Walnut cracker

A technology for openers and walnuts, which is applied in the field of walnut openers and daily necessities, and can solve problems such as walnut kernel damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

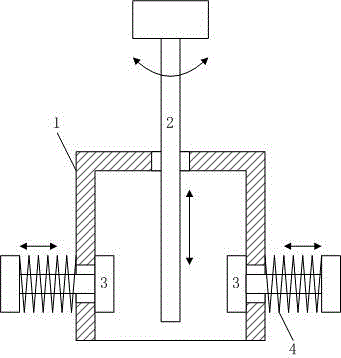

[0019] The walnut opener of the present embodiment, structural representation is as figure 1 shown. The walnut opener includes a sleeve 1 with an open lower end, a straight screwdriver 2 inserted from the top of the sleeve 1, and arranged at the clamping end 3 of the side wall of the sleeve 1;

[0020] The slotted screwdriver 2 is inserted from the center position of the upper bottom of the sleeve 1, can move along the direction of the central axis of the sleeve 1, and can rotate in a plane perpendicular to the central axis of the sleeve 1; the top of the slotted screwdriver 2 is provided with a handle;

[0021] The side wall of the sleeve 1 is symmetrically provided with a through hole, and the clamping end 3 is inserted through the through hole. Between the middle part of the "I" shape structure and the outer wall of the sleeve 1, a spring 4 in a compressed state is arranged.

specific Embodiment 2

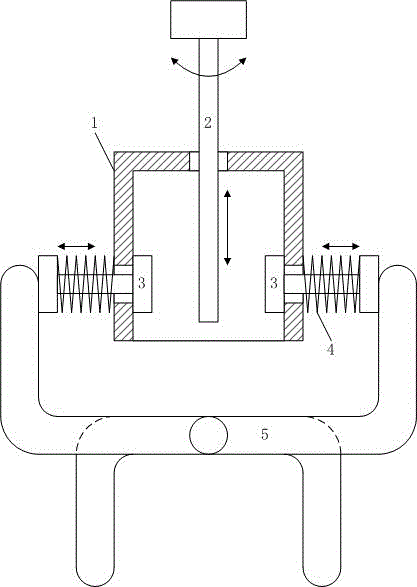

[0022] The walnut opener of this embodiment, on the basis of the specific embodiment 1, further defines that the clamping end 3 is connected to the pliers structure 5, such as figure 2 shown.

[0023] With this structural design, the clamping end 3 can be clamped by the pliers structure 5, and then walnut shells can be crushed, so that the walnut opener of the present invention can simultaneously have the function of a traditional walnut clamp.

specific Embodiment 3

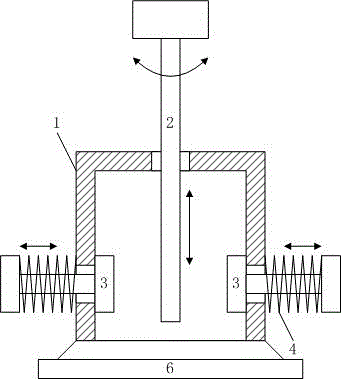

[0024] The walnut opener of this embodiment, on the basis of the specific embodiment 1, further defines that the screwdriver 2 and the sleeve 1 adopt a piston connection mode, and that the clamping end 3 and the sleeve 1 adopt a piston connection mode, and the sleeve The bottom of cylinder 1 is provided with rubber pad, also is equipped with the pad 6 that upper surface is smooth, as image 3 shown.

[0025] Wherein, the connection of the piston structure, the rubber pad and the pad 6 can all play a sealing role.

[0026] This structural design enables the walnut opener of the present invention to work in a semi-isolated state. When the screwdriver 2 is inserted into the walnut gap for demolition, the demolition work is carried out under an environment higher than a standard atmospheric pressure; when the screwdriver 2 is extracted To the uppermost end, use the clamping end 3 to crush the walnut shell, and the whole clamping work is carried out under an environment lower than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com