USB metal shell forming and welding equipment and method thereof

A technology for welding equipment and outer casings, applied in the field of USB metal casing forming and welding equipment, can solve problems such as affecting processing quality, side extrusion deformation of casings, short connection points, etc., so as to improve production and processing efficiency and ensure production quality. , the effect of convenient opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

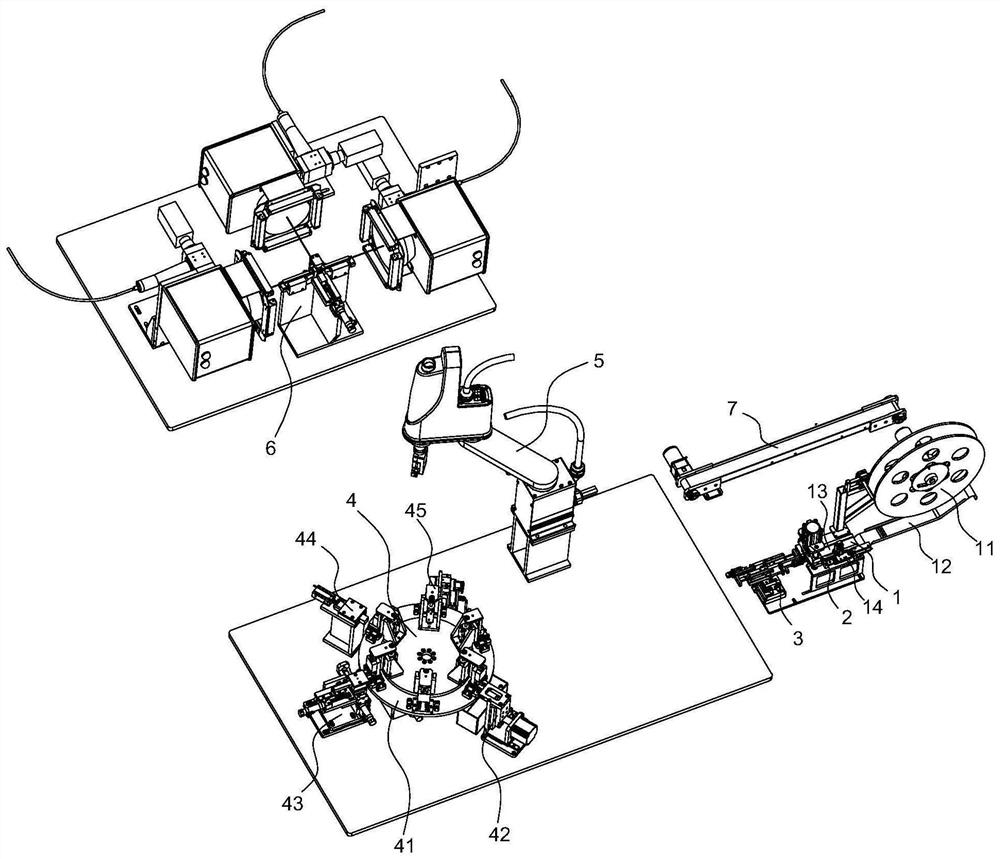

[0049] Such as figure 2 As shown, a USB metal casing forming welding equipment, the equipment includes a frame and a tape feeding device 1 installed on the frame, a tape cutting device 2, a rotary material transfer device 3, a turntable processing device 4, Handling manipulator 5, welding device 6 and discharging device 7. A tape cutting device 2 is arranged above the discharge end of the tape feeding device 1 , and the discharge end of the tape feeding device 1 is connected to the rotary transfer device 3 . The turntable processing device 4 is sequentially provided with a feeding station, a strip body breaking station, a first inspection station, a second inspection station and a turning and discharging station. The position of the rotary material transfer device 3 matches the loading station. The position of the moving manipulator 5 is matched with the turning and discharging station. The welding device 6 is located on one side of the turntable processing device 4 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com