Spiral fin condenser

A technology of spiral fins and condensers, applied in the field of condensers, can solve the problems of hidden dangers in the structure, damage of fins, unsatisfactory cooling effect of condensers, etc., and achieves reliable and stable form, guaranteed cooling effect, and guaranteed heat exchange. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

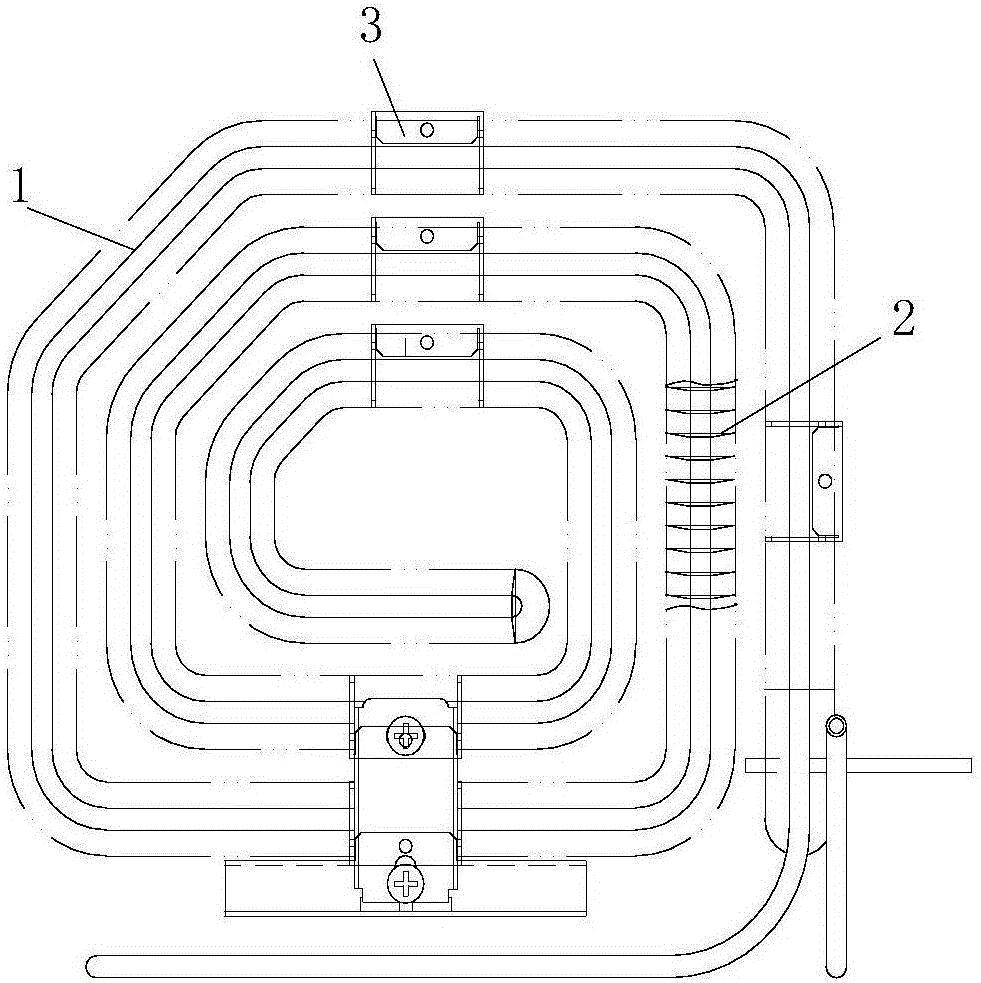

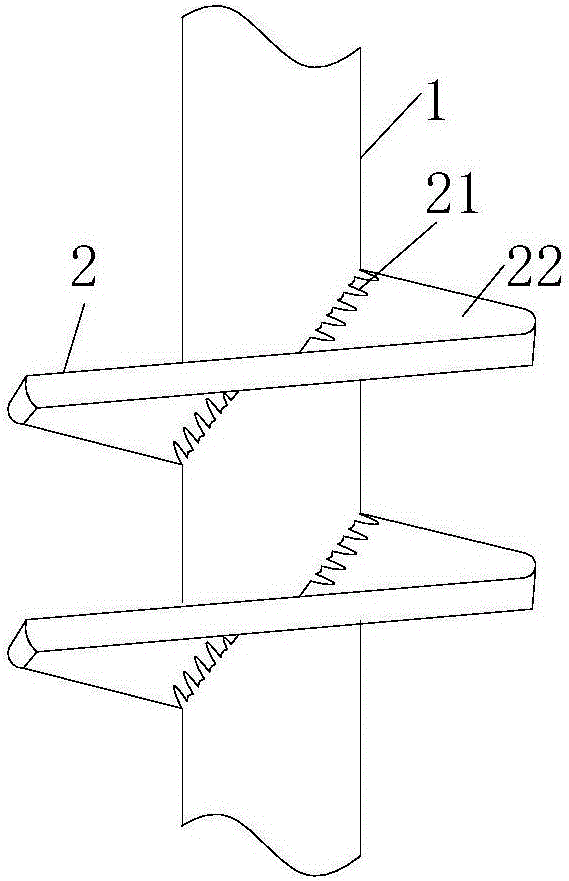

[0031] Example 1, such as Figure 1 to Figure 6 , The spiral fin condenser includes a condenser tube 1 and a fin 2. The fin 2 is spirally wound on the surface of the condenser tube 1. The inner side of the fin 2 connected with the heat dissipation tube 1 is a wave structure 21, The outer side is a smooth structure 22, and the inner side is connected by a wave-like structure. On the one hand, it is firmly connected and not easy to slide. It can disperse the force from the outside during the assembly process and is not easy to be damaged. On the other hand, it is used to guide and correct heat. The hot air flow is guided to quickly dissipate heat; the smooth structure on the outside can ensure that the heat dissipation direction formed by the fins during heat dissipation is uniform and overall linear heat dissipation. If the wave structure continues, it will cause the heat sink to dissipate non-linearly. The heat radiation has crossover and overlap, and the heat radiation waves wi...

Embodiment 2

[0035] Example 2, such as Figure 7 Of course, the card is a rigid structure. In order to prevent it from breaking and to shrink the card smoothly, three adjustment slots 325 are provided at the bottom of the card slot 324, which extend to the mounting plate.

Embodiment 3

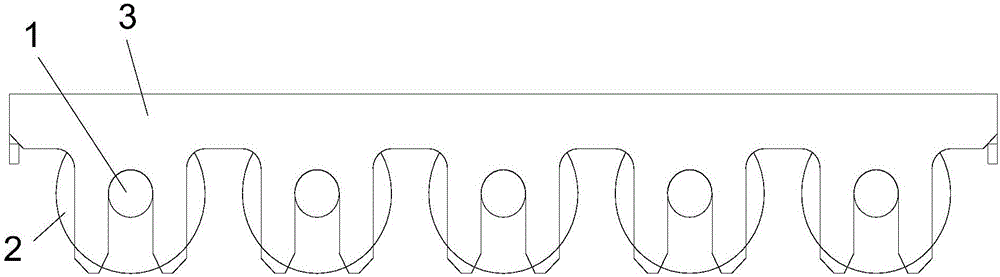

[0036] Example 3, such as Figure 8-11 The fixed bracket 3 includes a mounting plate 31 and a plurality of cards 323 on both sides respectively. The cards on both sides are staggered. The two sides of the mounting plate are bent twice to form a T-shaped structure. Generally speaking, the first The second bend is 180° at A, and the second bend is 90° at B. Of course, the bending sequence can also be reversed. A slot 324 is formed between the cards 323 on both sides that is compatible with the condenser tube. The end of the mounting plate becomes the limit part to ensure that the condenser tube is stuck in the card slot. The plane of the card is lower than the plane of the mounting plate, so that all the cards can be on the same plane after bending and forming, which can effectively correct The condenser tube is clamped and fixed, and the mounting plate can cover more fins to prevent deformation of the fins when the fixed bracket or condenser is installed.

[0037] Such as Pictur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com