Bottle transport device

A transmission device and bottle technology, which is applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of bottle 3 deformation, inaccurate measurement, bottle mouth pollution, etc., and achieve the effects of low cost, reduced frictional resistance, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The bottle conveying device of the present invention will be further described in detail through specific examples below.

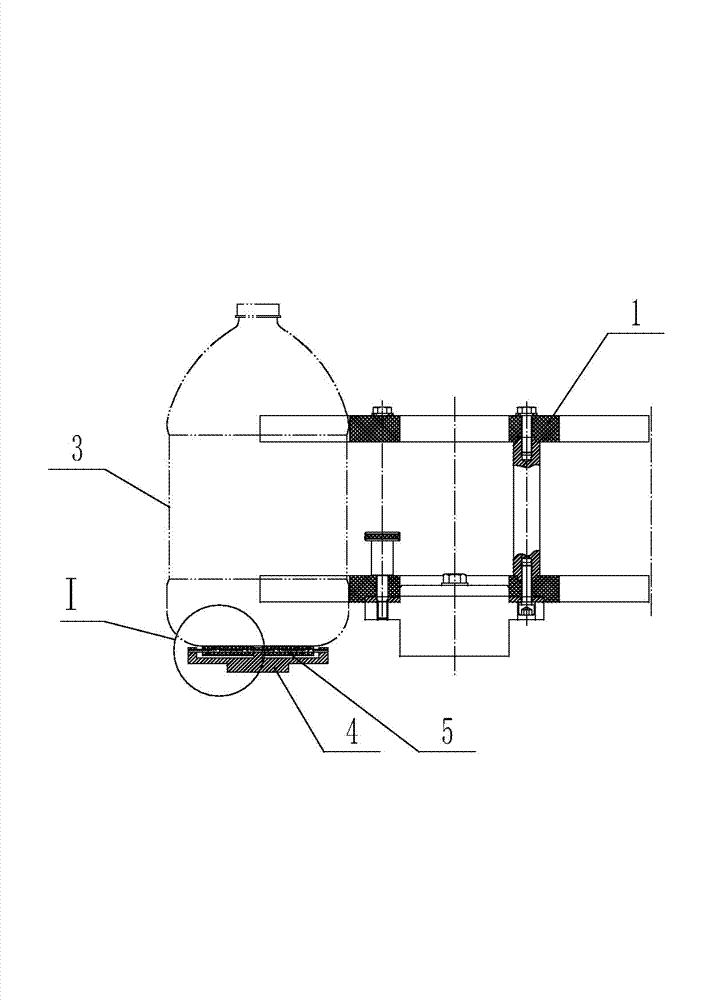

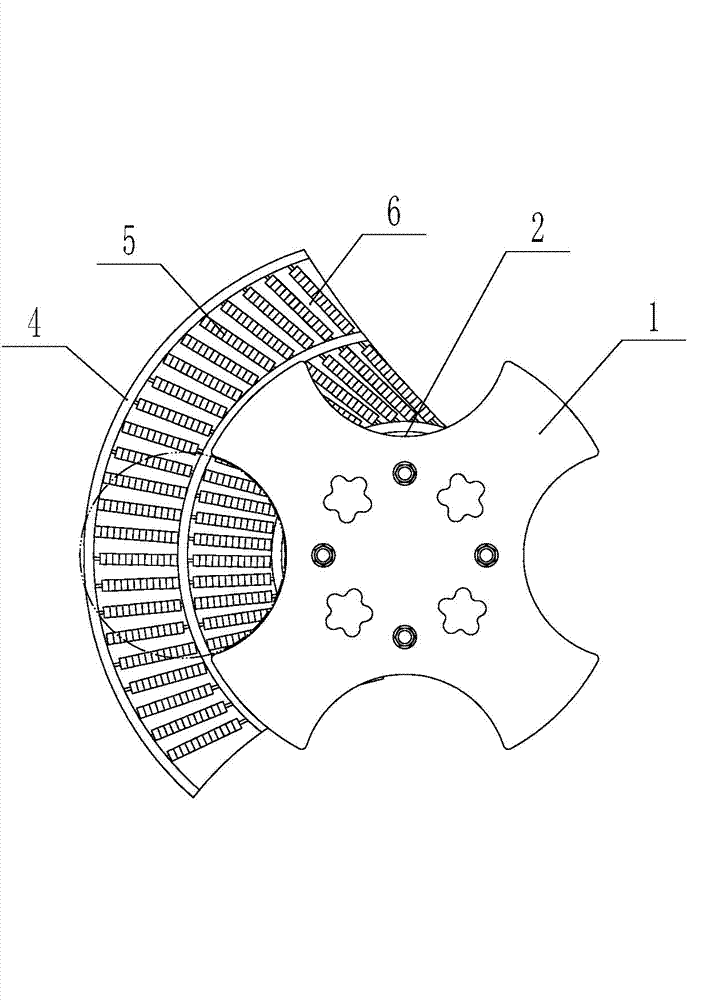

[0017] Such as figure 1 , figure 2 As shown, the bottle conveying device includes a rotatable star wheel 1. Several bottle slots 2 are arranged on the peripheral wall of the star wheel 1. The size of the bottle slots 2 matches the size of the bottle 3. The bottom of the star wheel 1 is provided with Bottle supporting plate 4, in the present embodiment, bottle supporting plate 4 is fan-shaped structure, and the structure of bottle supporting plate can be changed according to the actual situation on the spot, and described bottle supporting plate 4 is provided with several freely rotatable rolling bodies. The rotating direction of the rolling body is consistent with the conveying direction of the bottle 3 .

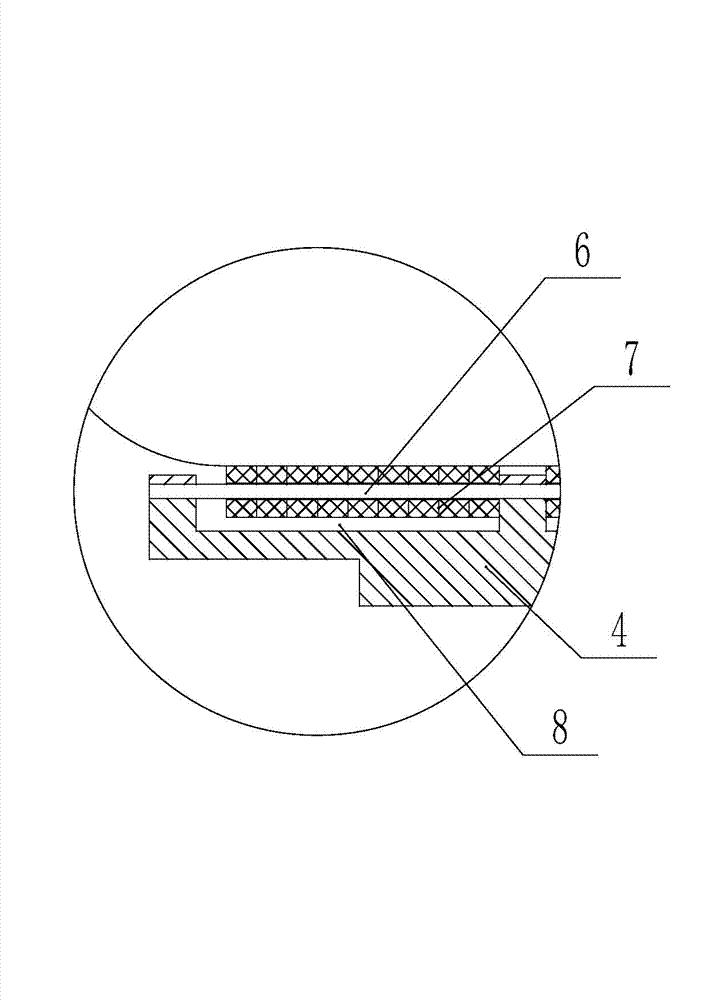

[0018] As a preferred solution, the rolling elements are rollers 5 . Such as figure 1 , image 3 As shown, the roller 5 includes a roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com