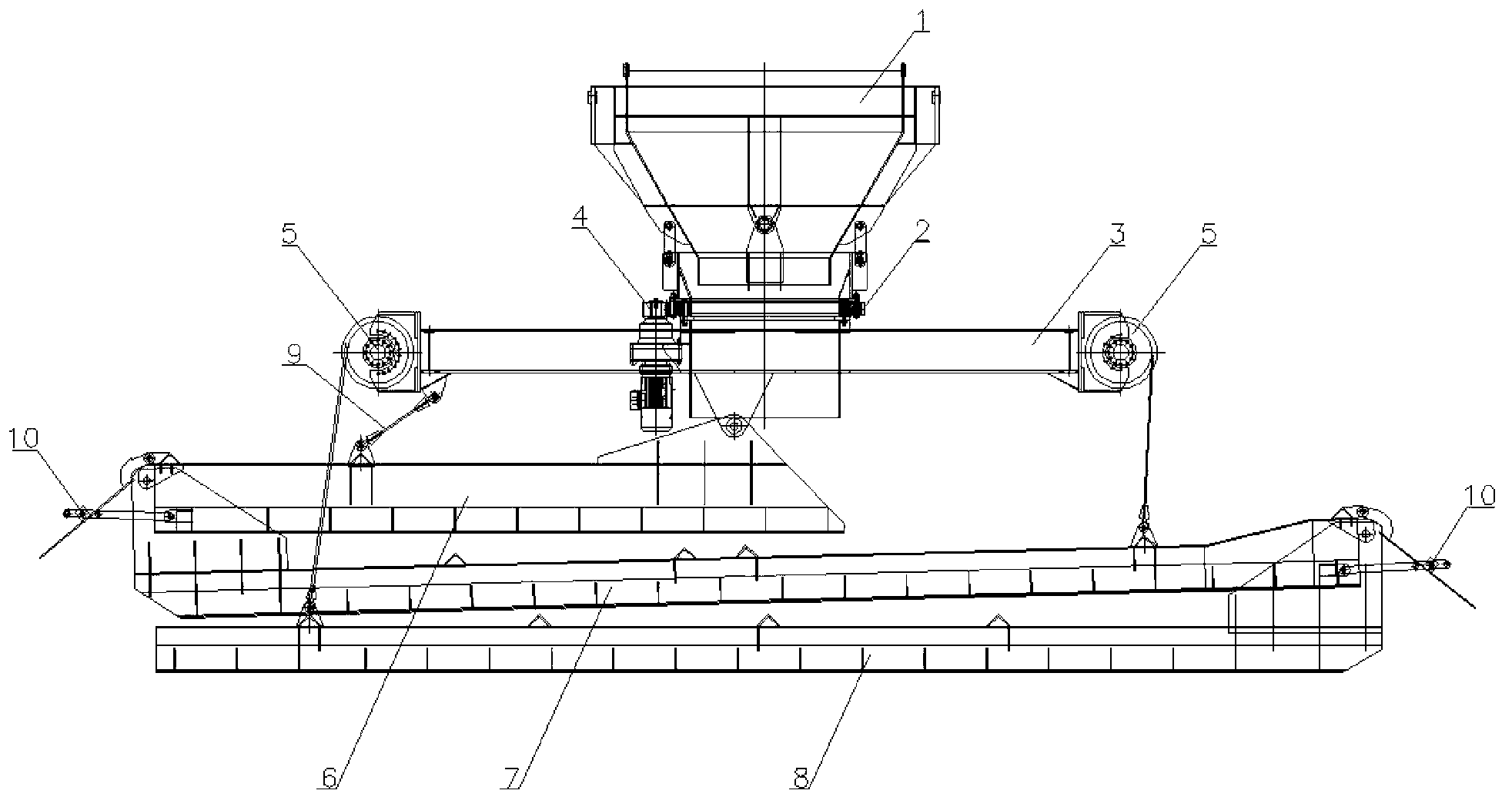

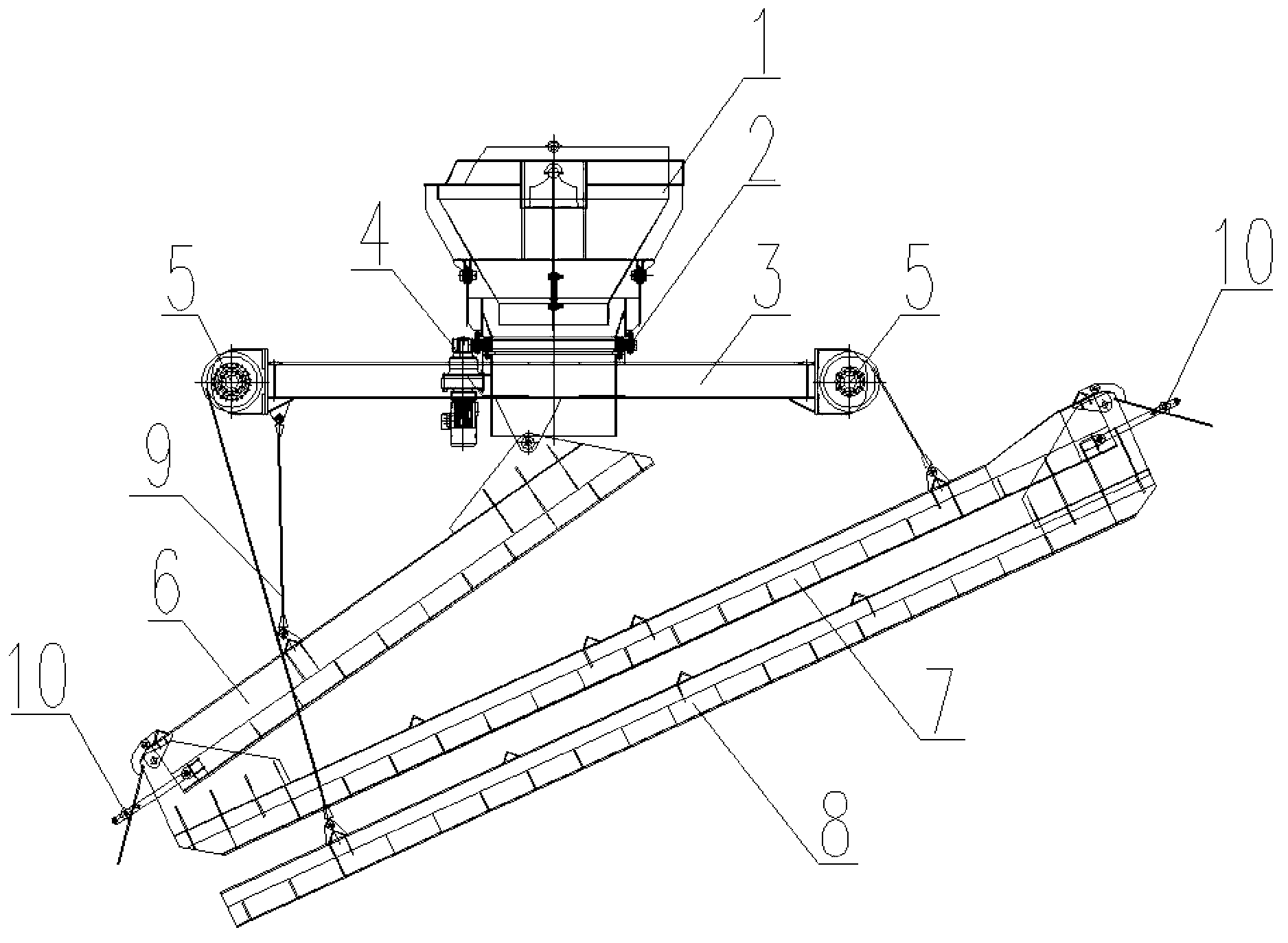

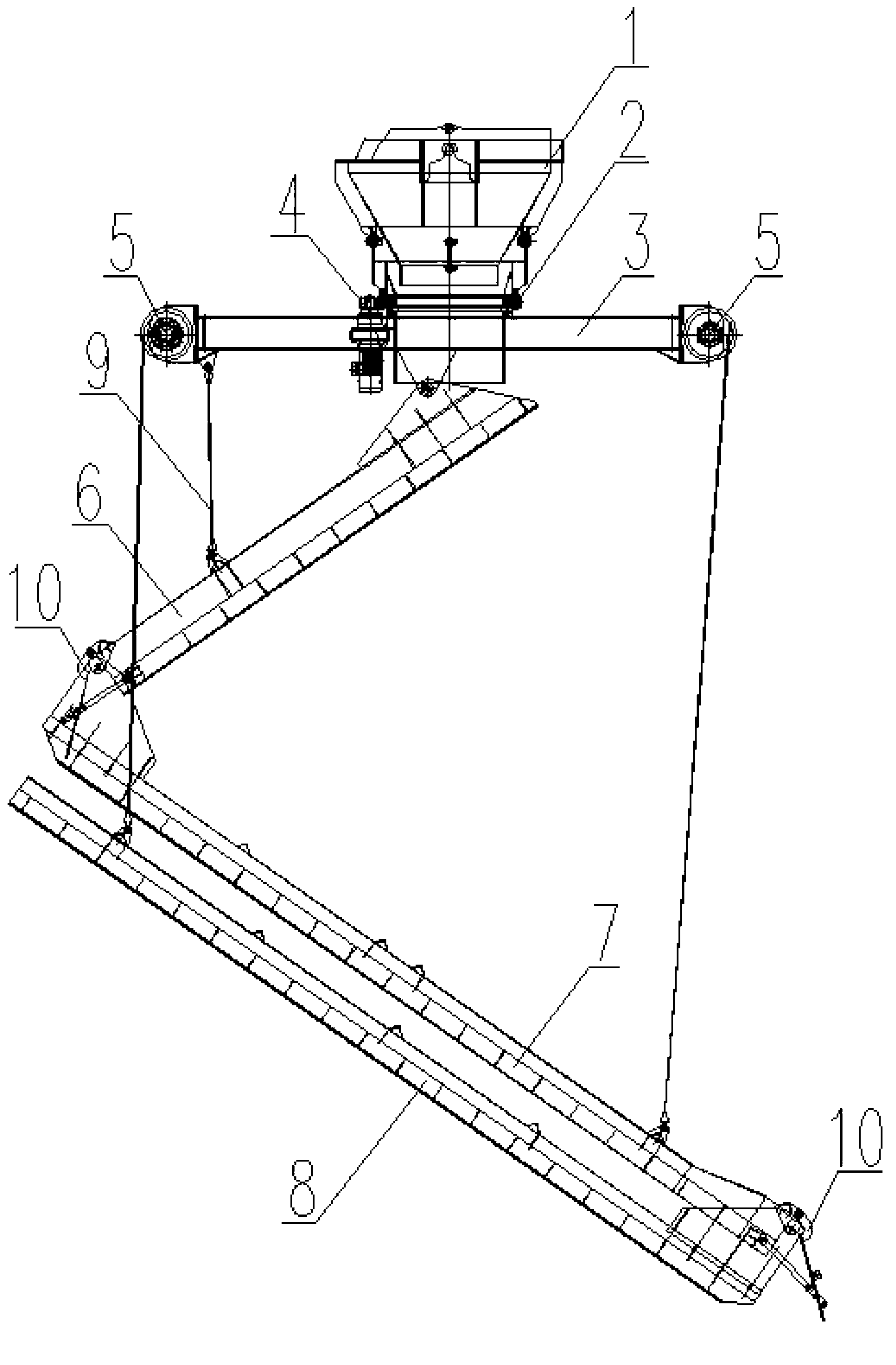

Z-shaped slow-descending chute discharging device

A technology of unloading device and slow descending, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of small coverage area and excessive blanking height difference, and achieve the effect of improving production efficiency and reducing power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The specific embodiment of the present invention is shown in the accompanying drawings, which is composed of a material guide cylinder 1, a slewing bearing 2, a slewing frame 3, a slewing drive mechanism 4, a folding hoist 5, a material guide groove and a baffle; it is characterized in that The lower part of the material guide cylinder 1 is connected with the rotary frame 3 through the rotary bearing 2; the rotary drive mechanism 4 is installed on the rotary frame 3, the pinion 4.3 on the rotary drive mechanism 4 and the bearing outer ring gear 2.2 on the rotary bearing 2 The material guide groove is installed in the lower part of the material guide cylinder 1; the two ends of the slewing frame 3 are symmetrically equipped with a folding hoist 5, and the traction wire ropes of the two folding hoists 5 are connected with the second-level material guide groove of the material guide groove respectively. 7 and the third-level guide trough 8 are connected; iron chains 9 are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com