Shitake mushroom color protection liquid and color protection method of shitake mushroom color protection liquid

A technology for color protection liquid and shiitake mushrooms, which is applied in the fields of application, food preparation, food science, etc., can solve problems such as affecting the nutritional quality of shiitake mushrooms, and achieve the effects of protecting the appearance of shiitake mushrooms, rationalizing the formula, and reducing the amount of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

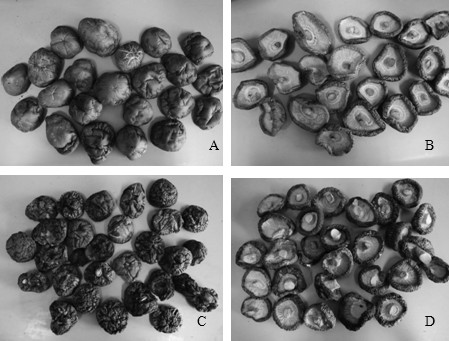

Image

Examples

Embodiment 1

[0018] The mushroom color protecting liquid is prepared by dissolving 4 parts of calcium chloride, 0.12 part of citric acid, 0.15 part of tea polyphenol and 0.08 part of L-cysteine in 1000 parts of water in parts by weight.

[0019] Color protection method using mushroom color protection solution: heat the prepared mushroom color protection solution to 50°C, spray 5 mL of heated mushroom color protection solution per kilogram of mushroom on the surface of mushrooms with a water content of 75%-80% (weight) liquid, and then dried until the water content in the shiitake mushrooms is 13% (by weight). After drying, the surface of the mushroom umbrella remains light brown, and the shape is full without large area shrinkage.

Embodiment 2

[0021] The mushroom color protecting liquid is prepared by dissolving 6 parts of calcium chloride, 0.15 parts of citric acid, 0.2 part of tea polyphenol and 0.1 part of L-cysteine in 1000 parts of water in parts by weight.

[0022] Color protection method using mushroom color protection solution: heat the prepared mushroom color protection solution to 55°C, spray 7.5 mL of heated mushroom color protection solution per kilogram of mushroom on the surface of mushrooms with a water content of 75%-80% (weight) liquid, and then dried until the water content in the shiitake mushrooms is 13% (by weight). After drying, the surface of the mushroom umbrella remains light brown, and the shape is full without large area shrinkage.

Embodiment 3

[0024] The mushroom color protection solution is prepared by dissolving 8 parts of calcium chloride, 0.18 parts of citric acid, 0.25 parts of tea polyphenols and 0.12 parts of L-cysteine in 1000 parts of water in parts by weight.

[0025] Color protection method using mushroom color protection solution: heat the prepared mushroom color protection solution to 60°C, spray 10 mL of heated mushroom color protection solution per kilogram of mushroom on the surface of mushrooms with a water content of 75%-80% (weight) liquid, and then dried until the water content in the shiitake mushrooms is 13% (by weight). After drying, the surface of the mushroom umbrella remains light brown, and the shape is full without large area shrinkage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com