Straw bale picking device

A technology of bale and shaft, which is applied in the field of bale picking devices, can solve the problems of damage to the shape of the bale, easy failure, complex structure, etc., and achieve the effects of improving efficiency, prolonging service life, and simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

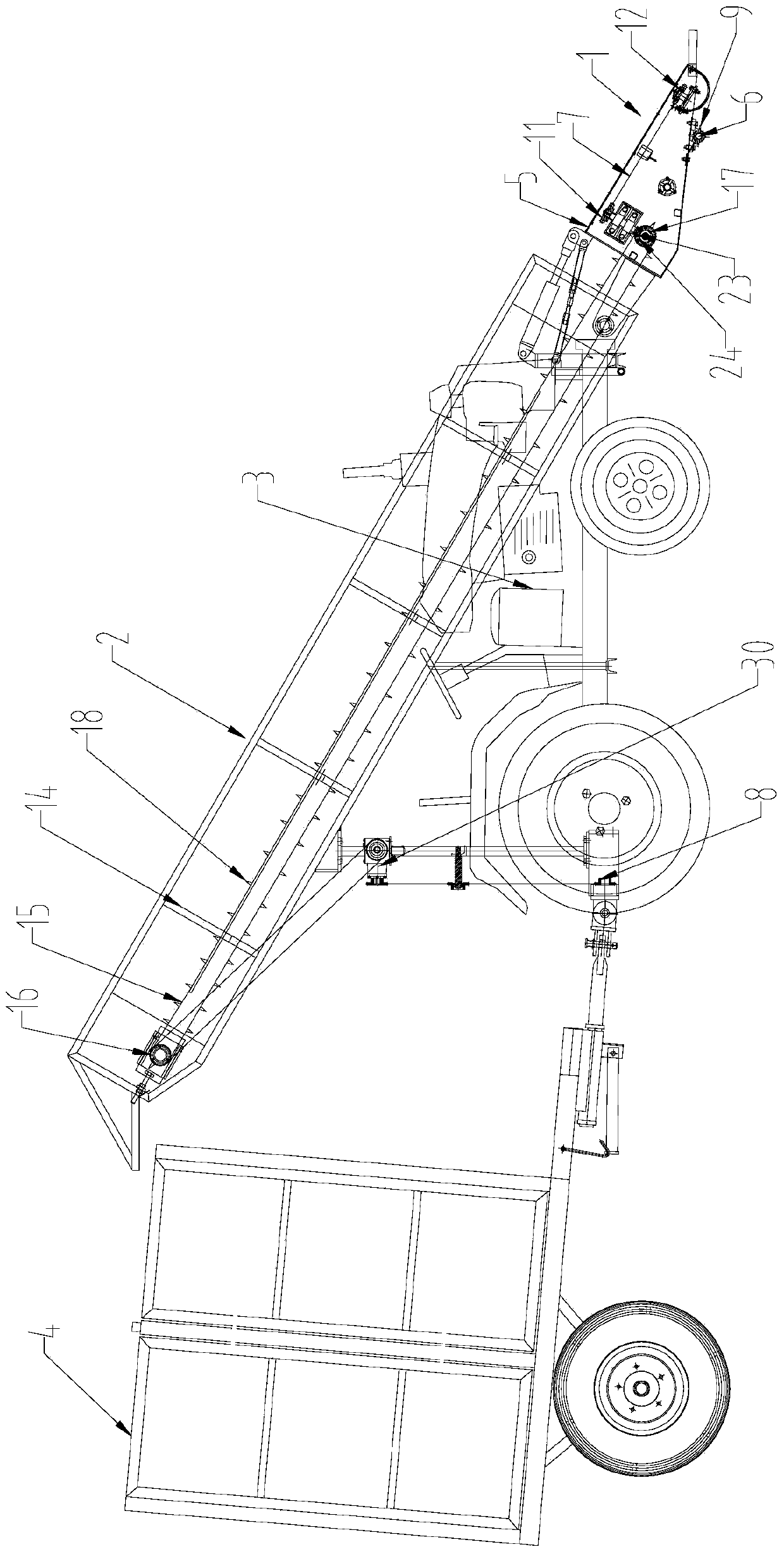

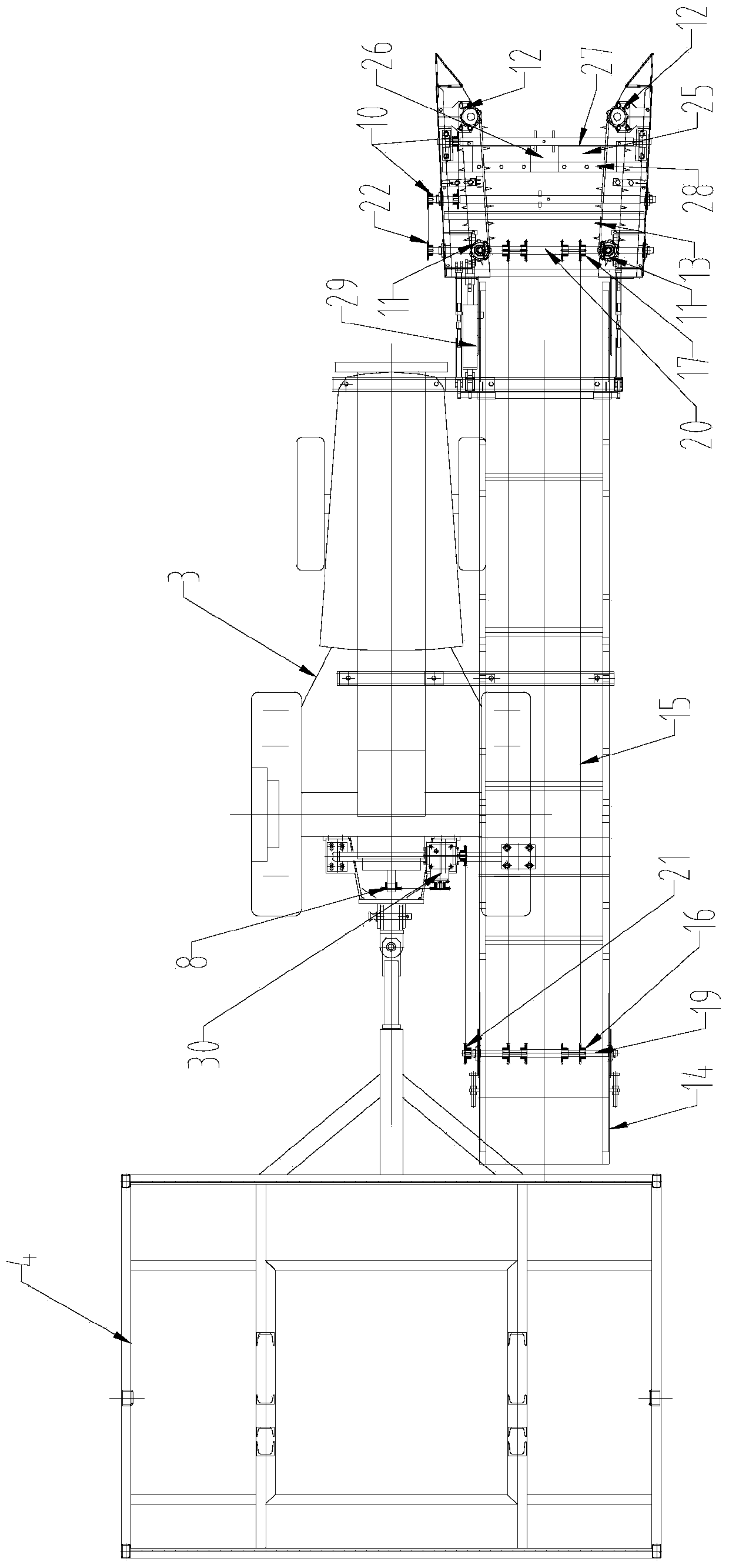

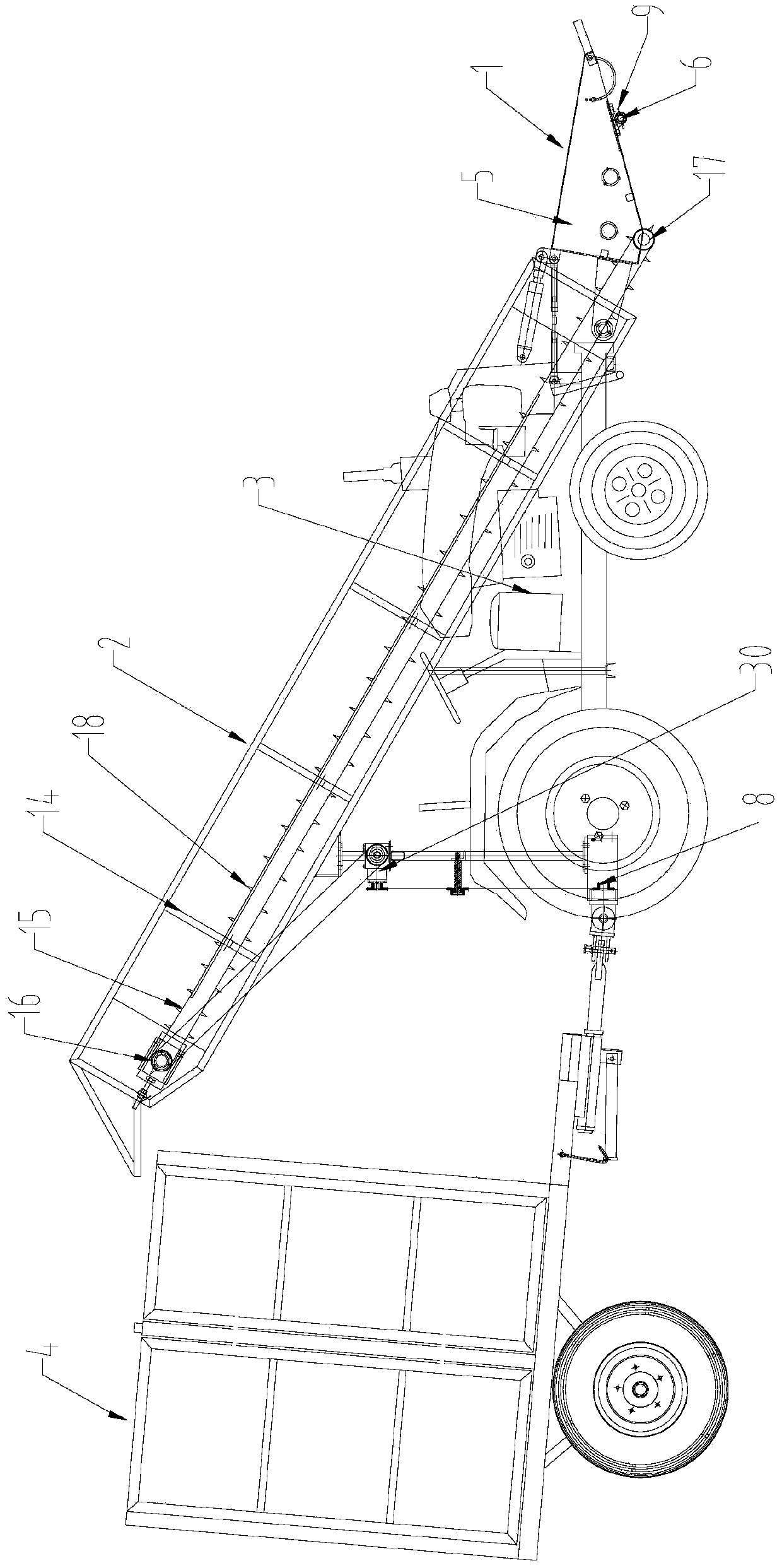

[0046] A bale picking device according to the present invention, the bale picking device includes: a picking structure 1 for picking up the bale from the ground, a pick-up structure 1 located at one end of the picking structure 1 for delivering the bale to a designated position Transmission structure 2 and a power-providing chassis 3, said pick-up structure 1 at least includes a trough-shaped pick-up frame 5 fixedly connected to the chassis 3, a pick-up rotating shaft 6 at the bottom of the pick-up frame 5, and pick-up frames at both sides of the pick-up frame 5 The pick-up chain 7, the pick-up rotating shaft 6 rotates, and the pick-up chain 7 rotates, and they work together to move the bale obliquely upwards, and after the bale is picked up, the bale is transported to the designated position through the transmission structure 2, thereby realizing the bale pick-up. Mechanization and automation improve the efficiency of picking and loading, without manual picking, which greatly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com