Image sensor and formation method thereof

A technology of image sensor and curved surface structure, which is applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problem of optical crosstalk that needs to be improved, and achieve the effects of reducing reflection, improving efficiency, and reducing light crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the existing image sensor technology, the optical signal passes through the lens module to the lens structure for focusing, and then passes through the filter to reach the independent pixel (for example, including a photodiode) for photoelectric conversion. Among them, when the lens structure captures the incident light, it is filtered by the filter structure to remove irrelevant light and form monochromatic light. The incident photons reach the semiconductor substrate and are absorbed by the pixel device to generate photogenerated carriers to output electrical signals. However, in the prior art, the problem of optical crosstalk still needs to be improved.

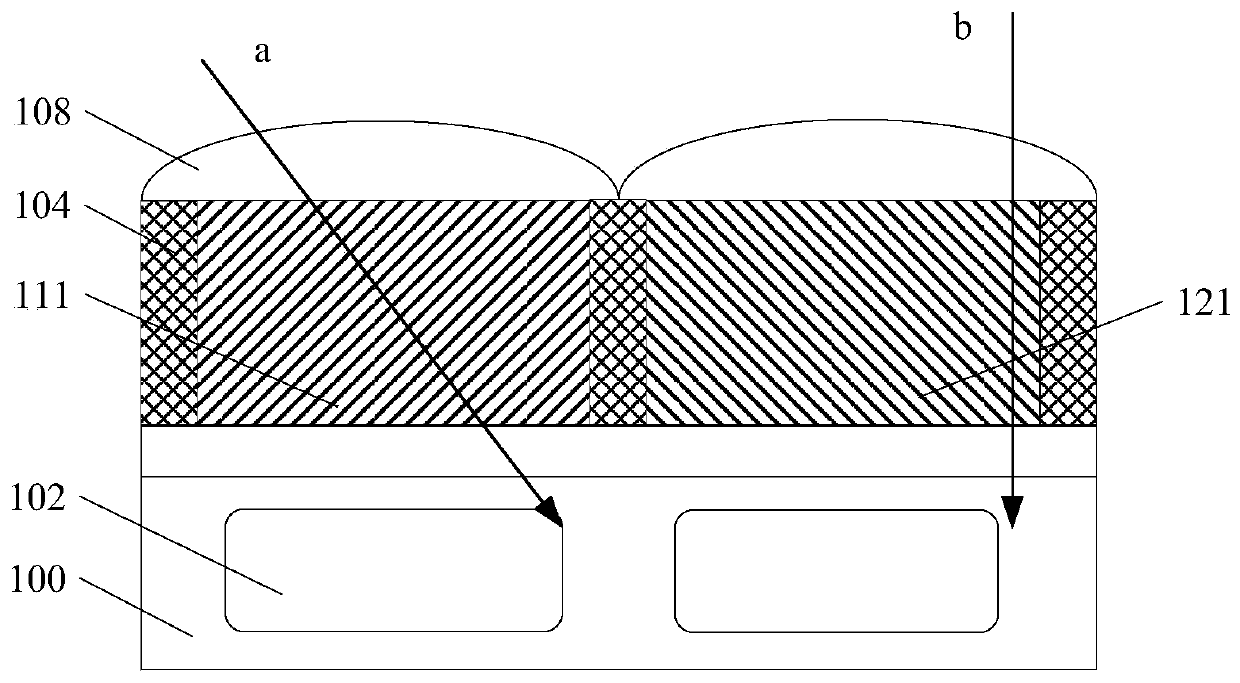

[0030] refer to figure 1 , figure 1 It is a schematic diagram of a device cross-sectional structure of an image sensor in the prior art.

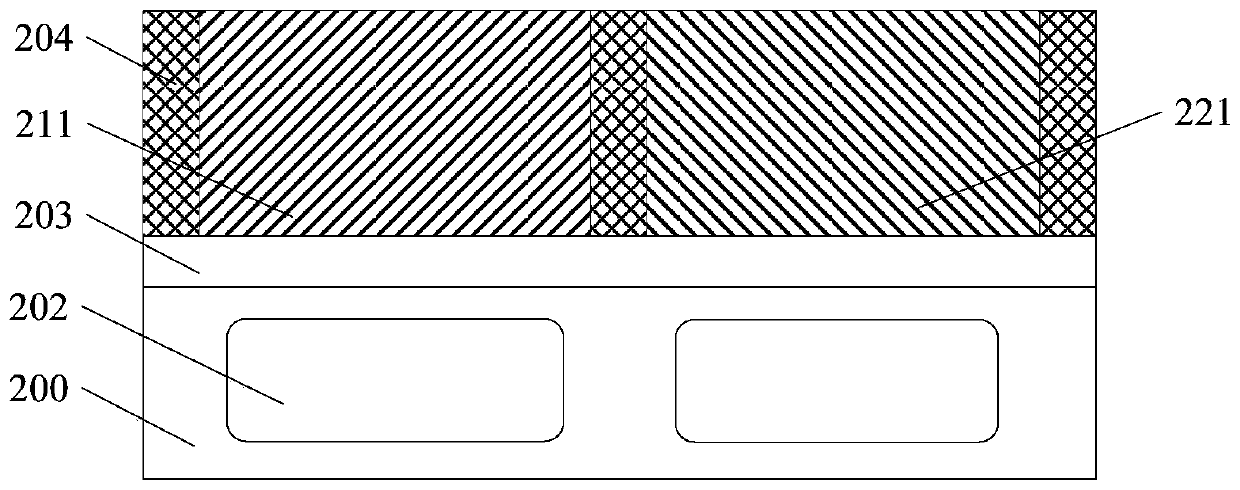

[0031] In an existing image sensor, a semiconductor substrate 100 may be provided, grid structures 104 are formed on the surface of the semiconductor substrate 100, color fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com