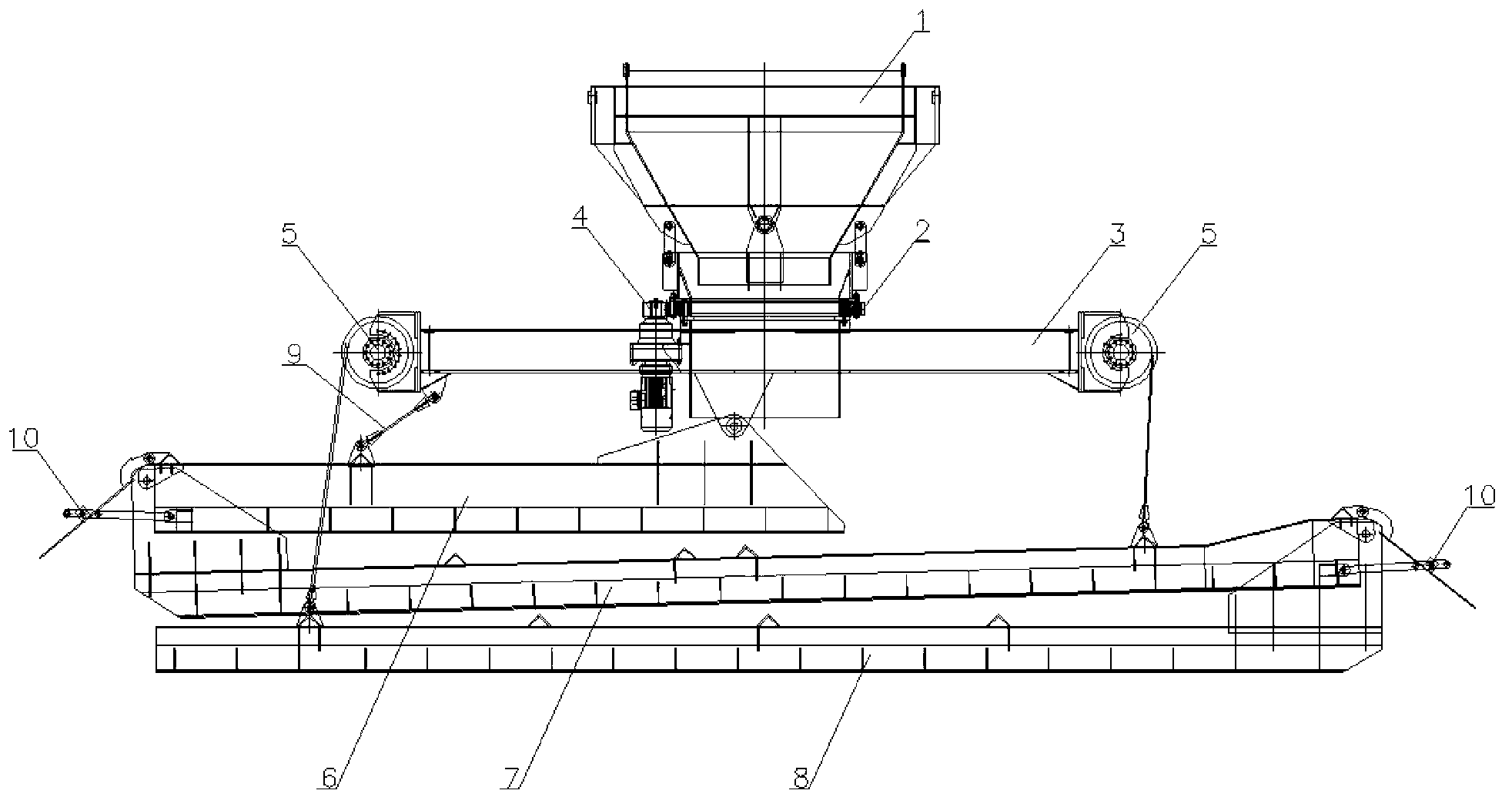

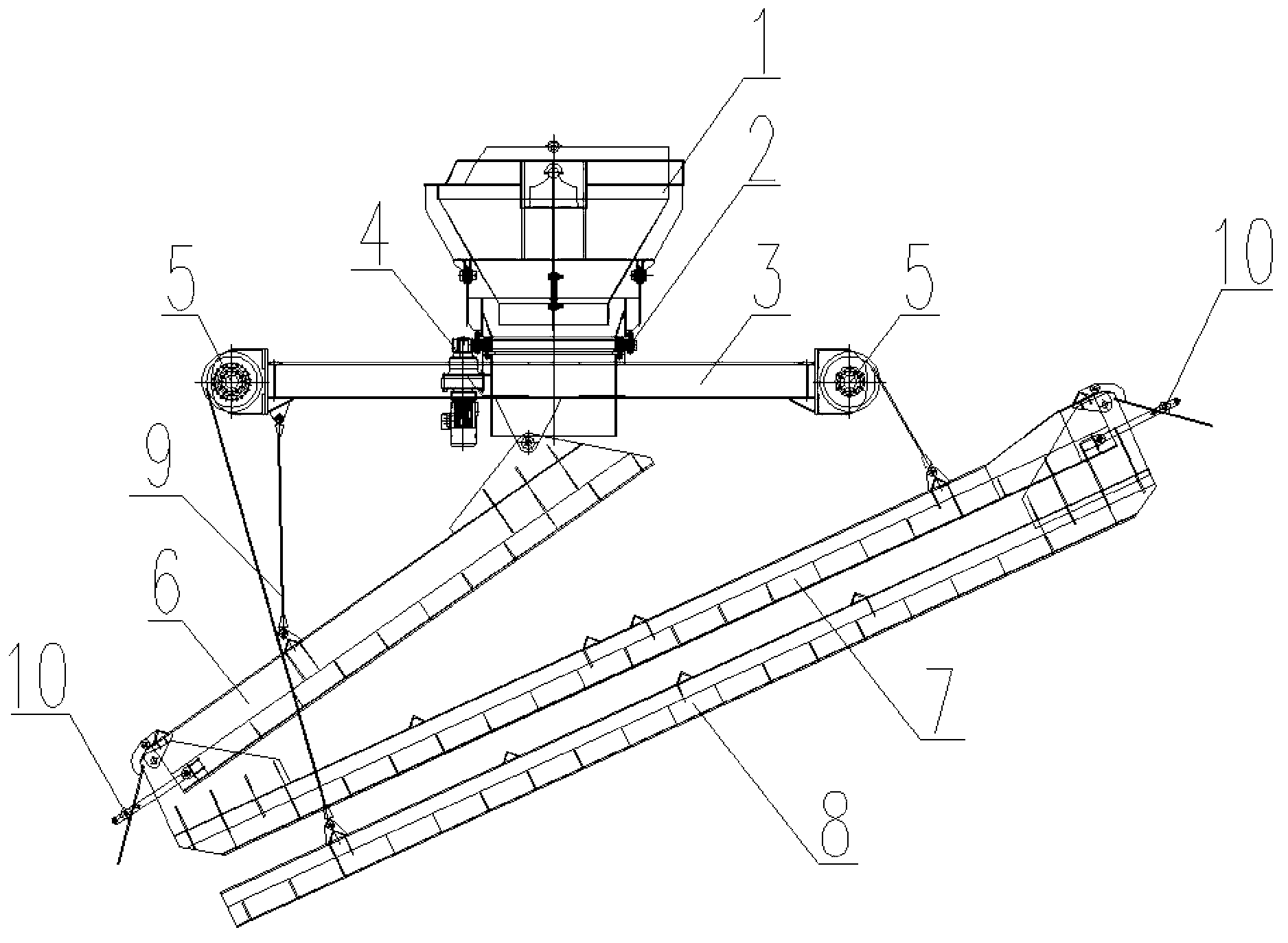

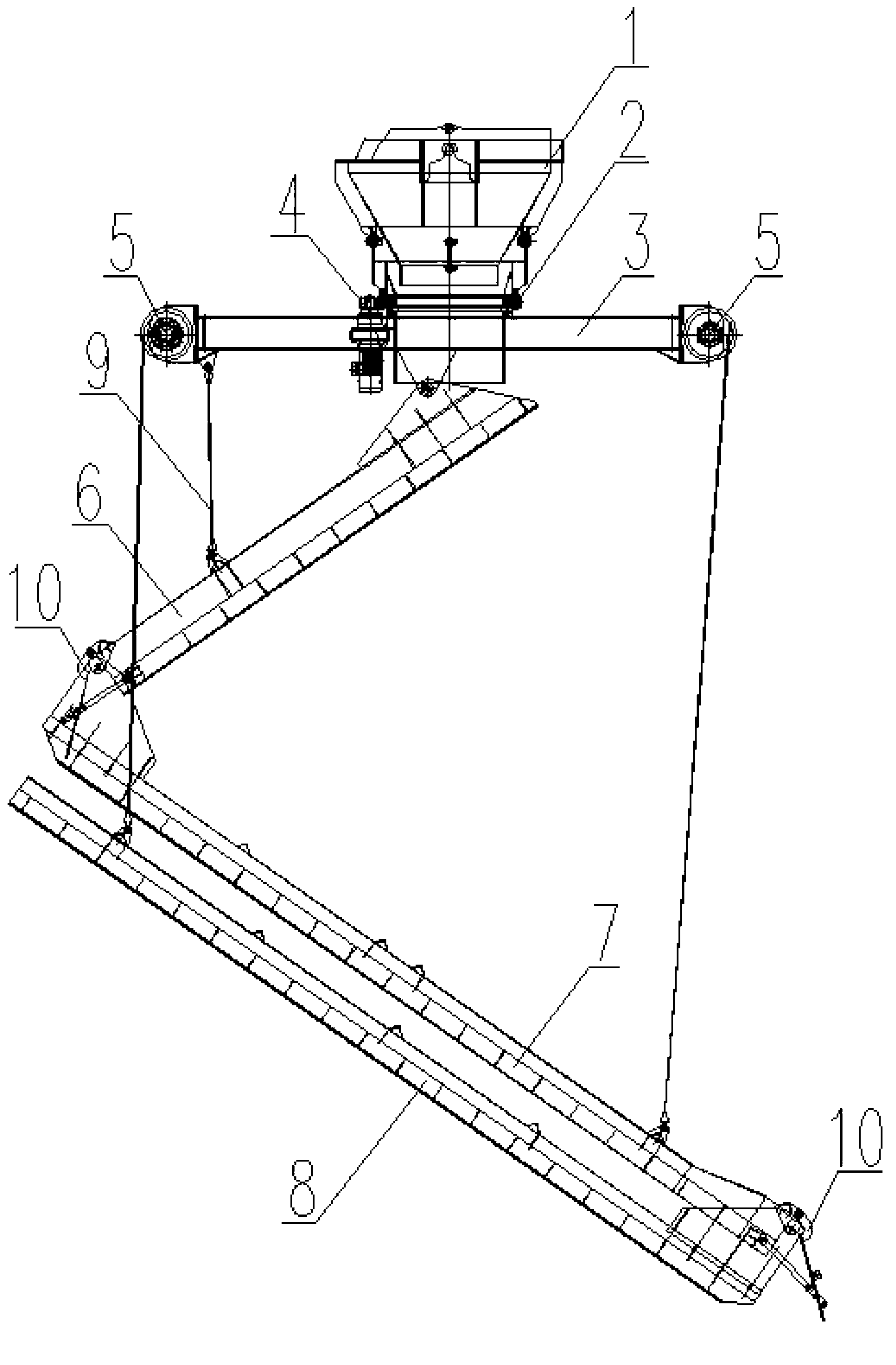

Z-shaped slow-descending chute discharging device

ActiveCN103224148AAchieve coveragePlay the role of linking the previous and the nextLoading/unloadingEngineeringWindlass

The invention provides a Z-shaped slow-descending chute discharging device and relates to a discharging device for bulk materials, particularly for bulk materials, such as bread iron, corn and wheat, which are suitable for loading and unloading by a ship loader. The discharging device adopts the structure that the lower end of a material guide cylinder is connected with a reversing frame through a pivotal bearing; a revolution drive mechanism is mounted on the reversing frame; a pinion wheel of the revolution drive mechanism is meshed with a bearing external gear ring of the pivotal bearing; material guide grooves are formed in the lower part of the reversing frame; two folding windlasses are symmetrically arranged on two ends of the reversing frame respectively; traction steel wire ropes of the two folding windlasses are connected with a secondary material guide groove and a tertiary material guide groove respectively; an iron chain is mounted between the reversing frame and a primary material guide groove of the material guide grooves; and baffles are mounted at the bottom ends of the primary and the secondary material guide grooves. The discharging device has the characteristics of novel structure, simplicity and convenience in processing, convenience in use, safety, reliability, high operating efficiency and the like.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

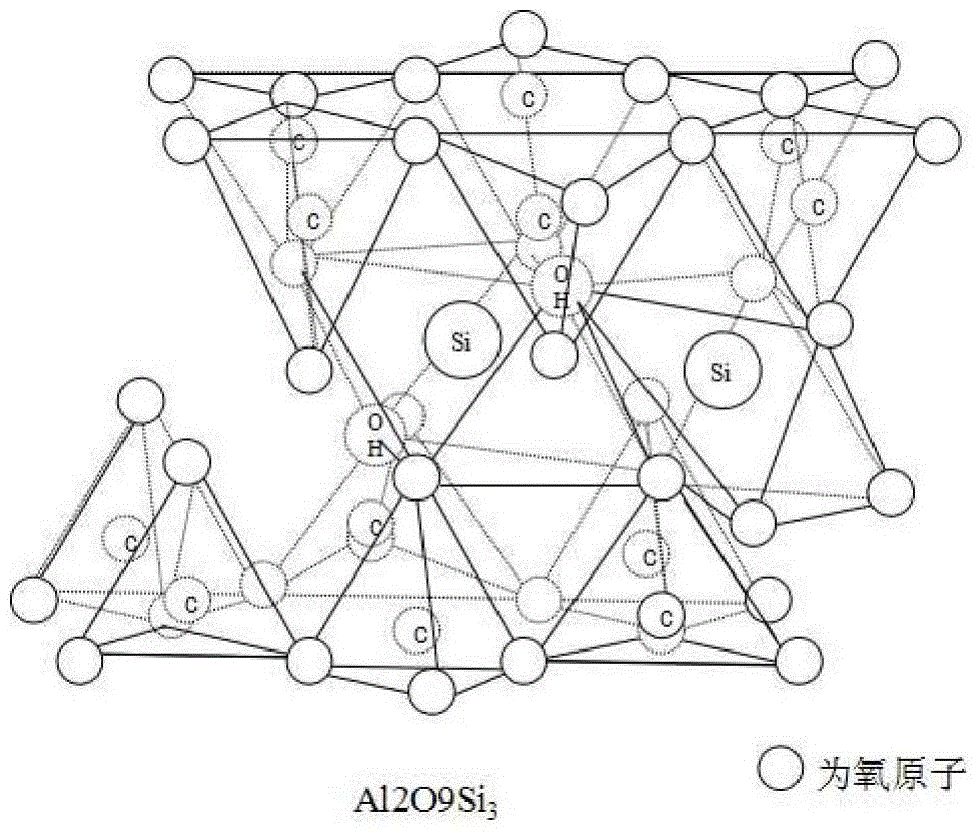

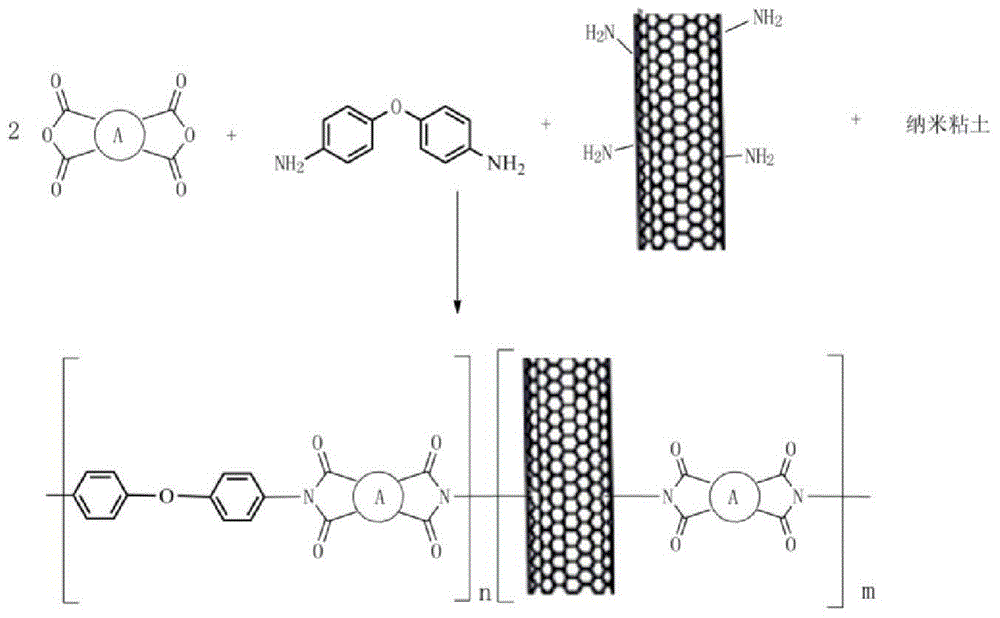

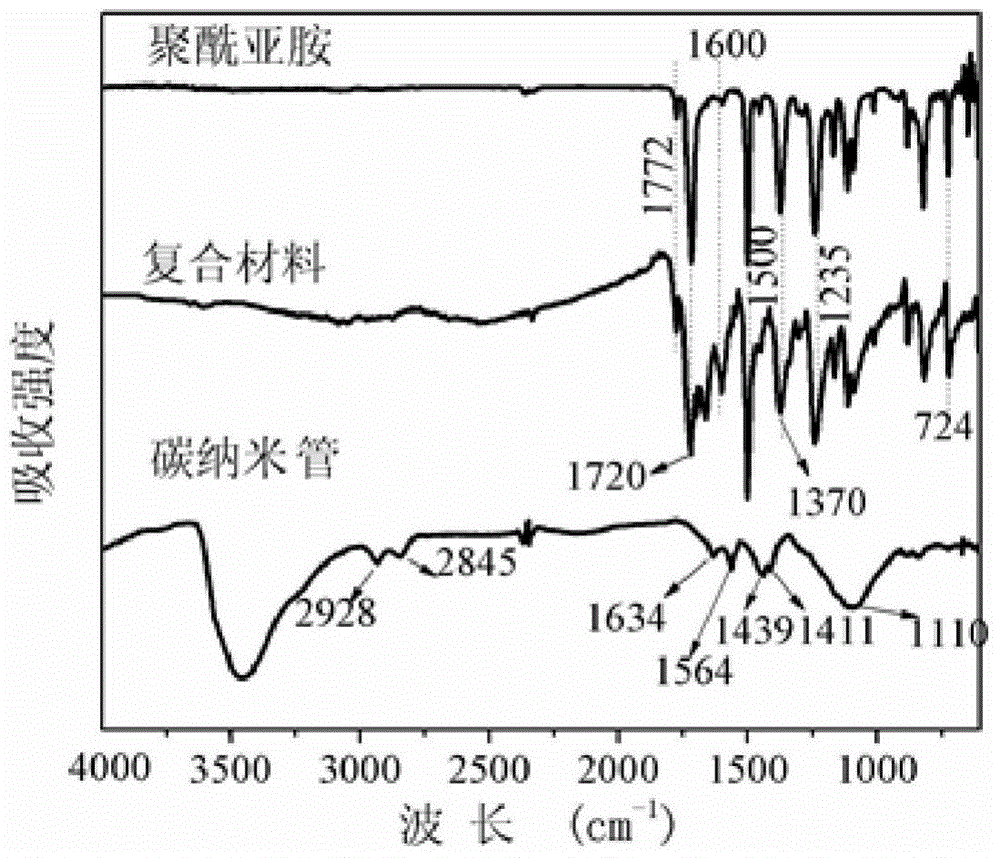

Polyimide composite material and preparation method and application thereof

InactiveCN104945902AOvercome the shortcomings of short service life and unsatisfactory radiation resistanceOvercome the disadvantages of being harmful to the human environmentDiaminodiphenyl etherCarbon nanotube

The invention discloses a polyimide composite material. Aminated carbon nanotube and diaminodiphenyl ether, which are used cooperatively as diamine, and another dianhydride monomer, namely PMDA (pyromellitic dianhydride) or BPDA (3,3',4,4'-biphenyltetracarboxylic anhydride), are polymerized to form polyamide acid; and during the process of forming a polyamide acid solution, nano-clay is added, and the composite material is formed by a hot-pressing technology after amidation of the system. The aminated carbon nanotube is directly bonded to the polyimide system through chemical bonding, but nano-clay is doped to the polyimide system through physical function. The aminated carbon nanotube-bonded and nano-clay-doped polyimide material obtained by the above method has good thermal neutron shielding property. The invention also discloses a preparation method of the above aminated carbon nanotube-bonded and nano-clay-doped polyimide material and its application in neutron radiation shield.

Owner:SOUTHEAST UNIV

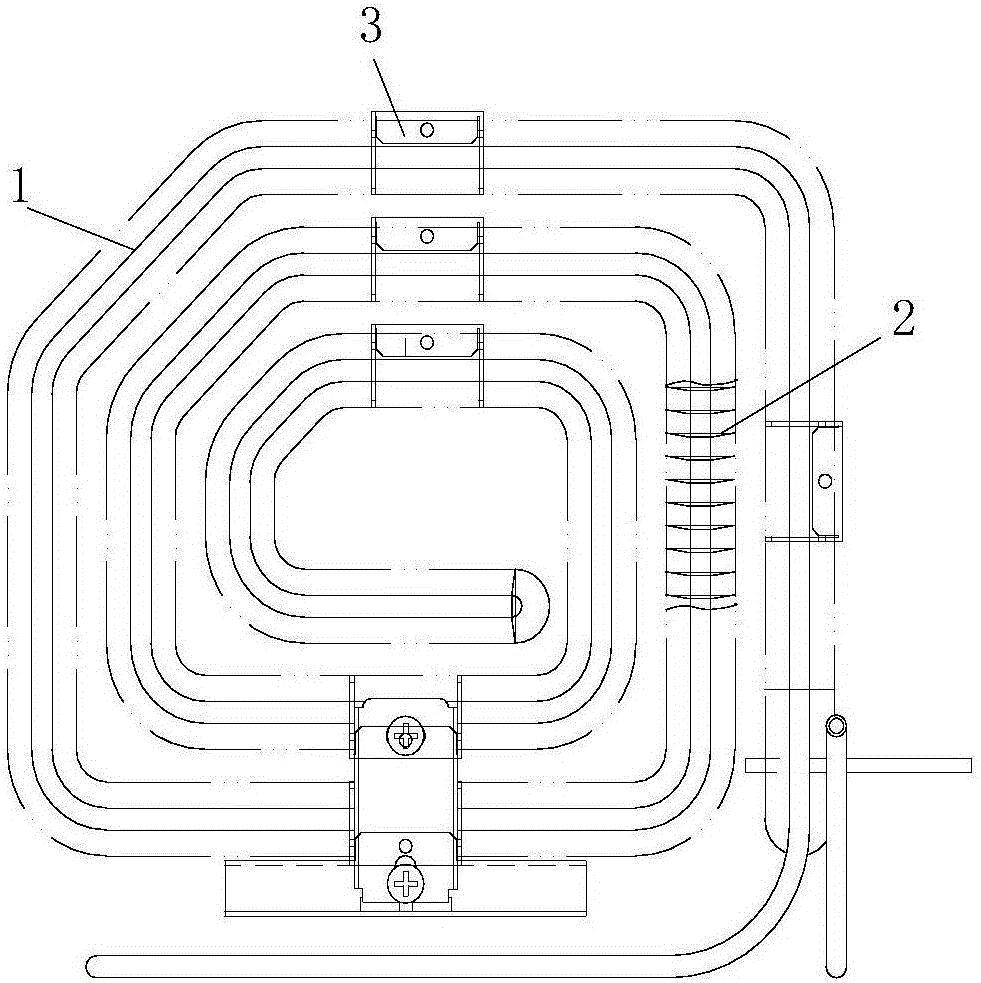

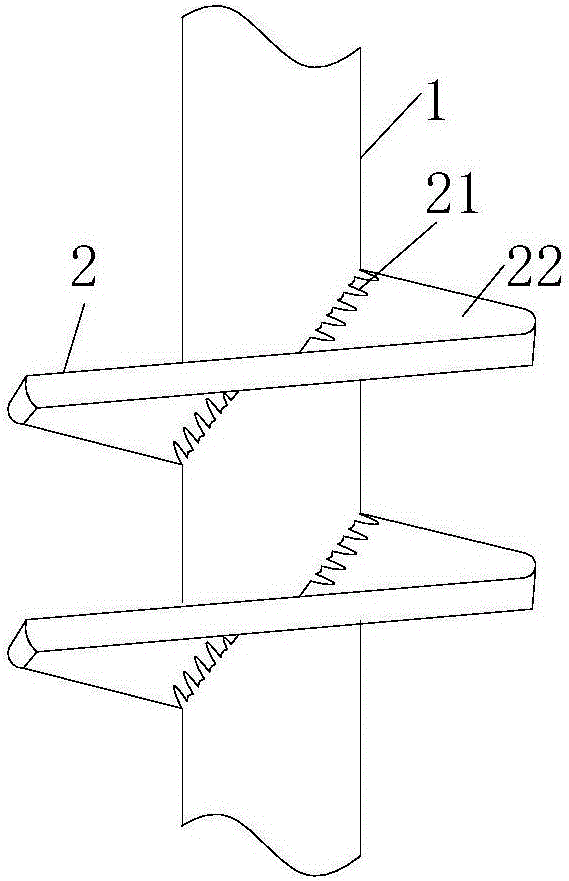

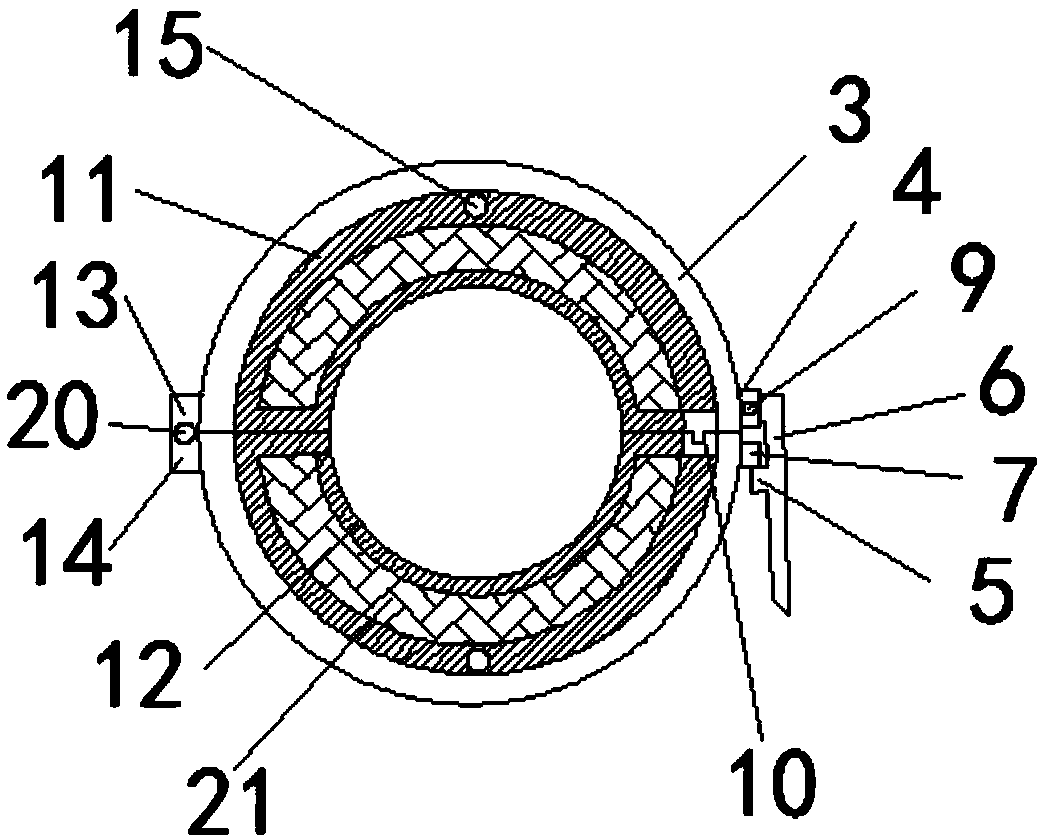

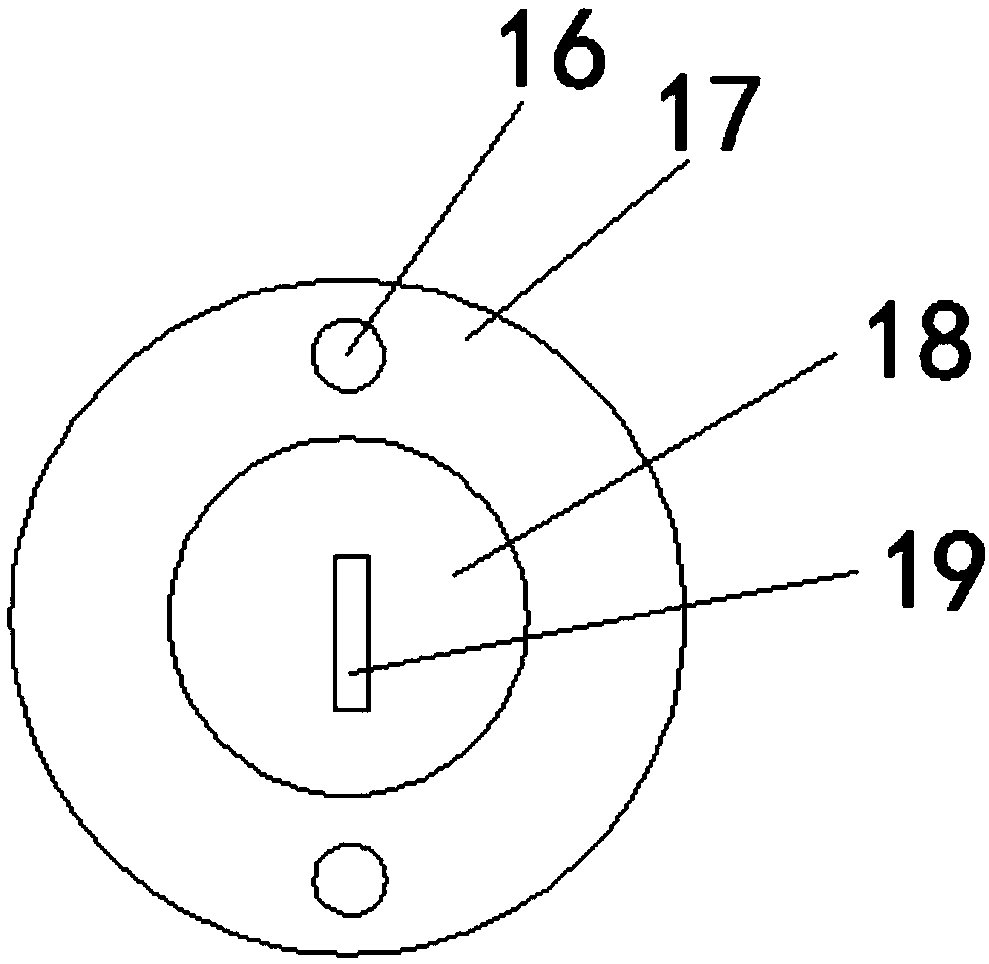

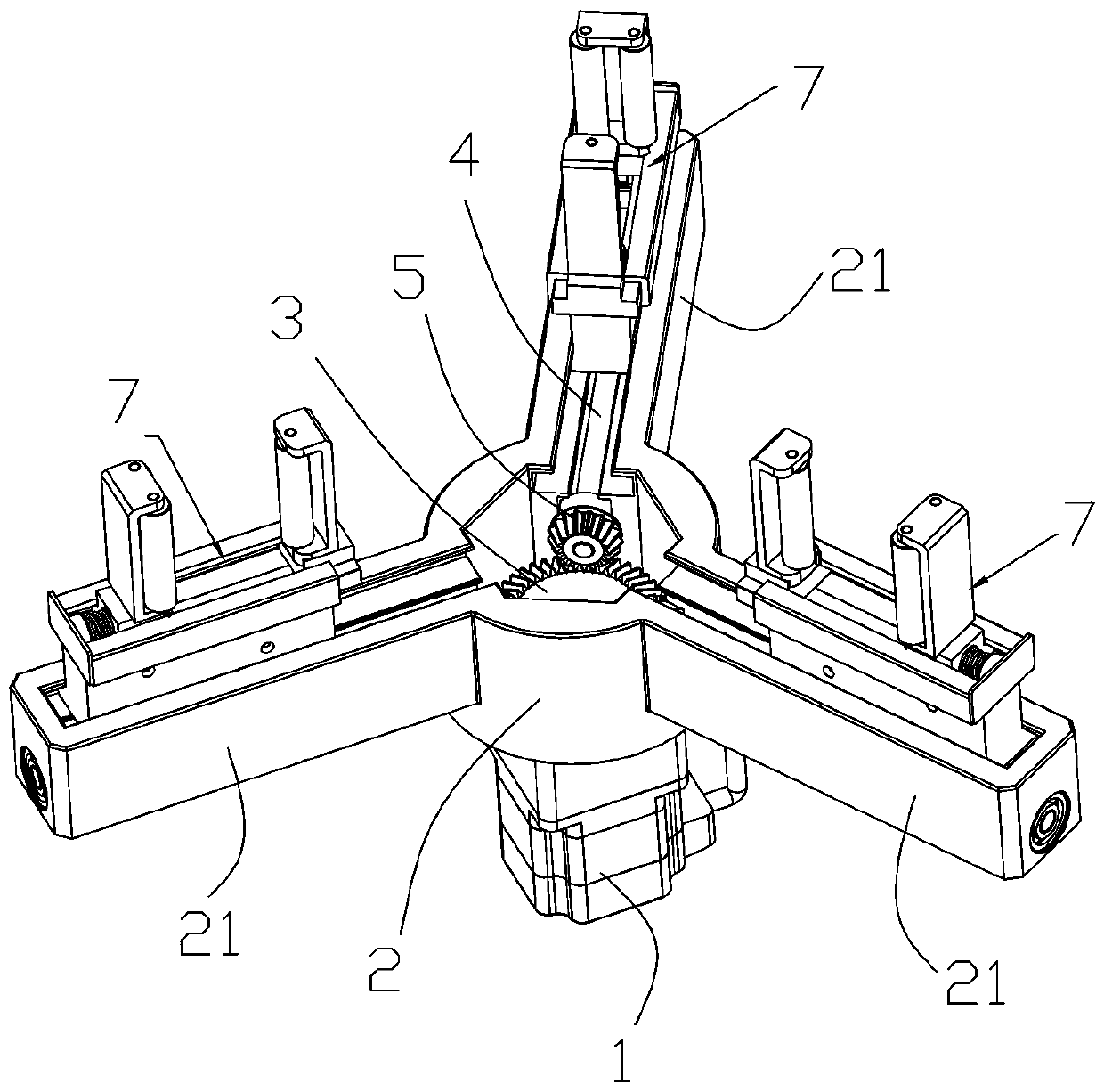

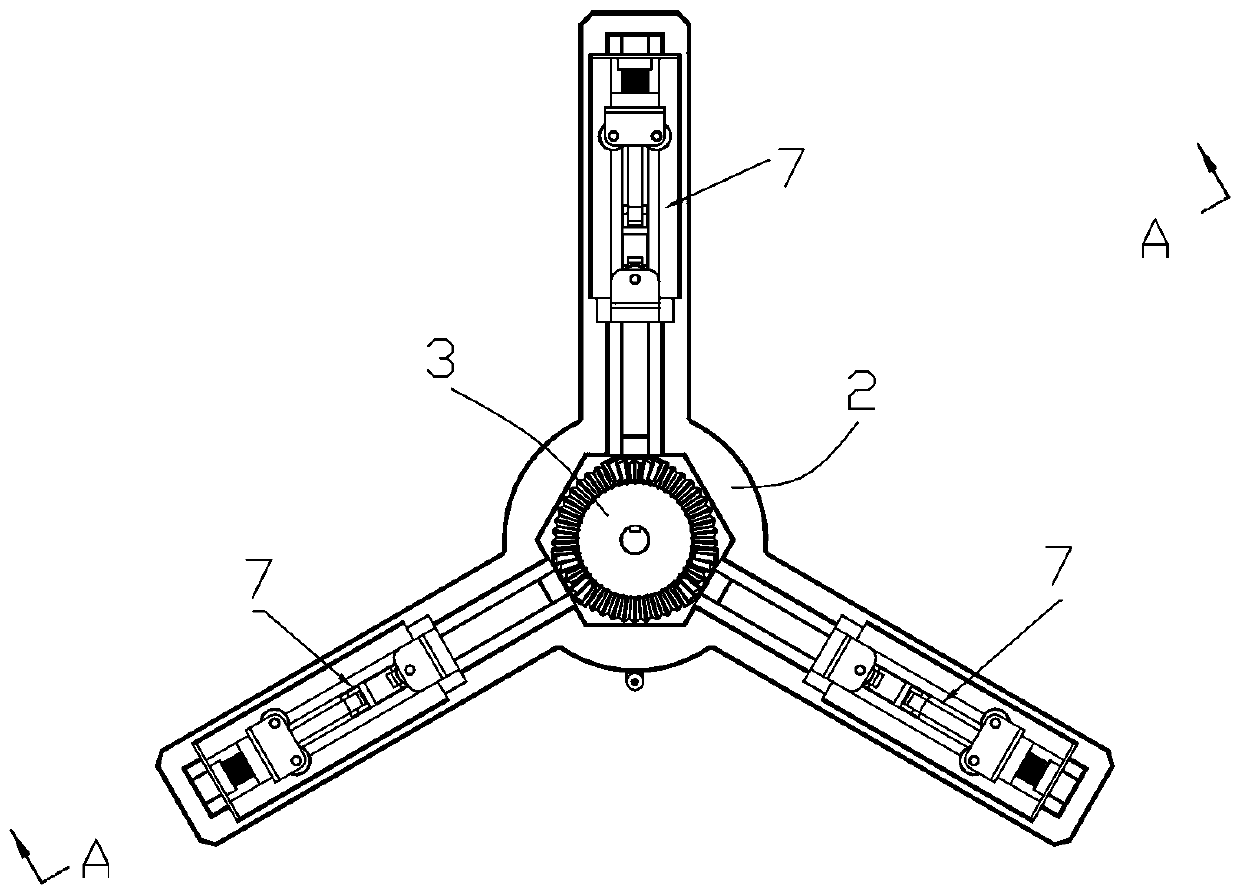

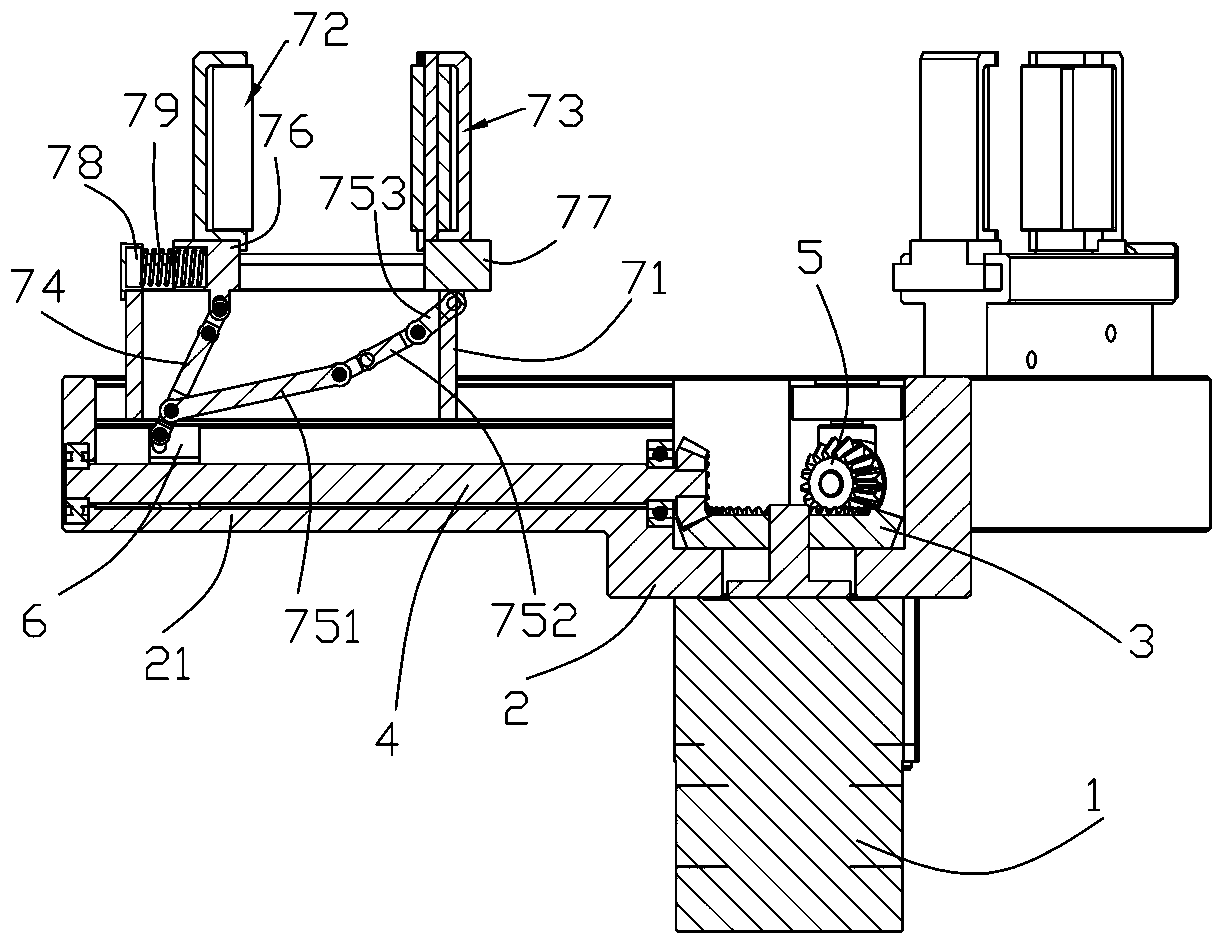

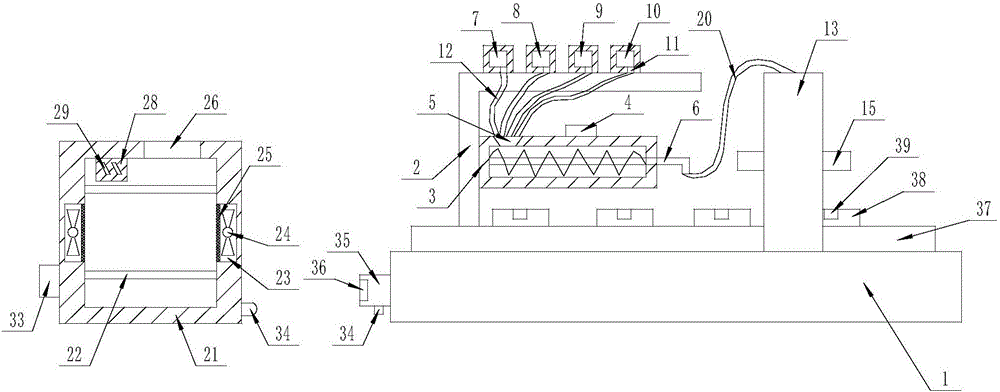

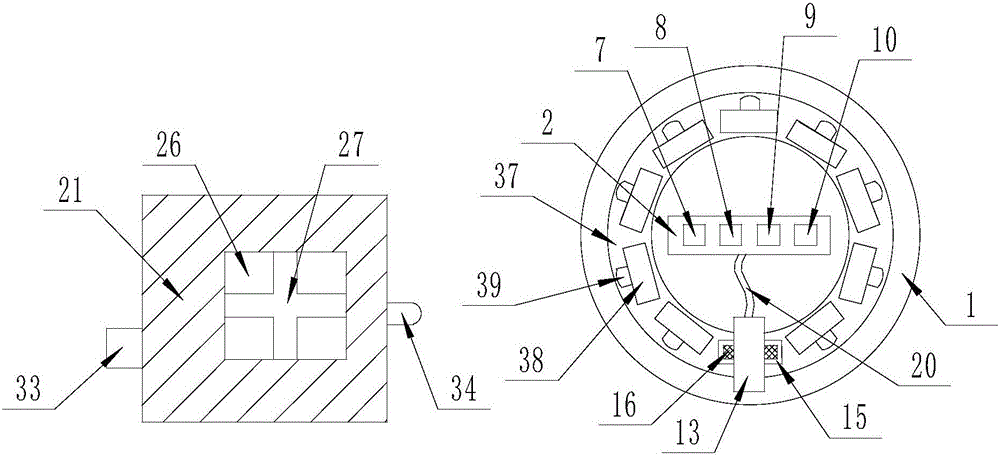

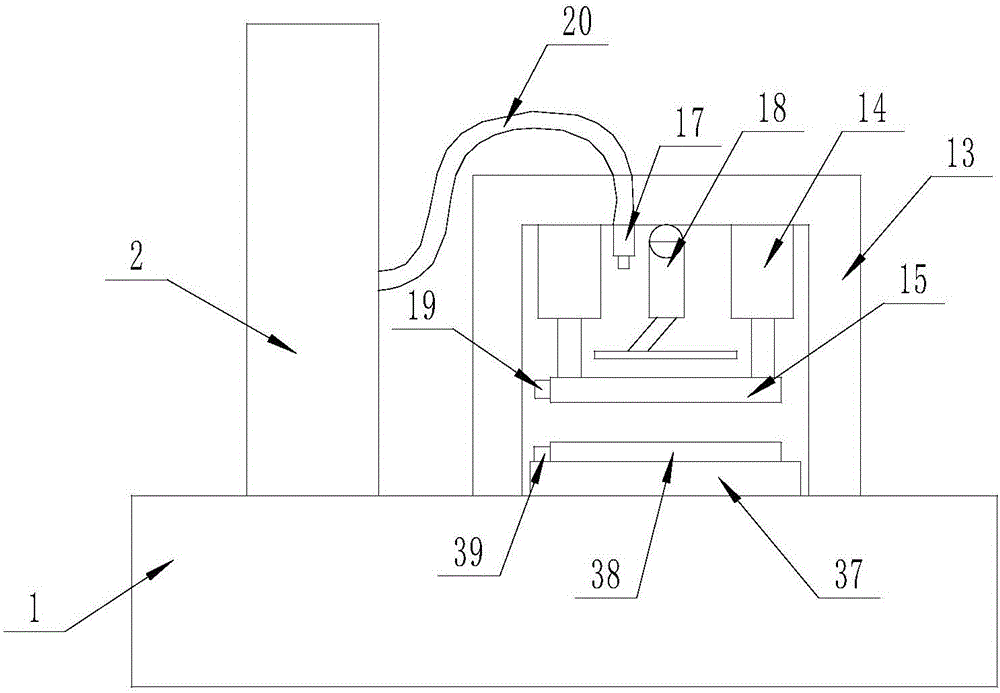

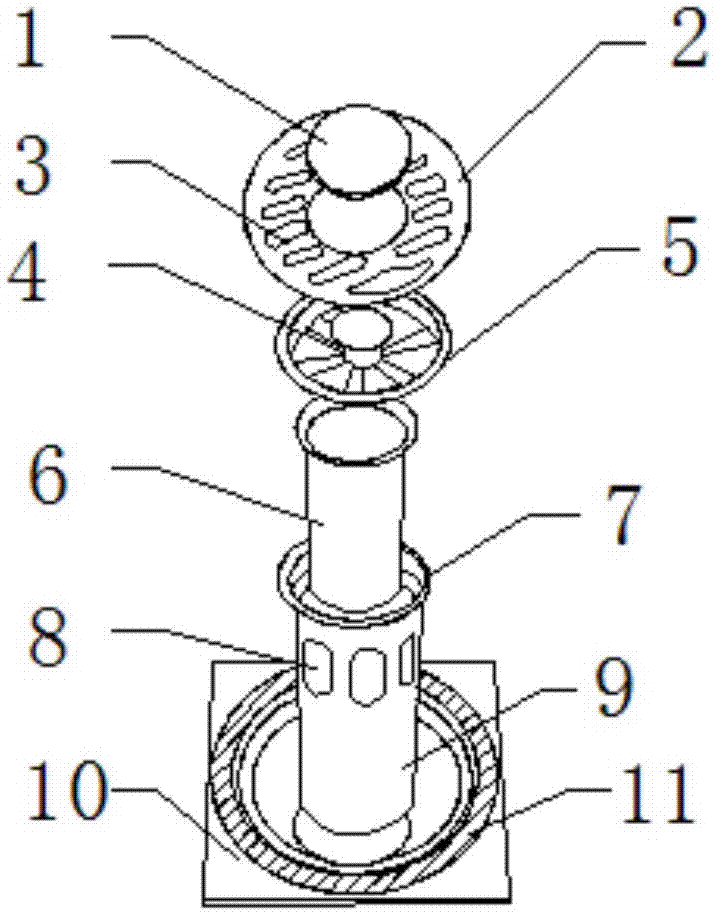

Self-adaptive circular tubular thin-wall part clamping jaw

InactiveCN110842958AReduce local deformationReduce the possibility of deformationGripping headsElectric machineryEngineering

Owner:荆门禾硕精密机械有限公司

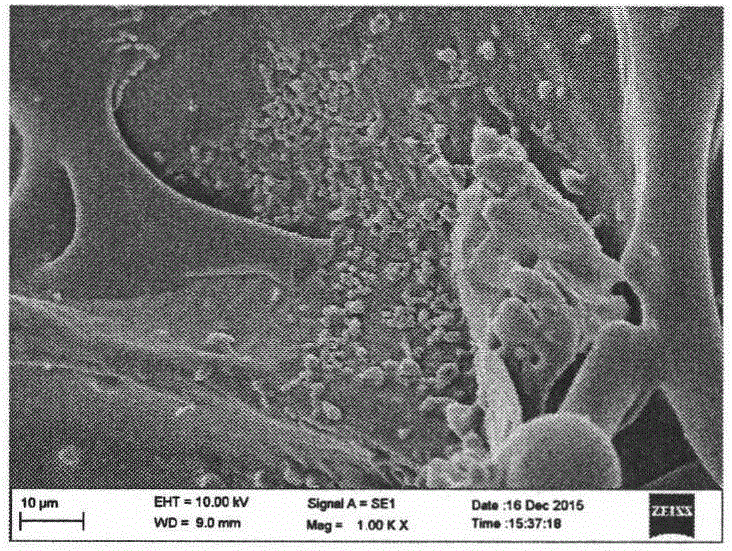

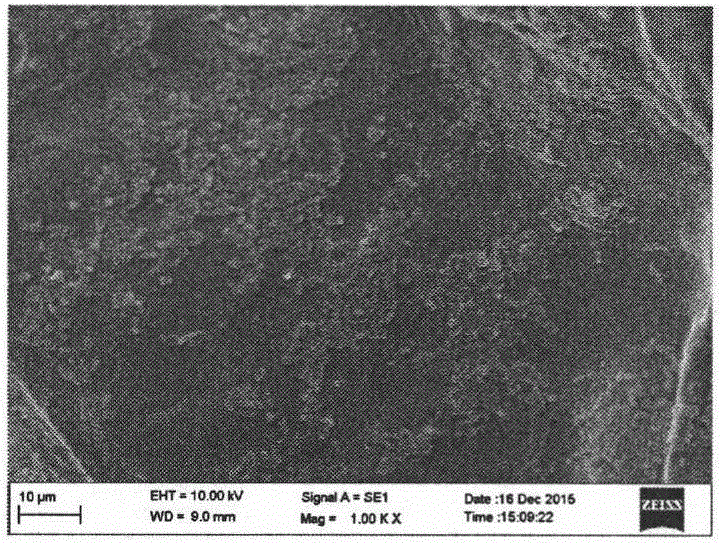

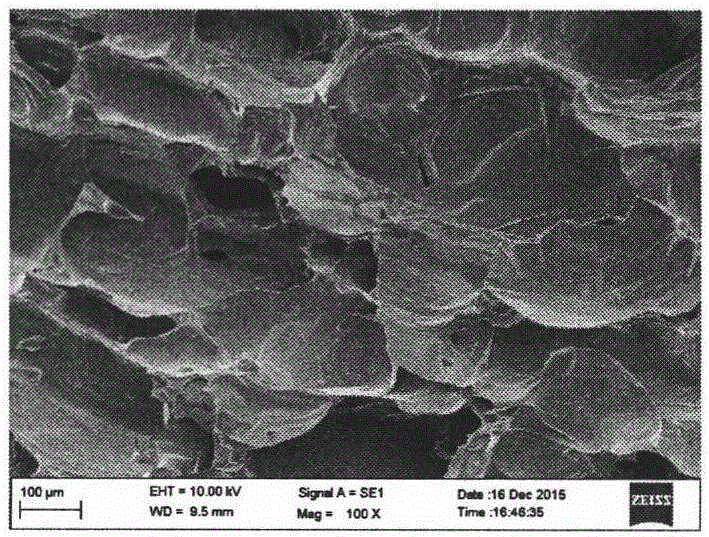

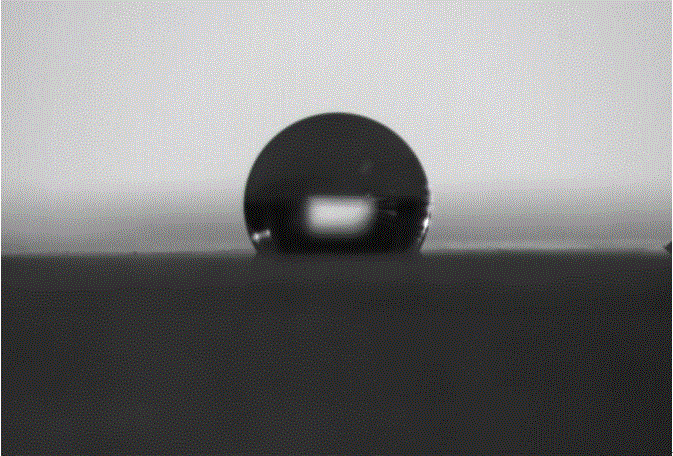

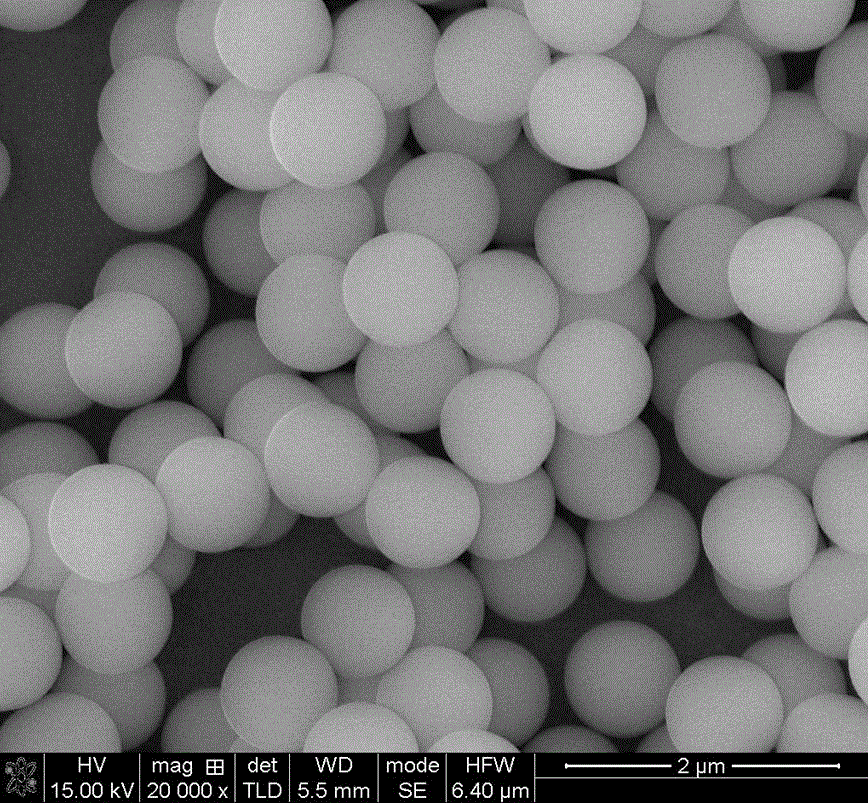

Hydrophobic modification method of nano silica particles

InactiveCN106745006AProtect shapeProtection DispersionSilicaBulk chemical productionSilica particleFreeze-drying

The invention provides a hydrophobic modification method of nano silica particles. The method utilizes freeze drying technology to protect the shape and monodispersion of nano silica particles, utilizes supercritical technology to enhance the diffusion capacity of ethanol, increases the reaction activity, acquires hydrophobically modified nano silica particles having higher coating rate with higher efficiency, and does not cause agglomeration of nano silica particles easily. The method has the advantages of low cost, simple process, no pollution, and pure product without impurity.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

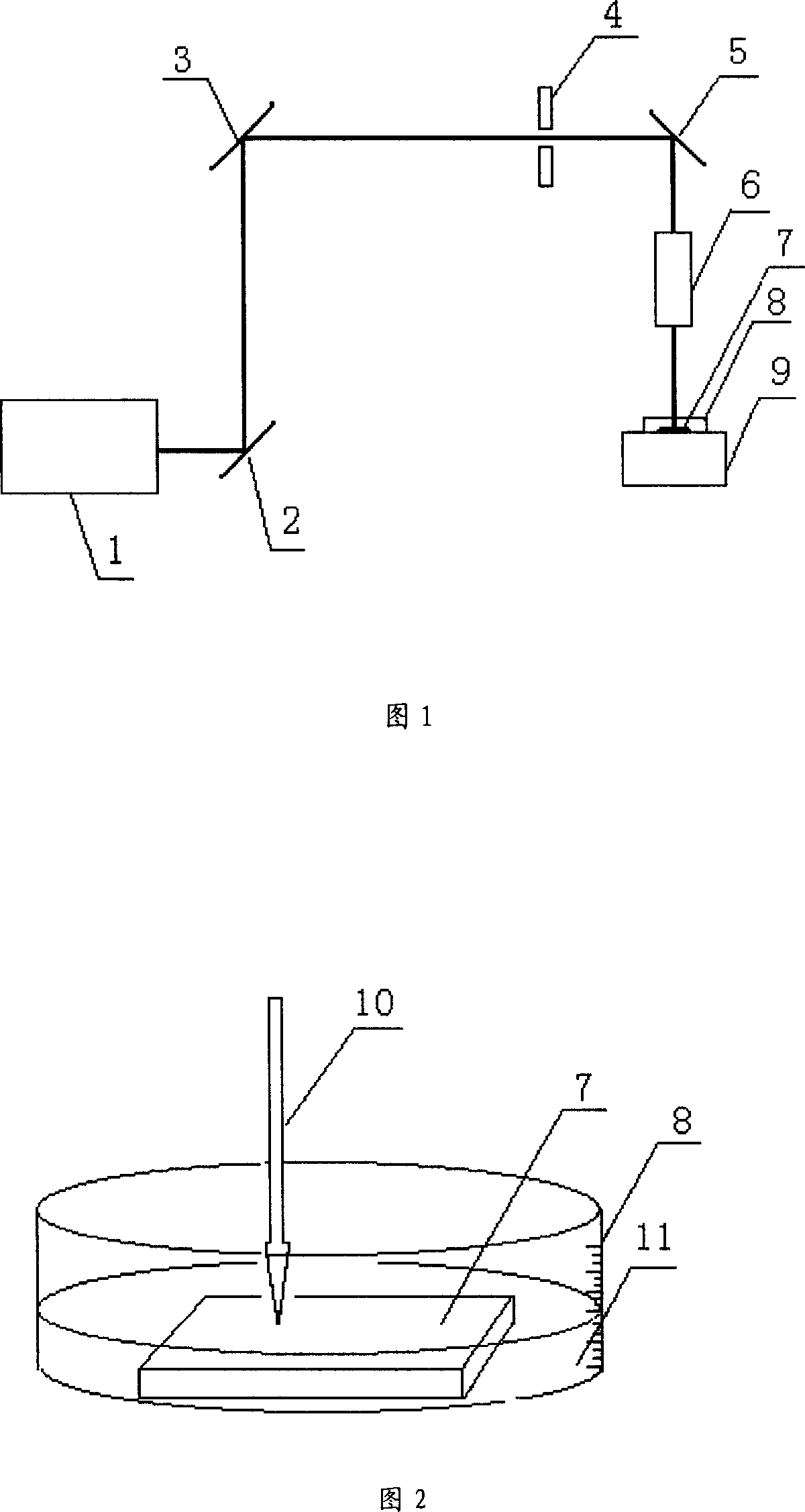

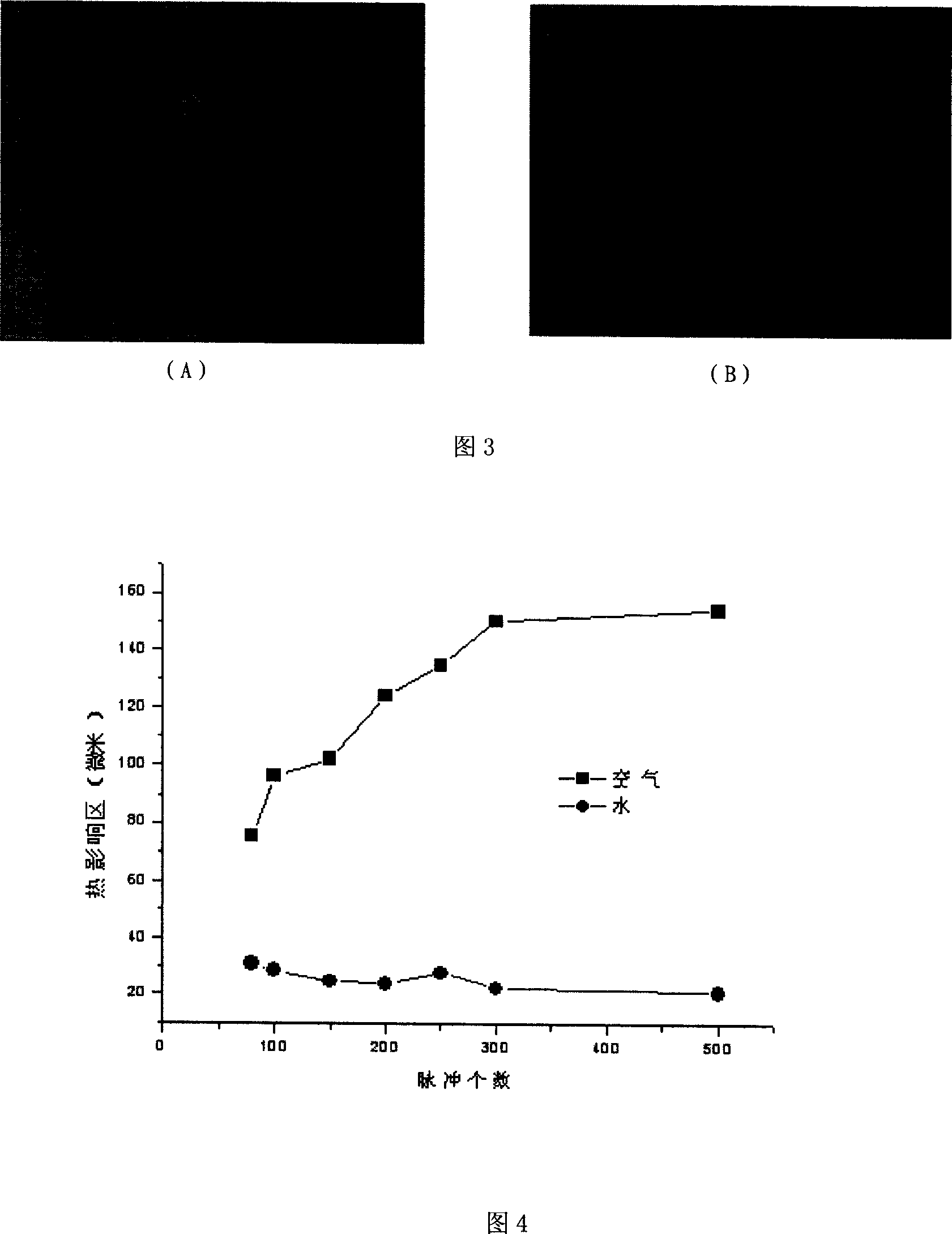

Method for reducing horizontal affection area caused by quasi-molecule laser etching

InactiveCN1994653AImprove cooling effectPrevent oxidationLaser beam welding apparatusLaser etchingLight beam

The invention relates to a device for reducing horizontal affect area of molecule laser etching technique, wherein it comprises laser (1), mask (4), projection object lens (6), and sample (7). The light beam of laser (1) via the first mirror (2) and the second mirror (3) reaches mask (4), to reflect its pattern via the second mirror (5) to the object lens (6); the reduced pattern via lens (6) is imaged on the face of sample (7), to etch. The invention is characterized in that: the sample (7) is at the bottom of water groove (8); the groove (8) is filled with liquid; the etching face of sample (7) is lower than liquid level. The invention can improve the quality with simple process.

Owner:BEIJING UNIV OF TECH

Water-in-water multicolor paint containing color sand

ActiveCN106085062AImprove stabilityHigh viscosityAntifouling/underwater paintsPaints with biocidesCellulosePowder mixture

The invention discloses water-in-water multicolor paint containing color sand. The water-in-water multicolor paint comprises color-sand-containing basic paint, a protective glue solution, cladding gloss oil and an addition agent; basic slurry is prepared from the following raw materials in parts by mass: 200-400 parts of water, 3-8 parts of cellulose ether, 7.5 parts of propylene glycol, 1 part of a moist dispersing agent, 1 part of a PH adjusting agent, 10 parts of a film-forming addition agent, 1 part of an antifoaming agent, 80-130 parts of a kaolin and heavy calcium powder mixture, 1-2 parts of barium metaborate, 200-400 parts of an acrylic emulsion, 1 part of bactericides, 1 part of a dispersing agent, 1 part of a stabilizing agent, 50 parts of 6.5% protective glue, 0.5-1 part of aqueous polishing paste, and 1-2 parts of sodium phosphate tripolymer. The water-in-water multicolor paint is level in surface and not liable to cause ash deposition, can maintain whole appearance for a long term, and has dirty resistance. The specially-made cladding gloss oil can maintain the color of the surface of the water-in-water multicolor paint containing color sand bright for a long time, and has weather resistance. The water-in-water multicolor paint has good water resistance and anti-corrosive properties, and protects the whole modeling of a building. Shaped patterns are plain, and elegant in appearance. Besides, the water-in-water multicolor paint has good stability and extremely high market economy value.

Owner:ZHEJIANG KEDA NEW BUILDING MATERIALS

Manipulator operation head applicable to carry product liable to be deformed

The invention discloses a manipulator operation head applicable to carry a product liable to be deformed. The manipulator operation head comprises a mounting part, a rotary supporting plate assembly which is arranged under the mounting part and supports the product liable to be deformed on a production line, and a rotary pushing block assembly which is arranged at the upper end of the rotary supporting plate assembly and pushes the product liable to be deformed to a supporting plate. The rotary supporting plate assembly is composed of a first rotary shaft fixed to the mounting part, an inclined supporting plate connected to the first rotary shaft, and a first elastic pad wrapping the surface of the inclined supporting plate. The rotary pushing block assembly is composed of a second rotary shaft, a pushing block connected to the second rotary shaft, and a second elastic pas wrapping the end of the pushing block. Through the manipulator operation head applicable to carry the product liable to be deformed, the position of the pushing block can be effectively adjusted, and the manipulator operation head is suitable for the products liable to be deformed in various shapes and sizes and is wide in application range; and the whole process is automatic, the efficiency is high, and labor force is reduced.

Owner:镇江玄润电气设备有限公司

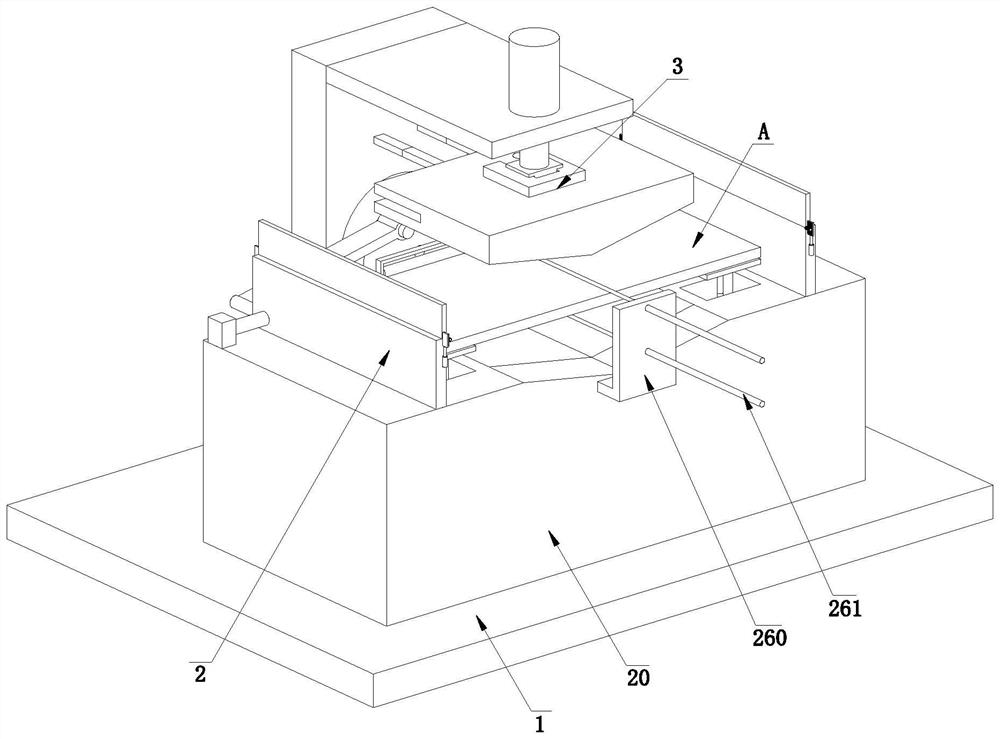

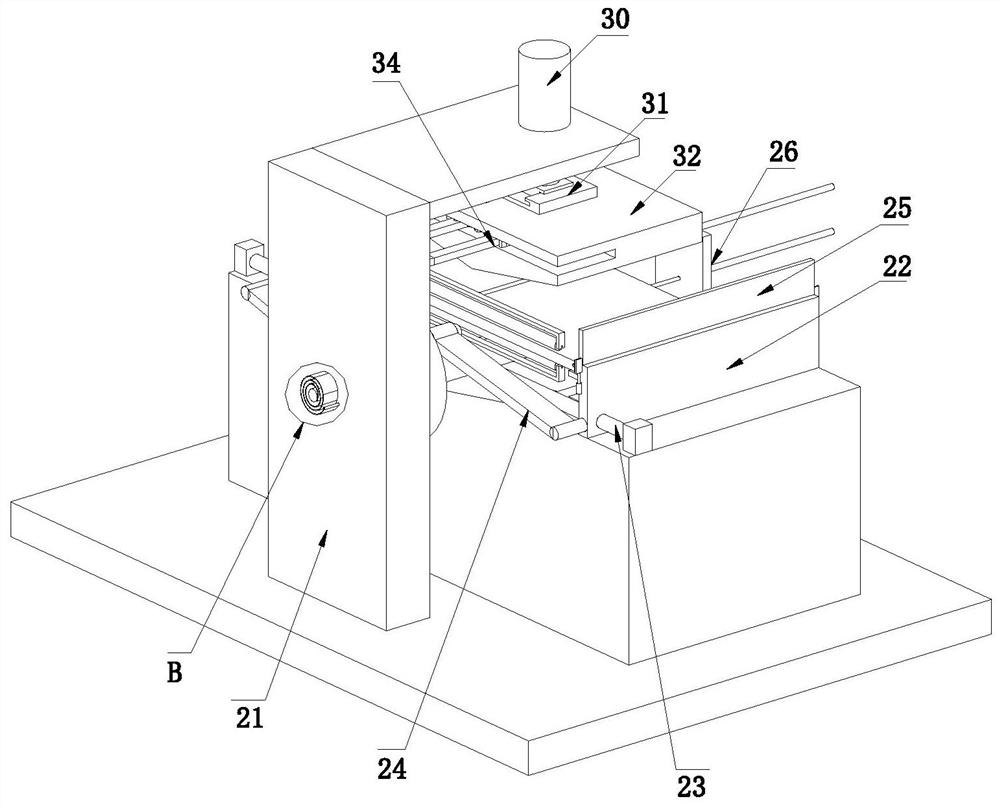

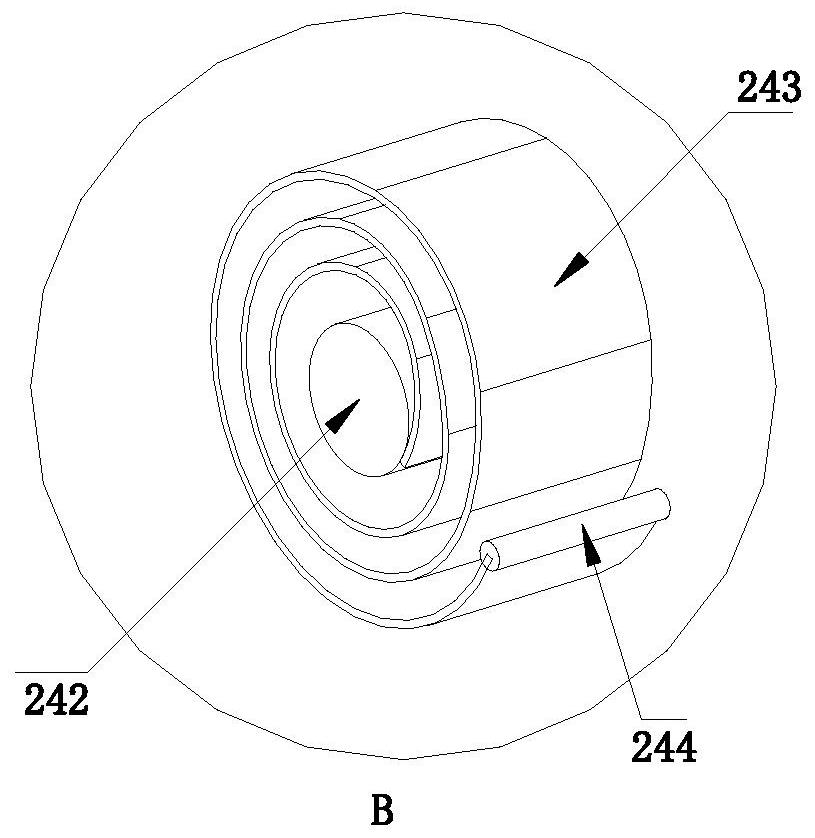

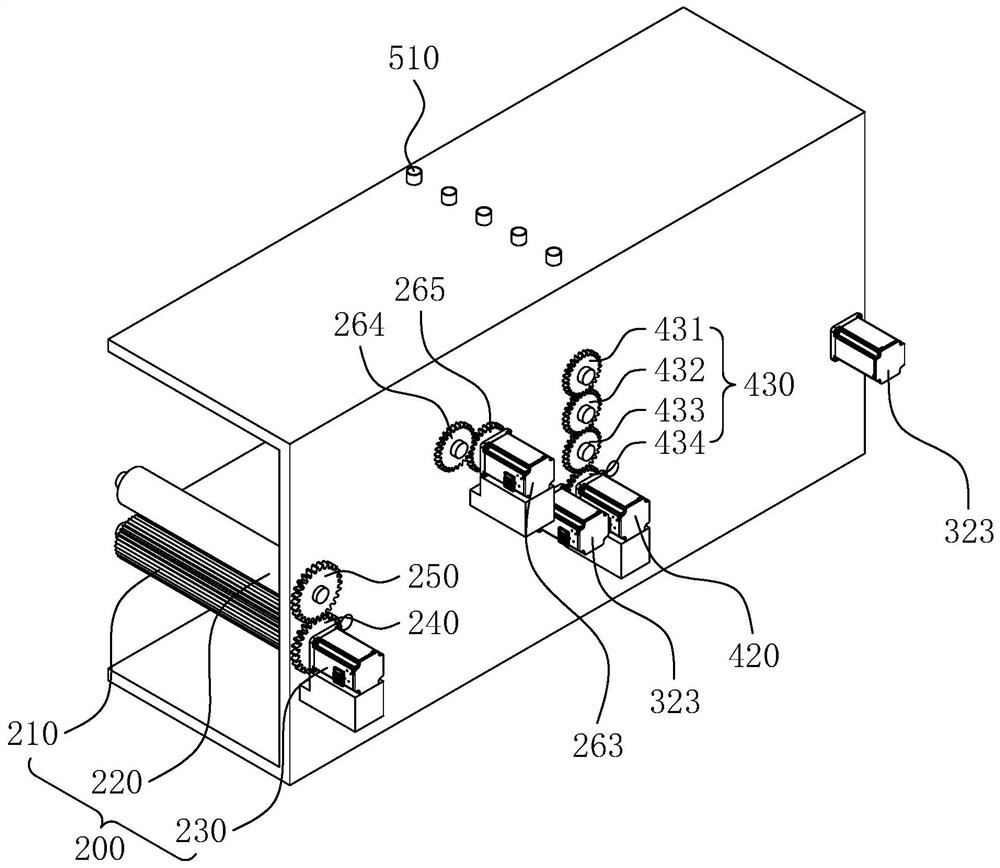

Machine tool protective cover unit sheet metal machining equipment

PendingCN114589219AAvoid offsetGuaranteed stabilityShaping toolsMetal-working feeding devicesPunchingMetal machining

The invention provides machine tool protective cover unit sheet metal machining equipment, and relates to the technical field of sheet metal stamping machining, the machine tool protective cover unit sheet metal machining equipment comprises a bottom plate, a fixing device and a stamping device, the fixing device is fixedly installed on the bottom plate, the stamping device is installed on the bottom plate, and the stamping device is located above the fixing device; in addition, the machine tool protective cover can solve the problems that in the machining process of an existing machine tool protective cover, a raw material steel plate of the machine tool protective cover is prone to deviation, and consequently the machined steel plate is asymmetric; 2, in the machining process of an existing machine tool protective cover, a steel plate is attached to a die of a punching machine and is difficult to take out, so that the punching efficiency of the steel plate is greatly influenced, the steel plate is cut into a plurality of plate-shaped steel plates in a cutting mode before being punched, scrap iron generated in the cutting process is adsorbed to the surface of the steel plate, and the punching efficiency of the steel plate is influenced. And when the steel plate is punched, the surface of the steel plate is easy to damage.

Owner:徐州艾奇川自动化设备有限公司

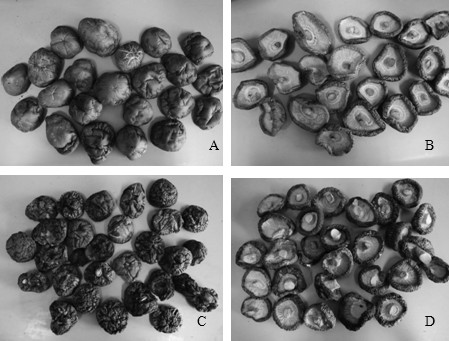

Shitake mushroom color protection liquid and color protection method of shitake mushroom color protection liquid

InactiveCN102630929ASame color protection effectProtect shapeFood preparationBiotechnologyPhenolic content in tea

The invention discloses a shitake mushroom color protection liquid which comprises the following components of calcium chloride, citric acid, tea polyphenol and L-cysteine, wherein the weight ratio of calcium chloride, citric acid, tea polyphenol and L-cysteine is 4-8:0.12-0.18:0.15-0.25:0.08-0.12. According to the shitake mushroom color protection liquid, the format is unique, the raw materials are easy to obtain, and the prepared shitake mushroom color protection liquid can effectively prevent the shitake mushroom from brown stain. The invention also discloses a color protection method utilizing the color protection liquid. The shitake mushroom processed by the color protection liquid has good color and luster. The shitake mushroom color protection liquid and the color protection method can be used for the preparation of dried shitake mushroom and have a wide application prospect.

Owner:SOUTHWEST UNIV

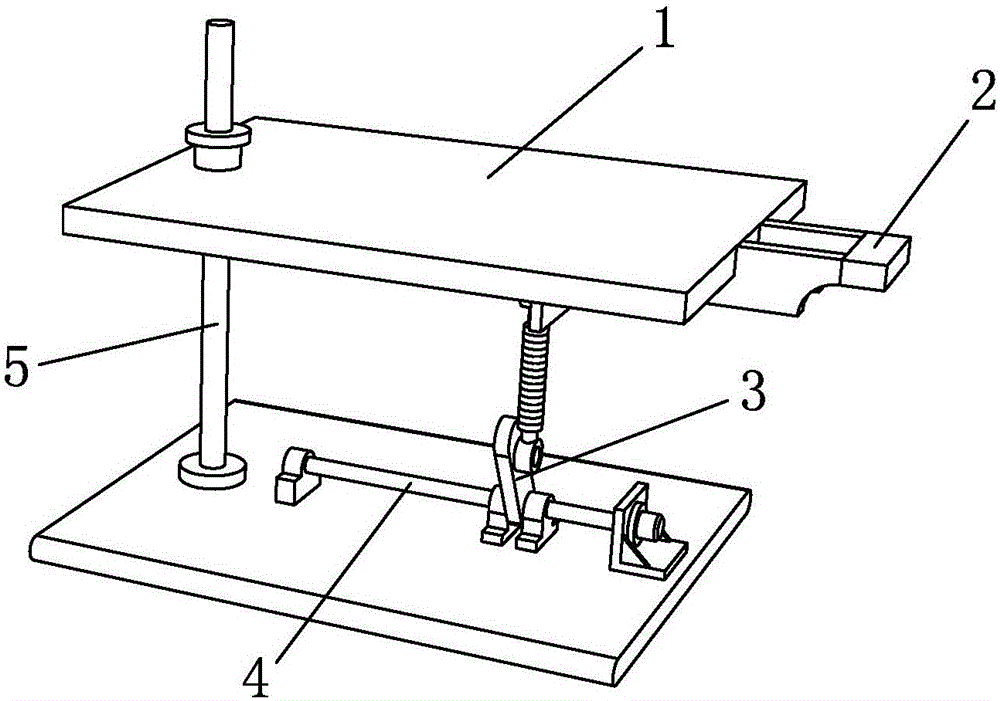

Black color paste preparing and black color paste printing and air drying technology

The invention discloses a black color paste preparing and black color paste printing and air drying technology. A worktable is included. A printing unit is arranged on one side of the upper surface of the worktable. A supporting frame is arranged on the other side of the upper surface of the worktable. A conveying auger is arranged on the lower surface of the supporting frame. A vibration block is arranged on the conveying auger. A feeding port is machined in the upper surface of the conveying auger. A bent pipe is arranged at one end of the conveying auger. A dye barrel, an acrylic emulsion barrel, a water storage barrel and a thickening agent barrel are arranged on the upper surface of the supporting frame. A discharging port is formed in each of the dye barrel, the acrylic emulsion barrel, the water storage barrel and the thickening agent barrel, and each discharging port is fixedly connected with the feeding port through a guide pipe. A discharging head is fixedly connected with the bent pipe through a material guide pipe. The black color paste preparing and black color paste printing and air drying technology has the beneficial effects that environment-friendly dyeing is achieved, ecological emission is achieved, the color mixing fusion degree is high, and the buckling printing efficiency is high.

Owner:绍兴市天基印刷材料厂

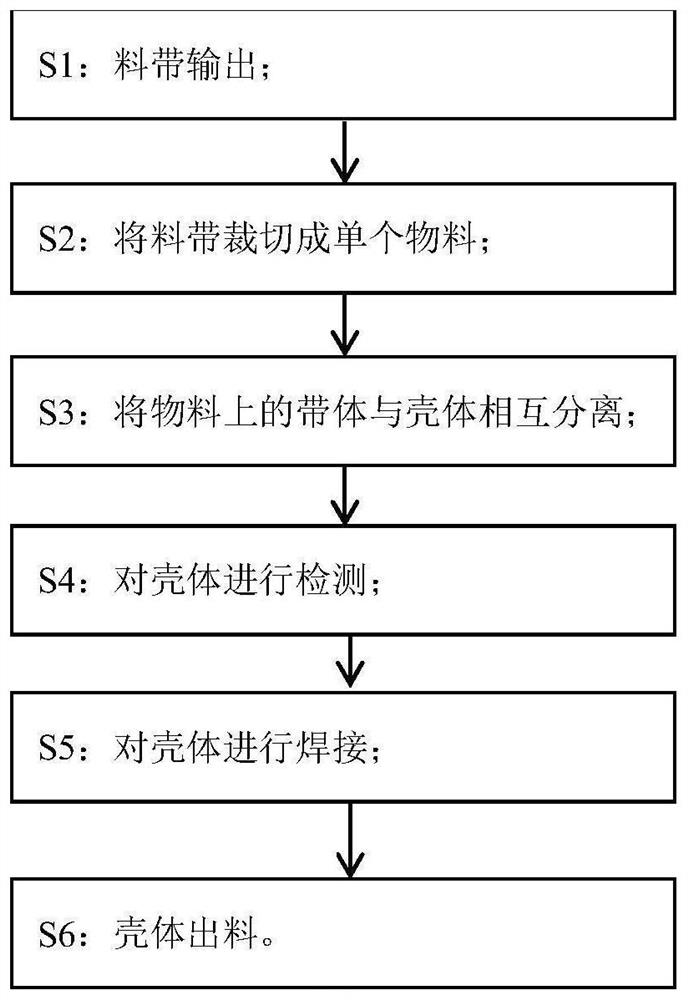

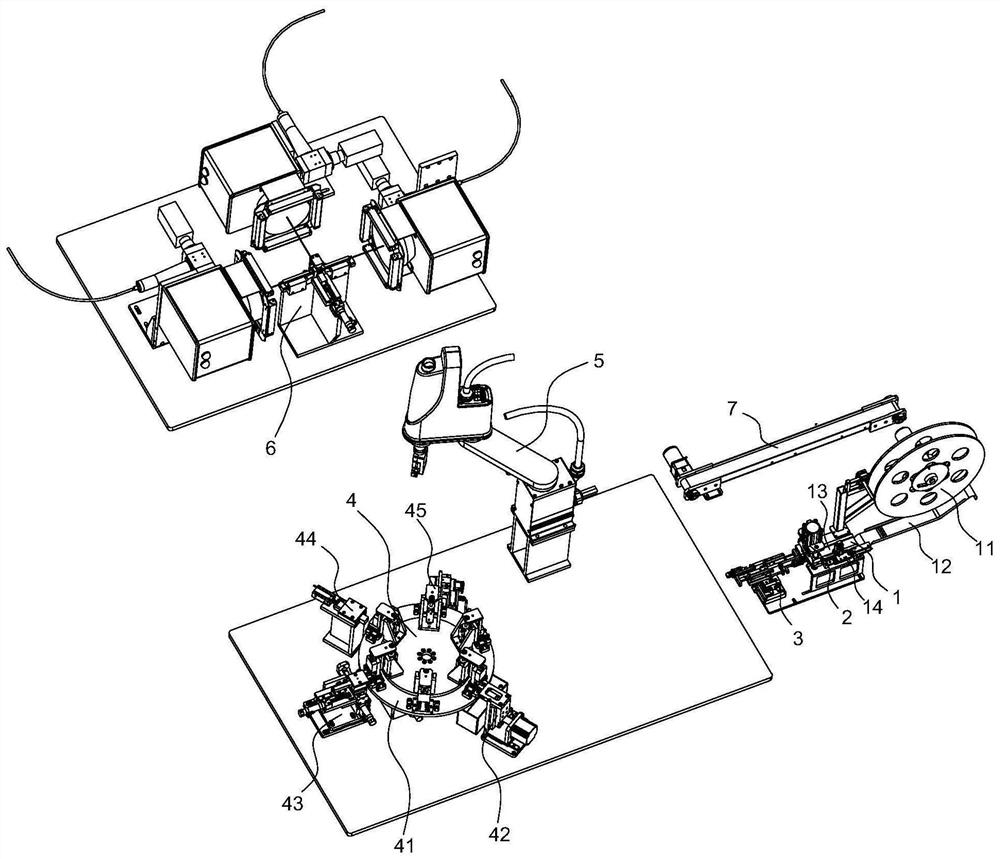

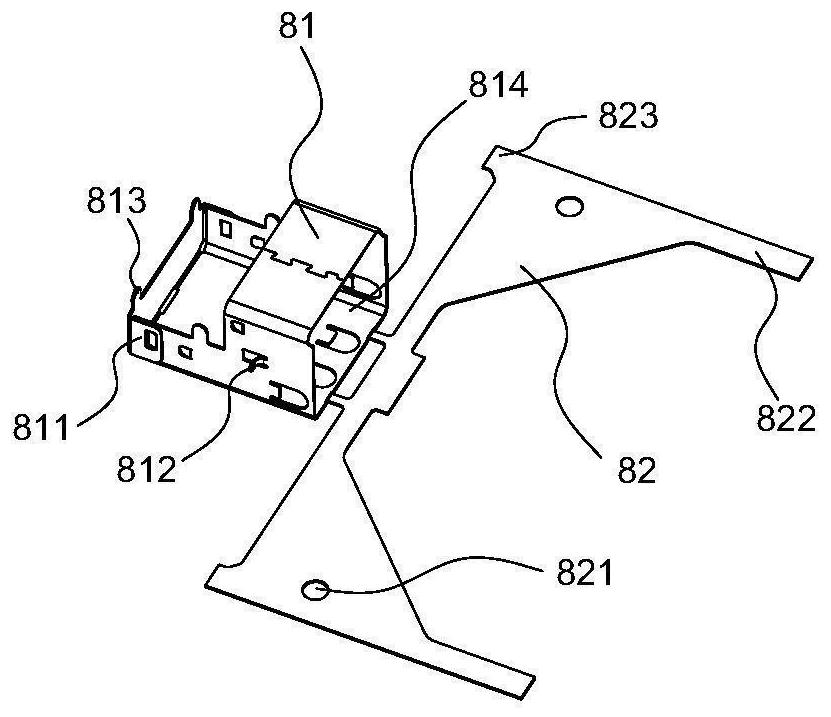

USB metal shell forming and welding equipment and method thereof

ActiveCN113146261AGuarantee product qualityRealize fully automatic processingMeasurement/indication equipmentsCouplings bases/casesEngineeringUSB

The invention relates to the field of digital electronic equipment manufacturing, in particular to USB metal shell forming and welding equipment and a method thereof. The USB metal shell forming and welding equipment comprises a material belt feeding device, a material belt cutting device, a rotary material moving device, a turntable processing device, a moving manipulator, a welding device and a discharging device; and the material belt cutting device is arranged above the discharging end of the material belt feeding device, and the discharging end of the material belt feeding device is connected with the rotary material moving device. The position of the rotary material moving device is matched with that of a feeding station; the position of the moving manipulator is matched with a turnover discharging station; and the welding device is located on one side of the turntable processing device, and the turntable processing device and the welding device are connected through the moving manipulator. The discharging device is arranged on the side of the moving manipulator. According to the USB metal shell forming and welding equipment and the method thereof, full-automatic machining is achieved, the production quality of a shell can be guaranteed, and the production and machining efficiency can be improved.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

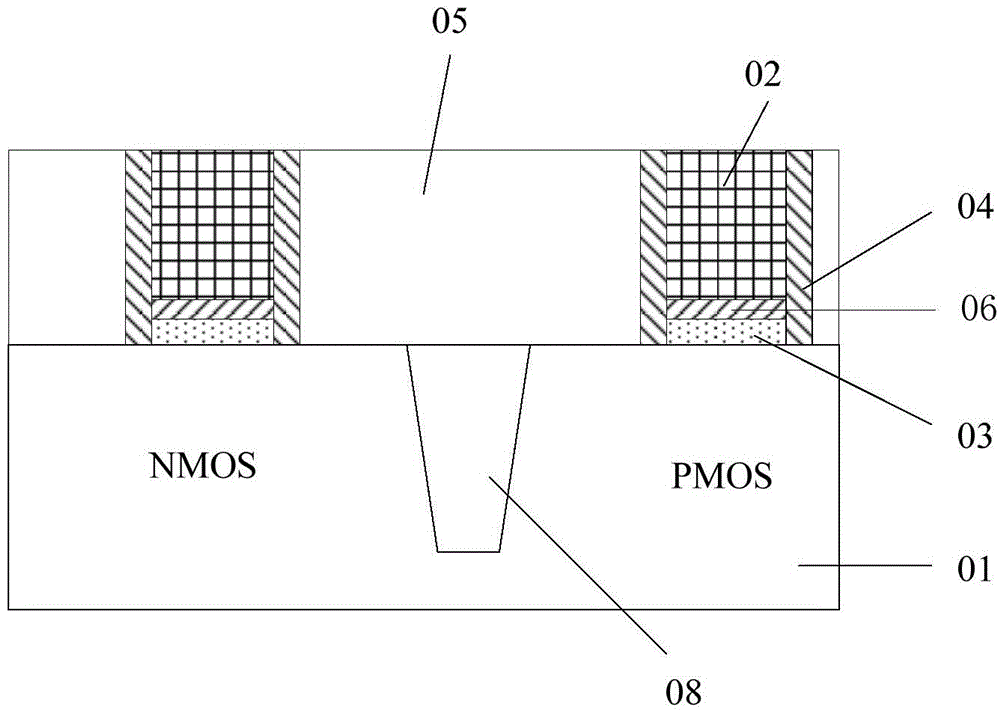

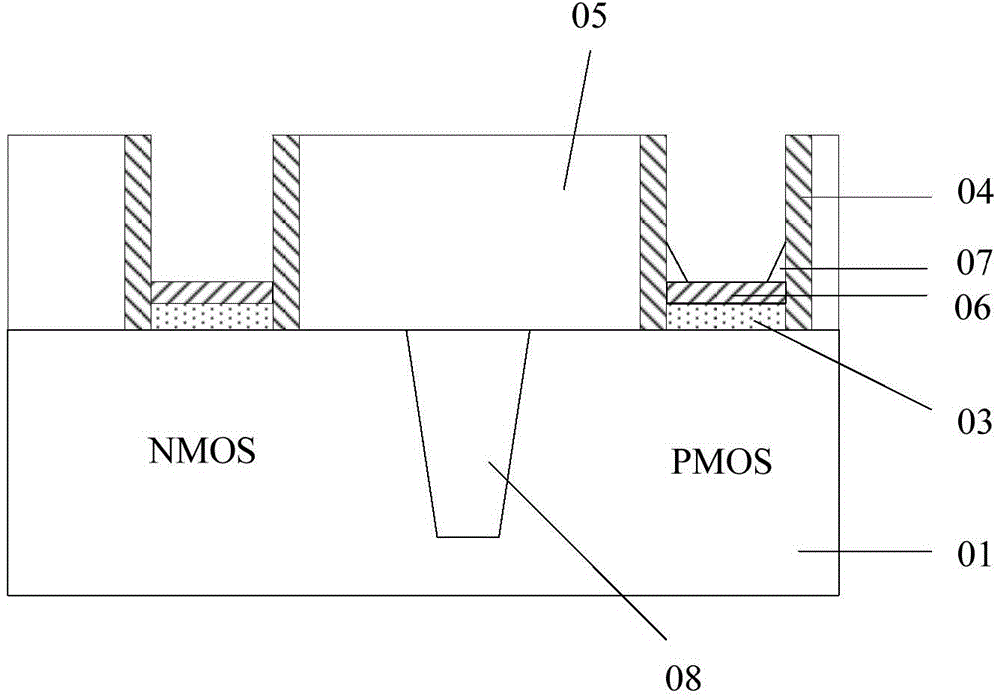

Transistor forming method

ActiveCN104701170AImprove etching effectAvoid pollutionSemiconductor/solid-state device manufacturingSemiconductor devicesMedia layerDry etching

The invention provides a transistor forming method. The method includes providing a substrate; forming a false grid structure comprising a false grid on the surface of the substrate; forming a source region and a leak region on the substrate exposed in the false grid structure; forming an interlayer medium layer aligned with the false grid structure on the substrate; removing majority of the false grid of the false grid structure by dry etching; performing first dry washing on the surface of the remained false grid; performing wet washing on the surface of the remained false grid; performing second dry washing on the surface of the remained false grid; removing the remained false grid by wet etching, and forming an opening corresponding to the false grid in the shape; forming a grid medium layer and a metal grid electrode in the opening. By means of the first dry washing, the wet washing and the second dry washing, the contaminant remained on the surface of the false grid is removed after the false grid is formed by dry etching, and the performance of a transistor is optimized.

Owner:SEMICON MFG INT (SHANGHAI) CORP

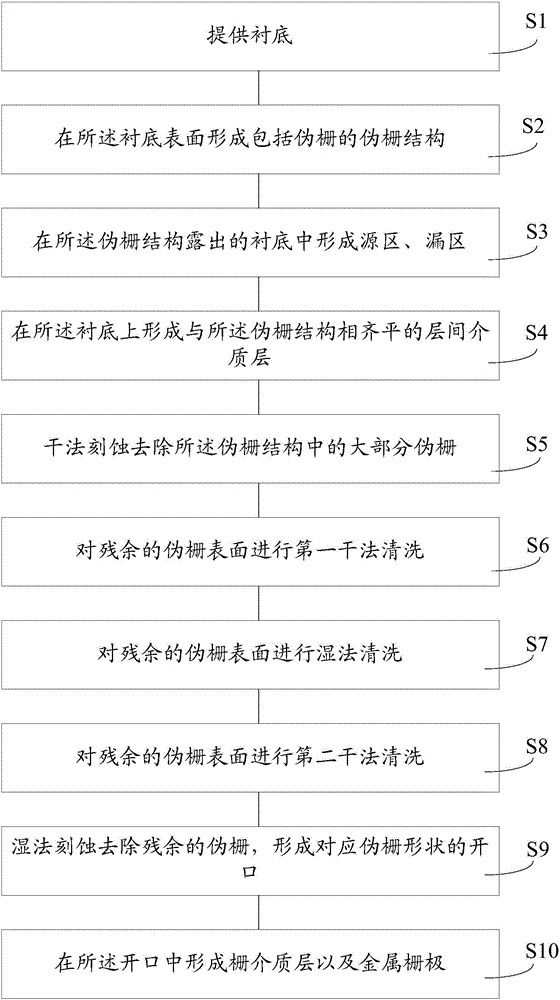

Orange osmanthus dried flowers and color-protecting shaping process thereof

The invention discloses orange osmanthus dried flowers and a color-protecting shaping process thereof. According to the process, orange osmanthus fresh flowers are used as raw materials, and orange osmanthus dried flower products can be obtained through steam blanching, cooling and color-protecting shaping treatment and then two-stage temperature hot air dewatering and drying. The orange osmanthus dried flowers produced through the process are good in color, fragrance and taste, high in nutritive value, free from safety risks caused by sulphur fuming color protection in a traditional process, high in safety, capable of greatly improving commodity value and economic value added of the orange osmanthus dried flowers and reducing environment pollution, and have great significance in industrialization application of quality products of the orange osmanthus dried flowers.

Owner:FUJIAN AGRI & FORESTRY UNIV

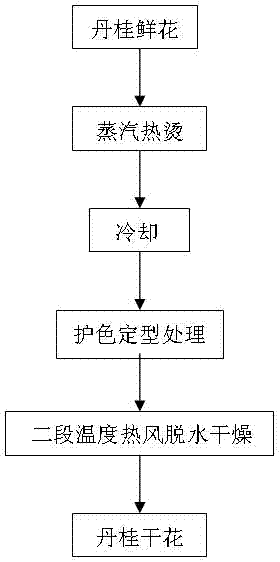

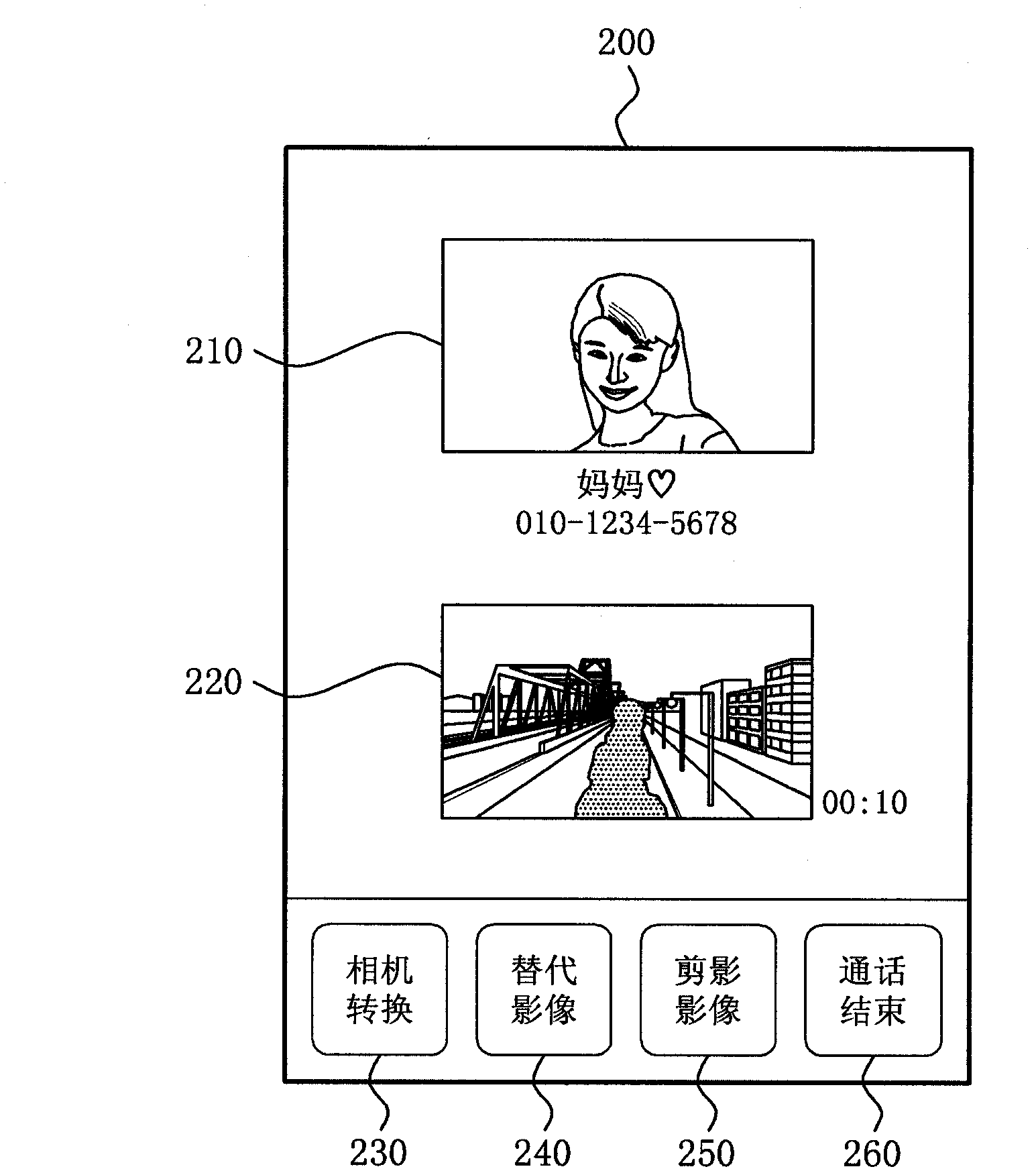

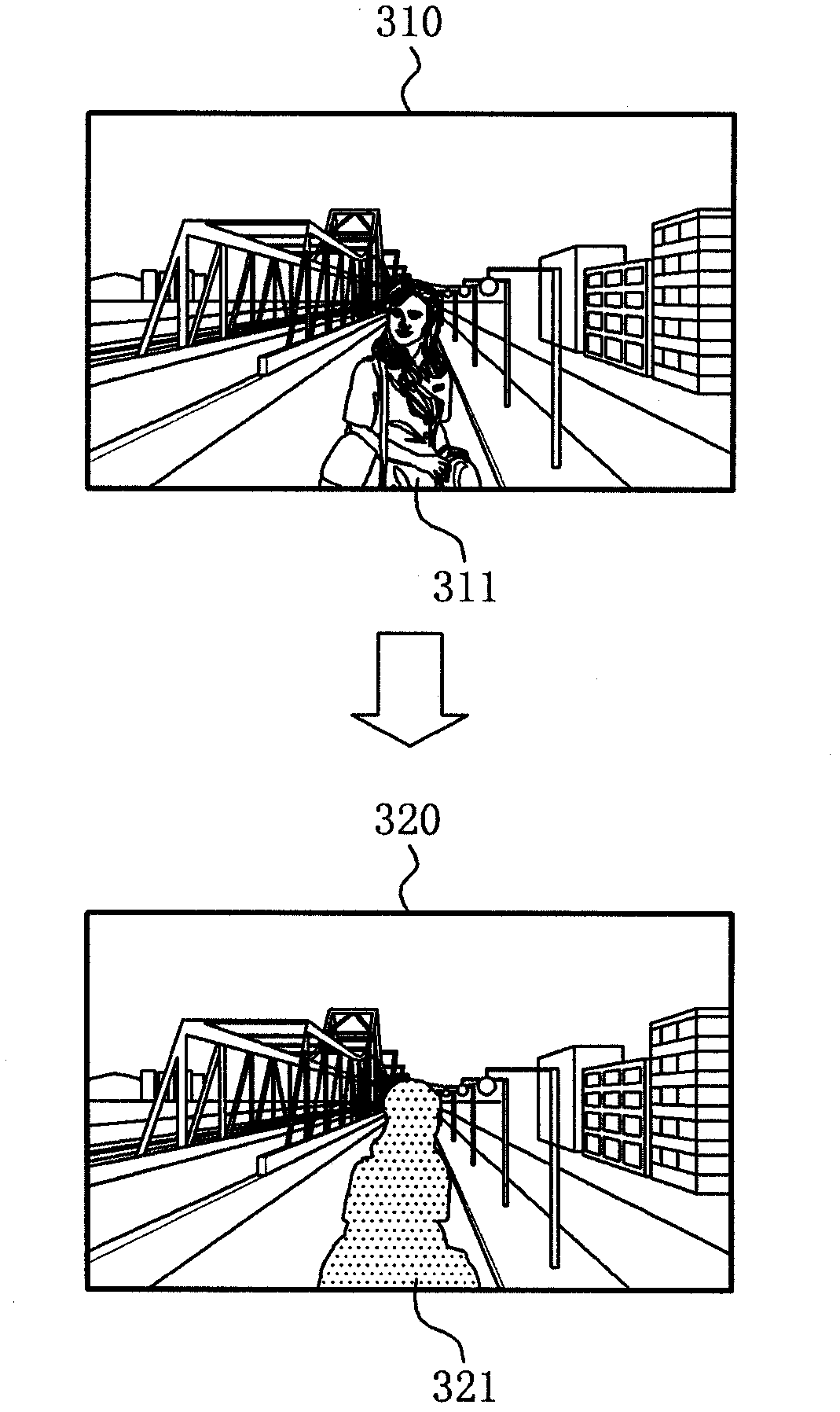

Communication terminal for providing silhouette function on video screen for video call and method thereof

InactiveCN103037194AProtect shapeMaintain substanceSubstation equipmentTwo-way working systemsVideo imageBody images

A communication terminal provides a silhouette function on a video screen for a video call and a method thereof. The communication terminal may include a video input unit to receive an input of a video signal for a video call from a camera, a body recognition unit to recognize a body image of a user captured through the camera in the video signal, a silhouette processing unit to silhouette an area corresponding to the body image in the video signal, and a video output unit to output the video signal including the silhouetted body image to at least one opposite party communication terminal.

Owner:HANWHA SOLUTION & CONSULTING

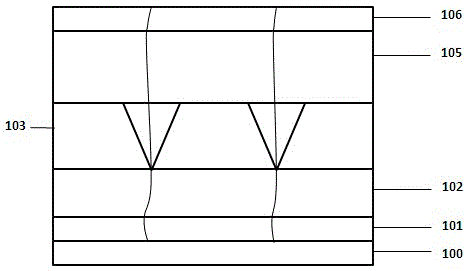

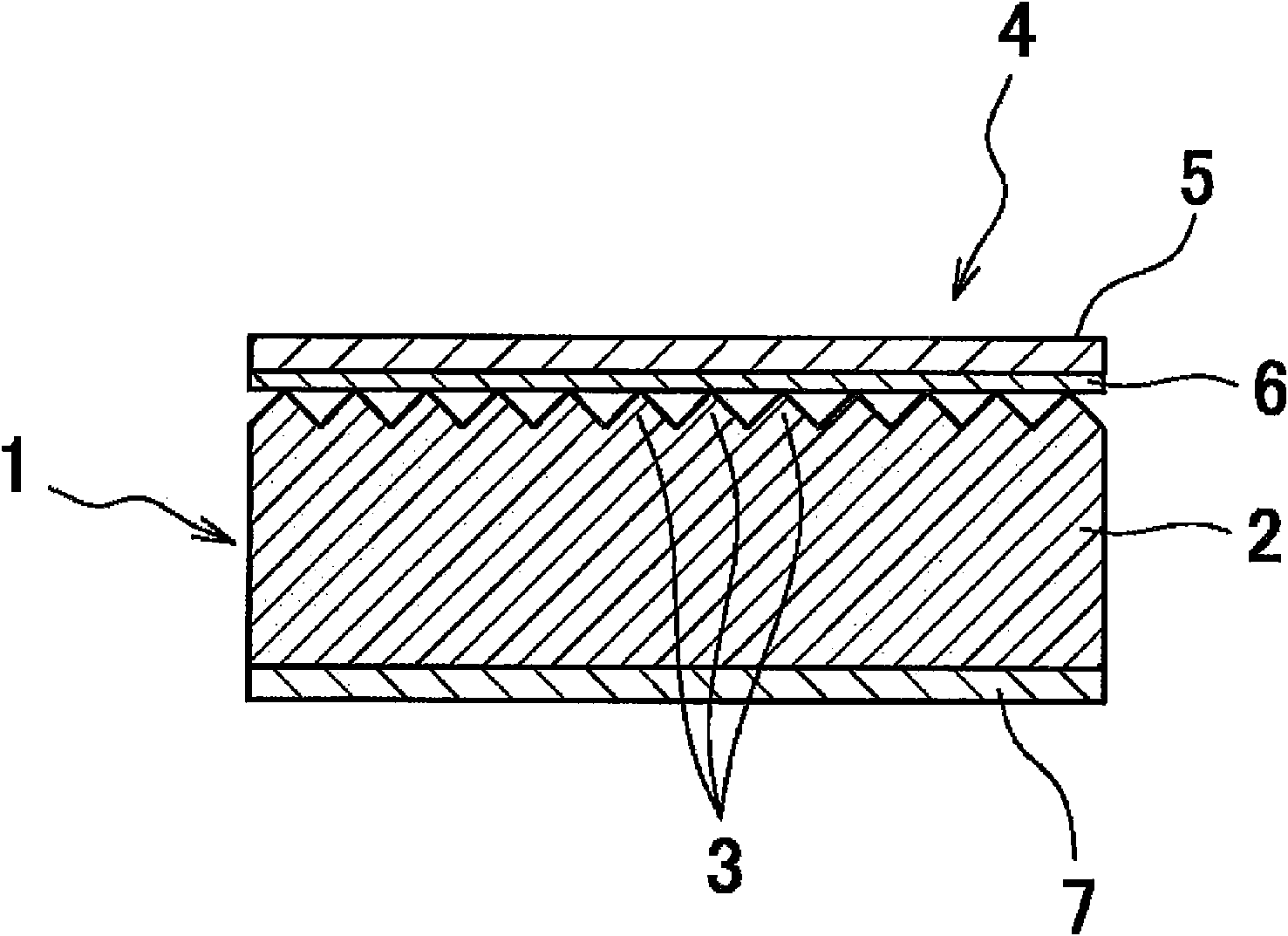

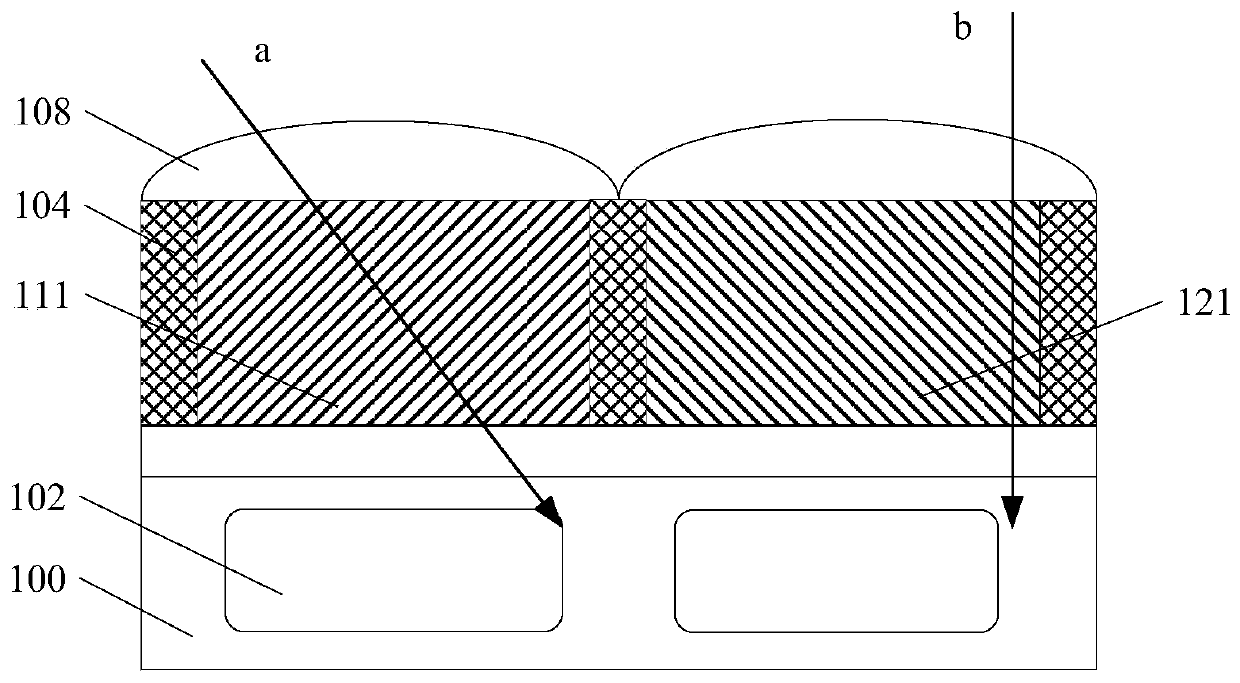

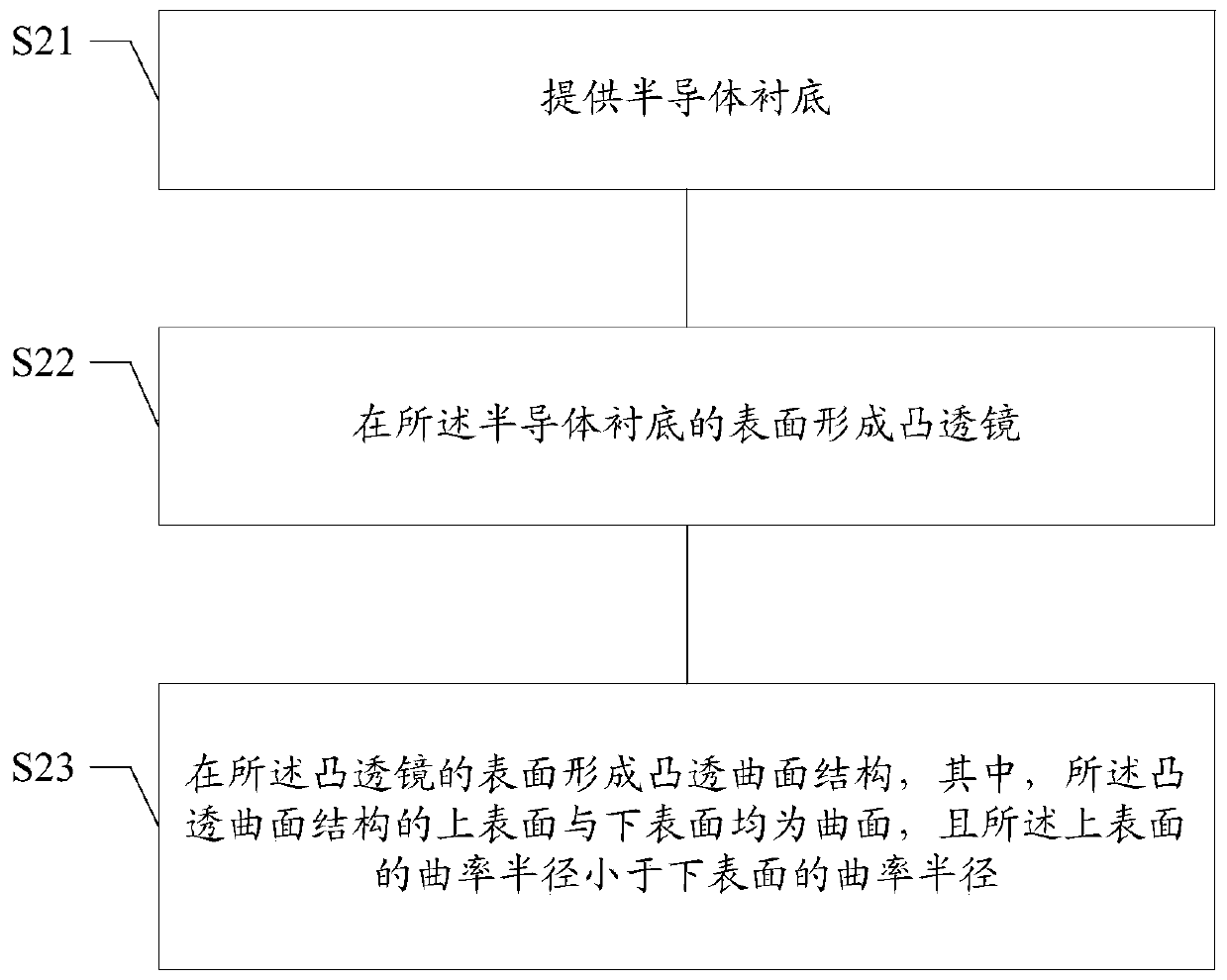

Image sensor and formation method thereof

InactiveCN110400816AReduce reflectionReduce crosstalkSolid-state devicesRadiation controlled devicesEngineeringPhotoelectric conversion

The present invention provides an image sensor and a formation method thereof. The image sensor comprises: a semiconductor substrate; a convex lens located on the surface of the semiconductor substrate; and a convex transparent surface structure located on the surface of the convex lens, wherein the upper and lower surfaces of the convex transparent surface structure are curved surfaces, and the radius of curvature of the upper surface is smaller than that of the radius of curvature of the lower surface, the upper surface of the convex transparent surface structure is a surface far away from the semiconductor substrate, and the lower surface of the convex transparent surface structure is a surface close to the semiconductor substrate. According to the scheme, the image sensor and the formation method thereof facilitate reduction of light crosstalk and improvement of the efficiency of photoelectric conversion.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

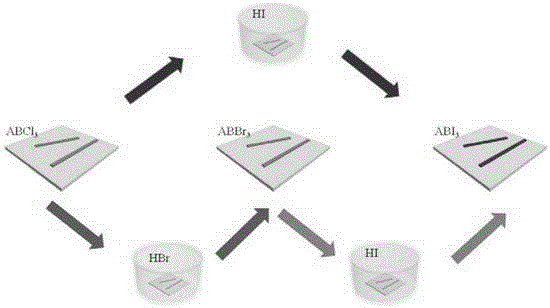

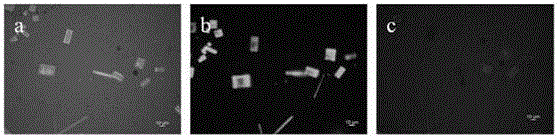

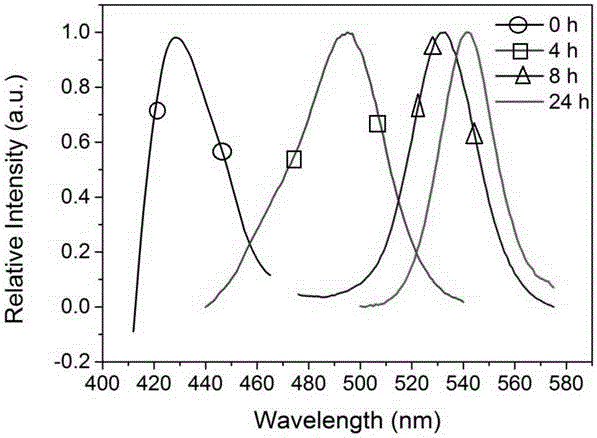

Preparation method and application of multicolor halogen perovskite fluorescent material

ActiveCN106753336ANo damage to shapeEnables tunable color emissionGroup 4/14 organic compounds without C-metal linkagesSolid-state devicesHalogenPerovskite

The invention discloses a preparation method of a multicolor halogen perovskite fluorescent material. The preparation method comprises the following steps: (1) preparing ABX3, wherein A is Cs or CH3NH3, B is Pb or Sn, and X is Cl; and (2) preparing ABXnY3-n from ABX3 in HY gas, wherein n is more than or equal to 0 and less than 3, and Y is Br or I; or preparing ABBXY1mY23-n-m from ABX3 in HY1 and HY2 gases sequentially, wherein n is more than or equal to 0 and less than 3, m is more than or equal to 0 and less than or equal to 3, (3-n-m) is more than or equal to 0 and less than or equal to 3, Y1 is Br, and Y2 is I. The preparation method disclosed by the invention has the advantages that fluorescence color of halogen perovskite can be well regulated and controlled and morphology of the halogen perovskite can not be destroyed.

Owner:CAPITAL NORMAL UNIVERSITY

Anti-blockage floor drain with automatic cleaning capacity

The invention discloses an anti-clogging floor drain with automatic cleaning ability, which comprises a cover plate decorative cover, a cover plate, a cover plate filter buckle, a fixing bump, a basket filter layer, a floor drain inner core, a connecting ring, a water outlet tank, and a floor drain Outer core, panel, filter ring, annular debris tank, fixing hole, inner core ring, U-shaped nozzle, buffer inner wall and water outlet. The beneficial effects of the present invention are: firstly, the discharged sewage is buffered through the buffer inner wall, which can effectively reduce the impact on the water outlet below the buffer inner wall. When there is soil or gravel deposited in the U-shaped nozzle, when flowing water enters from above, the flowing water will impact the U-shaped nozzle, causing the soil or sand to slide slowly from both sides of the U-shaped nozzle to the middle. It can be discharged smoothly, which effectively increases the self-cleaning ability of the floor drain, increases the service life of the floor drain, and reduces the cost of replacing the floor drain.

Owner:防城港市港口区明途建材有限公司

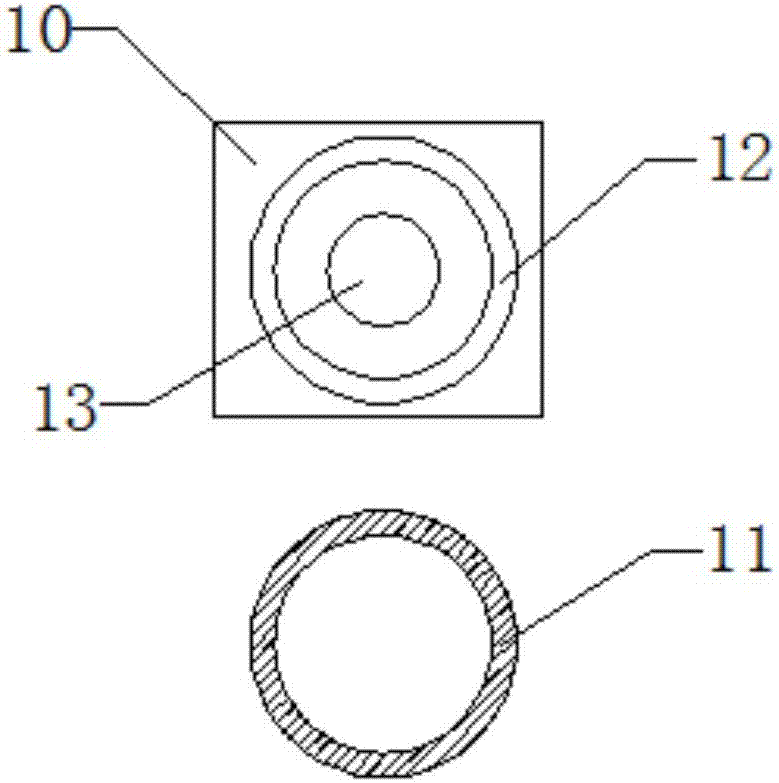

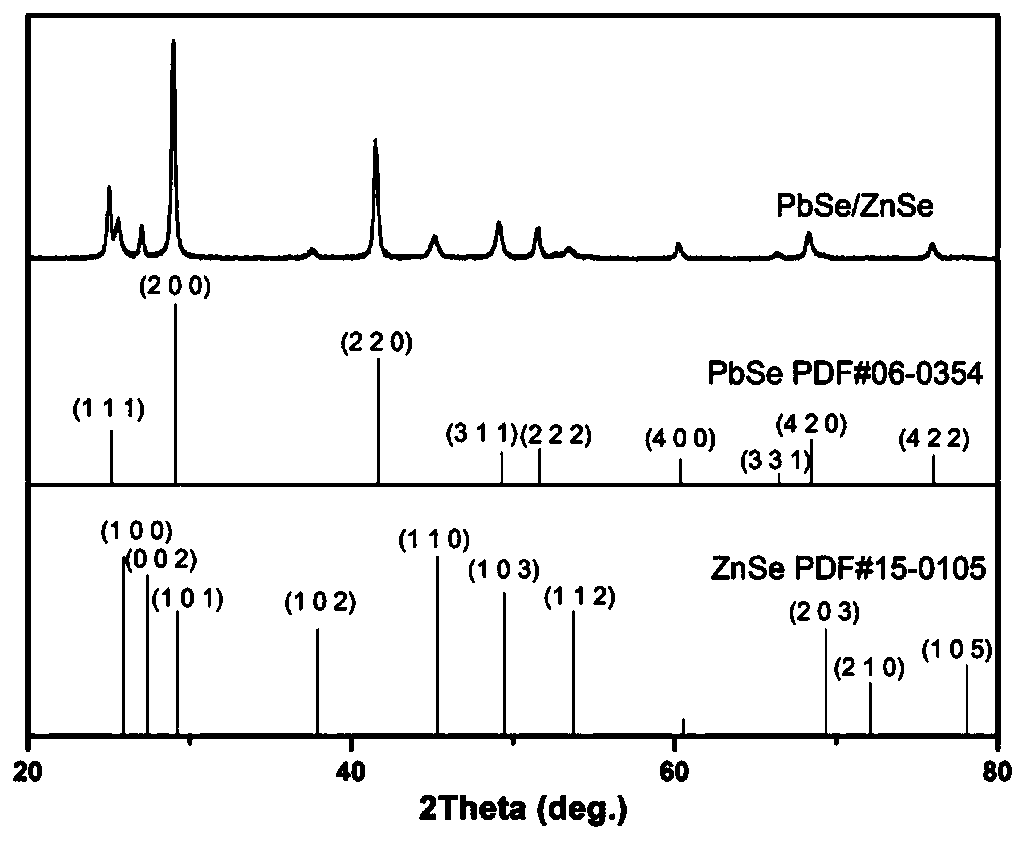

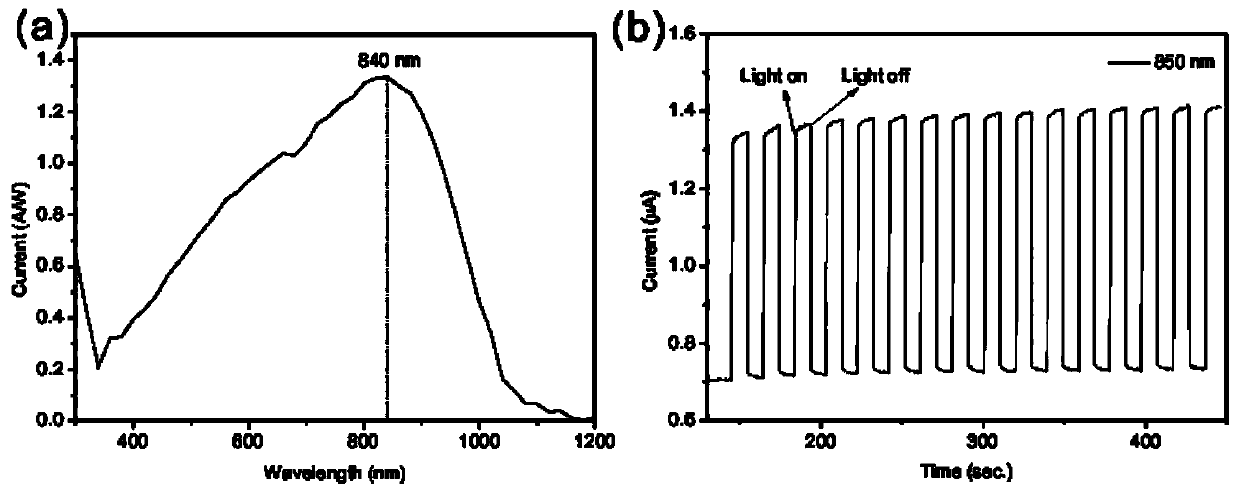

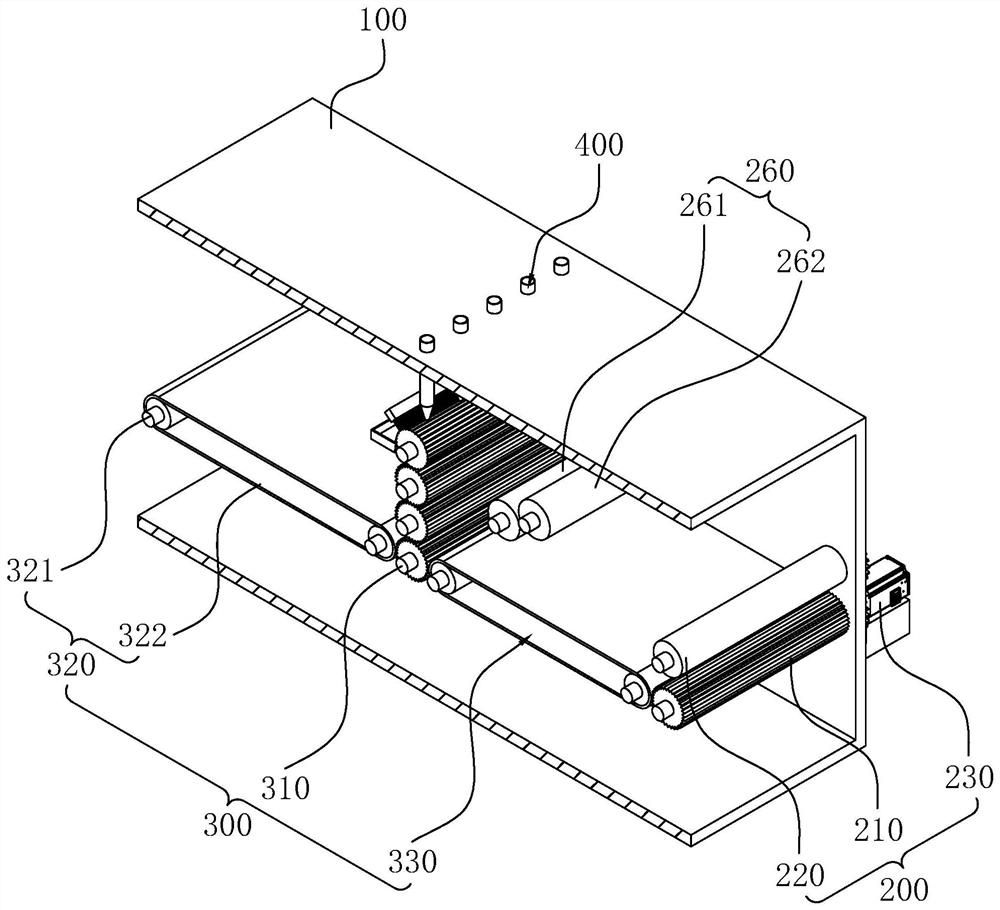

Strip-shaped PbSe/ZnSe heterojunction nanomaterial, and preparation method and application thereof

ActiveCN111573632AIncrease profitSolve the disadvantagesEnergy inputMetal selenides/telluridesHeterojunctionPyrrolidinones

The invention discloses a preparation method of a strip-shaped PbSe / ZnSe heterojunction nanomaterial. The preparation method comprises the following steps: dropwise adding a Pb(NO3)2 solution into a precursor ZnSe.0.5N2H4 nanobelt solution containing polyvinylpyrrolidone, carrying out uniform mixing and heating successively, keeping the reached temperature, conducting centrifuging, taking a precipitate, and washing, drying and calcining the precipitate to obtain the strip-shaped PbSe / ZnSe heterojunction nanomaterial. The invention further discloses the strip-shaped PbSe / ZnSe heterojunction nanomaterial which is prepared according to the preparation method of the strip-shaped PbSe / ZnSe heterojunction nanomaterial. The invention further discloses application of the strip-shaped PbSe / ZnSe heterojunction nanomaterial in a photoelectric sensor, a photoresistor, an infrared detector and a solar cell. The defects that a single semiconductor-based photosensitive material is low in absorption threshold value, high in electron-hole recombination rate and low in solar energy utilization rate are effectively overcome.

Owner:ANHUI UNIVERSITY

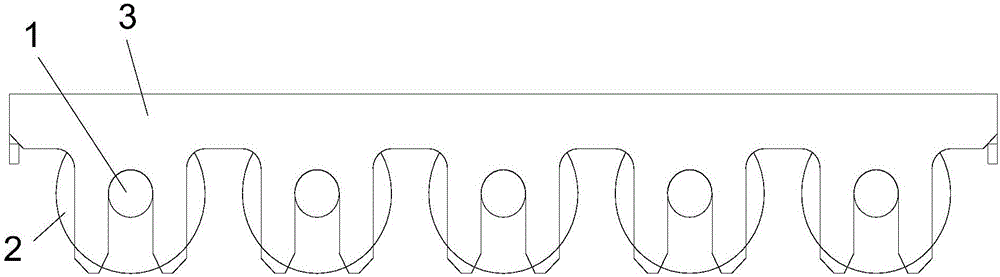

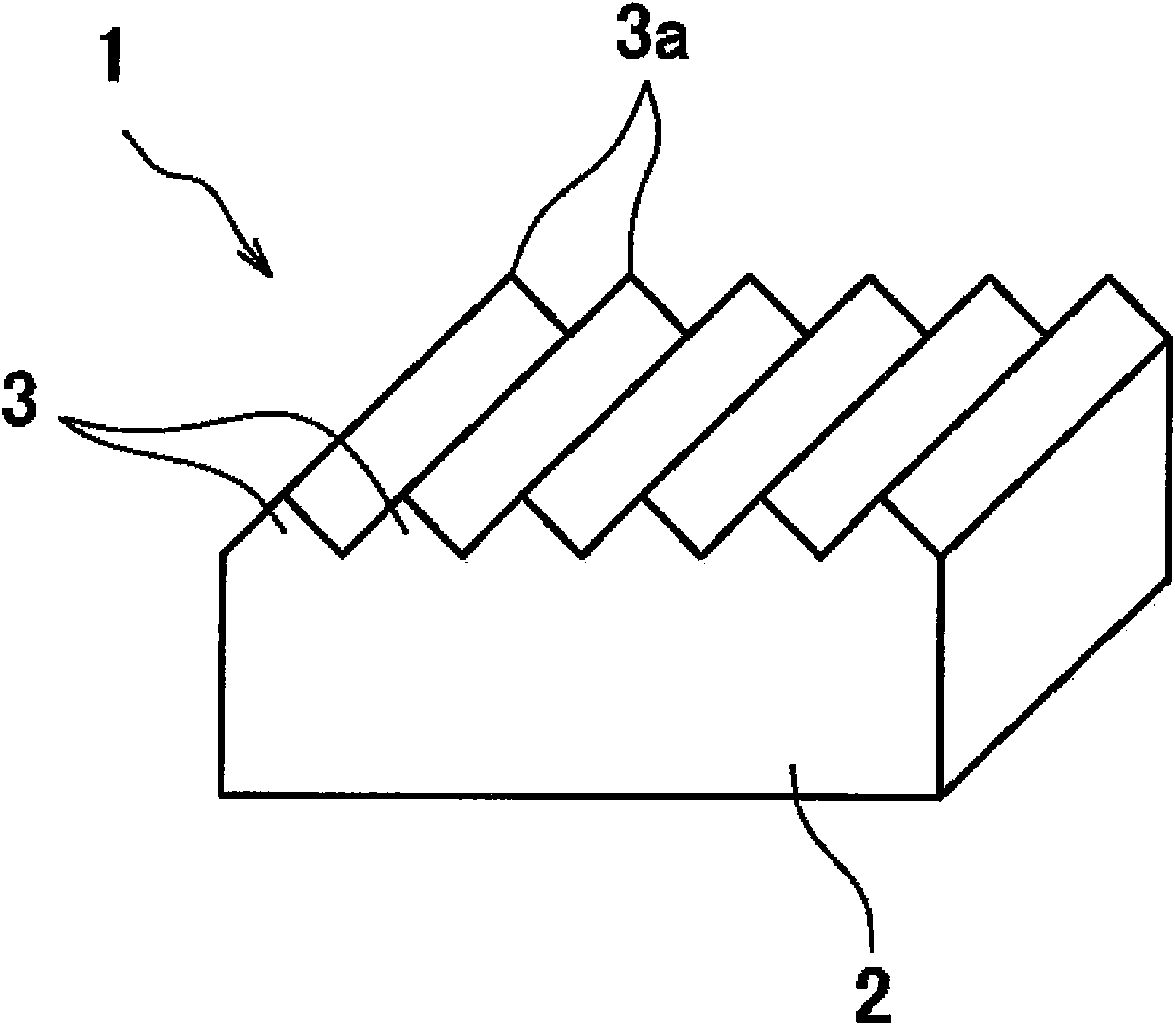

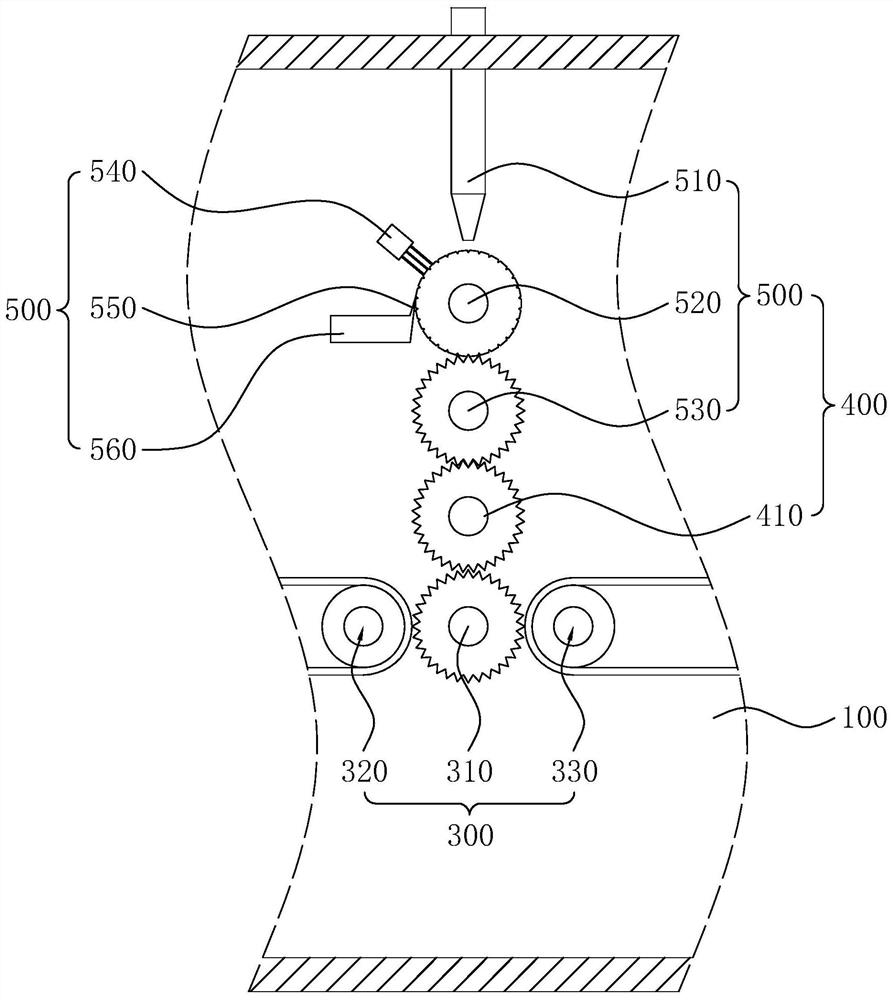

Gluing mechanism, corrugation pressing device and single facer

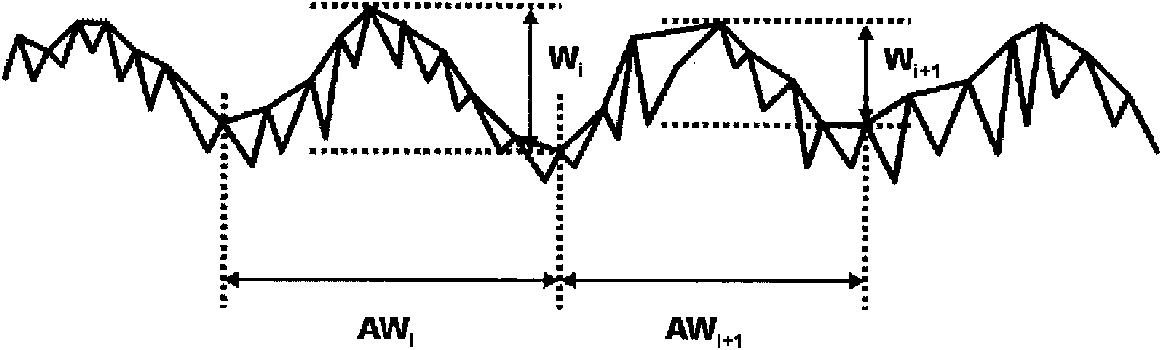

PendingCN113524799AReduce dosageReduce wasteLiquid surface applicatorsMechanical working/deformationDry gluePaper production

The invention relates to a gluing mechanism, a corrugation pressing device and a single facer, and relates to the technical field of corrugated paper production. The gluing mechanism comprises a gluing roller and a dry glue nozzle, wherein a plurality of first clamping grooves are formed in the peripheral surface of the gluing roller; the corrugation pressing device comprises a corrugation pressing roller; second convex strips are fixedly connected to the peripheral surface of the corrugation pressing roller; the second convex strips can be connected with the first clamping grooves in a clamped mode; the single facer comprises a first pasting roller and a second pasting roller; and third convex strips are fixedly connected to the peripheral surface of the first pasting roller. Under the action of the first clamping grooves, wave crests of corrugated paper are selectively glued, the using amount of dry glue is reduced, and waste of the dry glue is reduced.

Owner:济南晨彩包装印刷有限公司

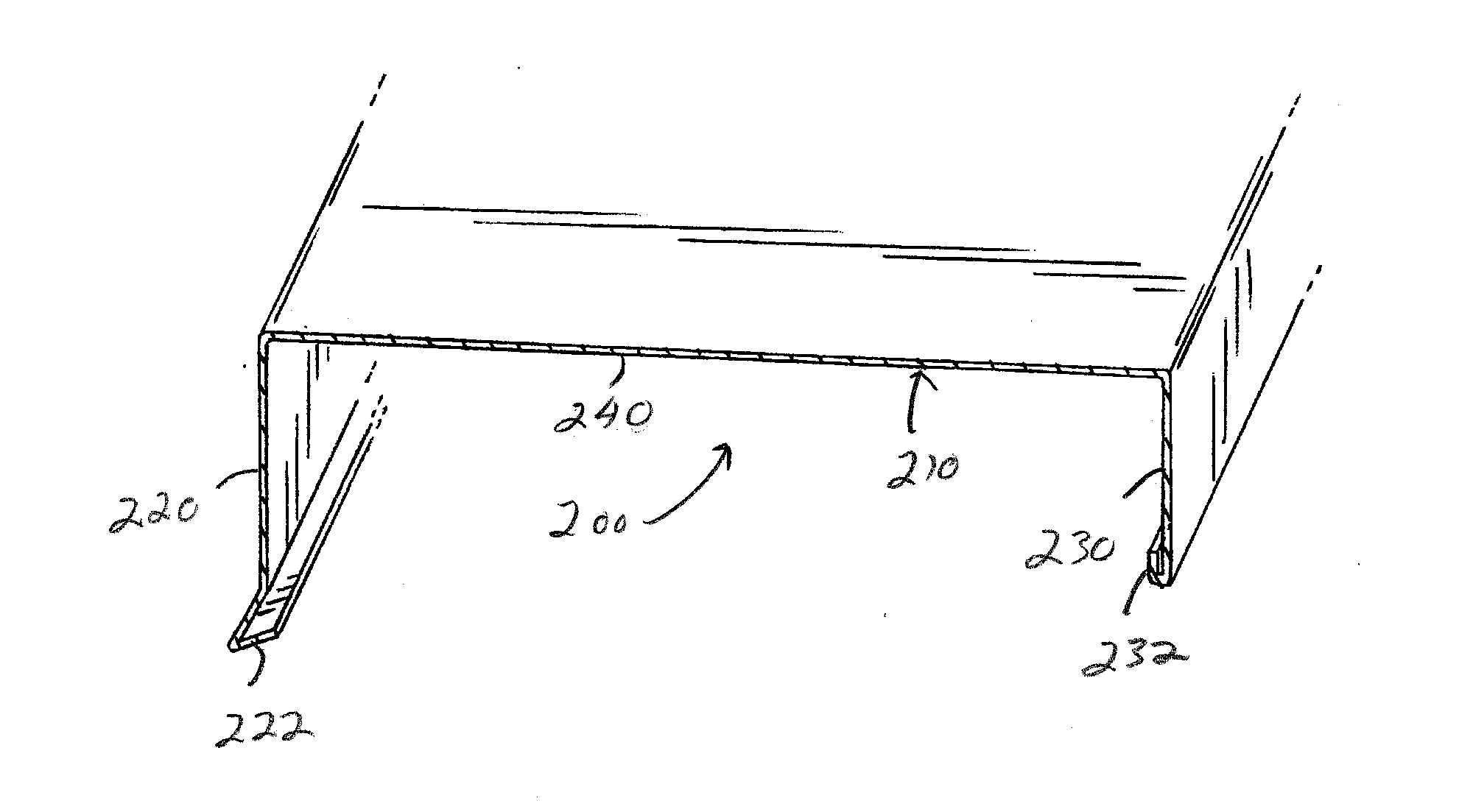

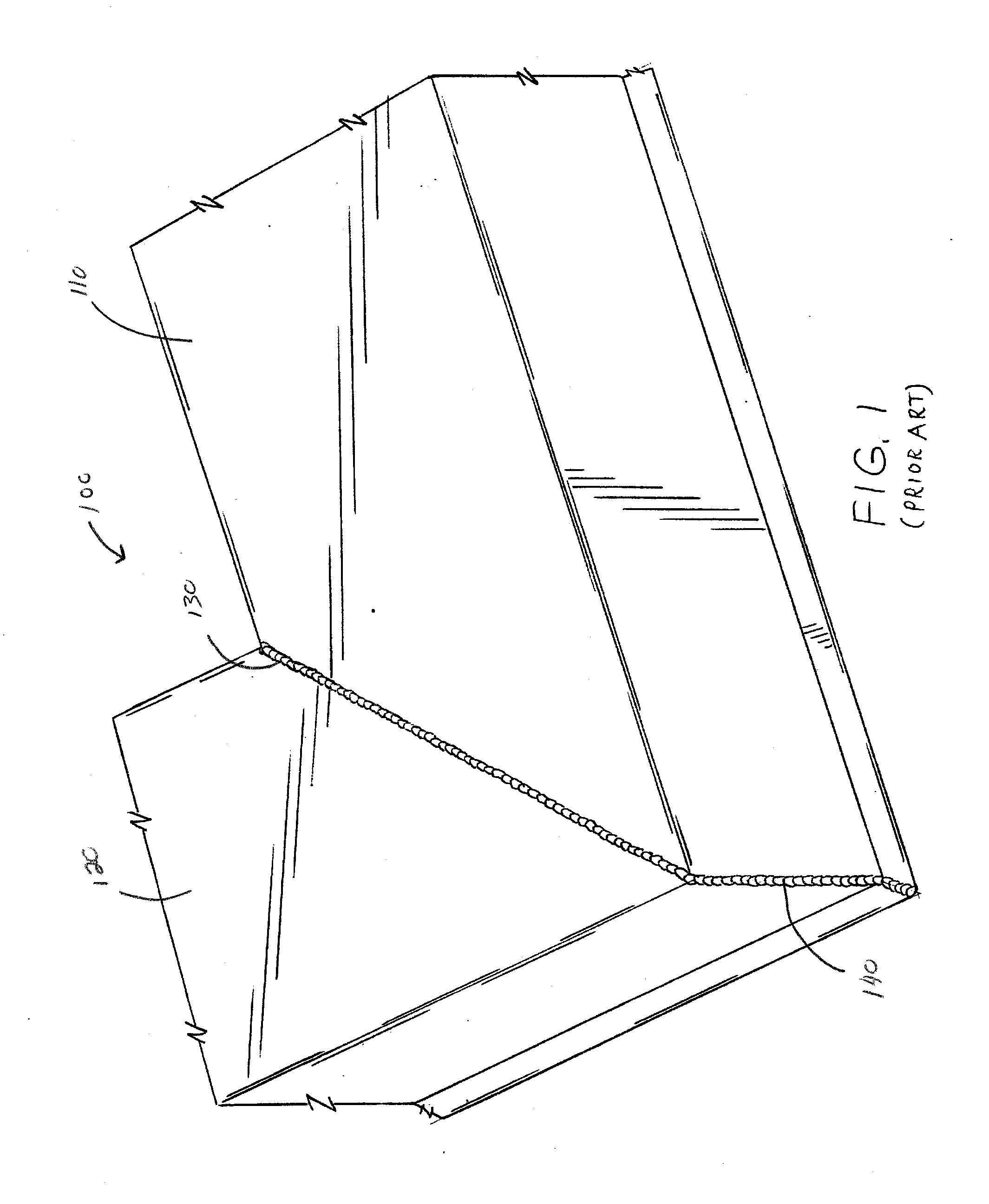

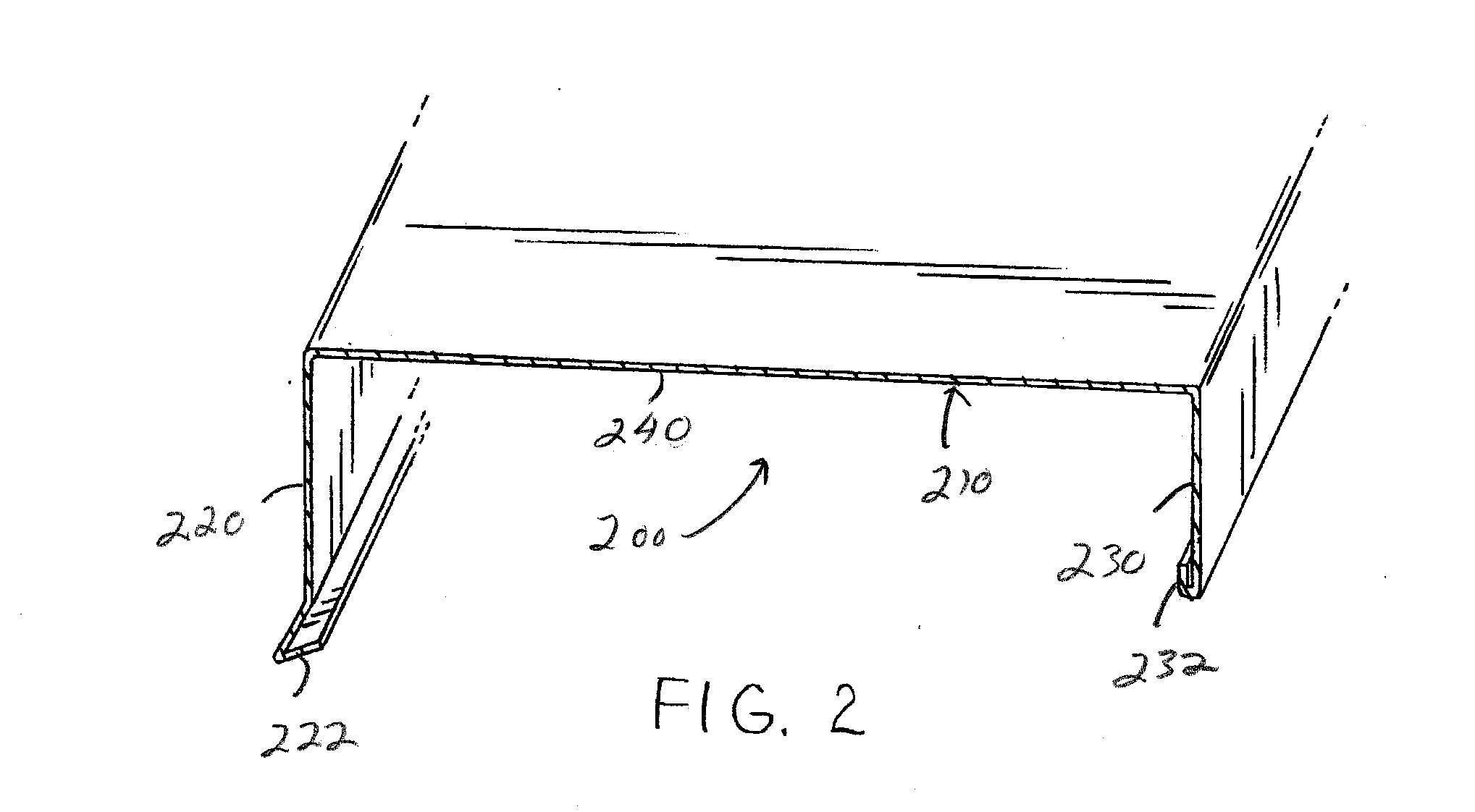

Non-welded coping caps and transitions

ActiveUS20130291464A1High strengthSolve the lack of durabilityRoof covering using slabs/sheetsAdhesive processesAdhesiveEngineering

A design and fabrication technique whereby a coping cap and / or transition can be supplied with mitered corner sections and other transitional components which utilize the identical prefinished or bare sheet metal material(s) without any reliance on exposed mechanical fasteners, welding, soldering, or post-applied paints. This is essentially accomplished by joining the pre-finished sheet material(s) together using a mesh screen and adhesive on the underside (non-exposed) face of the sheet material(s).

Owner:GARLAND INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com