Hydrophobic modification method of nano silica particles

A nano-silica, hydrophobic modification technology, applied in the production of silica, silicon oxide, bulk chemicals, etc., can solve problems such as difficult industrial promotion and application, complicated preparation process, environmental pollution, etc., and achieve hydrophobic modification method Simple, good dispersibility, less agglomeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

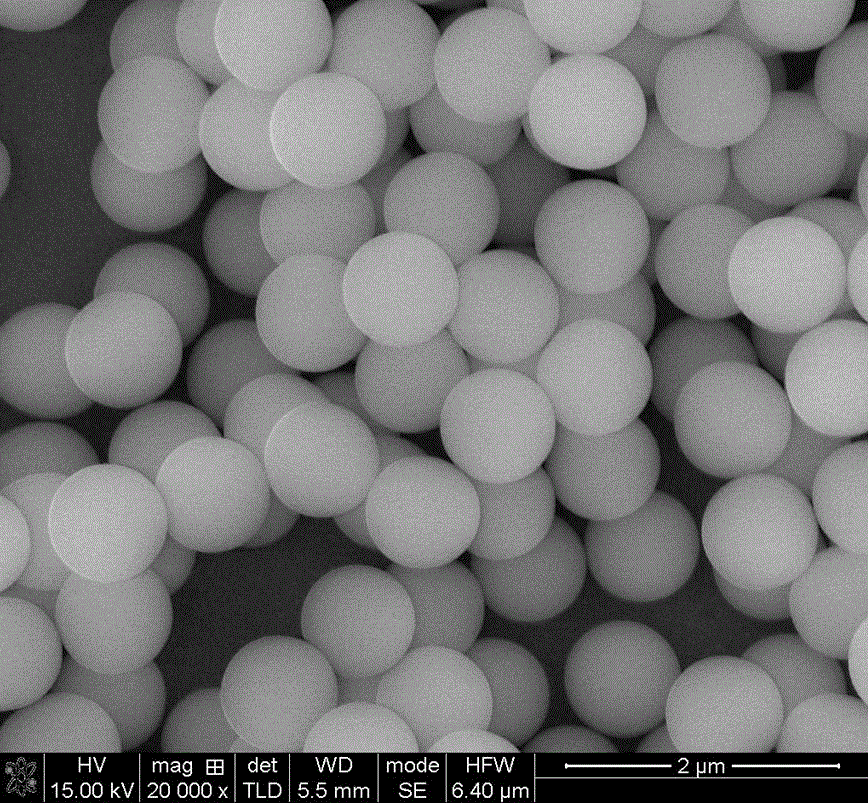

[0016] 1a. After the nano-silica product prepared by the stober method is washed with alcohol and water, then freeze-dried to obtain a monodisperse nano-silica powder A;

[0017] 1b. Put the monodisperse nano-silica powder A with a diameter of 800nm into ethanol with a purity of 98% or more. The ratio of monodisperse nano-silica powder A to ethanol with a purity of 98% or more is 1g:25mL, and ultrasonically disperse After 2 minutes, system B was obtained;

[0018] 1c. Put the system B in the reaction kettle, seal it, preset the temperature at 270°C, and the pressure at 21MPa. After the temperature and pressure are stable, keep it for 3 hours, and then slowly release the pressure to atmospheric pressure to obtain hydrophobically modified nano-dioxide silicon particles.

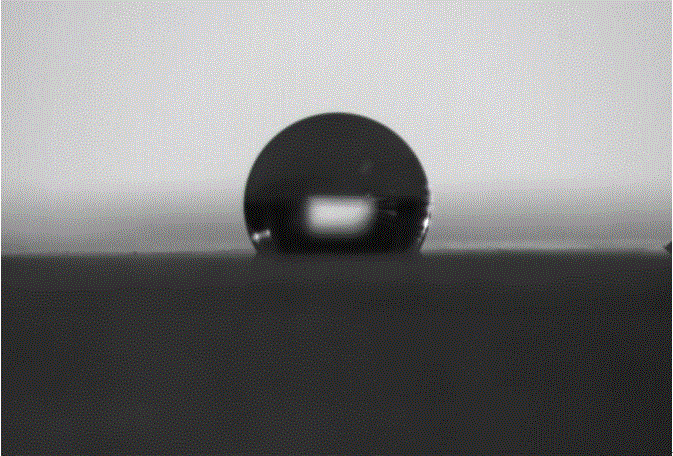

[0019] Such as figure 1 Shown, the contact angle that the nano-silica particle that embodiment 1 obtains is recorded after tabletting is 119 °, and the hydrophobic effect of nano-silica particle is obvious;...

Embodiment 2

[0021] The embodiment of this embodiment is basically the same as that of Example 1, the main difference is that the diameter of monodisperse nano silica powder A is 100nm, and the ratio of monodisperse nano silica powder A to ethanol with a purity of more than 98% is 4g: 25mL, the preset temperature of the reaction kettle is 250°C, and the pressure is 15MPa. After the temperature and pressure are stable, keep it for 5h. The contact angle of the nano-silica particles prepared in Example 2 is 120°.

Embodiment 3

[0023] The embodiment of this embodiment is basically the same as that of Example 1, the main difference is that the diameter of monodisperse nano silica powder A is 500nm, and the ratio of monodisperse nano silica powder A to ethanol with a purity of more than 98% is 3g: 25mL, the preset temperature of the reaction kettle is 300°C, and the pressure is 30MPa. After the temperature and pressure are stable, keep it for 3h. The contact angle of the nano-silica particles prepared in Example 3 is 127°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com