Manufacturing technology of hibiscus petal tea

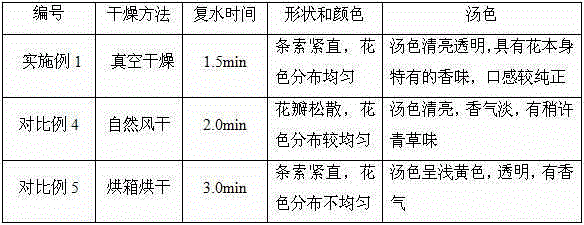

A production process, hibiscus petal technology, applied in the production process of hibiscus petal tea, can solve the problems of ignoring the shape, tea soup color, fragrance and nutritional value, etc., and achieve the effect of fresh and elegant taste, bright color and bright color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Petal pretreatment: Pick fresh pink and white hibiscus flowers at 8:00 in the morning, and then gently divide the hibiscus flowers into petals. Do not press them during the operation. The shape and size of the selection are basically the same. No damage, no color spots, brightly colored petals, then use an ultrasonic cleaning machine at 20kHz, power 600W, ultrasonic cleaning for 2 minutes, then spread it into a thin layer of 2cm thick, put it in a ventilated, cool and dry place, use a blower Blast and dry the petals at a wind speed of 2.0m / s for 20 minutes;

[0030] (2) Stamping forming: place the pretreated petals obtained in step (1) flatly on a butterfly-shaped die, and perform stamping, cutting and forming to obtain formed petals;

[0031] (3) Color protection: place the shaped petals obtained in step (2) in a color protection solution completely submerged at 25°C (the mass percentage of each component in the color protection solution is: magnesium chloride 1.0w...

Embodiment 2

[0039] (1) Petal pretreatment: pick fresh pink and red hibiscus flowers at 7:00 in the morning, and then gently divide the hibiscus flowers into petals. Do not press during the operation, and the shape and size of the selection are basically the same , no damage, no color spots, and brightly colored petals, then use an ultrasonic cleaner at 30kHz, power 300W, ultrasonic cleaning for 3 minutes, then spread it into a thin layer of 1cm thick, put it in a ventilated, cool and dry place, use The blower blows and dries the petals for 30 minutes at a wind speed of 1.5m / s;

[0040] (2) Stamping forming: place the pretreated petals obtained in step (1) flatly on a heart-shaped die, and perform stamping, cutting and forming to obtain formed petals;

[0041] (3) Color protection: place the shaped petals obtained in step (2) in a color protection solution at 20°C (the mass percentage of each component in the color protection solution is: magnesium chloride 0.8wt%, citric acid 3.0wt%, carbox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com