Cement casting die for manufacturing of electric wire pole

A technology for pouring molds and utility poles, applied in molds and other directions, can solve the problems of high cost, easy to roll, rupture and scrap, etc., and achieve the effect of improving service life, preventing slurry running, and saving production time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

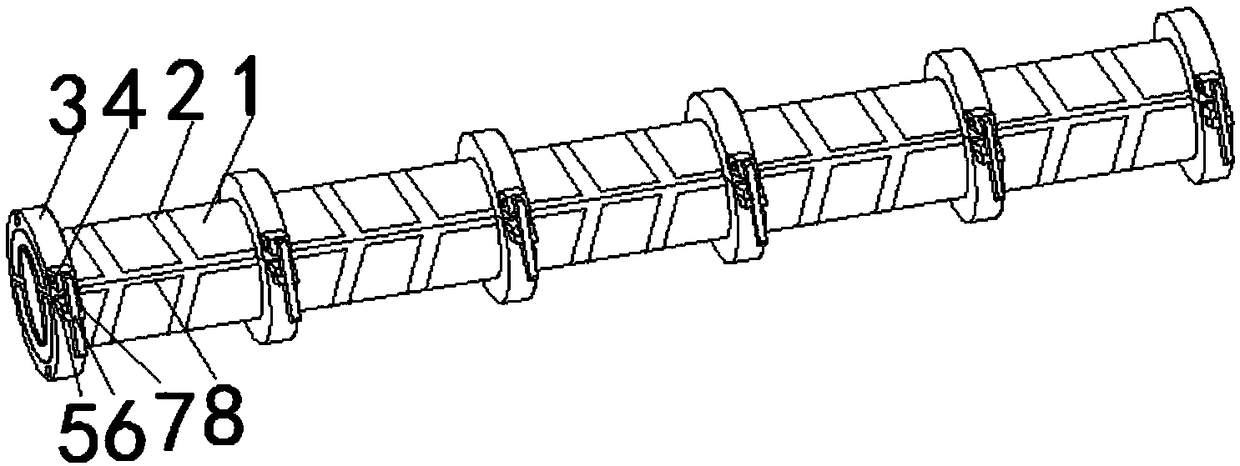

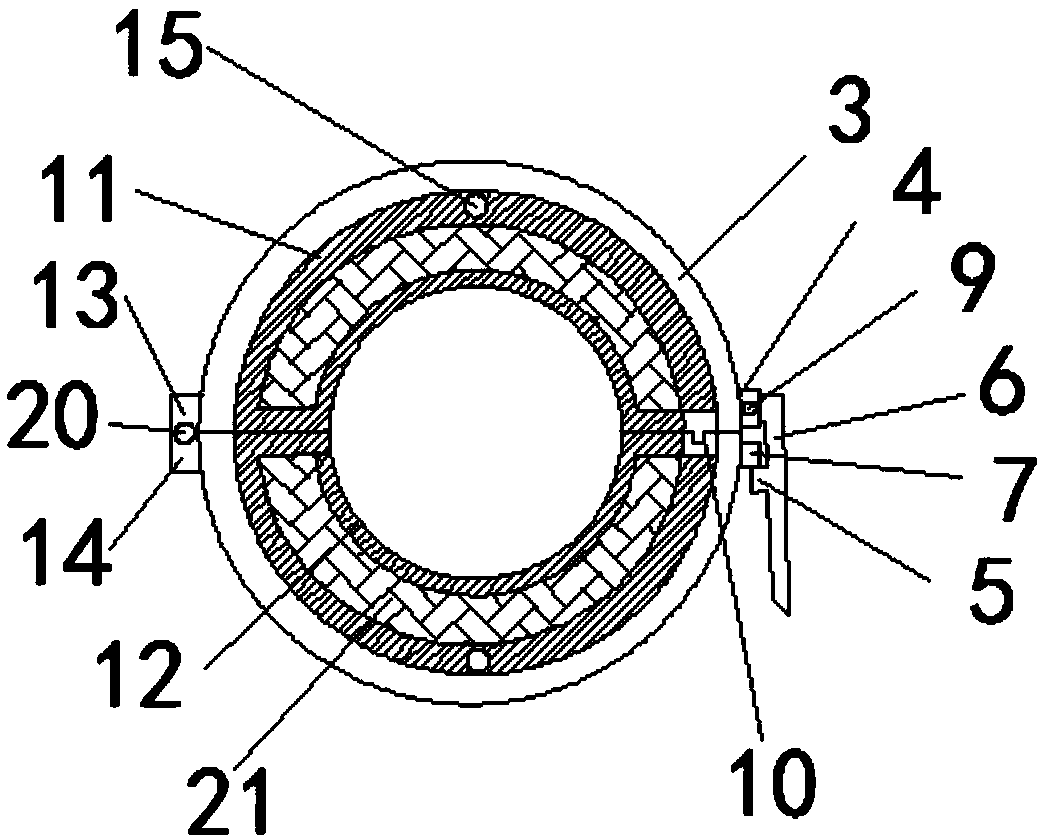

[0021] Such as Figure 1-Figure 4 As shown, a cement pouring mold for the manufacture of utility poles proposed by the present invention includes a mold body 1, longitudinal ribs 2 and reinforcement seats 3, and a plurality of reinforcement seats 3 are arranged on the mold body 1, and the interior of the reinforcement seats 3 is set There is an upper mold 11, a lower mold 12 is arranged symmetrically with the upper mold distance 11 in the reinforcement seat 3, and a buffer layer 21 is arranged in the upper film tool 11 and the lower mold 12;

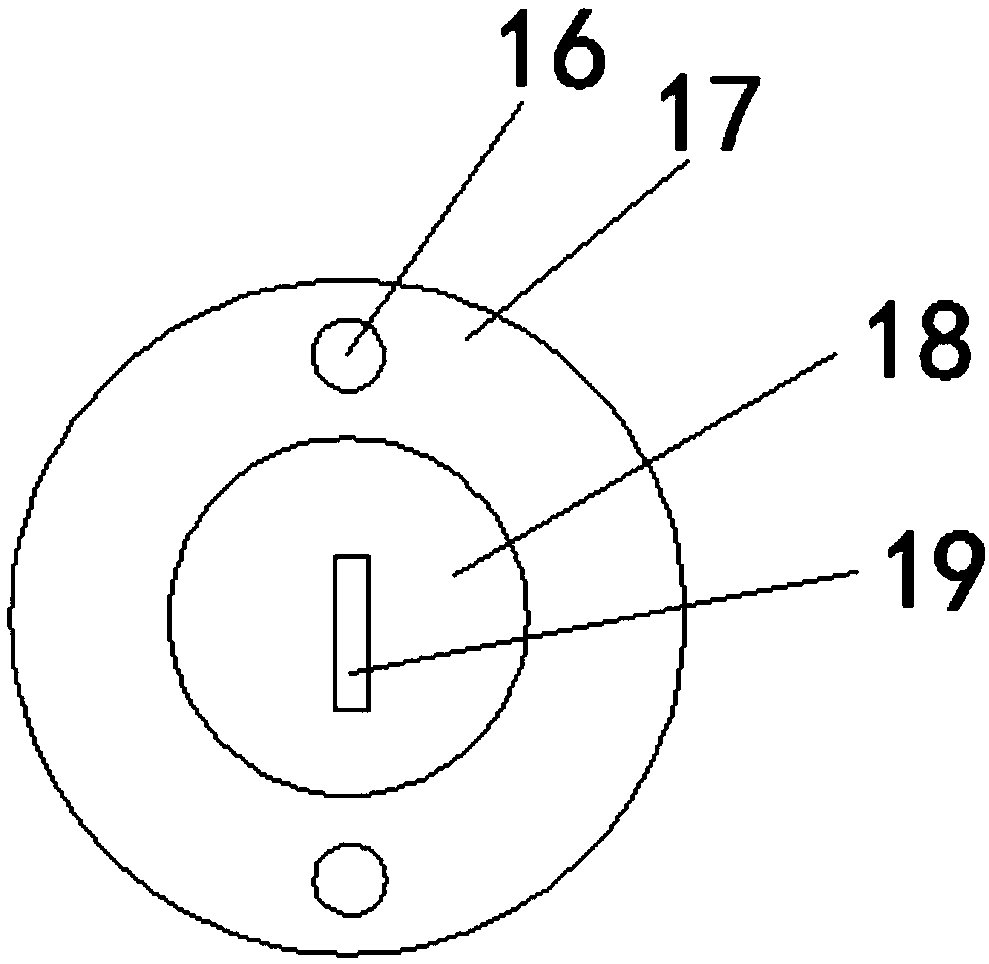

[0022] Reinforcement seat 3 is composed of upper and lower parts. The left side of the upper part of reinforcement seat 3 is provided with an upper flip fixed block 13. The upper flip fixed block 13 is rotationally connected with the lower flip fixed block 14 through the second rotating shaft 20. The right side is provided with a lock support block 4, the lock support block 4 is connected to the upper end of the locking handle 6 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com