Method for preparing sealing strip of scroll compressor

A machine sealing strip and sealing strip technology, which is applied in the direction of mechanical equipment, piston pump sealing device, machine/engine, etc., can solve the problems of cracking of the side wall of the groove, low working efficiency of the compressor, sealing failure, etc., and achieve good mechanical performance. And electrical insulation, excellent sliding properties, good thermal shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

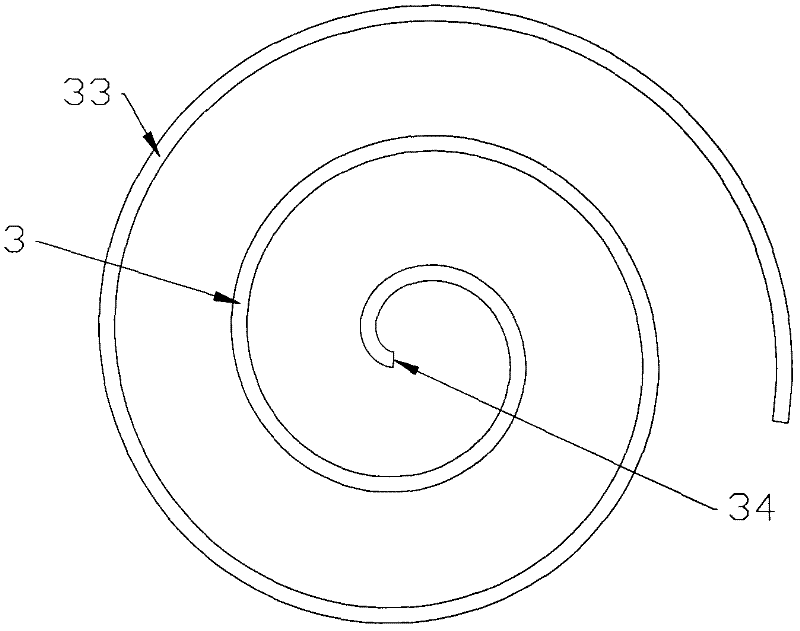

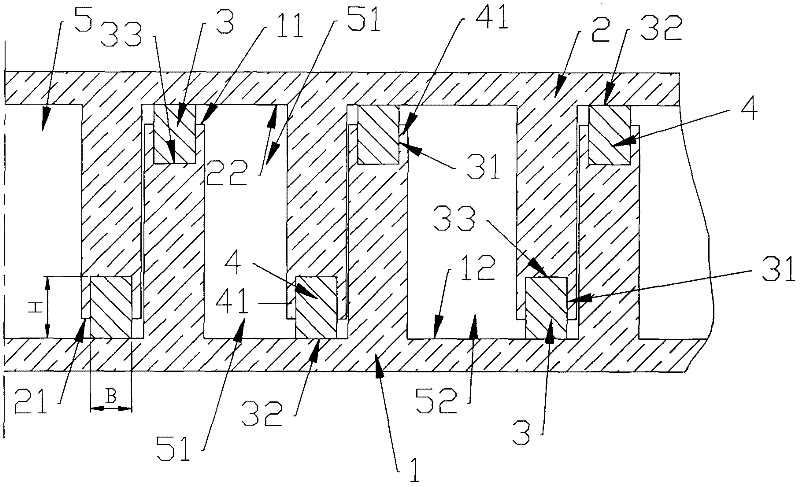

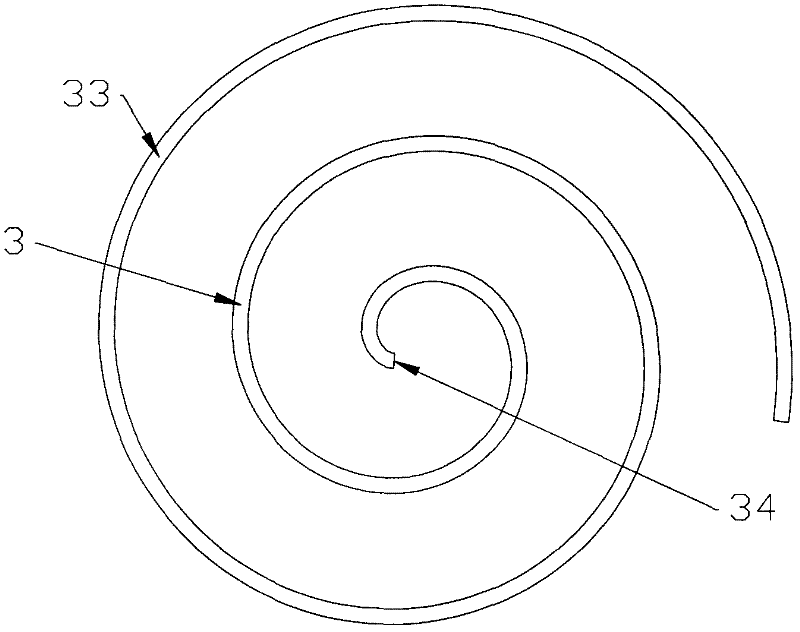

[0024] Such as image 3 , 4 The sealing strip 3 of the scroll compressor shown has an involute shape corresponding to the movable scroll. The height H of the sealing strip 3 in the direction of the base circle axis of the involute line gradually increases from the outside to the inside along the involute line. The width B of the sealing strip in the radial direction of the base circle is equal from the outside to the inside along the involute. See Figure 5 , Along the involute line from the outside to the inside of each section of the sealing strip is a rectangle with increasing height. The upper end surface 32 of the sealing strip in the direction of the base circle axis is a plane perpendicular to the base circle axis, and the lower end surface 33 is an inclined surface.

[0025] The preparation method of the scroll compressor sealing strip is to mix the components polybenzimidazole, polyether ether ketone, carbon fiber, and molybdenum disulfide according to the weight parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com